Automatic cutting device for packaging bags

An automatic cutting device and packaging bag technology, applied in the direction of packaging, transportation and packaging, sending objects, etc., can solve the problems of high leakage risk, waste, time-consuming and labor-intensive, etc., achieve automatic and precise cutting, improve production efficiency, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

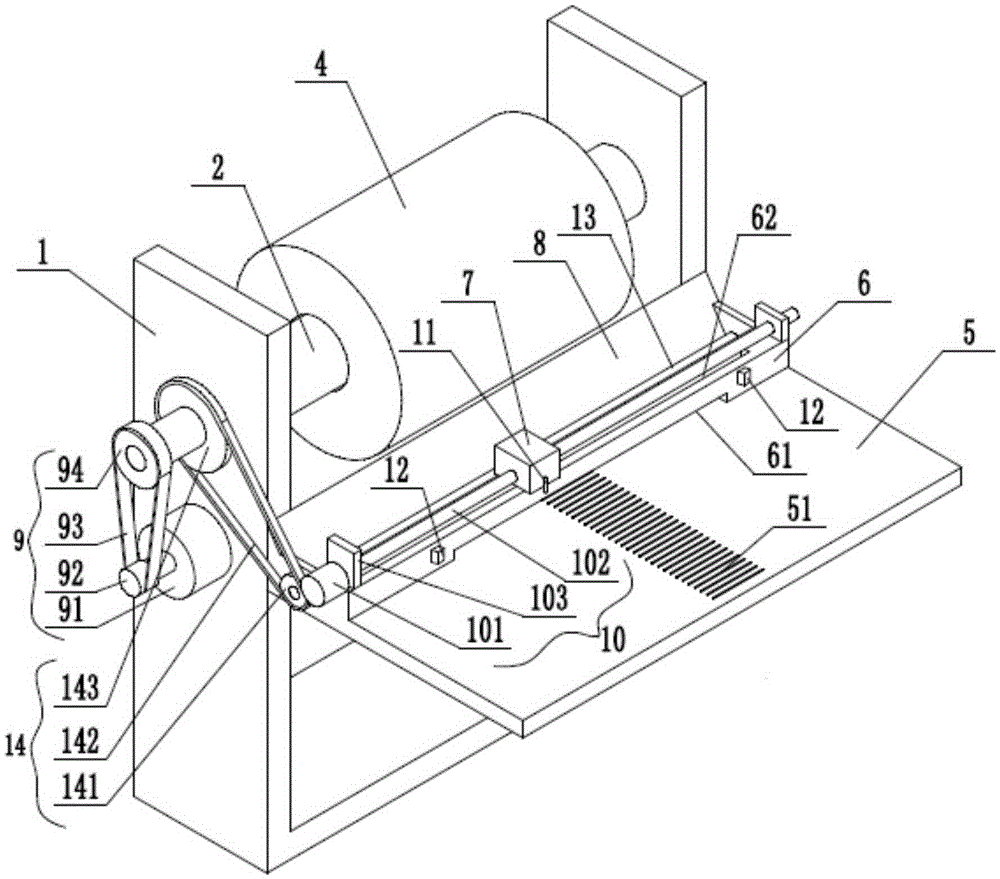

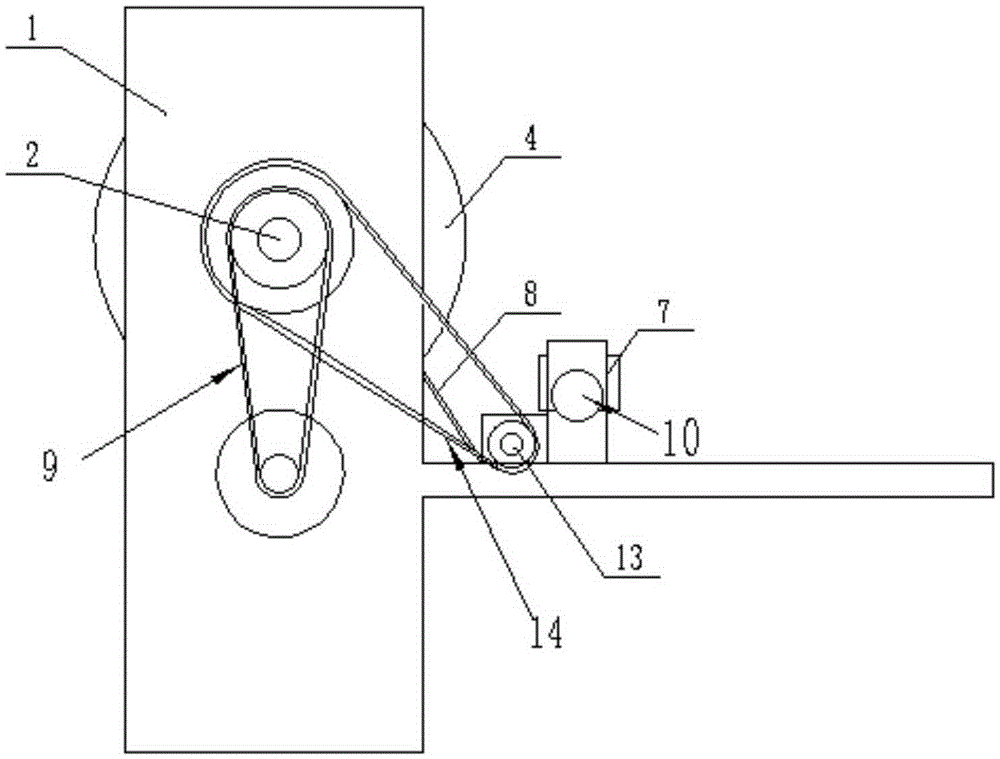

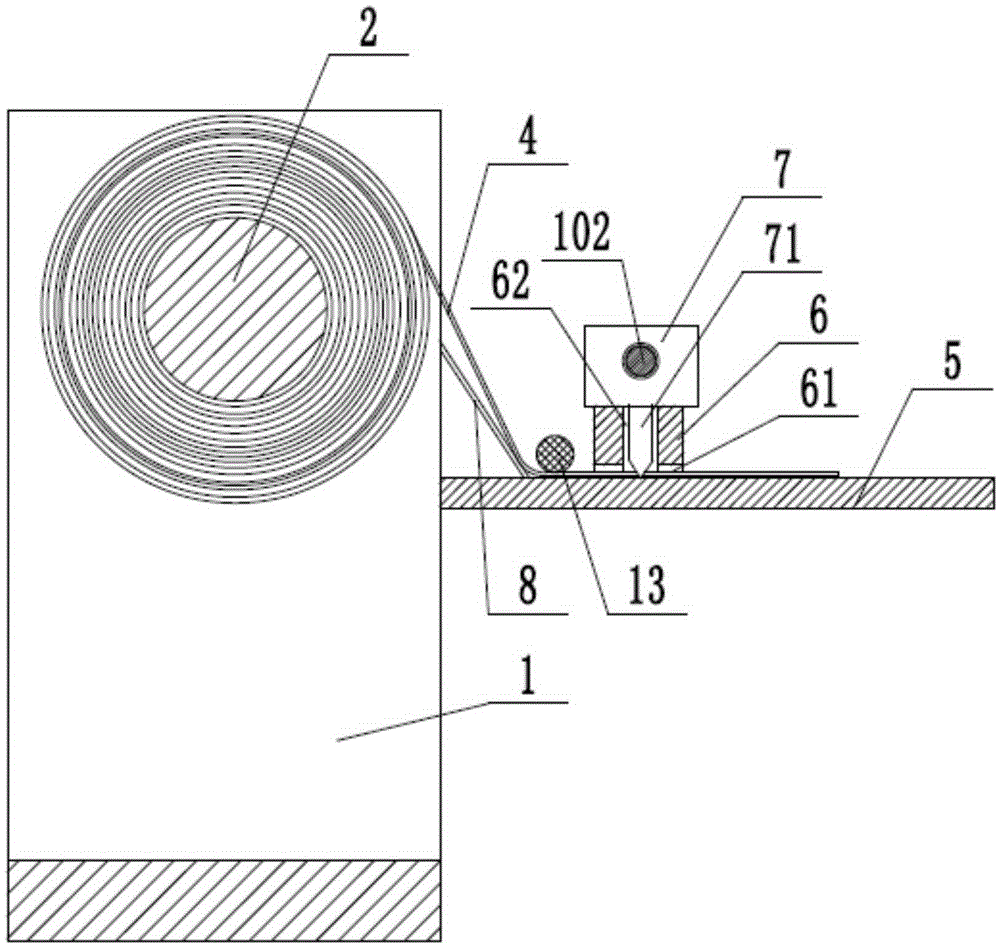

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0017] see Figure 1-3 , an automatic cutting device for packaging bags, including a U-shaped bracket 1, and a horizontal rotating shaft 2 is movably worn on the arms on both sides of the U-shaped bracket 1, and the horizontal rotating shaft 2 is used to place roll-shaped packaging The bag 4 is horizontally extended on the U-shaped bracket 1 located below the horizontal rotating shaft 2 and is provided with a cutting base plate 5, on which a bar-shaped pressing block 6 parallel to the horizontal rotating shaft 2 is installed, The lower part of the bar-shaped pressing block 6 is provided with a slit 61 for a single packaging bag 4 to pass through horizontally. 62 is equipped with a cutting knife 7, the cutting edge 71 of the cutting knife 7 is inserted downwards into the chute 62 and approaches or contacts the upper side of the cutting bottom plate 5, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com