Fuel supply device for internal combustion engine and control device for fuel supply device

A fuel supply device and fuel technology, applied in the direction of fuel injection devices, fuel injection control, special fuel injection devices, etc., can solve the driver's harsh hearing problems, achieve load reduction, improve startability, and suppress abnormal sounds Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0041] 1. The overall structure of the fuel supply device of the internal combustion engine

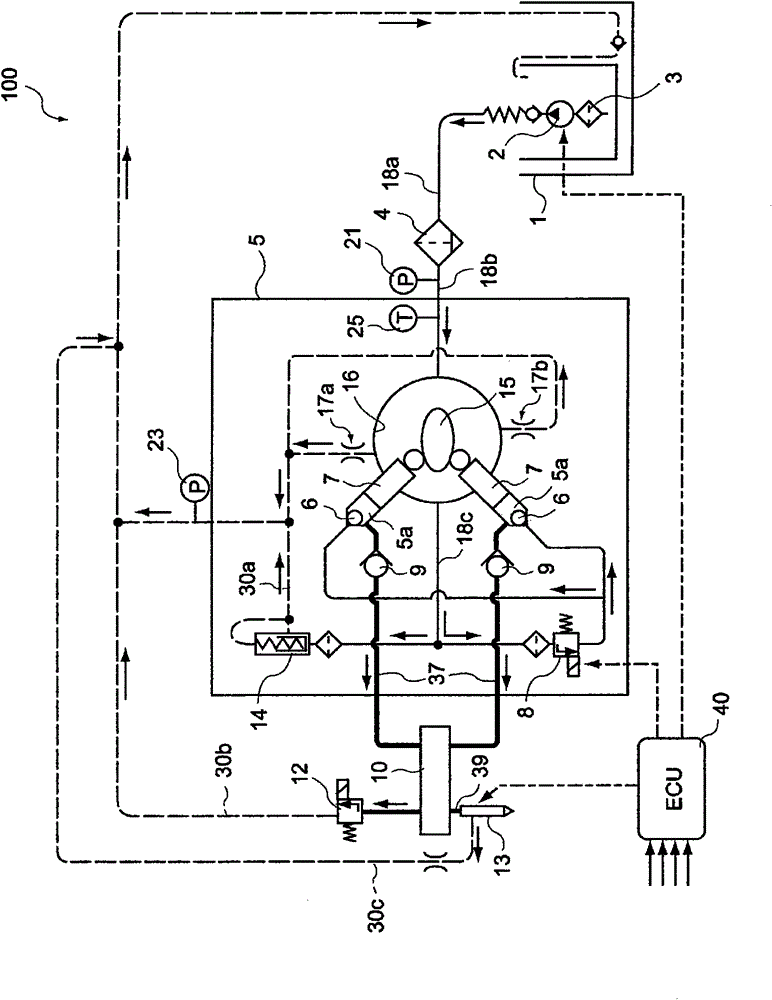

[0042] figure 1 A schematic configuration of a fuel supply device 100 for an internal combustion engine according to the present embodiment including a control unit (hereinafter referred to as "ECU": Electronic Control Unit) 40 of the fuel supply device according to the first embodiment of the present invention is shown.

[0043] figure 1 The fuel supply device 100 shown in is a fuel supply device 100 for a diesel engine, and includes a fuel tank 1, an electromagnetic low-pressure pump 2, a high-pressure pump 5, a common rail 10, and a fuel injection valve 13 as main components. Each component is connected by a fuel passage, in figure 1 Among them, the high-pressure fuel passage 37 is shown by a thick line, the low-pressure fuel passages 18a to 18c are shown by a thin line, and the fuel return paths 30a to 30c are shown by a dotted line.

[0044] The electromagnetic low-pressure...

specific example 1

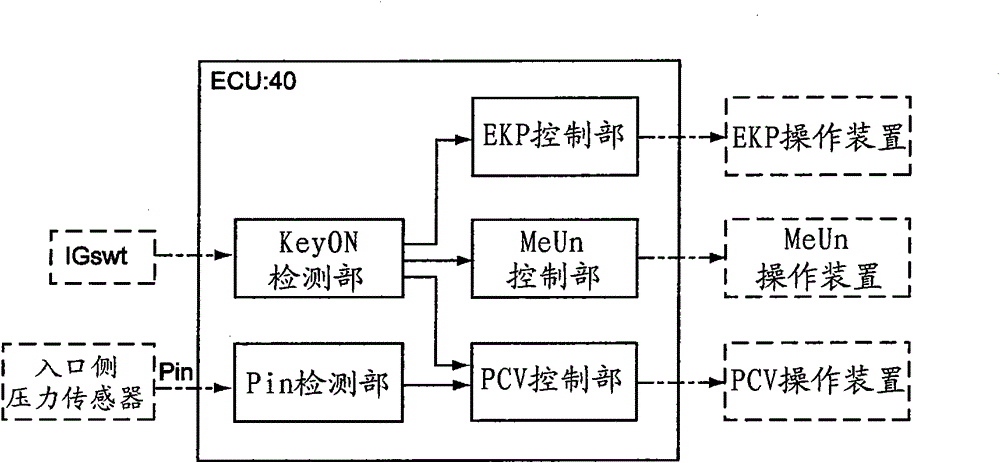

[0071] Below, based on Figure 4 flow chart and Figure 5 The timing diagram for the image 3 An example of the pre-start control of the internal combustion engine performed by the shown ECU 40 will be specifically described.

[0072] First, in step S1, it is detected that the ignition switch is turned on while the internal combustion engine is stopped ( Figure 5 in t1). As described above, in this step S1 , instead of detecting that the ignition switch is turned on, it is also possible to detect that the operation switch for the pre-start control of the internal combustion engine is turned on.

[0073] When it is detected that the ignition switch is turned on in step S1, in step 2, the flow control valve MeUn is fully open, while the pressure control valve PCV is fully closed ( Figure 5 in t2). In this embodiment, the flow control valve MeUn and the pressure control valve PCV of the normally open type are used. Since the flow control valve MeUn and the pressure control...

specific example 2

[0082] In the specific example 1 described above, the control of the pressure control valve PCV is started when the inlet pressure Pin of the high-pressure pump exceeds the reference value Pin0, but as shown in the following specific example 2, it can also be set to a preset value. The control of the pressure control valve PCV is started at the timing of the elapse of the reference time from the reference value of the elapsed time after the start of driving the electromagnetic low-pressure pump EKP.

[0083] Figure 7 and Figure 8 A flowchart and a sequence chart for explaining specific example 2 of this embodiment are shown.

[0084] First, as in steps S1 and S2 in the above-mentioned specific example 1, when it is detected in step S11 that the ignition switch is turned on ( Figure 8 In t11), in step S12, the flow control valve MeUn is fully open, while the pressure control valve PCV is fully closed ( Figure 8 in t12).

[0085]Next, in step S13, the drive of the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com