Extractor hood

A range hood and fan technology, applied in the field of range hoods, can solve the problems of smoke running out of the air inlet, poor effect of range hood, and reduced effect of range hood, and achieve the effect of uniform distribution of wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

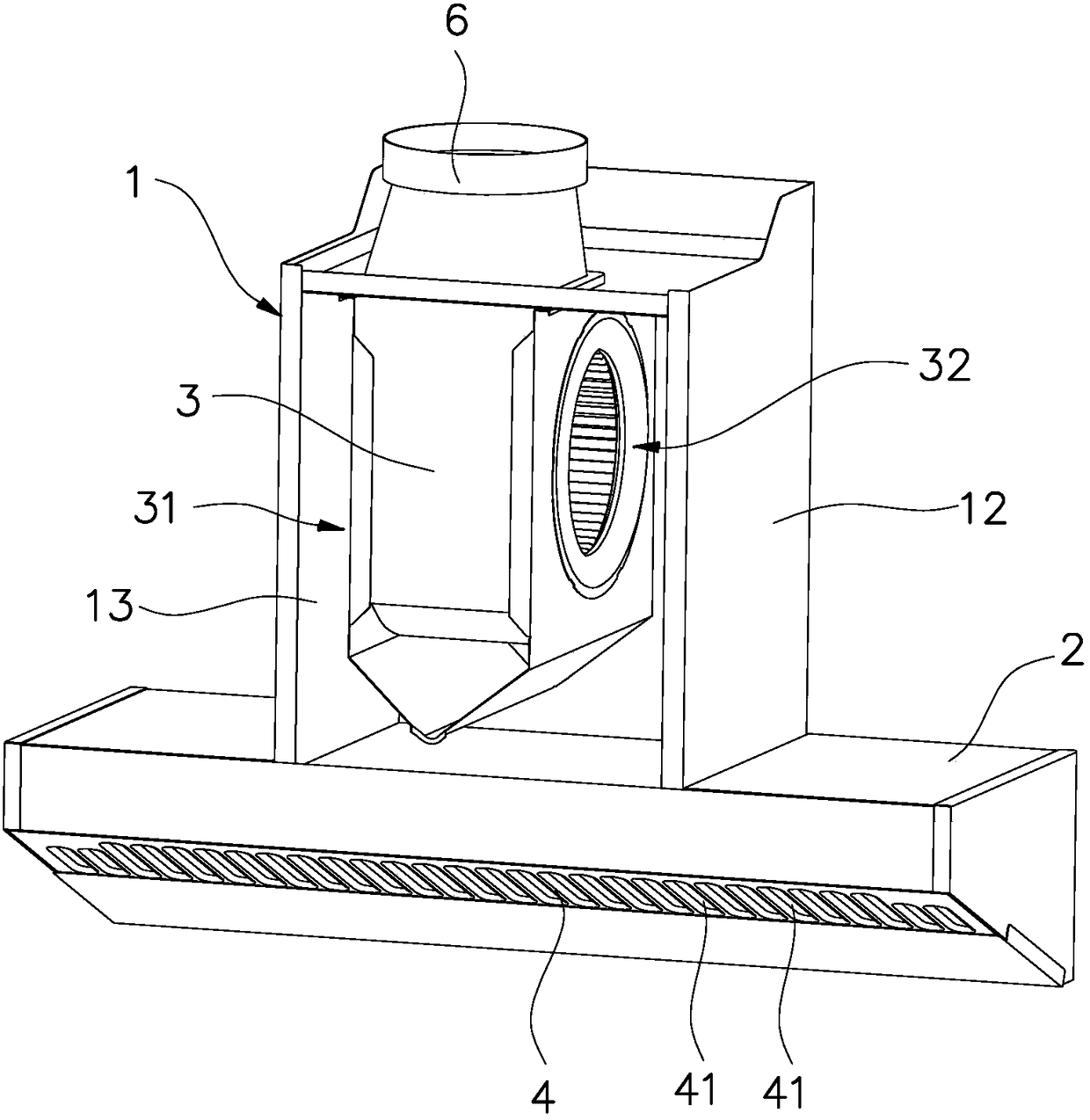

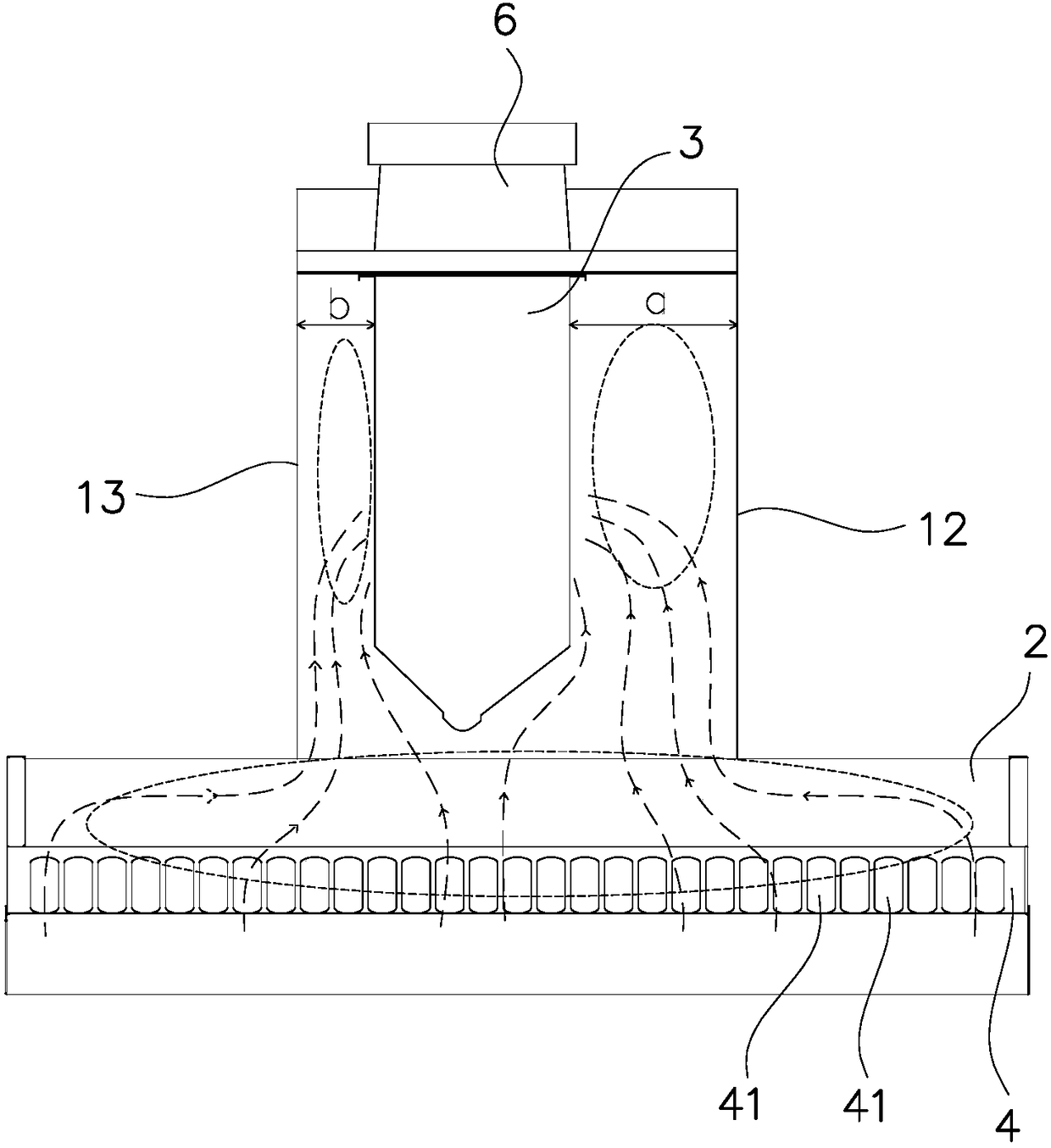

[0024] like Figure 1 to Figure 3 As shown, the range hood in this embodiment is a near-suction type range hood, which includes a fan housing 1, a smoke collection hood 2, a centrifugal fan 3, a first oil filter plate 4 and other components. Wherein, the smoke collecting hood 2 is arranged under the fan cover 1, and the inside of the fan cover 1 and the smoke collecting hood 2 together form a T-shaped inner cavity. The two ends are respectively adjacent to the corresponding sides of the smoke collecting hood 2, and the length of the wide air inlet 21 reaches about 1 meter. The first oil filter plate 4 is installed at the wide air inlet and its shape is adapted to the wide air inlet 21 . In addition, the range hood is equipped with an air outlet cover 6 connected to the air outlet of the centrifugal fan on the top of the fan housing 1 .

[0025] The centrifugal fan 3 of this embodiment is vertically installed in the fan housing 1 , and the central axis of the impeller 34 of t...

