Heat exchanger

A technology of heat exchangers and heat exchange parts, applied in heat exchange equipment, indirect heat exchangers, heat exchanger shells, etc., can solve problems such as abnormal sound, insufficient subcooling degree, and insufficient refrigerant supercooling degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, this embodiment will be described with reference to the drawings. In order to facilitate understanding and description, the same components are given the same reference numerals as much as possible in each drawing, and overlapping descriptions are omitted.

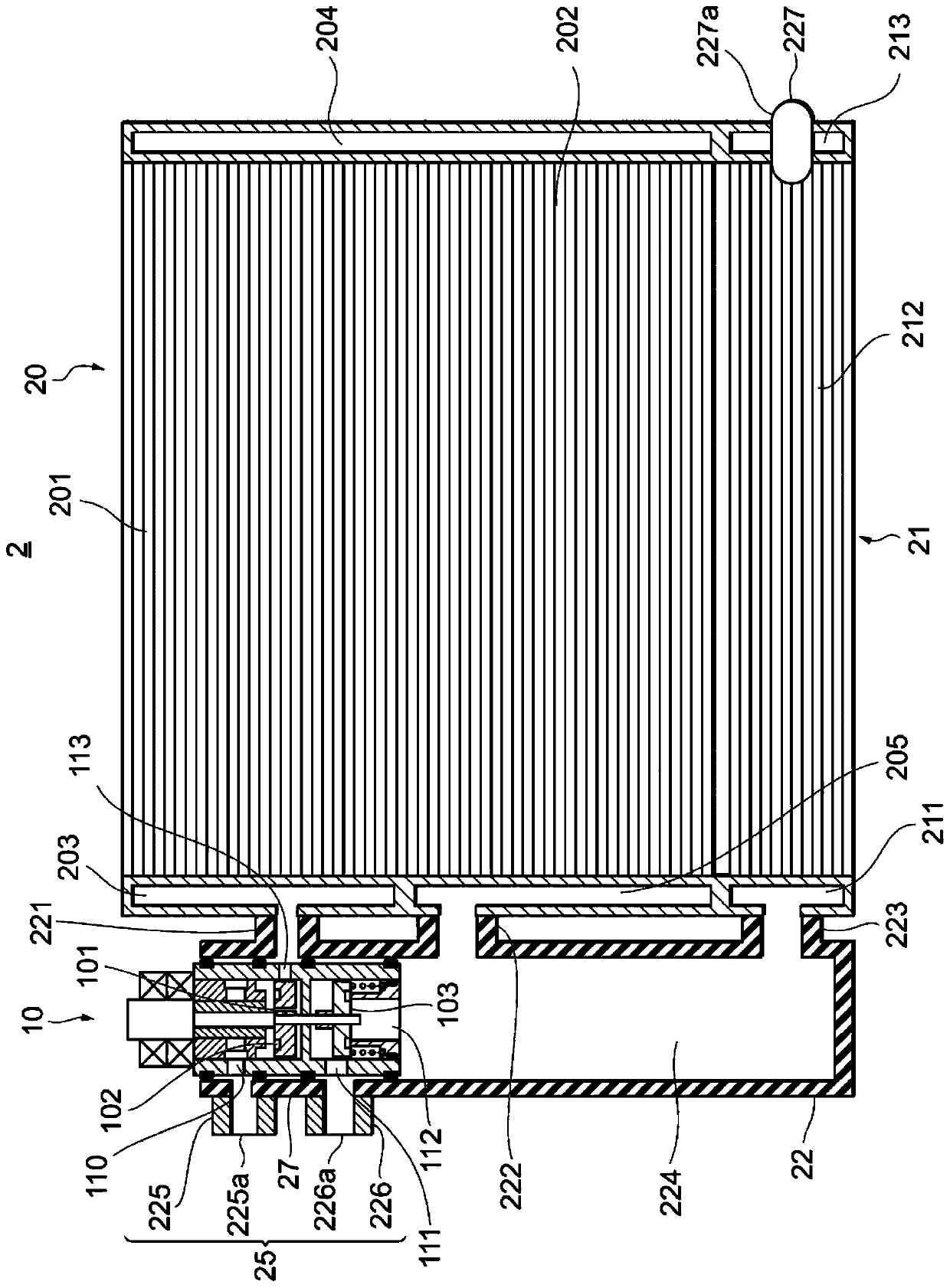

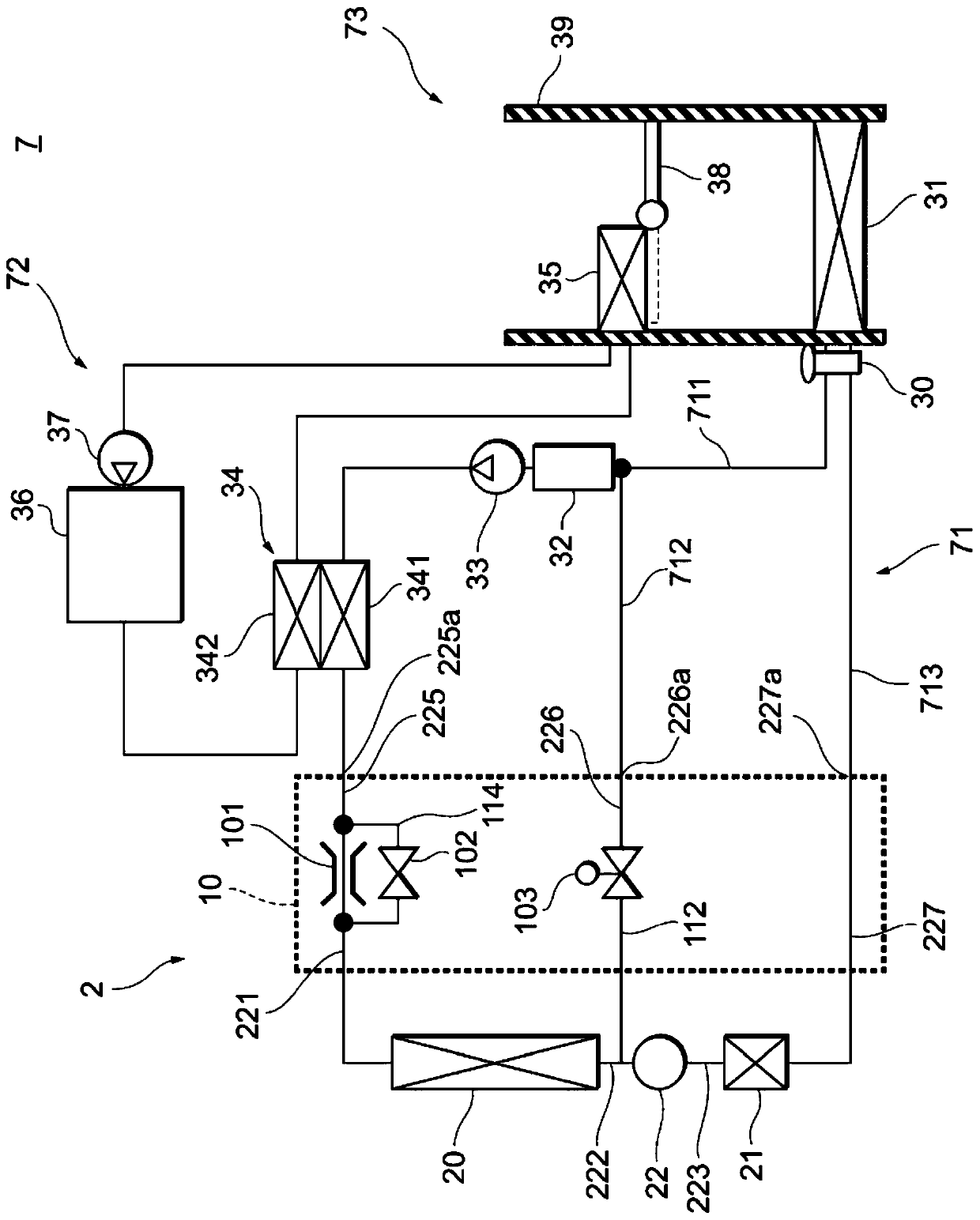

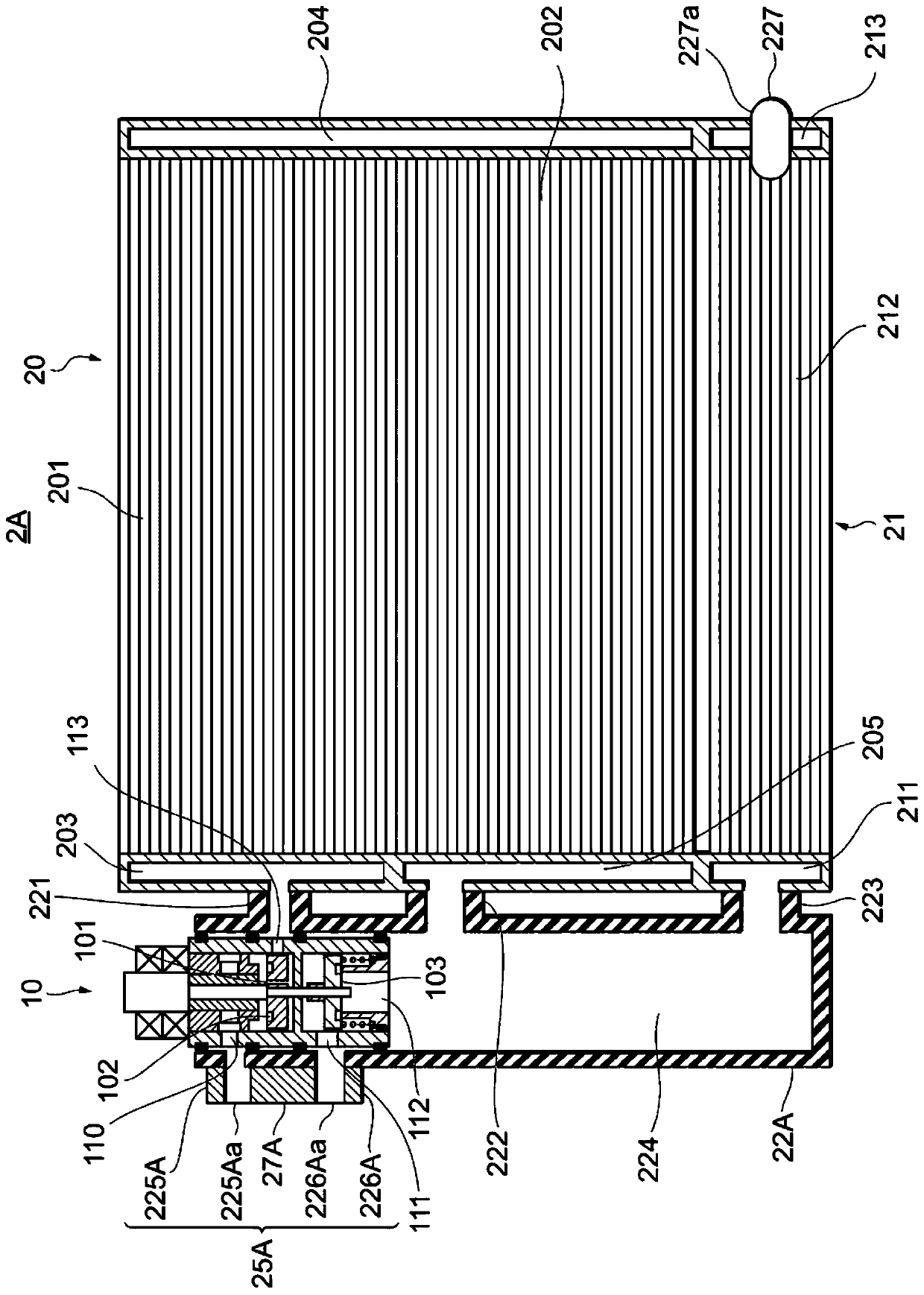

[0024] like figure 1 As shown, the heat exchanger 2 of the present embodiment includes an upstream heat exchange unit 20 , a downstream heat exchange unit 21 , and an accumulator 22 . The upstream side heat exchange unit 20 has two upstream side cores 201 , 202 and header tanks 203 , 204 , 205 . In the present embodiment, a configuration having two upstream cores 201 and 202 was shown as an example, but the number of cores may be one or three or more. The upstream side cores 201, 202 are parts for heat exchange between the refrigerant flowing inside and the air flowing outside, and have tubes through which the refrigerant passes and fins provided between the tubes. .

[0025] A header tank 203 is at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com