Plastic dropper mold blanking device and control method thereof

A dropper and mold technology, which is applied in the field of plastic dropper mold cutting devices, can solve the problems of controlling the quality of finished products, low cutting precision of blades, time-consuming and laborious, etc., so as to improve production efficiency, facilitate cutting, and improve precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

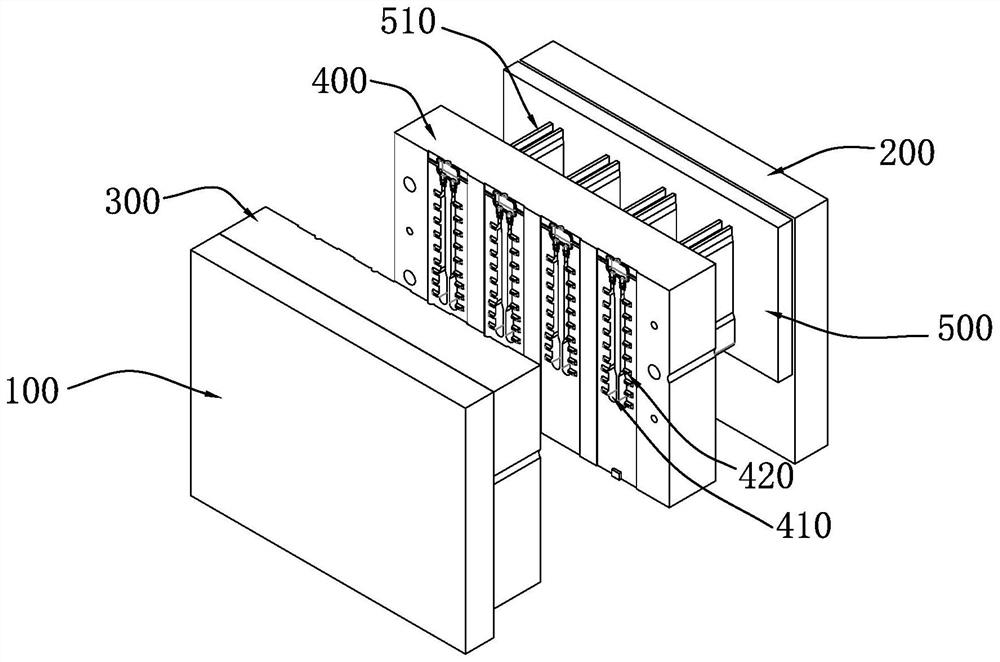

[0041] refer to figure 1 , the present embodiment provides a plastic dropper mold blanking device, including a fixed template 300 and a movable template 400, the movable template 400 is provided with a discharge port 410, the shape of the discharge port 410 is adapted to the shape of the plastic dropper. The cutting knife 510 can be extended into the feeding port 410 to cut the semi-finished plastic dropper after blow molding. Cutting, improve production efficiency. The first driving mechanism drives the movement of the fixed template 300, the second driving mechanism drives the movement of the cutter 510, and the first positioning device is set on the first driving mechanism, and the second positioning device is set on the second driving mechanism, which can ensure the first The accuracy of the action of the first driving mechanism and the second driving mechanism ensures the accuracy of material cutting.

[0042] Such as figure 1 As shown, in the present embodiment, optim...

