Structure for fastening metallic plate parts together

A technology for fixing structures and metal plates, which is applied in the direction of metal casings, closed casings, circuits, etc., can solve problems such as fewer fixed parts and abnormal sounds, and achieve the effects of suppressing abnormal sounds, preventing slack, and realizing assembly and disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

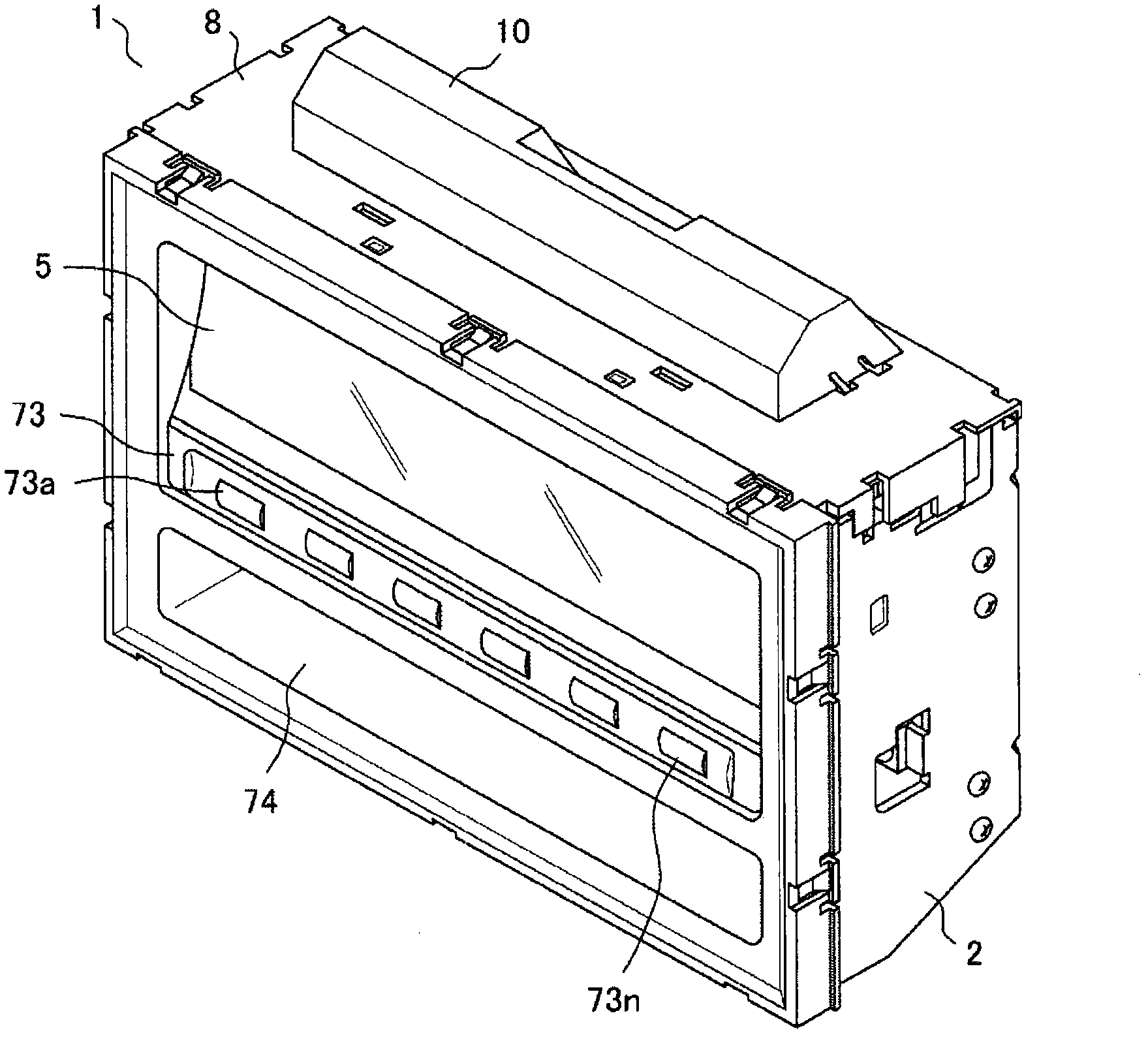

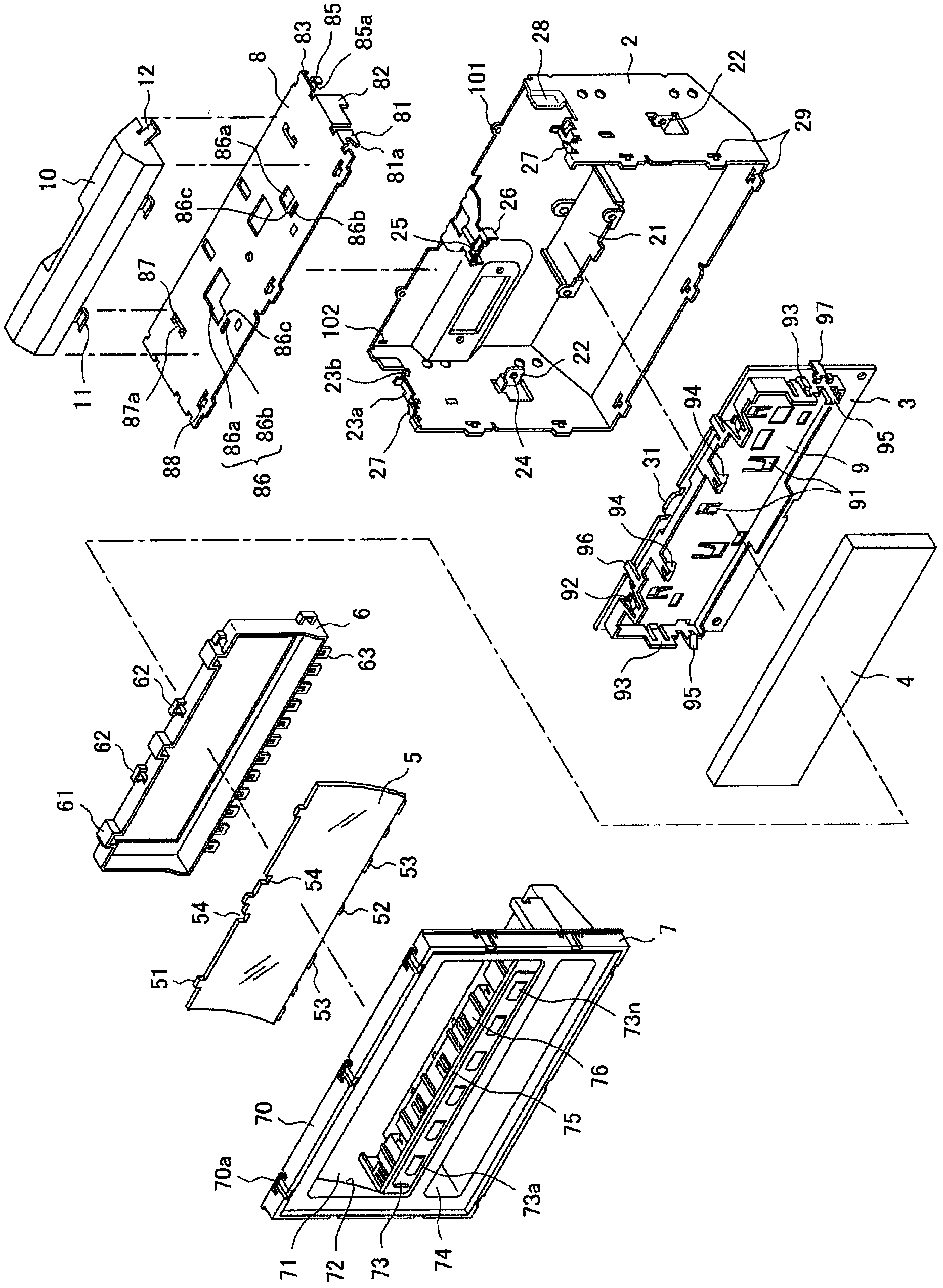

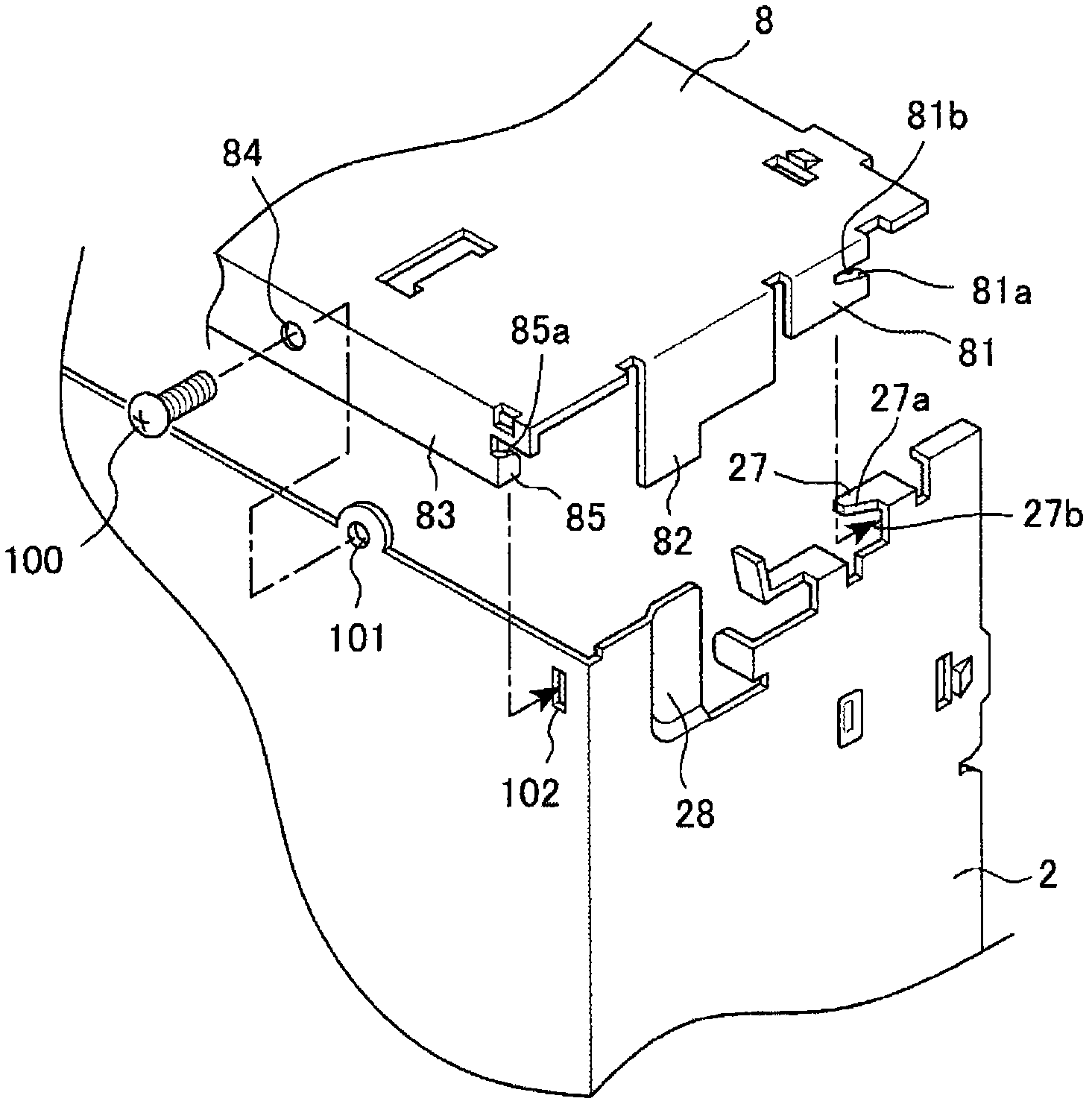

[0022] Hereinafter, the fixing structure of the metal plate parts of this invention is demonstrated based on drawing. First, according to figure 1 , figure 2 An outline of an electronic device using the fixing structure of metal plate parts of the present invention will be described. This electronic device 1 has: a box-shaped hollow casing 2 as a first metal plate part; a substrate 3 assembled inside the casing 2; a display 4 assembled on the substrate 3; a filter arranged opposite to the display 4 The device 5 and the cover 6 are installed together and assembled into the panel 7 in the casing 2; and the cover 8 as a second metal plate part that covers the opening of the casing 2 after all the above-mentioned components are assembled. The expressions of the upper and lower panels, front and rear panels, and left and right side panels in the following description are based on the state where the electronic device is installed at the use position.

[0023] The housing 2 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com