Hermetic compressor and refrigerating cycle device including the hermetic compressor

A compressor and hermetic technology, which is applied in the field of refrigeration cycle devices and hermetic compressors, can solve problems such as difficulty in ensuring reliability, increased number of parts, and cost, and achieve the effect of suppressing abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

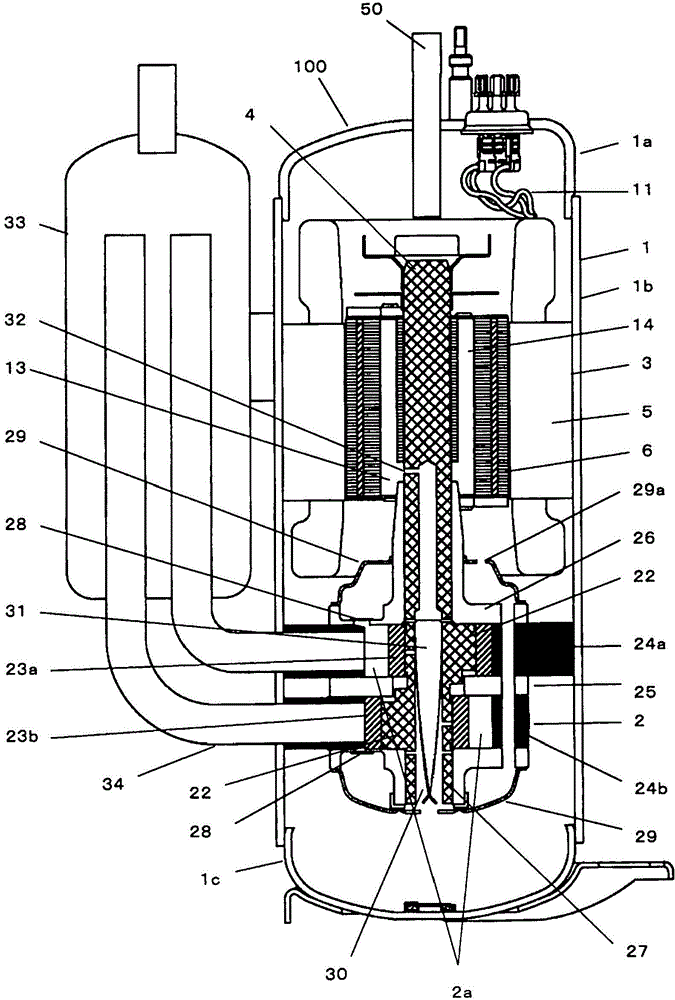

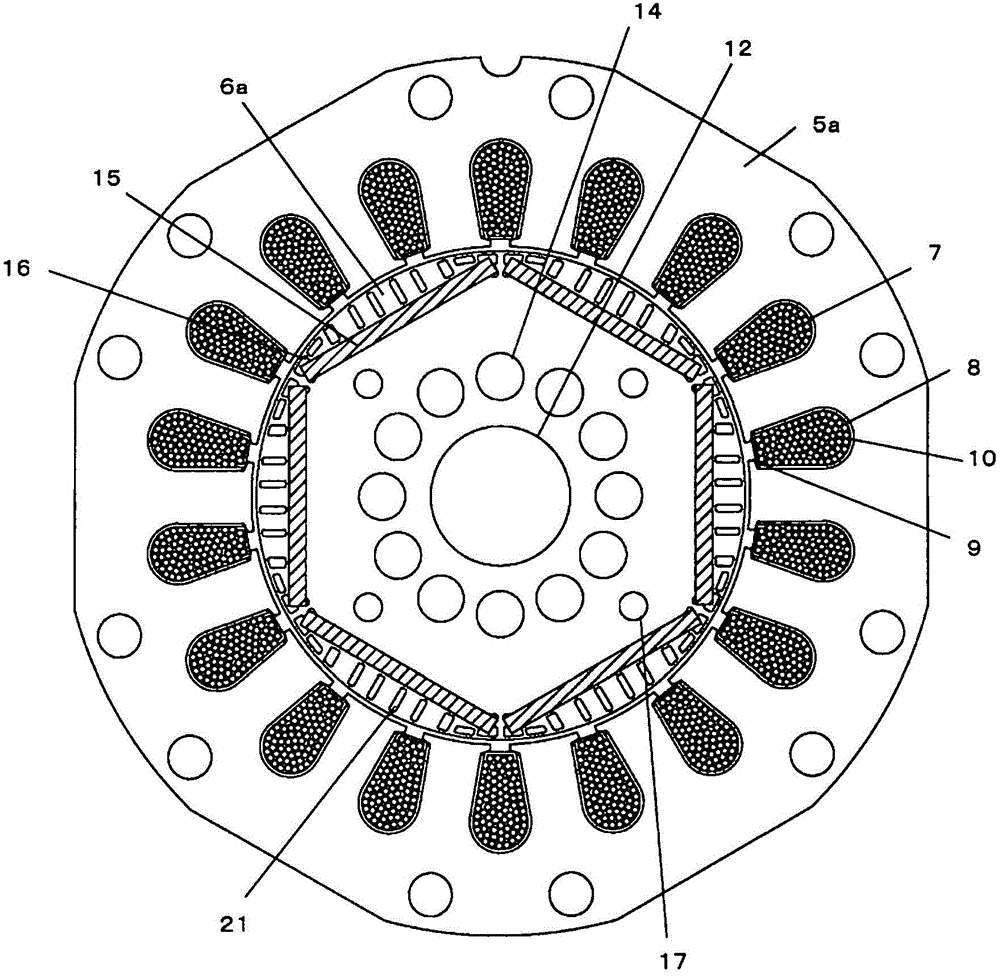

[0023] figure 1 It is a sectional view showing the hermetic compressor 100 according to Embodiment 1 of the present invention. use figure 1 The overall structure of the hermetic compressor 100 will be described. The hermetic compressor 100 will be described by taking a 2-cylinder rotary compressor as an example. The hermetic compressor 100 accommodates a compression mechanism unit 2 that compresses refrigerant and an electric element unit 3 that drives the compression mechanism unit 2 in a hermetic vessel 1 including an upper vessel 1a, an intermediate vessel 1b, and a lower vessel 1c. The compression mechanism unit 2 and the motor element unit 3 are connected by a crankshaft 4 , the compression mechanism unit 2 is housed in the lower part of the airtight container 1 , and the motor element part 3 is housed in the upper part of the airtight container 1 .

[0024] Such as figure 1 As shown, the electric element part 3 includes a stator 5 and a rotor 6, and is, for example, ...

Embodiment approach 2

[0039] In Embodiment 1, the structure in which the generation of abnormal noise is suppressed by providing the ventilation hole 14 penetrating the rotor 6 in the counterbore portion 13 of the rotor 6 is described, but in Embodiment 2, it is necessary to prevent the leakage of the refrigerating machine oil to the outside of the compressor. When the amount of circulation is large, the structure for suppressing the amount of circulation will be described.

