Motor, Motor device and pointer type display device

A motor, unconfigured technology, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of reducing bearing life, abnormal sound and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

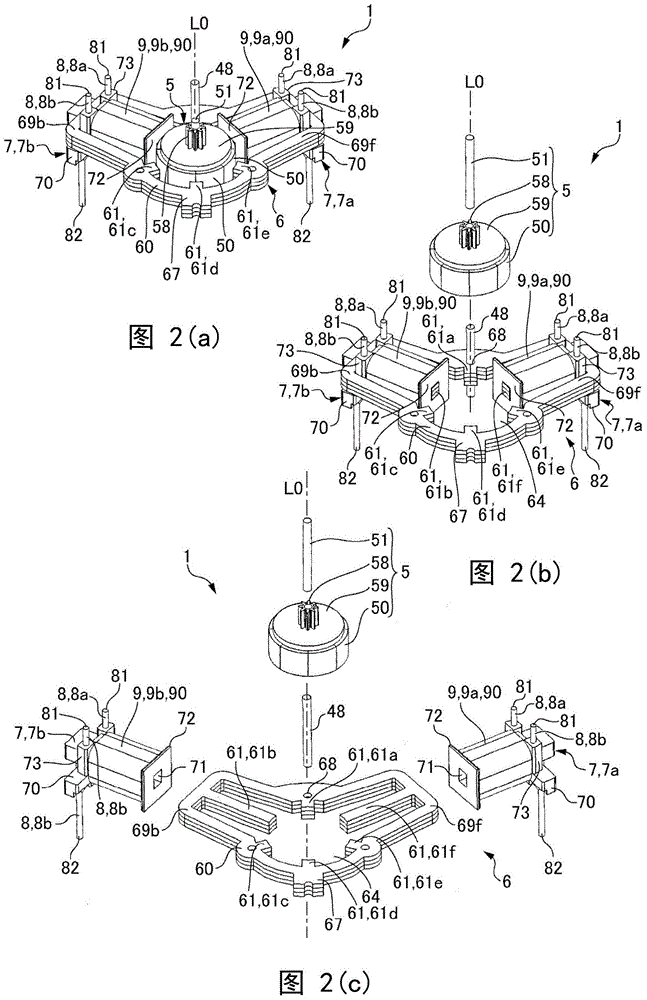

[0057] (The overall structure of the motor unit)

