Gantry type pipe and flat plate cutting machine

一种平板切割机、龙门式的技术,应用在焊接/切割辅助设备、焊接/焊接/切割物品、管状物品等方向,能够解决效率低、加工内容单一、不能满足企业加工需要等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

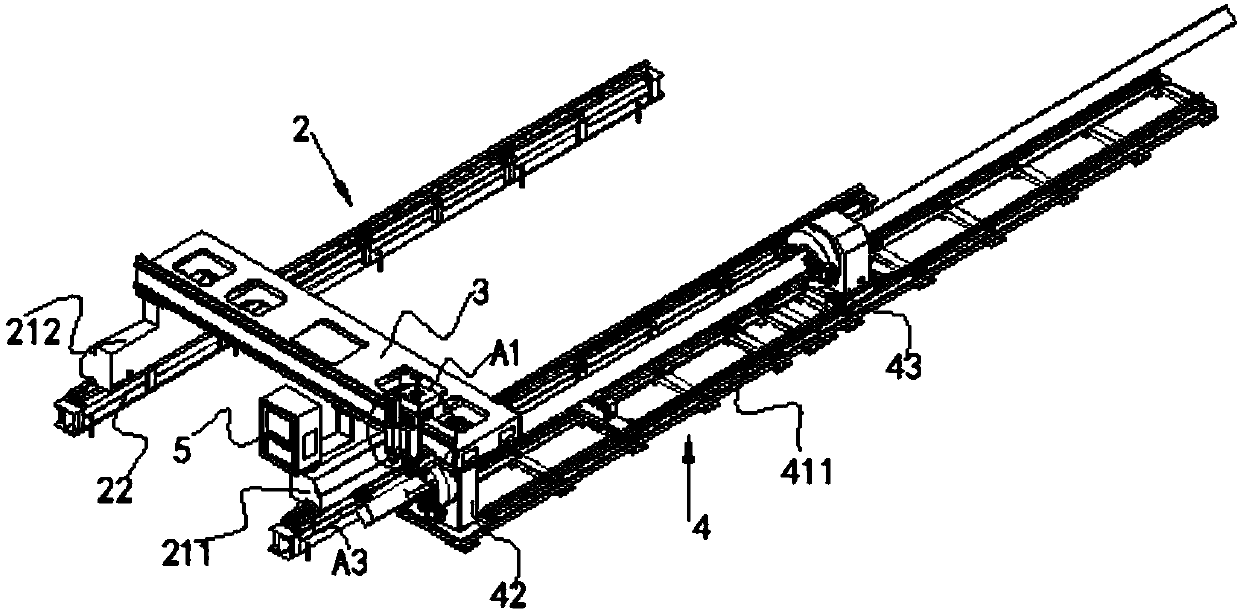

[0096] Embodiment: a kind of gantry type pipe flat cutting machine, such as Figure 1-Figure 25 As shown, it includes at least one group of cutting components, a plate cutting mechanism 2, a pipe cutting mechanism 4 for cutting rectangular pipes, and a crossbeam 3. The plate cutting mechanism is arranged side by side with the pipe cutting mechanism, and the crossbeam is located on the Above the plate cutting mechanism and the pipe cutting mechanism, the side with the cutting gun is defined as the front;