Embodiment 2

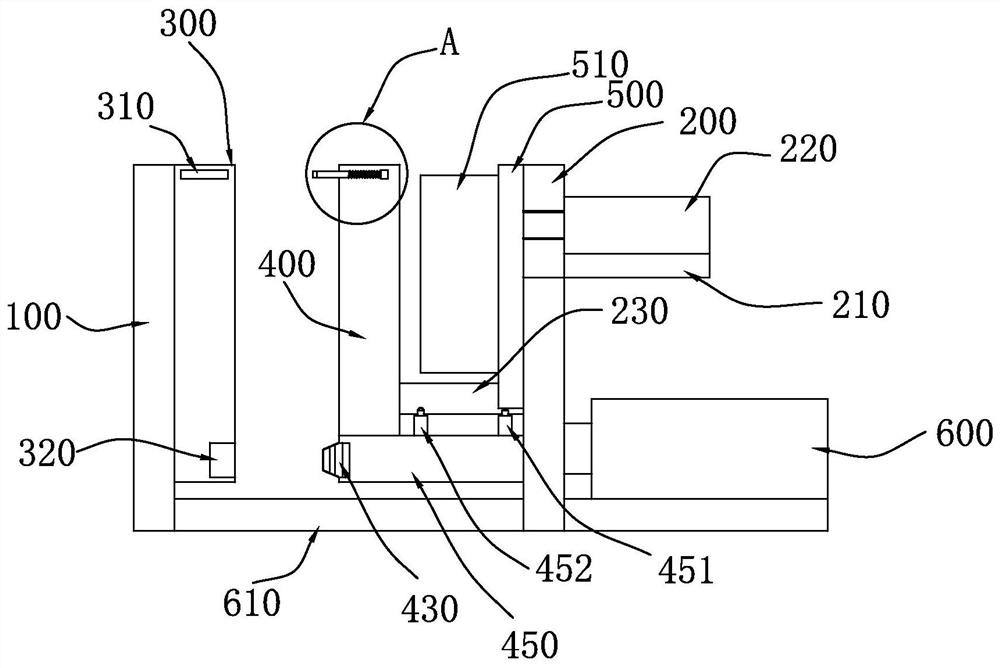

[0044] refer to figure 2 , This embodiment provides a plastic dropper mold blanking device, in addition to the technical features of the above embodiments, it also includes the following technical features.

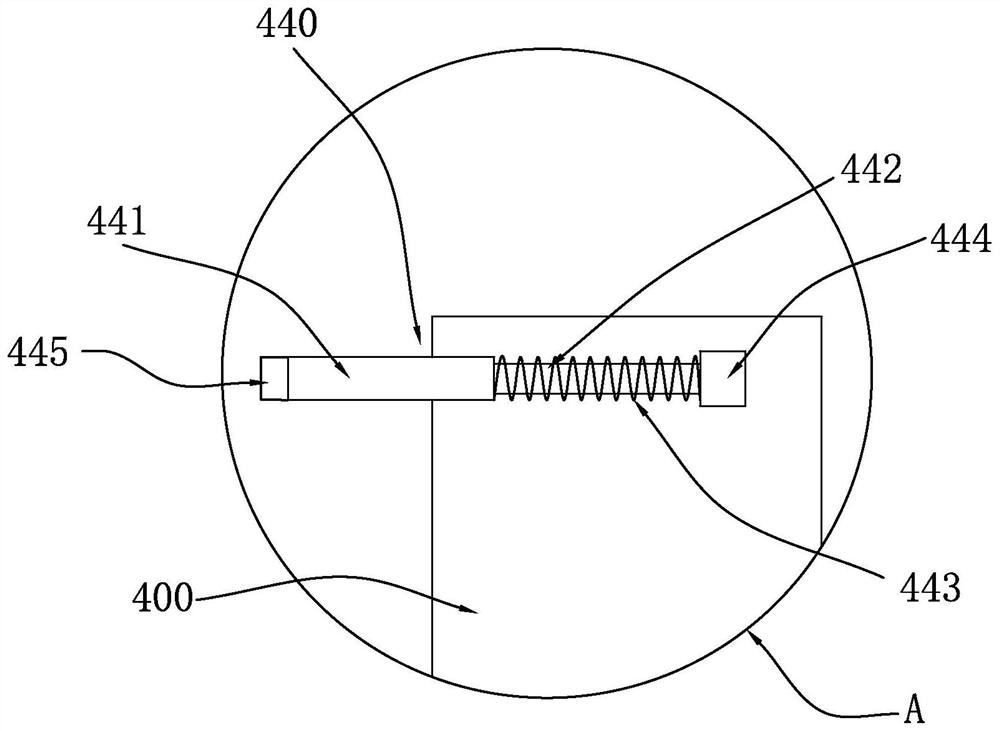

[0045] Such as figure 2 As shown, the first driving mechanism includes a first slide rail 610, a fixed mold base 100 is fixedly installed at one end of the first slide rail 610, and a movable mold base 200 is movably installed at the other end of the first slide rail 610. The mold base 200 is connected with a first pushing mechanism 600 , and the first pushing mechanism 600 can be a hydraulic cylinder, an air cylinder or an electric push rod, so that the movable mold base 200 can move toward the fixed mold base 100 on the first slide rail 610 . The fixed mold base 100 is installed on the side facing the movable mold base 200 with the fixed template 300, and the movable mold base 200 is installed on the side facing the fixed mold base 100. Clamping. A buffer mechanism...

Embodiment 3

[0047] refer to Figure 4 , Figure 5 , this embodiment provides a plastic dropper mold blanking device, in addition to the technical features of the embodiment, it also includes the following acceptance features.

[0048] Such as Figure 4 As shown, the receiving part 320 includes a receiving cavity 321 , a fixed body 322 and a movable body 323 are arranged in the receiving cavity 321 , the fixed body 322 is at one side of the receiving cavity 321 , and the movable body 323 is placed at the other side opposite to the fixed body 322 . Both the fixed body 322 and the movable body 323 are provided with inclined surfaces, so that the fixed body 322 and the movable body 323 form a trumpet-shaped structure. The movable body 323 can move in the direction towards the fixed body 322 in the receiving chamber 321 through the guide rail structure. The side wall, when the movable body 323 moves, the buffer rod 324 can expand and contract on the side wall of the receiving chamber 321, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com