Motor-driven valve

A technology of electric valves and valve seats, applied to valve devices, valve details, engine components, etc., can solve problems such as abnormal sounds and achieve the effect of reducing abnormal sounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

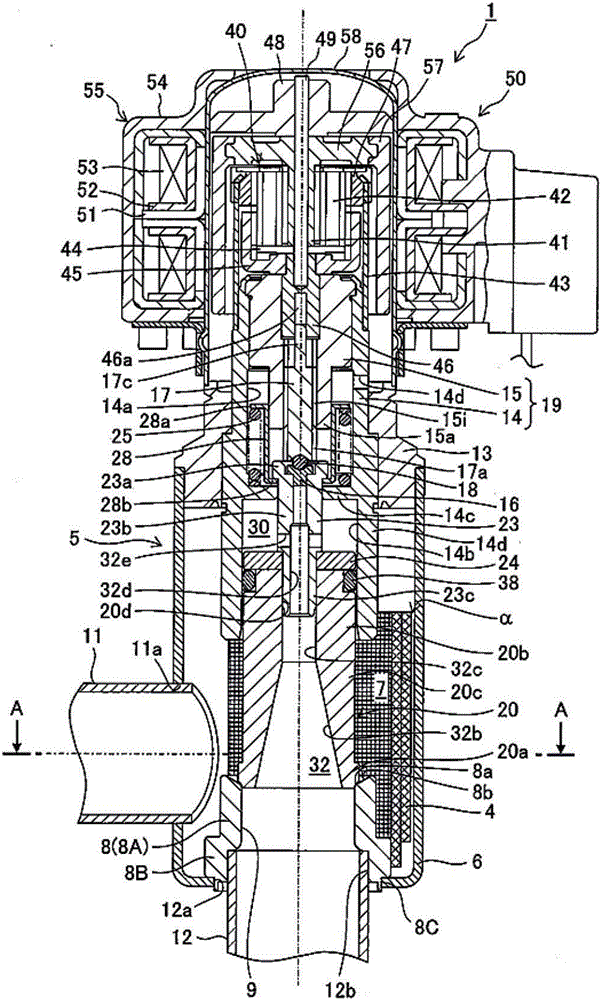

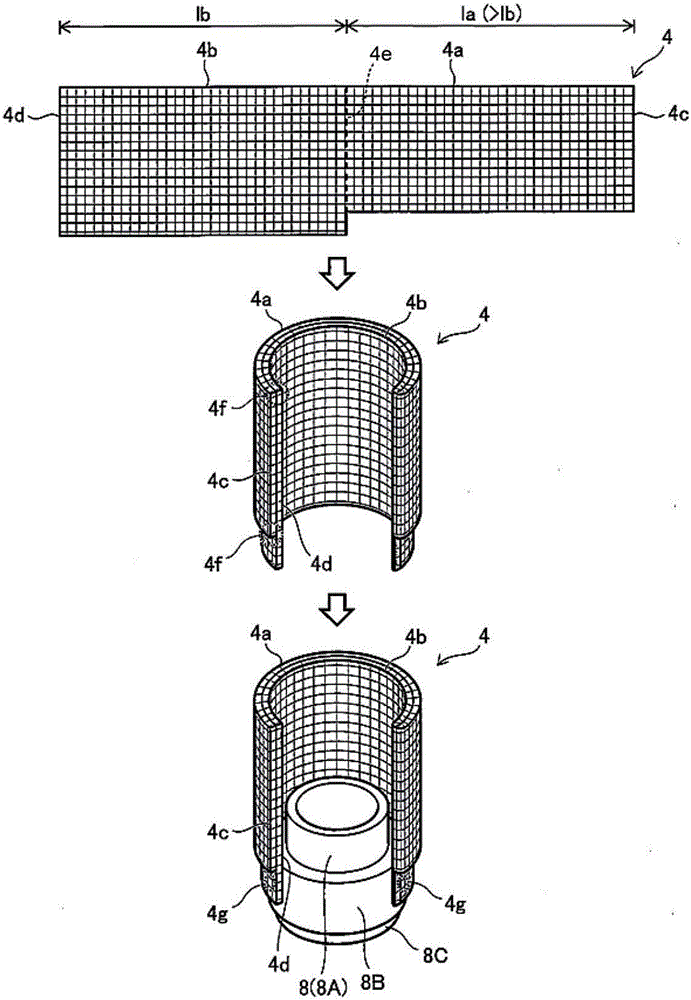

[0031] Hereinafter, specific embodiments of the electric valve according to the present invention will be described with reference to the drawings.

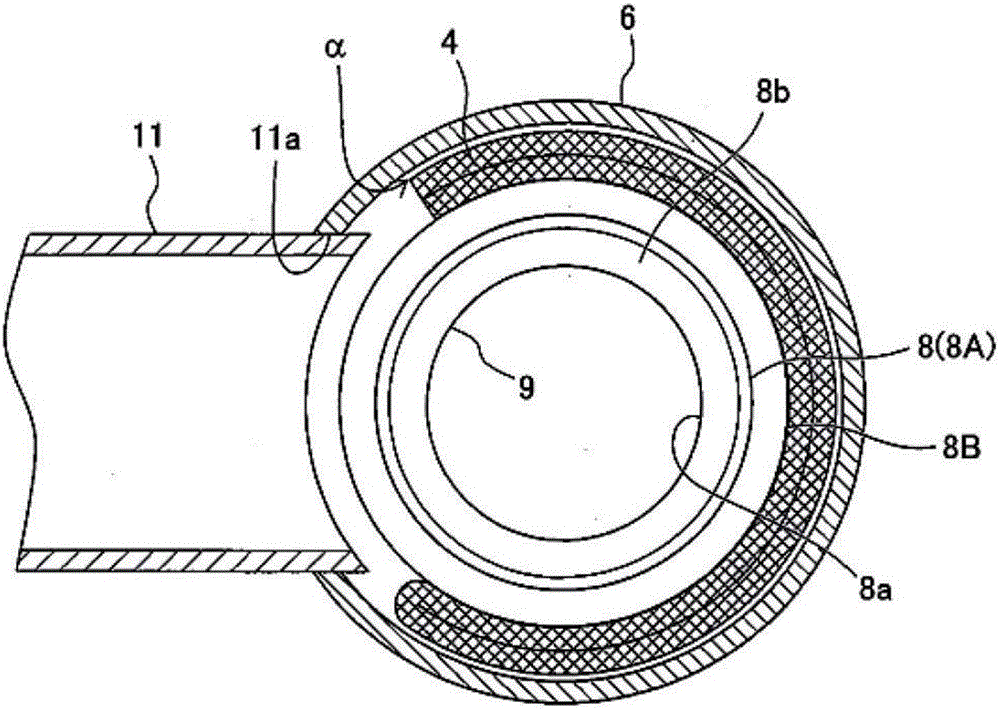

[0032] figure 1 A longitudinal sectional view showing an embodiment of an electric valve according to the present invention, figure 2 express figure 1 The cross-sectional view along the A-A arrow in the middle. In addition, in figure 2 Omit the valve body.

[0033] The electric valve 1 of the illustrated embodiment is used, for example, as an expansion valve in a heat pump type heating and cooling system, and fluid (refrigerant) flows in two directions (a first flow direction and a second flow direction opposite to it), and A bi-directional flow-through electric valve corresponding to a large flow flow path in at least one direction.

[0034]The electric valve 1 mainly includes: a valve body 5 having a cylindrical base body 6 made of a metal plate; a pot 58 fixed on the valve body 5; The supporting member 19; the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com