finned heat exchanger

A technology for heat exchangers and fins, applied in the field of heat exchangers, can solve the problems of increased ventilation resistance, increased fan performance, reduced performance, etc., and achieves the advantages of suppressing the generation of abnormal sound, improving heat exchange performance, and uniformizing wind speed distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

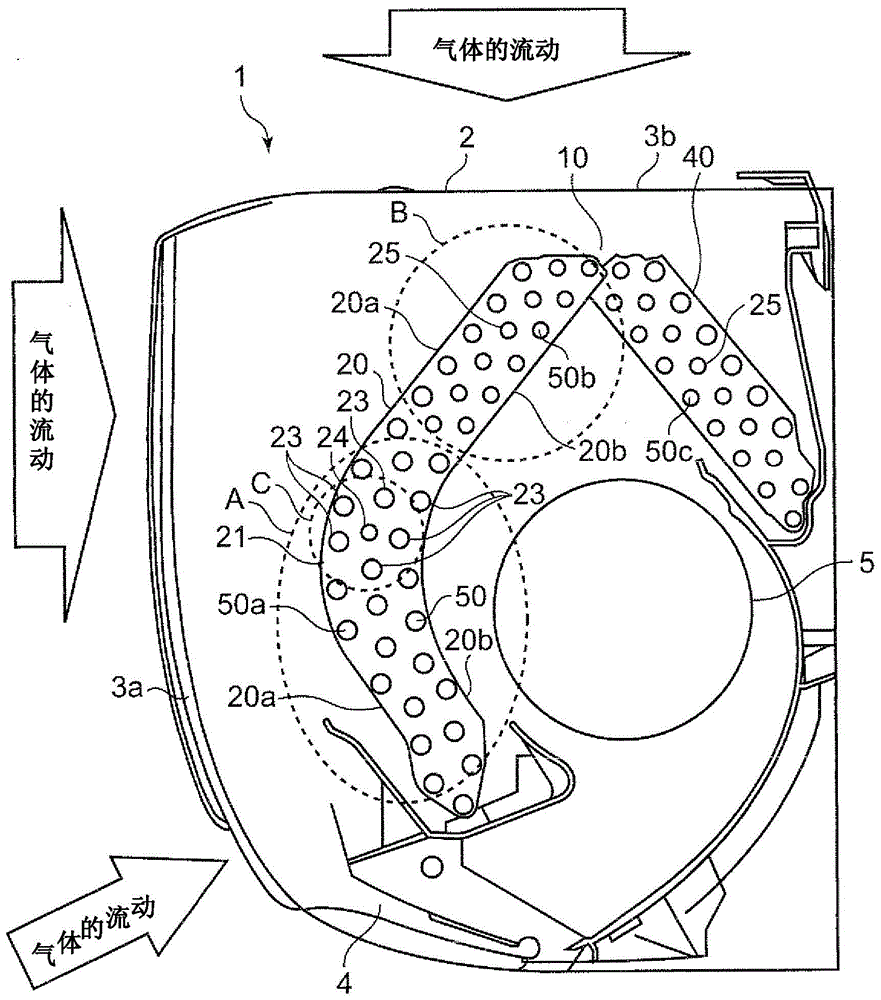

[0059] First, based on figure 1 The indoor unit of the air conditioner equipped with the finned heat exchanger of Embodiment 1 is demonstrated. figure 1 It is a longitudinal sectional view of the indoor unit equipped with the finned heat exchanger of Embodiment 1.

[0060] Such as figure 1 As shown, suction ports 3a and 3b are provided on the front surface and the upper surface of the housing 2 of the indoor unit 1 of this air conditioner, and an air outlet 4 is provided on the lower surface. exist figure 1 , for the gas that is sucked into the shell 2, the general direction of flow is shown by the arrow. A cross-flow fan 5 and a finned heat exchanger 10 are housed inside the casing 2 .

[0061] The finned heat exchanger 10 is arranged on the front side in the case 2 and includes a front side heat exchanger 20 formed in a convex shape so as to protrude toward the front side and a back side arranged on the back side in the case 2 . Heat exchanger 40. In addition, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com