Suction cup clamp for cutting of medium density fiberboard

A suction cup and cutting technology, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve problems that affect the clamping firmness, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the present invention easier to understand, specific embodiments of the present invention will be further described below.

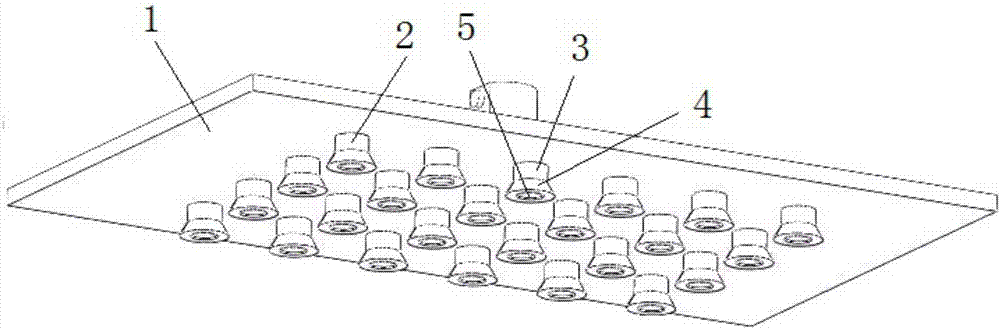

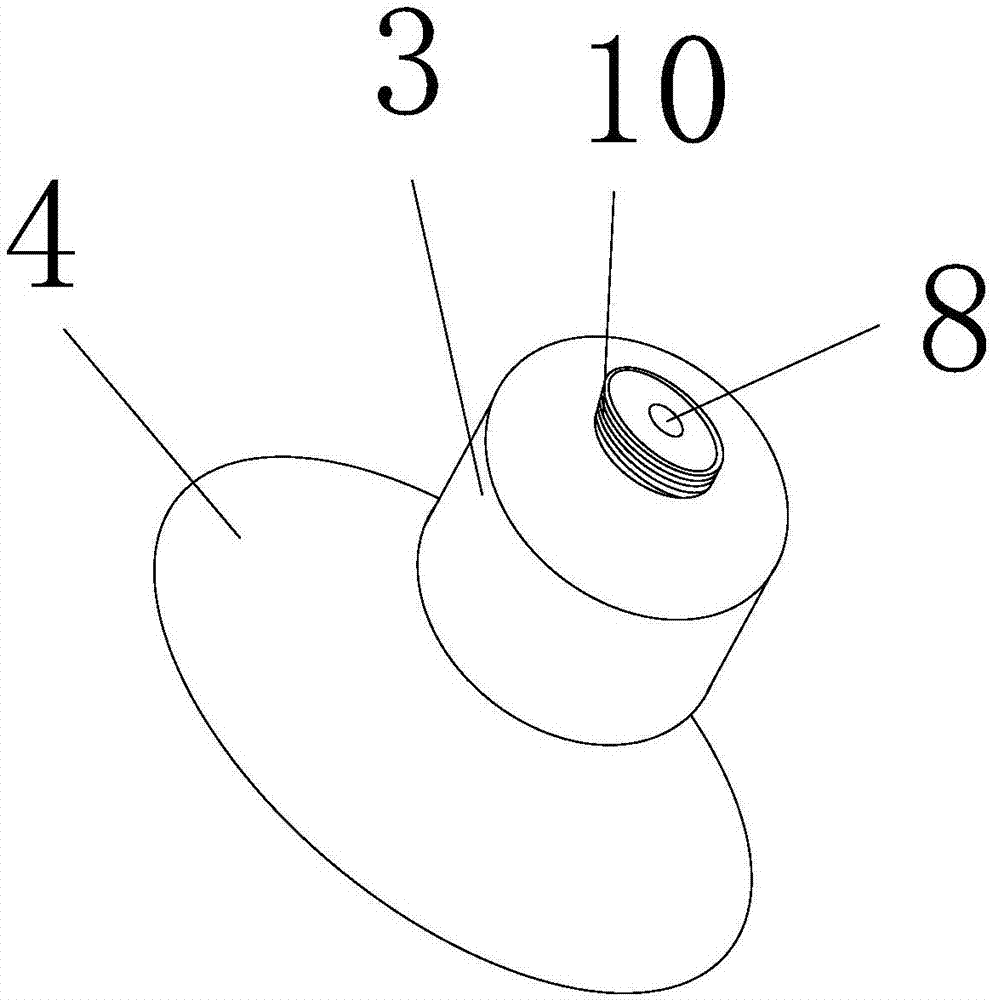

[0019] Such as figure 1 As shown, a kind of suction cup 4 clamps for MDF cutting, including a plate-shaped retrieving tray 1 and a number of adsorption parts 2, the adsorption parts 2 include a connecting column 3 and a bowl-shaped suction