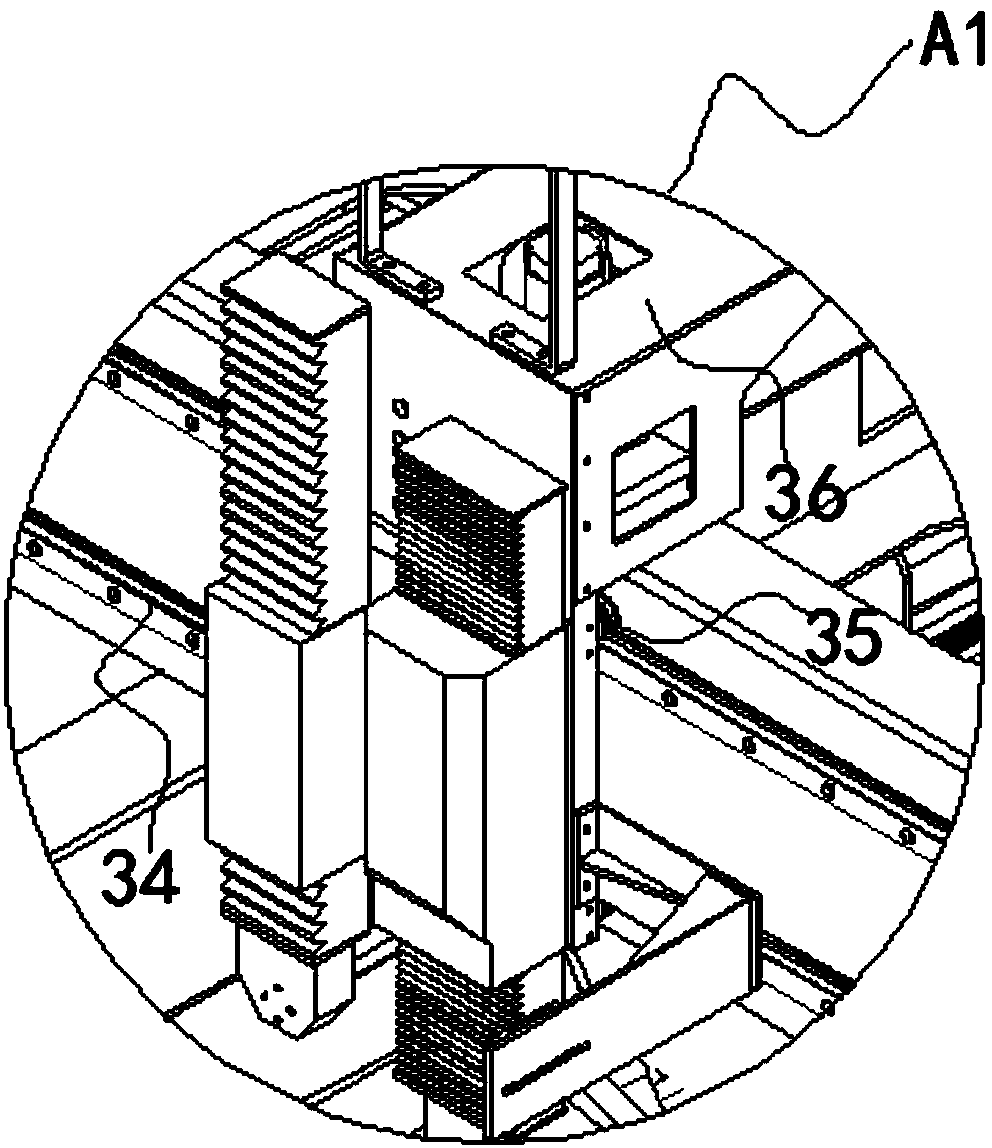

[0097] The crossbeam is provided with a transverse driving unit that drives the cutting assembly to move along the length direction of the crossbeam, and the cutting assembly is connected to the crossbeam through the cutting assembly mount 36, and the cutting assembly mount is provided with a lifting drive unit that drives the cutting assembly to move up and down;

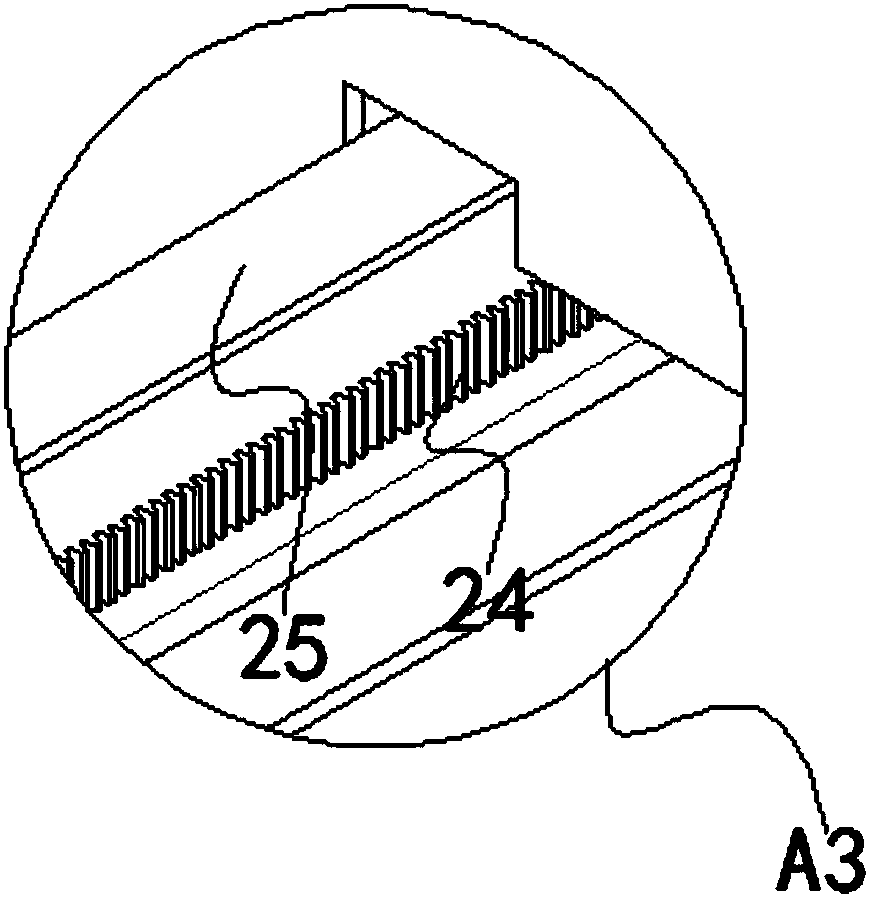

[0098] The transverse drive unit includes a first gear 31, a first rack 32, a first motor and a first track 34,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com