Embodiment 2

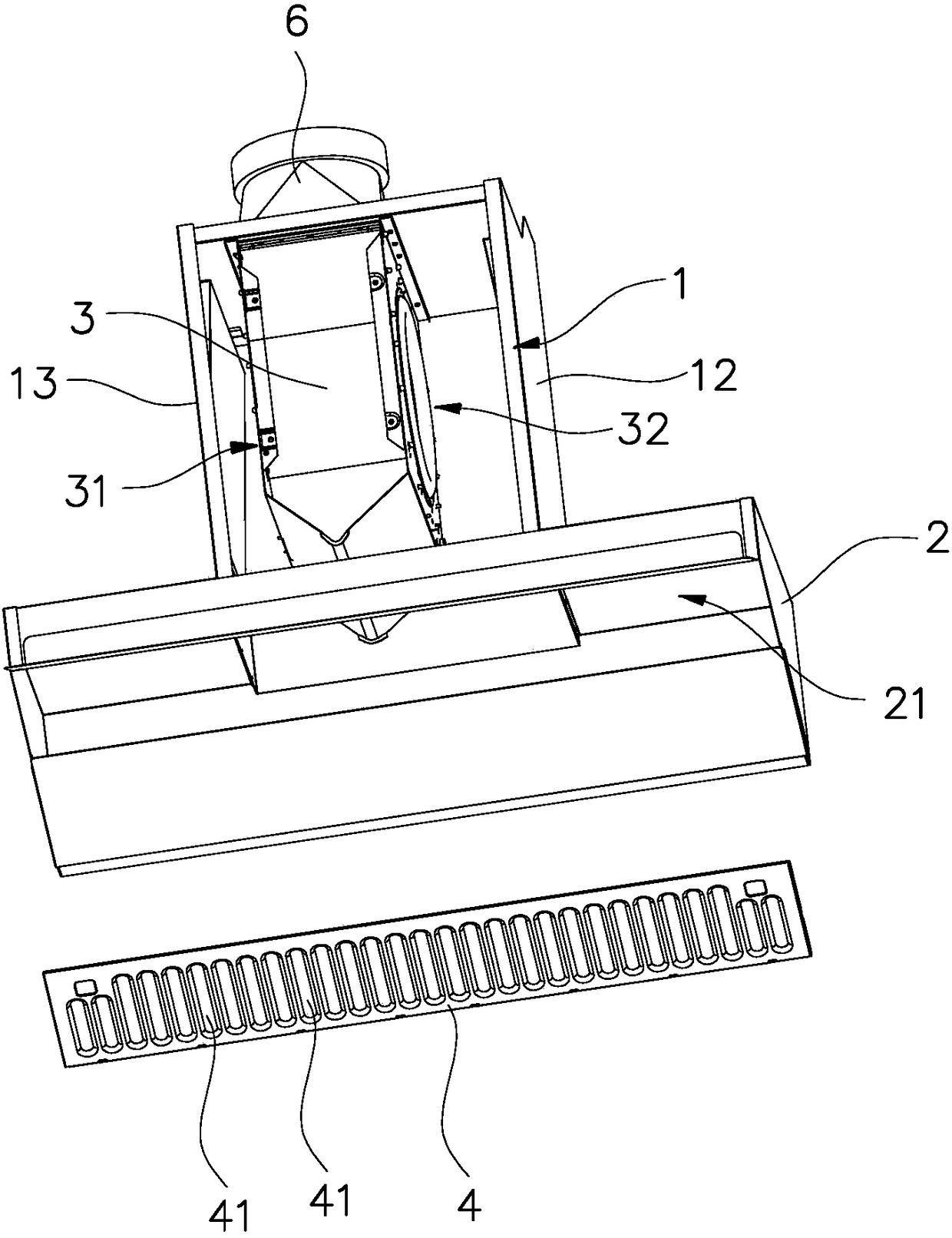

[0029] like Figure 4 to Figure 7 As shown, the range hood of this embodiment is a near-suction type range hood, the centrifugal fan 3 is biased left and right, the motor 33 of the centrifugal fan 3 is installed on the left side of the fan, and the left air inlet 31 of the fan is a secondary air inlet. The air inlet 32 on the right side is the main air inlet, and the smoke collecting hood 2 also adopts the wide air inlet 21. Compared with Embodiment 1, this embodiment adds a second oil filter plate 5, the second oil filter plate 5 is installed in the middle of the back of the first oil filter plate 4, and the second oil filter plate 5 is located at the side of the wide air inlet 21 In the middle, and the left and right width of the second oil filter plate 5 is equal to or smaller than the width of the fan housing 1 .

[0030] In the present embodiment, the first oil filtering holes 41 are formed on the first oil filtering plate 4 in order from left to right, and the length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com