Negative pressure booster

A supercharger and negative pressure technology, which is applied in the field of negative pressure superchargers, can solve problems such as sticking and slipping, hindering the smooth sliding of the valve cylinder, and generating abnormal sounds, so as to prevent deterioration, maintain good maintainability, and suppress abnormal sounds. the effect produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

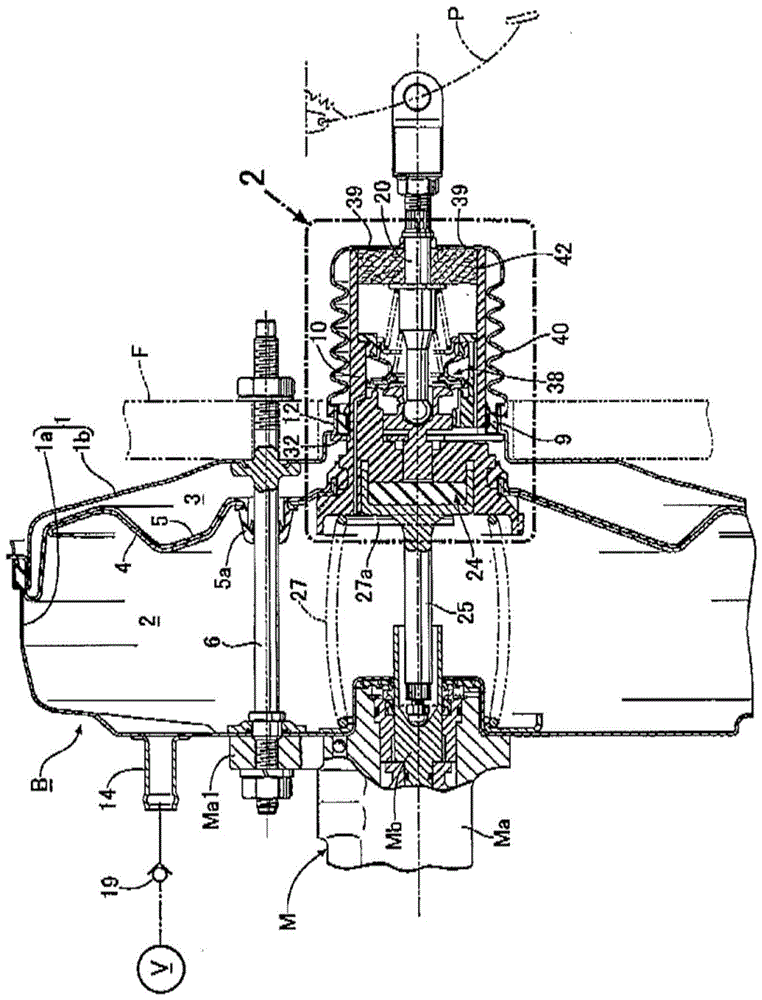

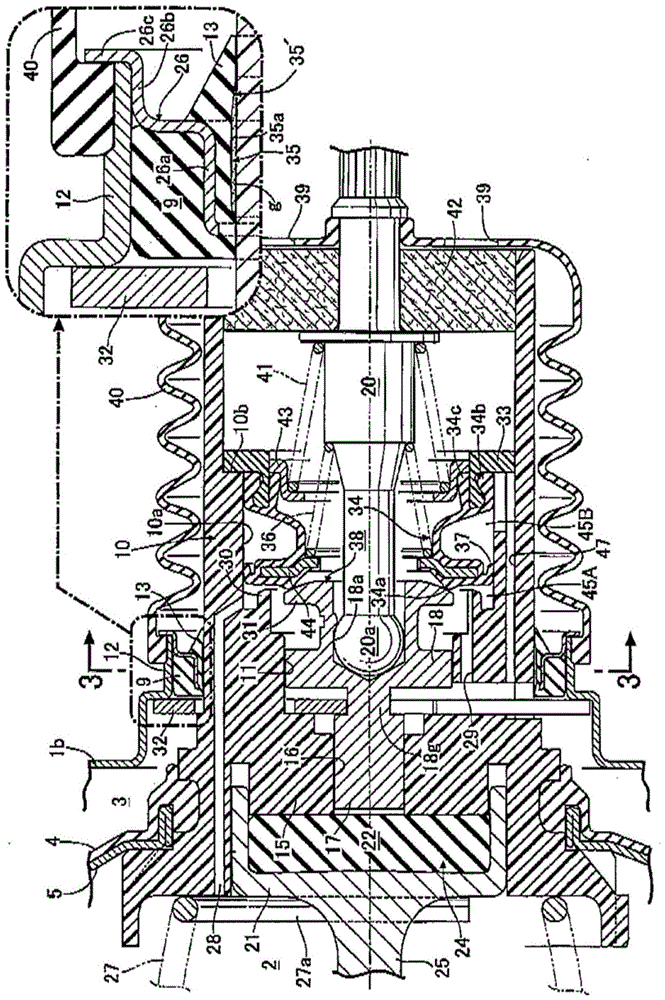

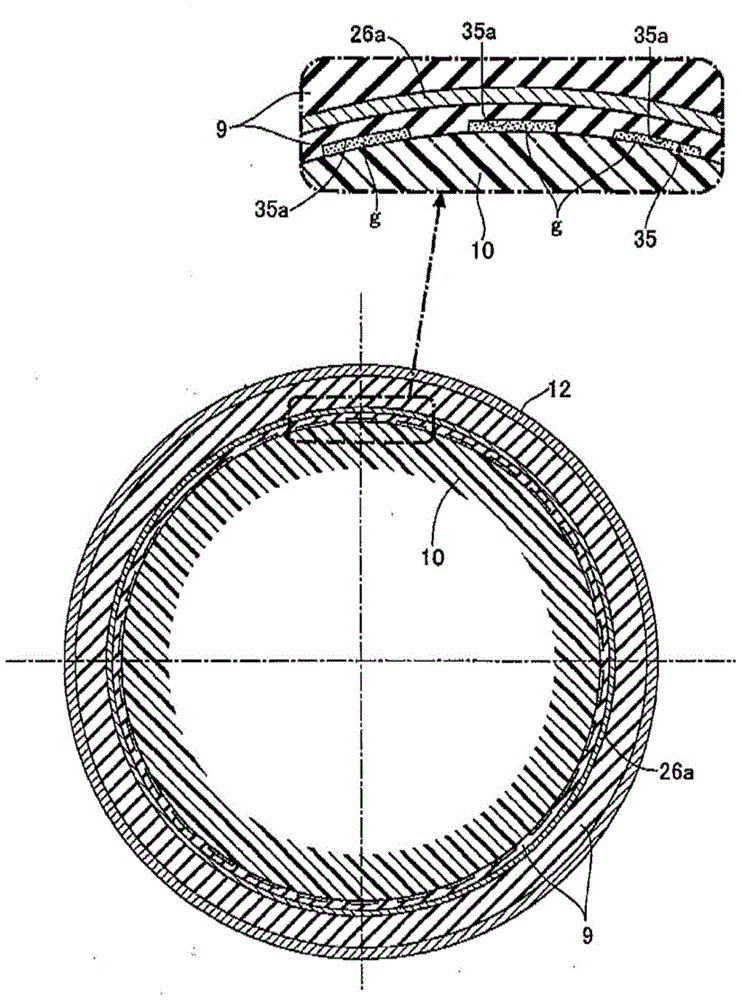

[0031] Embodiments of the present invention will be described below based on the drawings.

[0032] First, in figure 1 and figure 2 Among them, the booster case 1 of the negative pressure booster B is composed of a front case half body 1a and a rear case half body 1b which are respectively formed in a bowl shape and whose opposite ends are connected to each other. These front part housing half body 1a and rear part housing half body 1b are made of steel plate, and it passes through a pair of link rods 6 ( figure 1 Indicates only one of them) and combine. A pair of link rods 6 are arranged so as to sandwich the central axis of the supercharger housing 1, and these link rods 6 are connected to the front end surface of the front housing half 1a with the mounting flange Ma1 of the cylinder Ma of the master cylinder M. , In addition, using these links 6, the rear panel portion outer shell 1b is coupled to the front of the vehicle body F.

[0033] The interior of the supercharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com