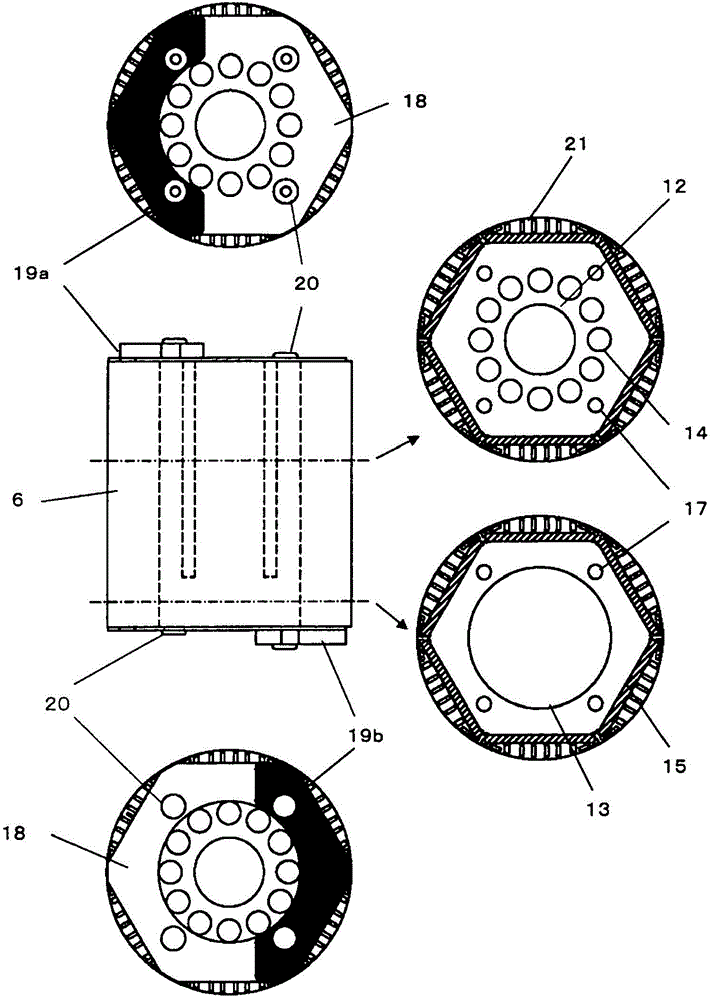

[0040] Figure 4 It is a structural diagram showing the rotor 6 according to Embodiment 2 of the present invention. In Embodiment 2, an opening portion 13A communicating with the ventilation hole 14 is formed on the side wall side of the counterbore portion 13 of the rotor 6 .

[0041] Figure 5 It is a schematic diagram which shows the refrigeration circuit of Embodiment 2 of this invention. The refrigerating circuit is sequentially connected to the hermetic compressor 100, the four-way switching valve 35 for switching the...

Embodiment approach 3

[0047] In Embodiment 1, the structure for suppressing the occurrence of abnormal noise was described by providing the ventilation hole 14 penetrating the rotor 6 in the counterbore portion 13 of the rotor 6. In Embodiment 2, the structure for reducing the amount of oil circulation was described. However, in Embodiment 3, a structure for suppressing the amount of oil circulation in a compressor having a structure in which the vent hole 32 provided in the crankshaft 4 is provided between the rotor 6 and the main bearing 26 will be described.

[0048] Figure 6 It is a sectional view showing the hermetic compressor 100 according to Embodiment 3 of the present invention. use Figure 6 The overall structure of the hermetic compressor 100 according to Embodiment 3 will be described.

[0049] The hermetic compressor 100 will be described by taking a single-cylinder rotary compressor as an example. The hermetic compressor 100 accommodates a compression mechanism unit 2 for compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com