Platform for carrying out numerical-controlled cutting on steel plate based on ships and using method thereof

A technology for steel plates and ships, which is applied in the field of CNC cutting steel plate platforms based on ships, can solve the problem of low precision of cutting steel plates, achieve the effects of high safety and mobility, improve work efficiency, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

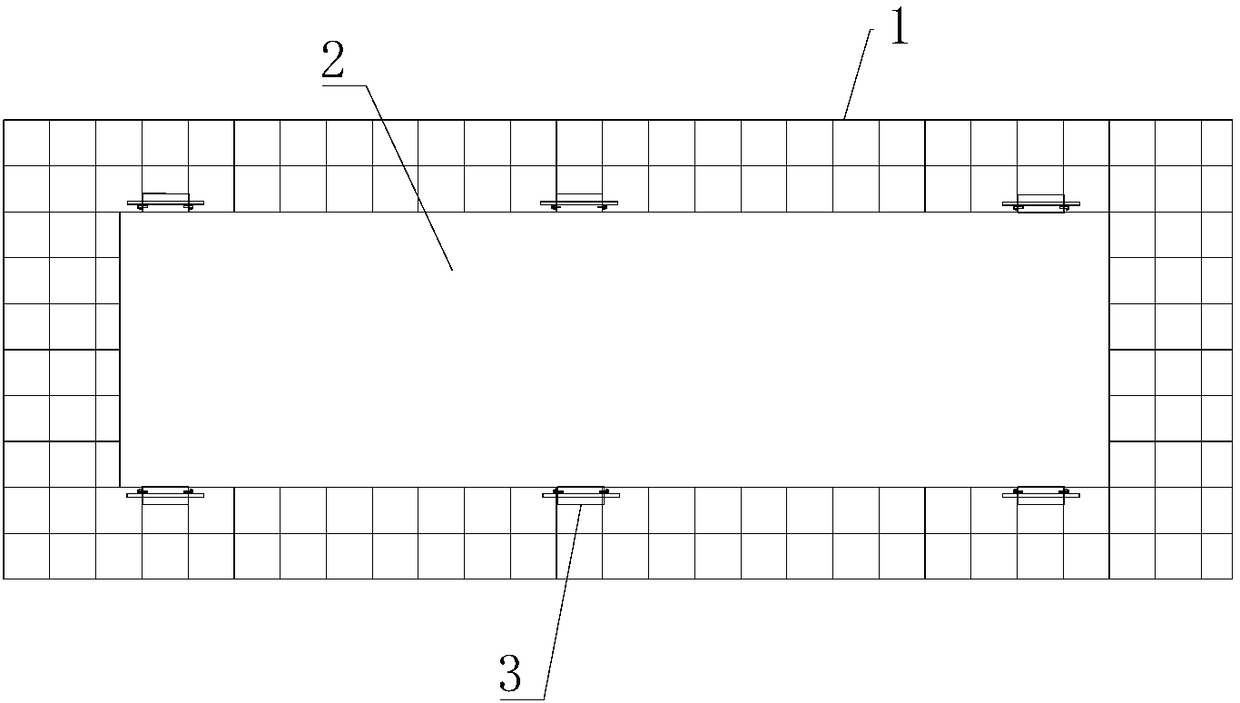

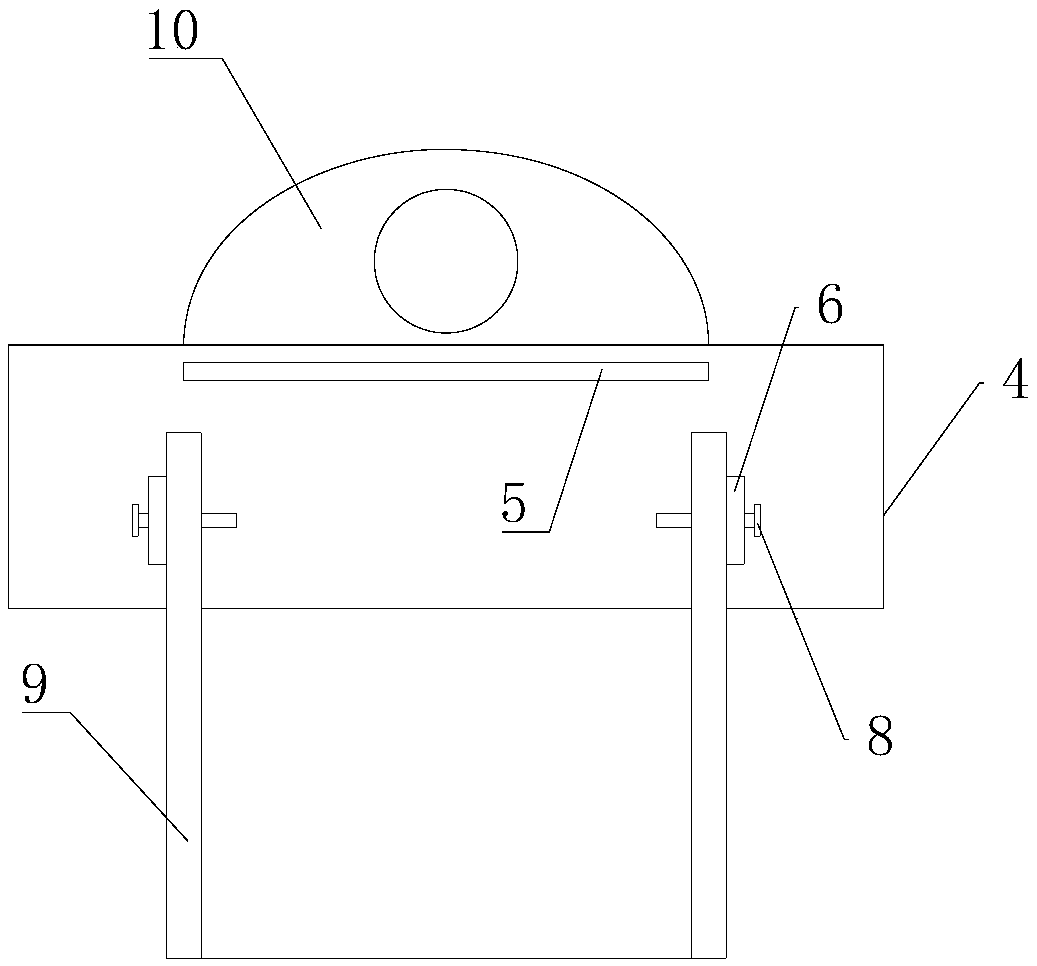

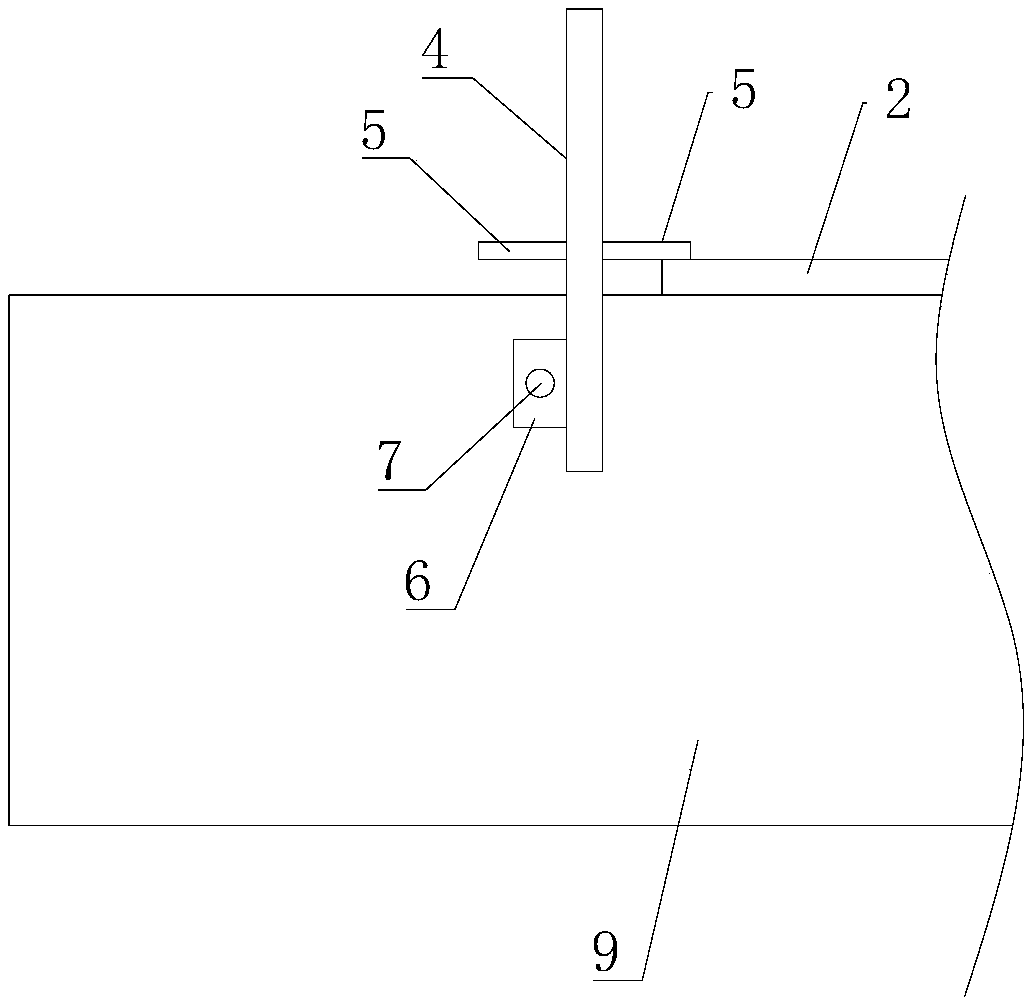

[0036] Such as figure 1 As shown, it is an embodiment of the present invention based on the ship's numerical control cutting steel plate platform. This embodiment includes a tire frame 1 placed horizontally, and a steel plate 2 to be cut is placed on the upper surface of the tire frame 1. The outer surface of