Torque transfer control mechanism and seat structure

A technology of rotating force transmission and control mechanism, which is applied in the direction of preventing/restricting/restoring the movement of parts of the control mechanism, movable seats, vehicle seats, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, the present invention will be described in further detail based on the illustrated embodiment.

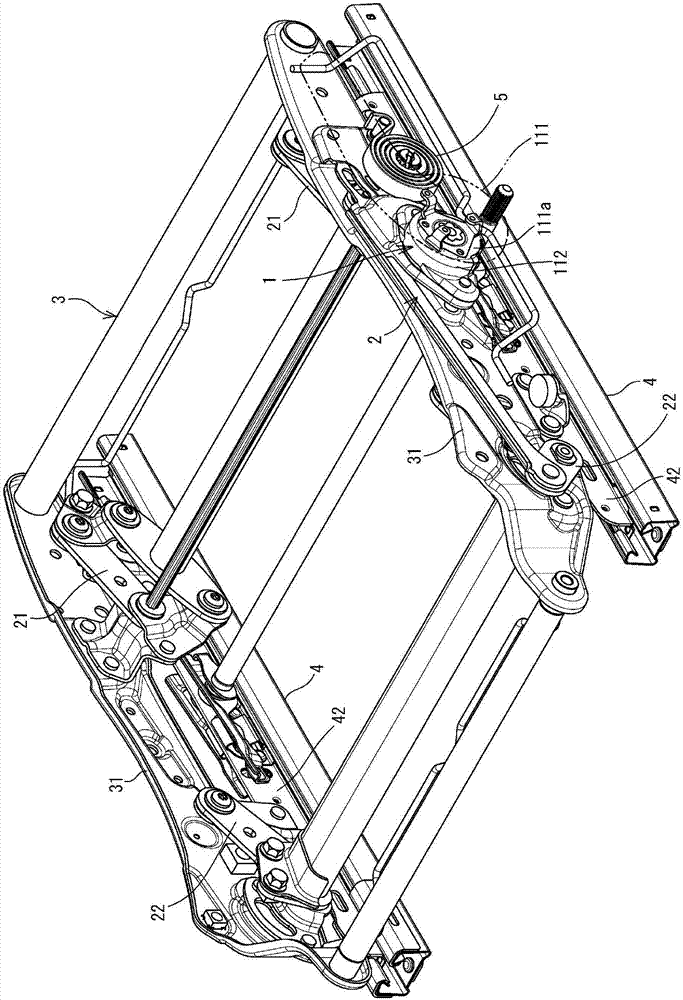

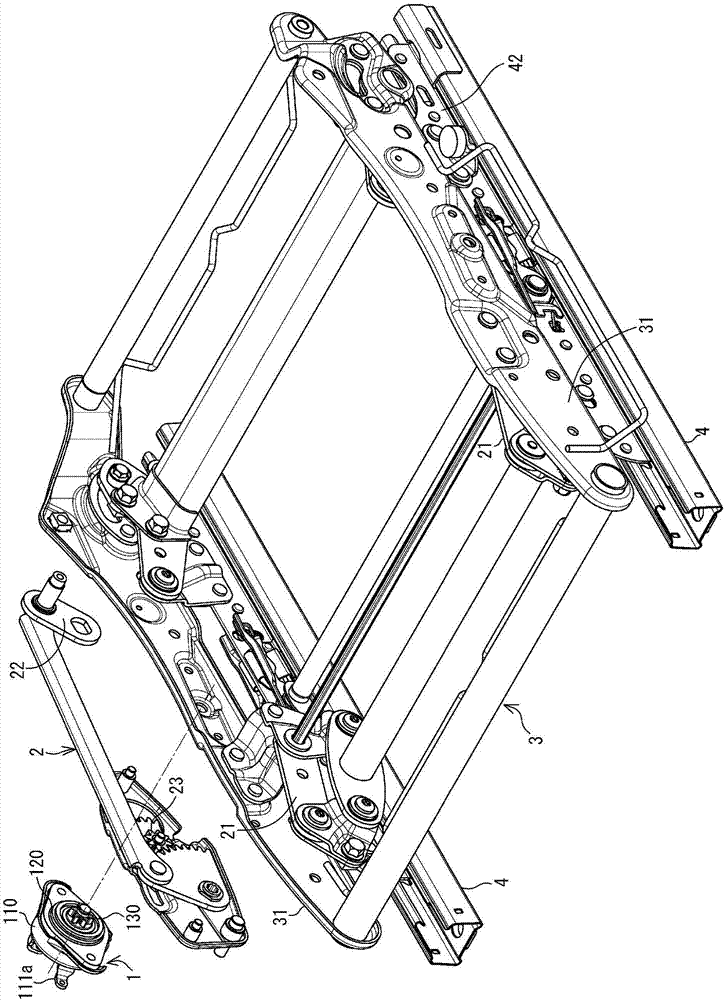

[0033] figure 1 The seat cushion frame 3 having the lifting mechanism 2 in which the rotational force transmission control mechanism 1 of one embodiment of the present invention is assembled is shown. The cushion frame 3 is supported