Device for cleaning pouring cup of investment casting mould shell

A technology of sprue cup and cleaning essence, which is applied in the direction of mold, mold composition, mold material cleaning/processing machinery, etc., can solve the hidden dangers of casting finishing, affect the sealing of castings, and scrap castings, etc., to achieve Eliminate casting defects, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

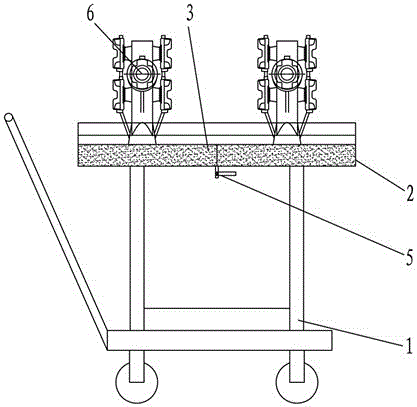

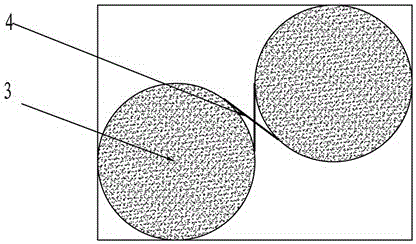

[0015] Such as figure 1 with figure 2 As shown, the device of the present invention for cleaning the sprue cup of a precision casting mold includes a cart 1, a water tank 2, and a grinding wheel 3. The water tank 2 is fixed on the cart 1. The bottom of the water tank 2 is fixed with two cross-arranged steel baffles 4, the two grinding wheel discs 3 are respectively clamped on the two opposite corners of the water tank 2, and they are waterproofed and bonded. Paste the grinding wheel disc 3 on the bottom of the water tank. The two grinding wheel discs 3 are equal in size, the sum of the diameters of the two grinding wheel discs 3 is equal to the length of the water tank 2, and the sum of the diameters of the two grinding wheel discs 3 is greater than the width of the water tank 2. The water tank 2 contains an appropriate amount of clean water, and the water level in the water tank 2 is higher than the upper surface of the grinding wheel 3 by 30-40mm. A control valve 5 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com