Outboard engine system

A technology of outboard engine and main body, which is applied in the direction of propulsion engine, ship propulsion, ship parts, etc., and can solve the problem of high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

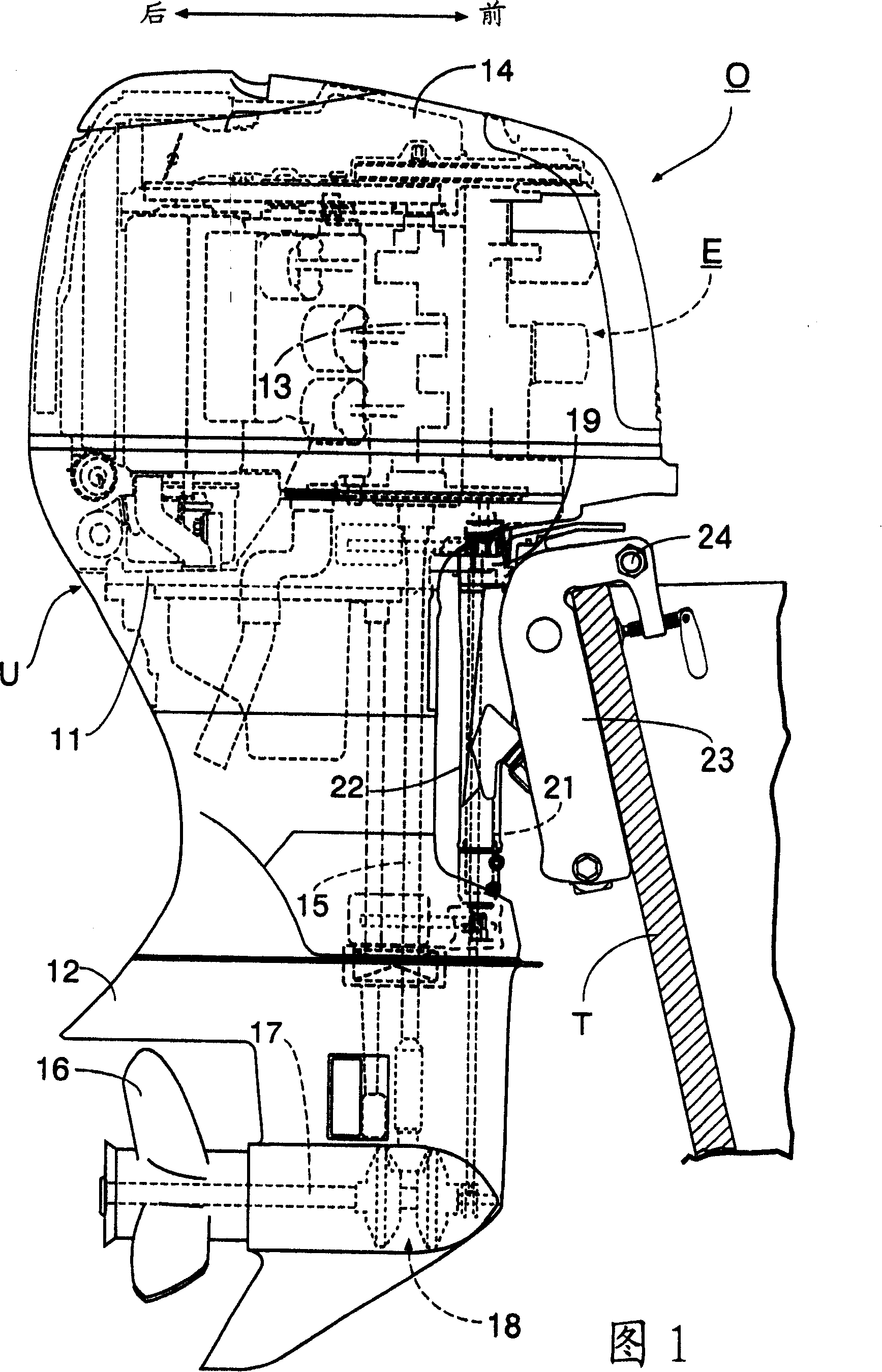

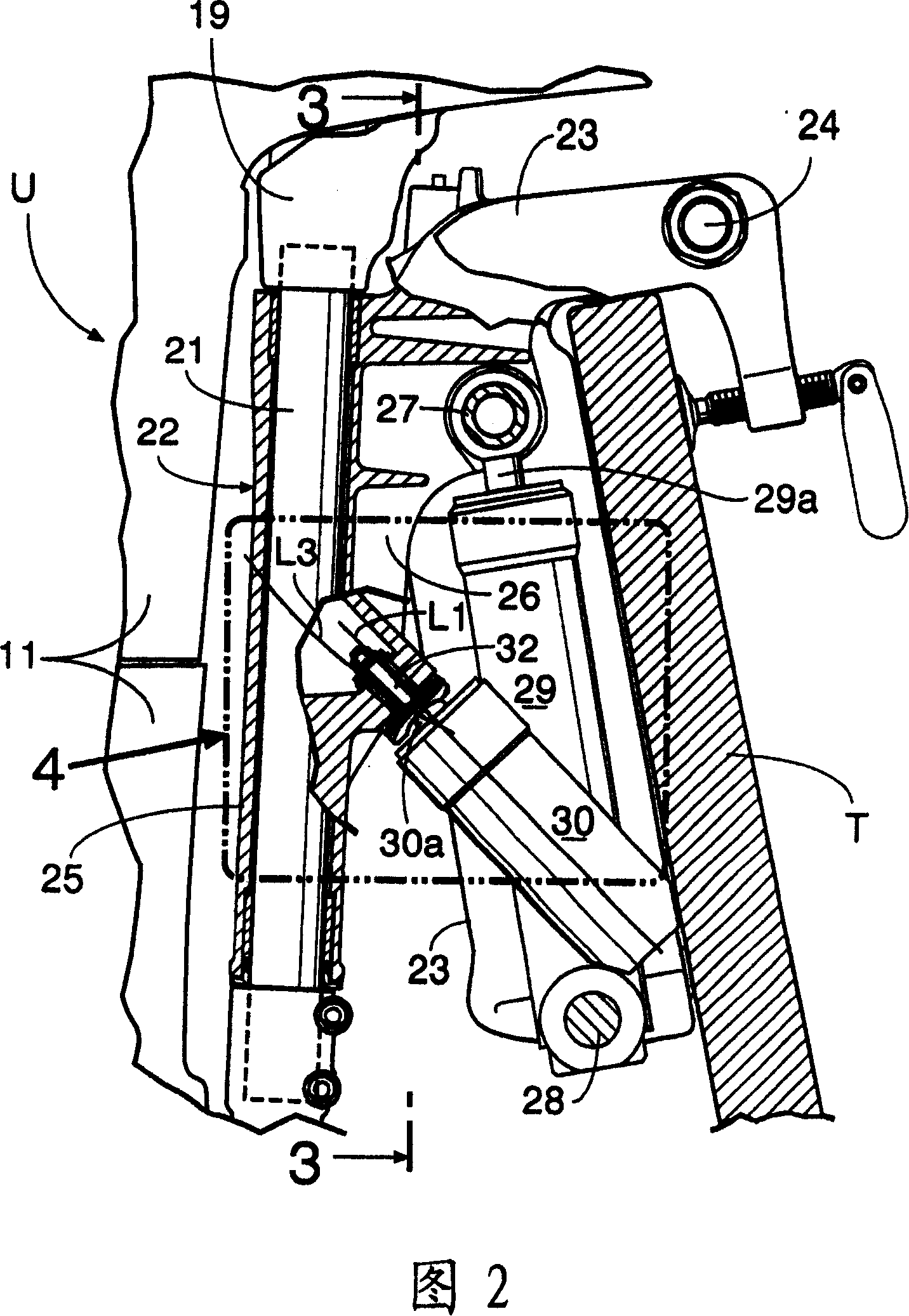

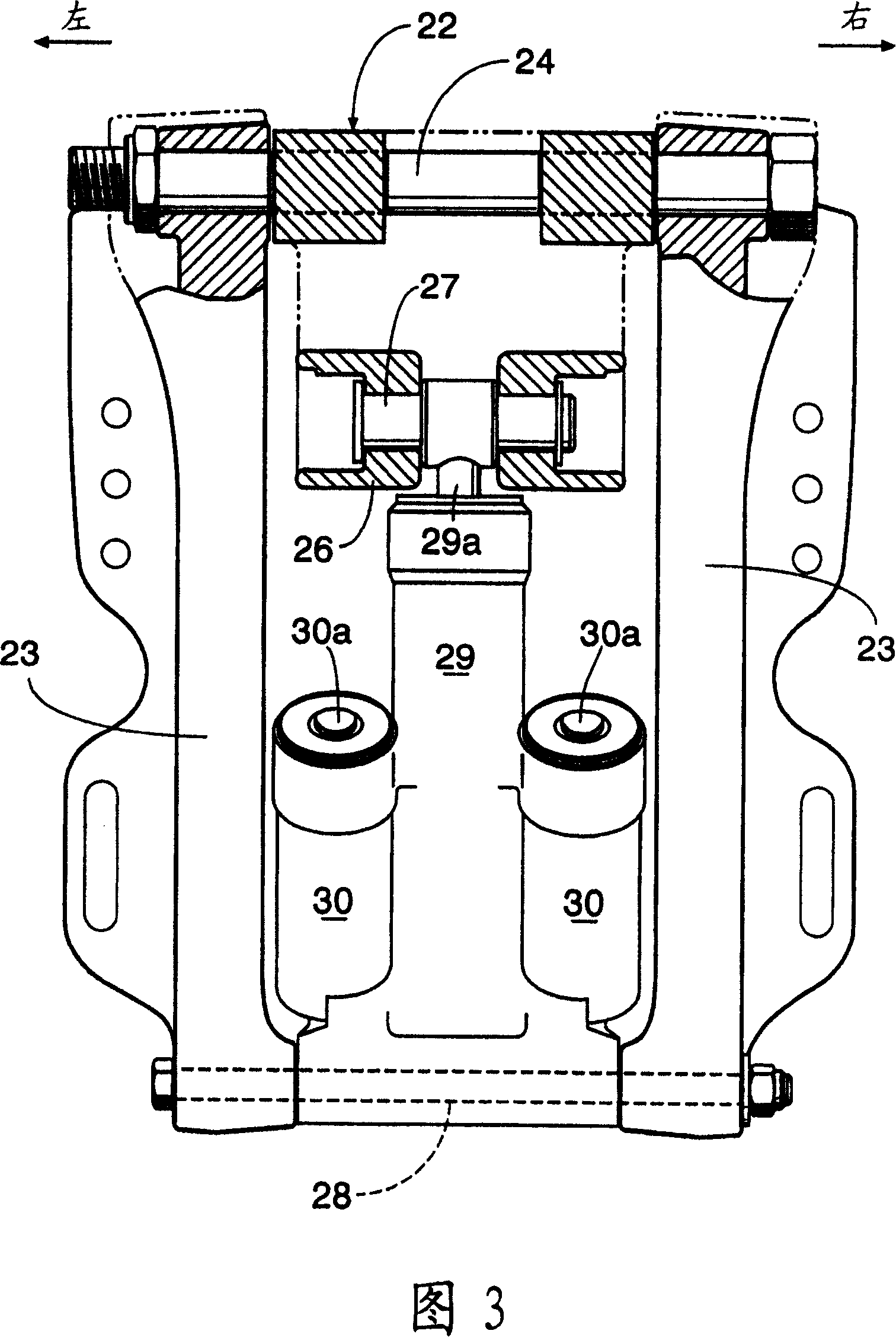

[0041] A first embodiment of the present invention will be described below with reference to FIGS. 1 to 12 .

[0042] As shown in FIG. 1 , the propulsion unit U constituting the main part of the outboard engine system 0 includes a support box assembly 11 and a gear box 12 connected to the lower portion of the support box assembly 11 . The water-cooled multi-cylinder 4-stroke engine E is installed on the upper part of the support box assembly 11, and its crankshaft 13 is arranged vertically. An engine cover 14 is openably and closably installed on the upper end of the support box assembly 11 so as to cover the engine E. As shown in FIG. In this application, the support box assembly 11 is a general term, which includes: the installation box, which supports the main body of the engine E; the extension box, which is connected with the lower part of the installation box; and the bottom cover, which covers the periphery of the installation box and the extension box. , and engage th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com