Paper compaction device for paper cutter

A technology of a pressing device and a paper cutter, which is applied in metal processing and other directions, can solve the problems of easy movement of paper, easy lifting of paper, damage to paper surface, etc., so as to improve cutting accuracy, increase market competitiveness, and prevent paper from being messed up. channeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

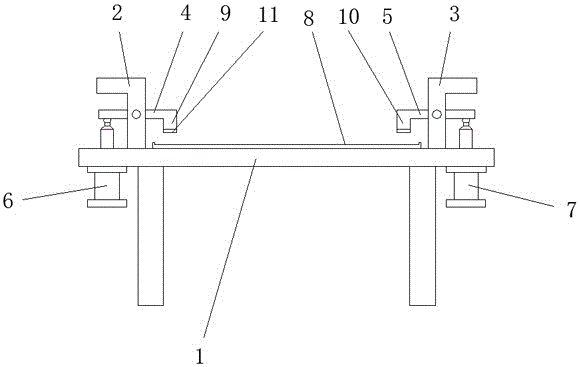

[0017] A paper pressing device for a paper cutter according to the present invention, such as figure 1 As shown, it includes: a platform 1, which is provided with a symmetrically distributed left bracket 2 and a right bracket 3 in an inverted "L" shape; the left bracket 2 is provided with a left pressure plate that can rotate around it 4. The corresponding right bracket 3 is provided with a rotatable right pressing plate 5; the left end of the left pressing plate 4 located outside the platform 1 is hinged to the piston rod of the left telescopic cylinder 6 fixed on the platform 1; One end of the right pressing plate 5 located on the outside of the platform 1 is hinged to the piston rod of the right telescopic cylinder 7 fixed on the platform 1; the platform 1 is provided with a cardboard 8; the cardboard 8 is in the shape of "concave" type; the left press plate 4 and the right press plate 5 are located at one end of the inner side of the stand 1 with a left press head 9 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com