by the upper rails 42 and 42 of the pair of sliders 4 and 4. The lifting mechanism 2 has front links 21, 21 and rear links 22, 22 arranged between the upper rails 42, 42 and the side frames 31, 31 constituting the seat cushion frame 3, and has an opposite side to the upper rail 42, 42 The scroll spring 5 that urges the seat cushion frame 3 (side frames 31 and 31) upward is configured to include the rotational force transmission control mechanism 1 of this embodiment.

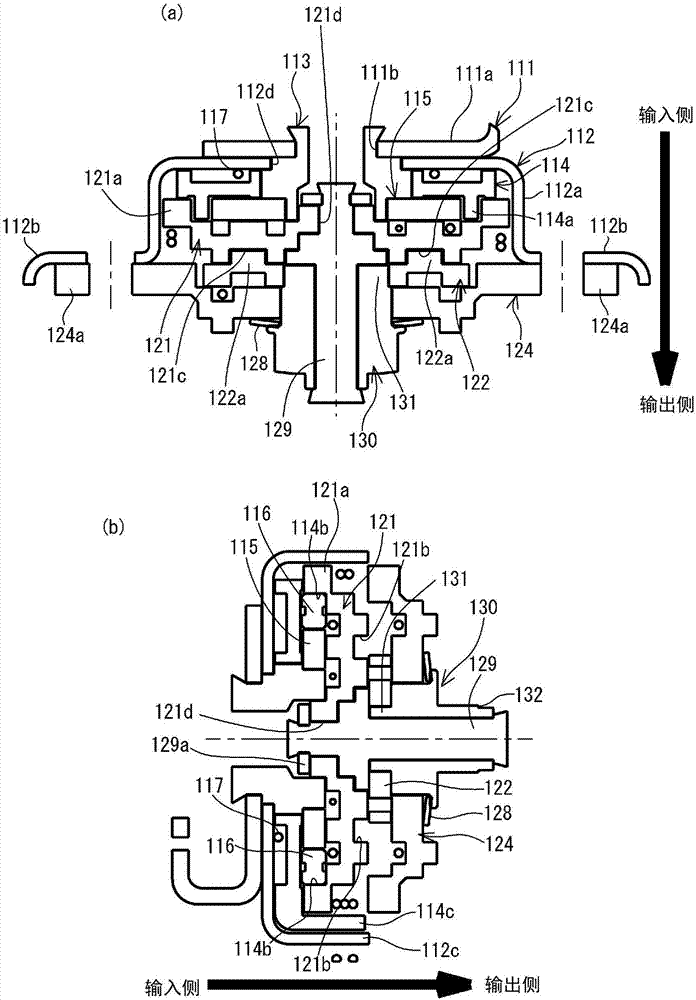

[0034] Such as Figure 2 ~ Figure 4 As shown, the rotational force transmission control mechanism 1 is configured to include a feeding mechanism 110, a rotation control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com