Torque restrictor

A technology of torque limiter and outer ring, used in couplings, slip couplings, mechanical equipment, etc., can solve the problem of insufficient rigidity of the arc part, and achieve the advantages of suppressing vibration, improving rigidity, and suppressing noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

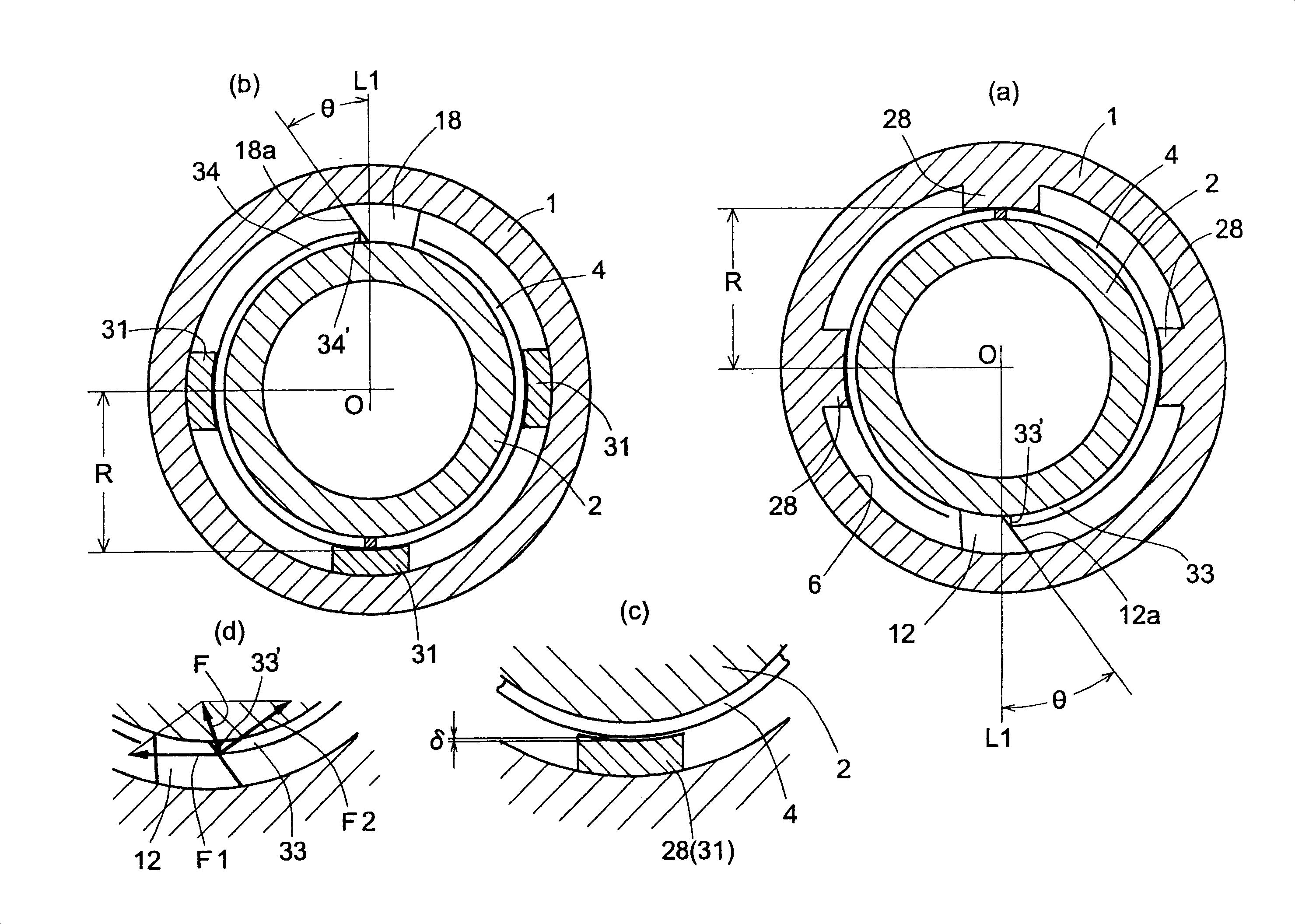

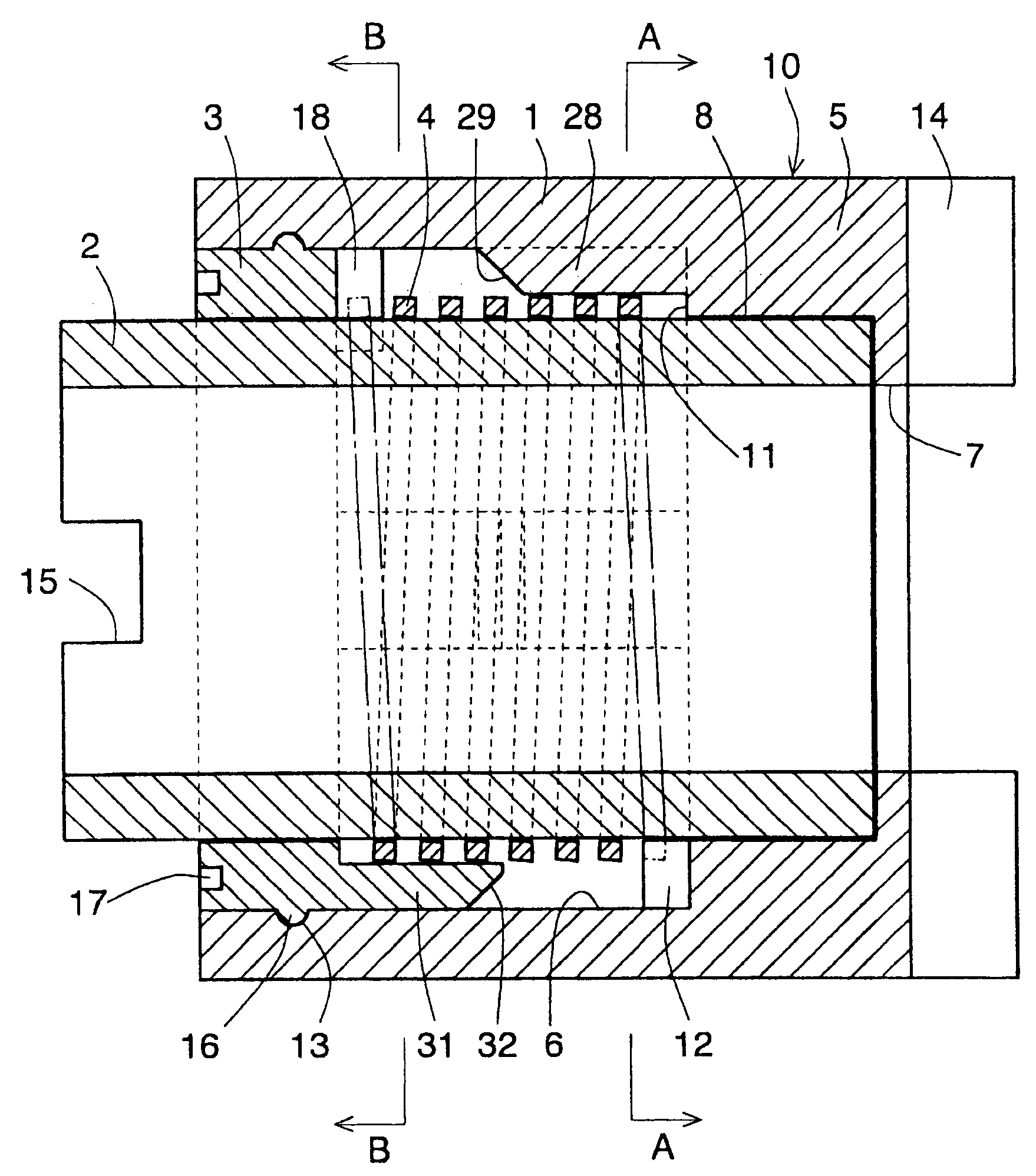

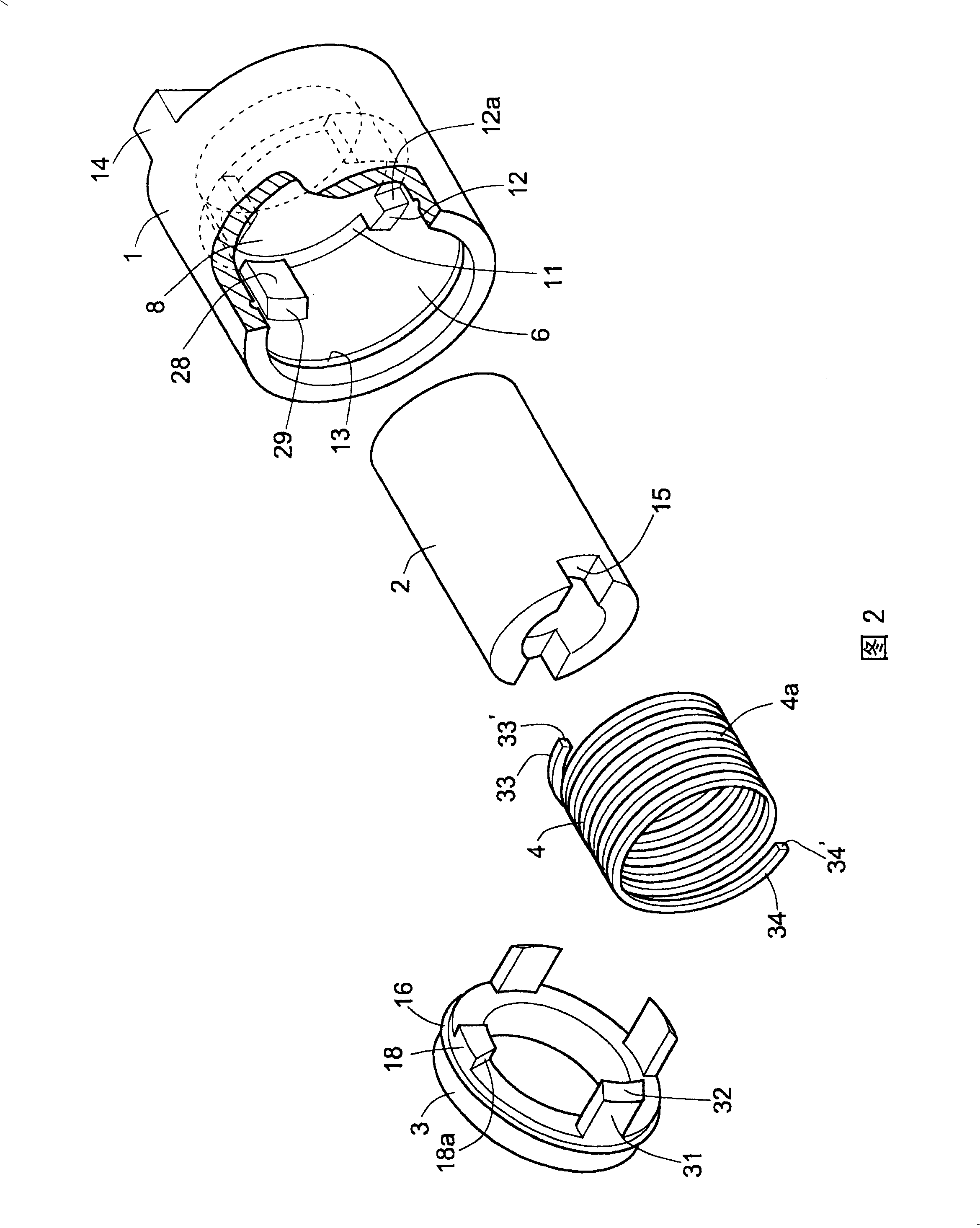

[0031] Embodiments of the present invention will be described below with reference to the accompanying drawings. As shown in FIGS. 1 to 3 , the torque limiter 10 of the present embodiment is composed of an outer ring member 1 , an inner ring 2 , an annular cover member 3 and a coil spring 4 as in the conventional case. A boss portion 5 is provided at one end of the outer ring member 1 , and an inner diameter surface 6 having a larger diameter than the coil spring 4 is formed between the boss portion 5 and the open end at the other end. A shaft insertion hole 7 is provided at the center portion of the boss portion 5 , and an inner ring support portion 8 having a larger diameter than the shaft insertion hole 7 is provided inside the shaft insertion hole 7 .

[0032] An outer ring member protrusion 12 is provided on a part of the sleeve portion inner end surface 11 forming the stepped portion between the inner ring support portion 8 and the inner diameter surface 6 (see FIG. 3( a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com