A three-dimensional stabilizer

A three-dimensional, mandrel technology, applied in the direction of drill pipe, casing, drilling tools, etc., can solve the problems of affecting the life of downhole tools and the uneven force of downhole tools, so as to improve the drilling efficiency, protect the drill bit and improve the drilling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

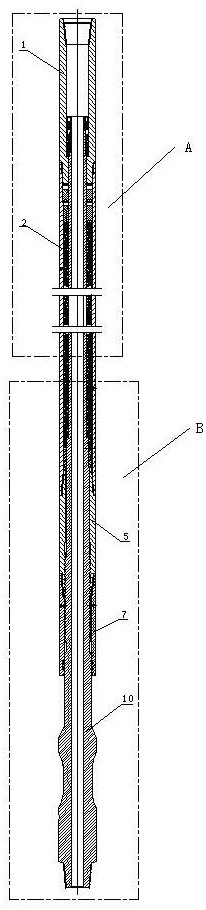

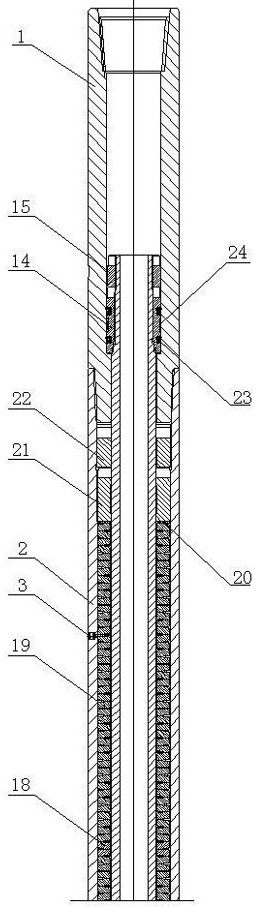

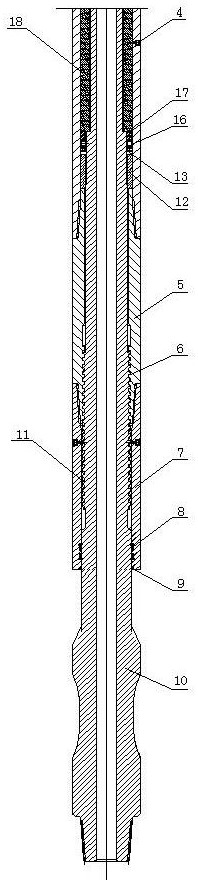

[0016] A three-dimensional stabilizer of the present invention is composed of an upper joint 1, a casing 2 and a mandrel 10. The lower end of the upper joint 1 is connected with the upper end of the casing 2 by a screw thread, and the lower end of the casing 2 is connected with the upper end of the transmission sleeve 5. The screw connection, the lower end of the transmission sleeve 5 is connected with the upper end of the protective sleeve 7 by the screw connection;

[0017] The upper end of the mandrel 10 is placed in the upper joint 1, the upper end thread of the mandrel 10 in the upper joint 1 is connected to the upper piston 14, and the mandrel 10 at the outer end of the upper piston 14 is installed with a locking nut 15; the lower end of the mandrel 10 Located outside the protective sleeve 7 , a seal 8 and a mudguard ring 9 are provided on the contact surface of the protective sleeve 7 and the lower end of the mandrel 10 .

[0018] The inner helix 6 on the transmission s...

Embodiment 2

[0021] In the three-dimensional stabilizer of the present invention, the upper joint 1, the casing 2, the transmission sleeve 5, the protective sleeve 7 and the mandrel 10 are all cylindrical, and the upper end of the upper joint 1 is a conventional drilling tool button type, which is combined with the upper drilling tool Connection, the lower part is connected with the shell 2 by thread, and the middle is for the fluid channel and the upper piston 14 to reciprocate. The casing 2, the upper oil injection hole 3 and the lower oil injection hole 4 constitute the casing assembly. The casing 2 houses the internal mechanism, connects the upper and lower parts, and transmits power; The moving mechanism is injected with lubricating oil to protect its normal operation. The upper oil injection hole 3 and the lower oil injection hole 4 are designed to facilitate oil injection and exhaust. The transmission sleeve 5, the inner screw 6 of the transmission sleeve, the protective sleeve 7, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com