cup 4, the connecting column 3 One end is connected to the bottom of the retrieving tray 1, and the other end is connected to the suction cup 4, the suction cup 4 is bowl-shaped, and the bowl-shaped bottom of the suction cup 4 is provided with a support protrusion 5, and the height of the support protrusion 5 is less than The height of the suction cup 4.

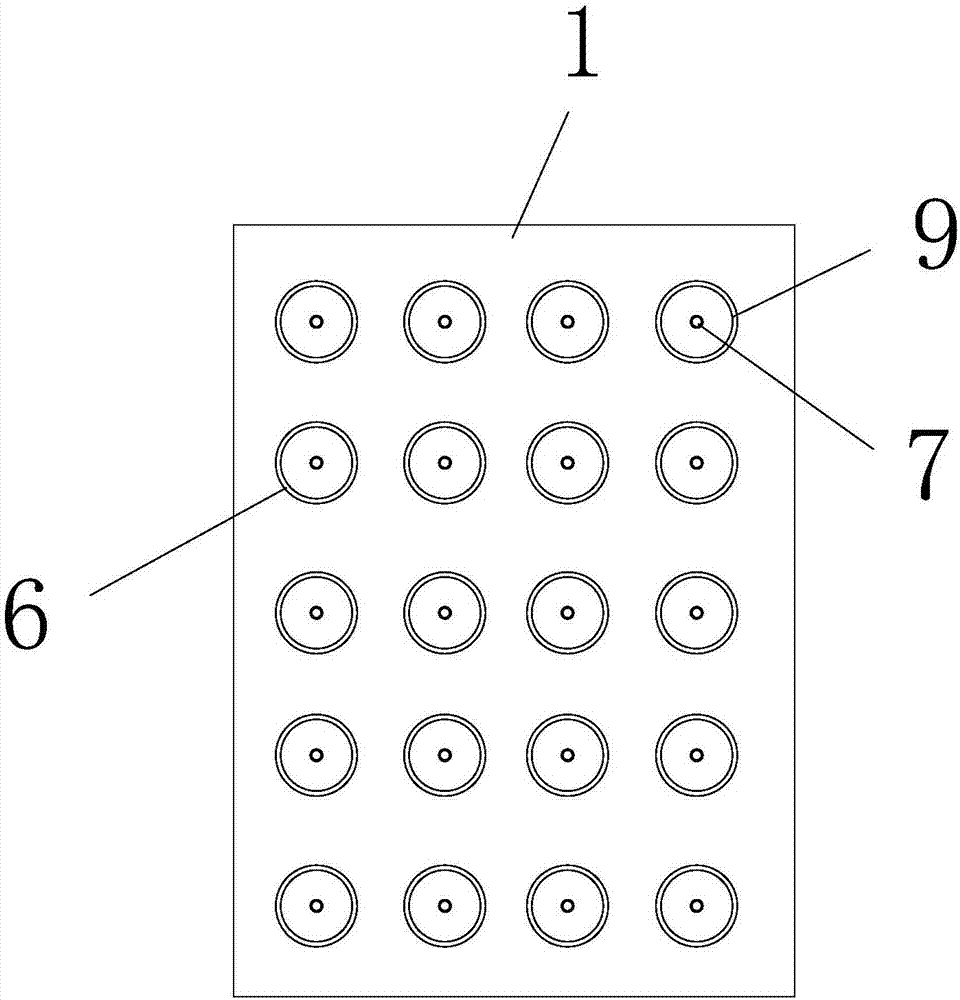

[0020] As a preferred embodiment of the present invention, the bottom of the retrieving tray 1 is provided with several connection points 6, and the connection points 6 are all provided with a first air passage 7, and the first air passage 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com