Glass plate structure, vibrating plate, opening member, and glass substrate for magnetic recording medium

A kind of glass plate, structure technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

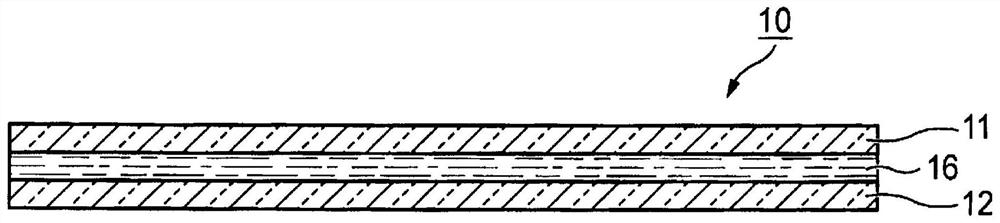

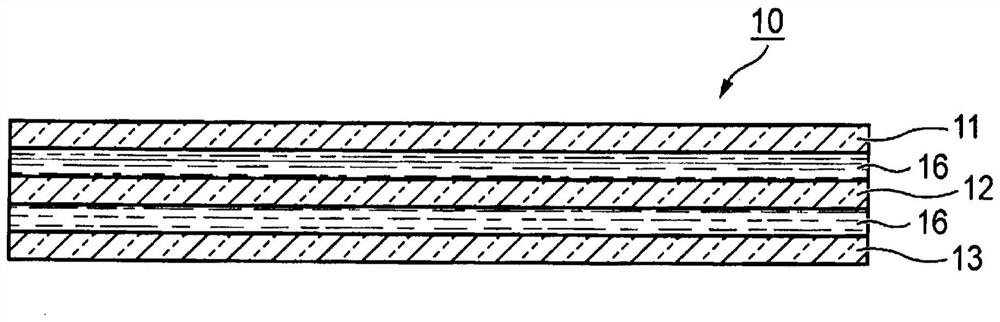

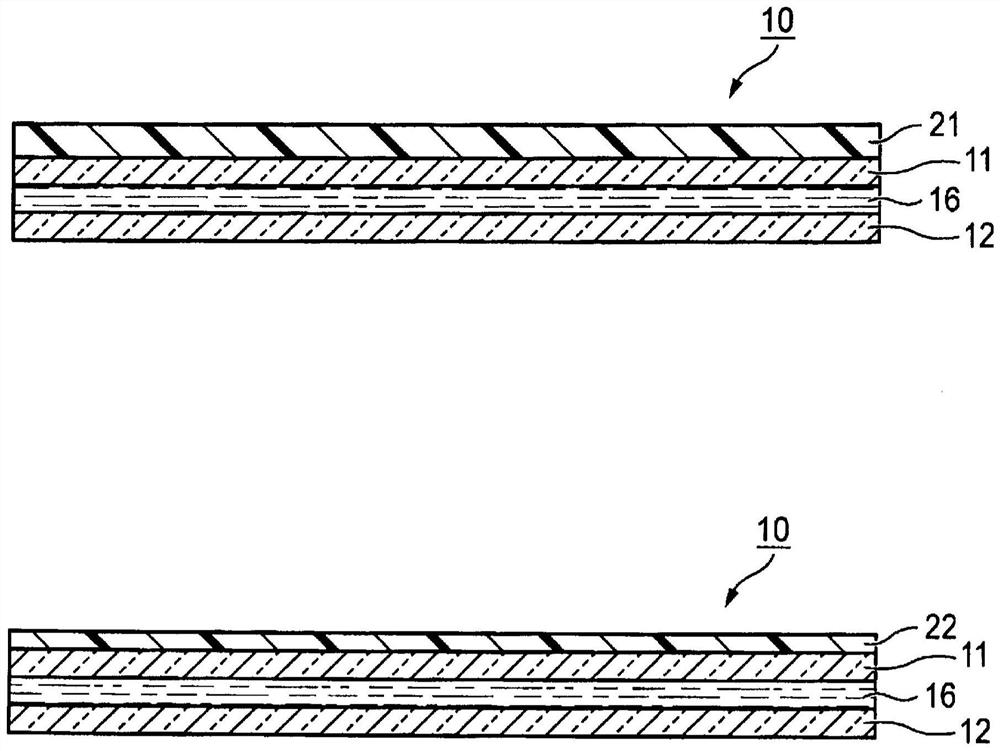

Embodiment 1

[0167] Prepare a glass plate 1 of 12 mm x 60 mm x 0.5 mm as a glass plate A, apply ion-exchanged water thereon as a liquid layer, and then adhere a glass plate 2 of 12 mm x 60 mm x 0.5 mm as a glass plate B to it, Thus, a glass plate structure of 12 mm x 60 mm x 1 mm was obtained. Compositions (% by mass) and physical property values of the glass plate 1 and the glass plate 2 are shown below.

[0168] (glass plate 1) SiO 2 : 60%, Al 2 o 3 : 17%, B 2 o 3 : 8%, MgO: 3%, CaO: 4%, SrO: 8%, Density: 2.5g / cm 3 , Young's modulus: 77GPa, specific elastic modulus: 3.1×10 7 m 2 / s 2

[0169] (Glass plate 2) SiO 2 : 61.5%, Al 2 o 3 : 20%, B 2 o 3 : 1.5%, MgO: 5.5%, CaO: 4.5%, SrO: 7%, Density: 2.7g / cm 3 , Young's modulus: 85GPa, specific elastic modulus: 3.2×10 7 m 2 / s 2

Embodiment 2~12

[0171] A glass plate structure was obtained in the same manner as in Example 1 except that the liquid layer was changed. In addition, in Example 6, instead of the glass plate 2 of the glass plate B, the glass plate 1 was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com