Resin composition and illuminating lamp shade made of the same

A technology of resin composition and components, which is applied in the field of lighting lampshades, can solve the problems of difficult discoloration and low abnormal sound, and achieve the effects of good balance performance, reduced abnormal sound and low frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

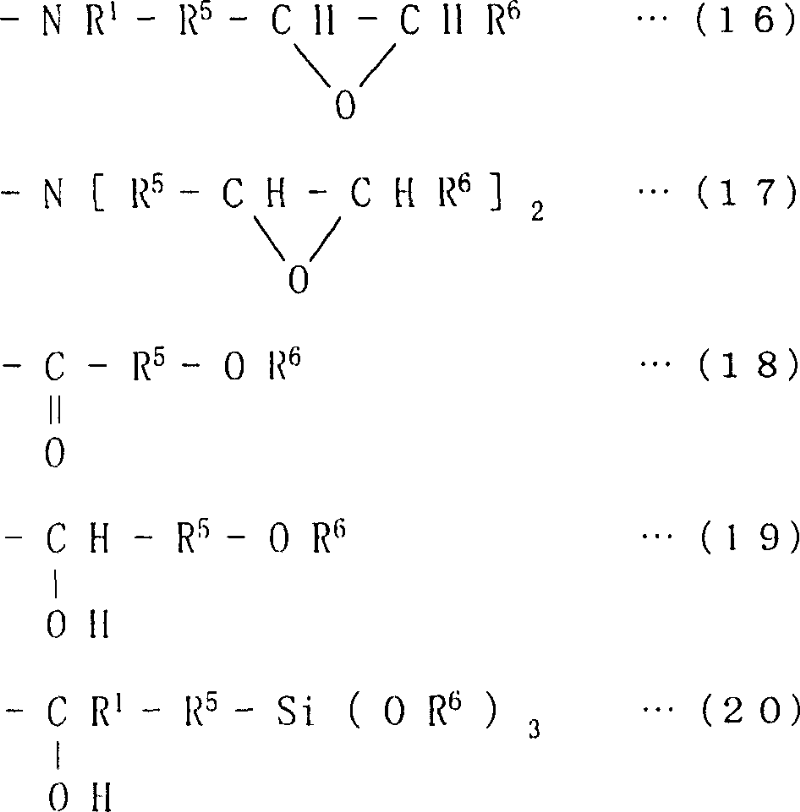

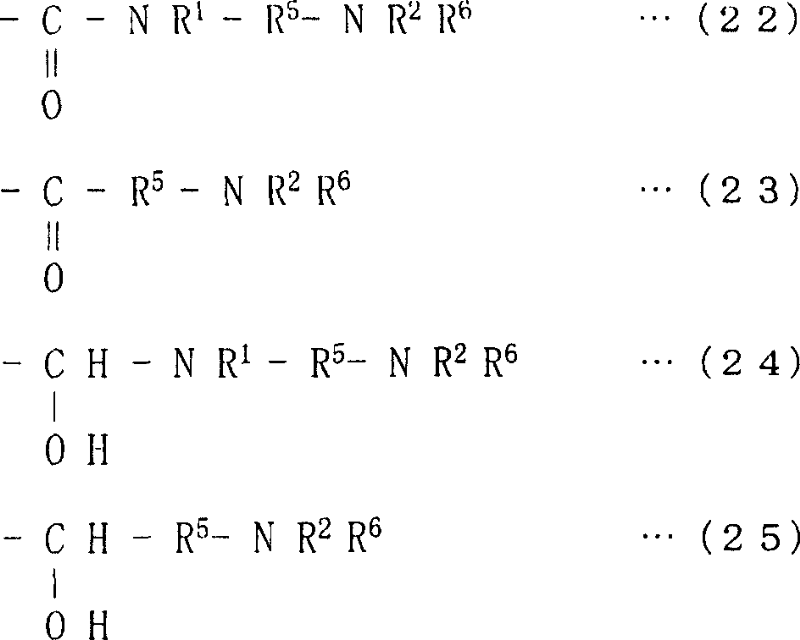

Method used

Image

Examples

Embodiment

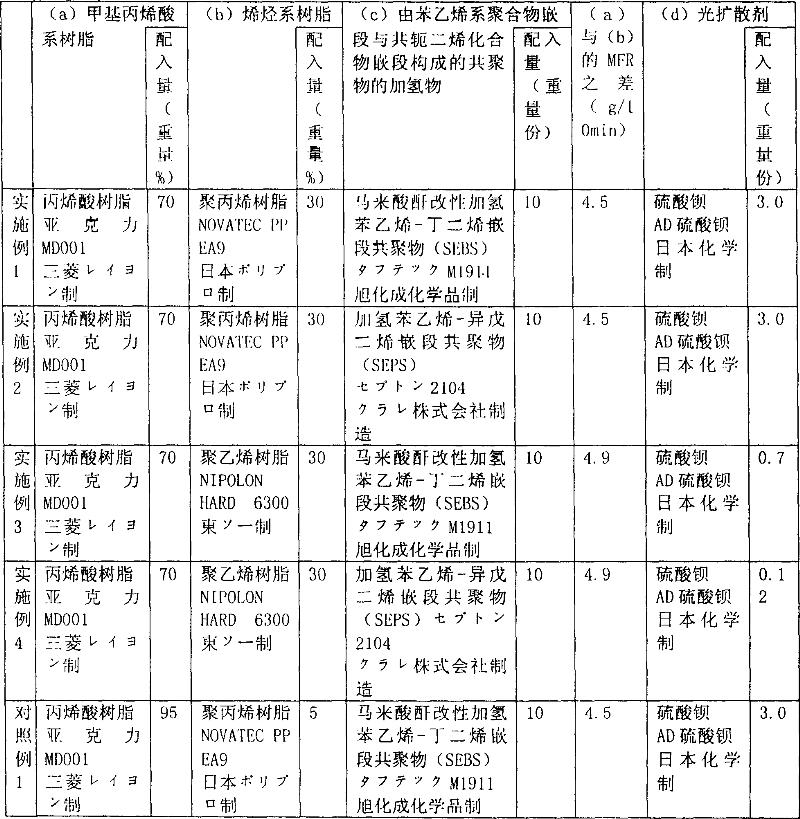

[0113] The present invention will be described in further detail below based on examples and comparative examples, but the present invention is not limited by these examples. First, the manufacturing methods of the lighting shades in Examples and Comparative Examples will be described.

[0114]A mixture of (a) methacrylic resin, (b) olefin resin, (c) at least one styrene polymer block and at least one conjugated diene compound block is prepared by using a rotary mixer. Hydrogenate, and (d) light diffusing agent, are added to required additives, and mixed. Use a co-rotating twin-screw extruder with a cylinder diameter of Φ47 mm and L / D=31.5 to melt and knead it at a temperature of 240° C. Cut to make pellets. Then, the above-mentioned pellets were melted at a temperature of 240° C. with a single-screw extruder with a cylinder diameter of Φ65 mm, and extruded with a T-die to obtain a sheet with a width of 750 mm and a thickness of 1.8 mm. Cut the sheet into a size of 650mm×65...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com