Method for operating a transmission and transmission having at least two shifting devices

A technology for shifting devices and transmissions, applied in transmission control, components with teeth, belts/chains/gears, etc., can solve problems such as stick-slip, reduce costs, improve shift quality, and reliable slip reversal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

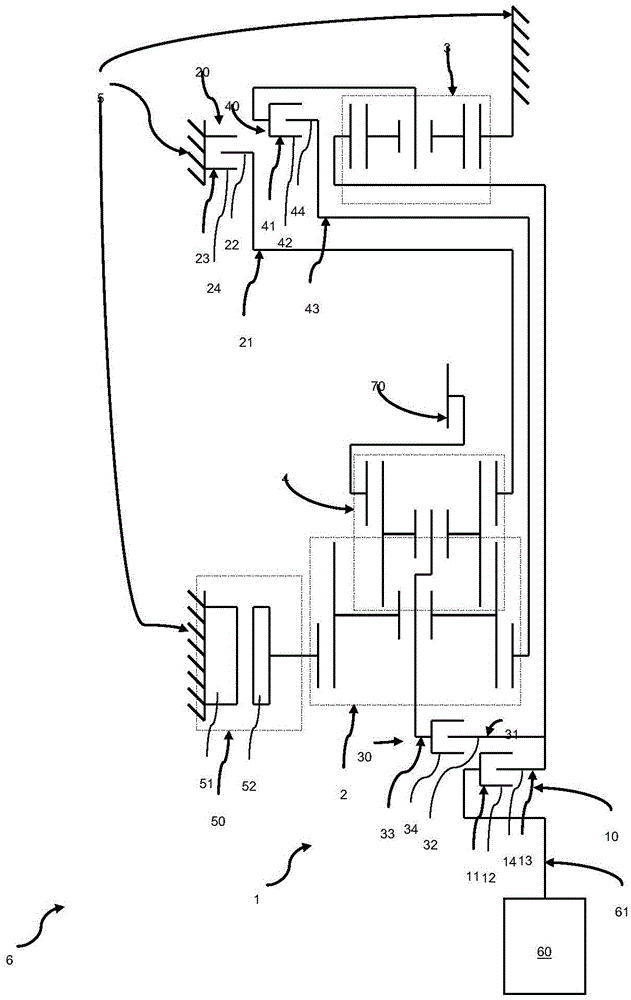

[0068] figure 1 The drive train 6 of the transmission 1 according to an embodiment of the invention is shown in a principle block diagram. The drive train 6 shown in this embodiment is that of a hybrid motor vehicle with an internal combustion engine 60 and an electromechanical energy converter 50 called an electric machine. By means of the transmission 1 , torque can be transmitted from the internal combustion engine 60 and / or the electric machine 50 to an output pinion 70 , wherein the output pinion 70 is connectable or connectable to driveable wheels of the hybrid motor vehicle.

[0069] Conversely, torque can also be transmitted from output pinion 70 to internal combustion engine 60 and / or electric machine 50 , in particular in the sense of a resistive torque operation of internal combustion engine 60 and / or by means of electric machine 50 in order to recover energy.

[0070] In this embodiment, the transmission 1 has a first shifting device 10 , a second shifting device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com