the steel plate 2 There are a plurality of auxiliary parts 3 detachably connected with the tire frame 1 at the edge, and the auxiliary parts 3 are symmetrically arranged on the outer circumference of the steel plate 2, and the auxiliary parts 3 fix the steel plate 2 on the On the tire frame 1, when cutting, a numerical control cutting machine (not shown in the figure) walks above the steel plate 2 to cut the steel plate 2. During this process, the auxiliary part 3 can firmly press the steel plate 2 On the tire frame 1, it is ensured that it does not bounce, the cutting accuracy is guaranteed, and peripheral equipment can be protected. The operation is simple, saves time a...

Embodiment 2

[0043] The present invention also proposes a method for using a ship's numerically controlled cutting steel plate platform, including the following sequential steps:

[0044] S1. After the tire frame is assembled and welded, fix it;

[0045] S2. Hoist and lay the steel plate to be cut on the upper surface of the tire frame;

[0046] S3. Use multiple auxiliary parts to fix the steel plate on the upper surface of the tire frame;

[0047] S4. The CNC cutting machine walks and cuts on the steel plate;

[0048]S5. After cutting, remove the auxiliary parts and remove the cut steel plate.

[0049] Wherein, in step S1, the tire frame is welded and fixed by a plurality of criss-cross flat steel; the flat steel is provided with a plurality of through holes for inserting pin shafts at intervals.

[0050] In step S3, the auxiliary part is connected to the tire frame through a pin shaft; the auxiliary part is pressed above the steel plate; and the auxiliary part is arranged symmetricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com