A kind of solid carbide hob and its manufacturing process

A solid carbide, manufacturing process technology, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as wear, chipping, thermal cracking, etc., achieve extremely low friction coefficient, increase hardness, and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

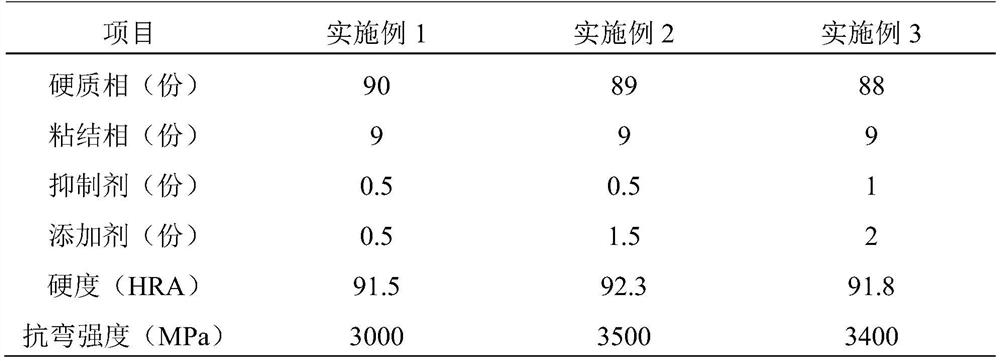

Embodiment 1

[0034] An integral hard alloy hob is composed of the following raw materials in parts by weight: 90 parts of hard phase, 9 parts of binder phase, 0.5 part of inhibitor, and 0.5 part of additive. The hard phase is tungsten carbide with a purity of 99.7% and a particle size of 0.5 μm; the binder phase is cobalt powder with a purity of 99.99%; the inhibitor is chromium carbide with a purity of 99.93% and tantalum carbide with a purity of 99.95%; Each component composition is respectively: 20% Tween 60, 30% Span 80, 0.01% graphene, and the balance is rare earth elements, and the composition of rare earth elements is lanthanum: yttrium: neodymium: praseodymium = 2:1: 4:1. Solid carbide hobs are made through the following process steps:

[0035] (1) Wet milling: the raw materials weighed according to the above proportions are wet milled by a drum ball mill, the wet milling medium is acetone, and the grinding balls are ultrafine cemented carbide balls (Fisher particle size 0.2 μm), ...

Embodiment 2

[0042]An integral hard alloy hob is composed of the following raw materials in parts by weight: 89 parts of hard phase, 9 parts of binder phase, 0.5 part of inhibitor, and 1.5 parts of additive. The hard phase is tungsten carbide with a purity of 99.7% and a particle size of 0.5 μm; the binder phase is cobalt powder with a purity of 99.99%; the inhibitor is chromium carbide with a purity of 99.93% and tantalum carbide with a purity of 99.95%; The composition of each component is: 30% Tween 60, 20% Span 80, 0.05% graphene, and the balance is rare earth elements, and the composition of rare earth elements is lanthanum: yttrium: neodymium: praseodymium = 2:1 :4:1. Solid carbide hobs are made through the following process steps:

[0043] (1) Wet milling: the raw materials weighed according to the above proportions are wet milled by a drum ball mill, the wet milling medium is acetone, and the grinding balls are ultrafine cemented carbide balls (Fisher particle size 0.2 μm), and th...

Embodiment 3

[0050] An integral hard alloy hob is composed of the following raw materials in parts by weight: 88 parts of hard phase, 9 parts of binder phase, 1 part of inhibitor, and 2 parts of additive. The hard phase is tungsten carbide with a purity of 99.7% and a particle size of 0.5 μm; the binder phase is cobalt powder with a purity of 99.99%; the inhibitor is chromium carbide with a purity of 99.93% and tantalum carbide with a purity of 99.95%; The components are respectively: 20% Tween 60, 30% Span 80, 0.1% graphene, and the balance is rare earth elements, and the composition of rare earth elements is lanthanum: yttrium: neodymium: praseodymium = 2:1: 4:1. Solid carbide hobs are made through the following process steps:

[0051] (1) Wet milling: the raw materials weighed according to the above proportions are wet milled by a drum ball mill, the wet milling medium is acetone, and the grinding balls are ultrafine cemented carbide balls (Fisher particle size 0.2 μm), and the ball-to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com