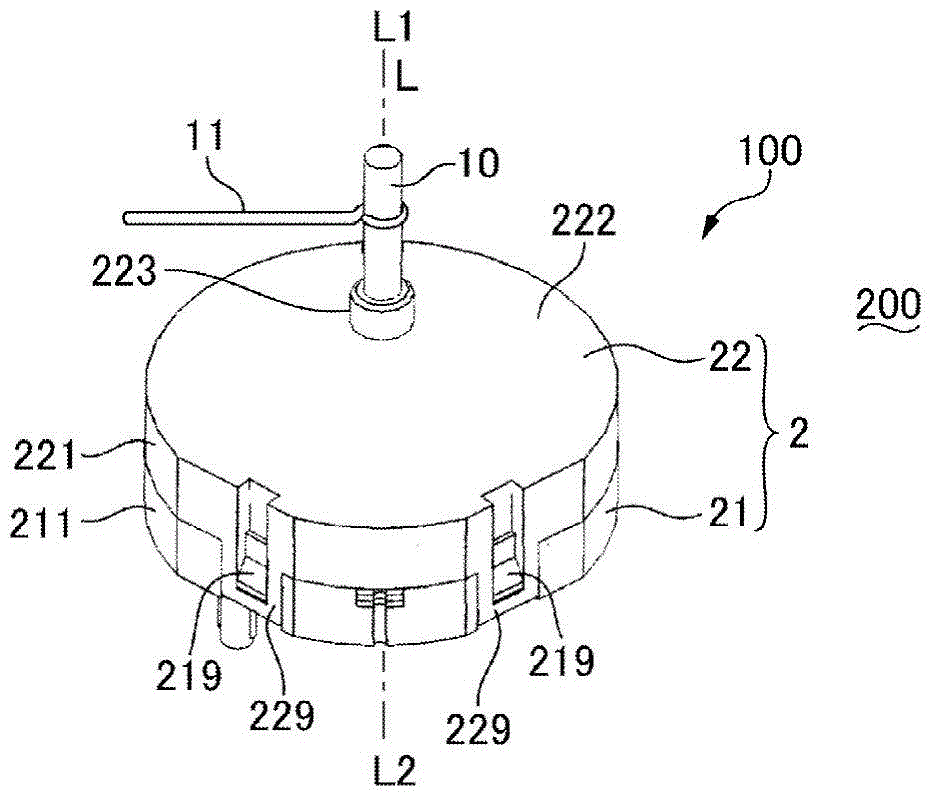

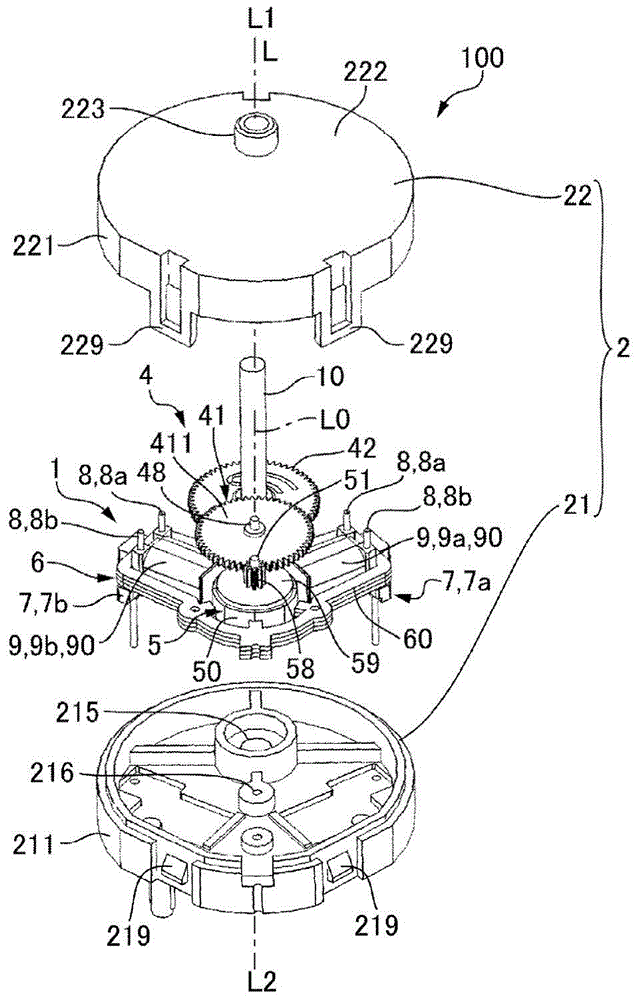

[0058] 1( a ) and FIG. 1( b ) are explanatory diagrams of a motor device 100 according to Embodiment 1 of the present invention, and FIG. As a perspective view, FIG. 1( b ) is an exploded view of the motor device 100 . In addition, in the following description, the side where the output shaft 10 protrudes in the direction in which the axis L of the output shaft 10 extends is taken as one side L1, and the side opposite to the side where the output shaft 10 protrudes is taken as the other side. One side L2. In addition, the axis of the rotor 5 in the motor 1 is defined as the rotation center axis L0. In addition, for the sake of convenience, one side of the rotation center axis L0 is also referred to as one side L1, and the other side of the rotation center axis L0 is also described as the other side L2.

[0059] The motor device 100 shown in FIG. 1( a ) and FIG. 1( b ) has a structure in which the output shaft 10 (output mem...

Embodiment approach 2

[0104] Figure 7 This is an explanatory diagram schematically showing the air gap between the salient pole 61 and the magnet 50 in the motor 1 applied to the motor device 100 according to Embodiment 2 of the present invention. In addition, since the basic structure of this embodiment is the same as that of Embodiment 1, the same code|symbol is attached|subjected and shown to a common part, and their description is abbreviate|omitted.

[0105] like Figure 7 As shown, in this embodiment, when the first gap g1 is narrower than the second gap g2, the end portions 610c, 610d, 610e of the first auxiliary poles (salient poles 61c, 61d, 61e) and the second auxiliary poles The end portion 610a of the pole (salient pole 61a) is located on an imaginary circle C inscribed with the end portions 610f, 610b of the two main poles (salient poles 61f, 61b). The center Co deviates toward the two main poles (salient poles 61f, 61b). In the present embodiment, the rotation center axis L0 of th...

Embodiment approach 3

[0116] Figure 9 It is an explanatory diagram schematically showing the air gap between the salient pole 61 and the magnet 50 in the motor 1 applied to the motor device 100 according to Embodiment 3 of the present invention. In addition, since the basic structure of this embodiment is the same as that of Embodiment 1, the same code|symbol is attached|subjected and shown to a common part, and their description is abbreviate|omitted.

[0117] like Figure 9 As shown, in this embodiment, the S poles and N poles of the magnet 50 are arranged at equal angular intervals on the outer peripheral surface in such a manner that they alternate along the circumferential direction. In the present embodiment, five pairs of S poles and N poles of the magnet 50 are formed. Therefore, in the magnet 50 , a total of ten S poles and N poles are formed at equal angular intervals, so that the angular positions between adjacent S poles and N poles in the circumferential direction differ by 36°.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com