Laser cutting device and laser cutting method

A technology of laser cutting and cutting lanes, which is applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc. It can solve the problems of low precision, small panels are prone to burrs, and it is difficult to meet the needs of industrial production, and achieve the effect of a wide detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

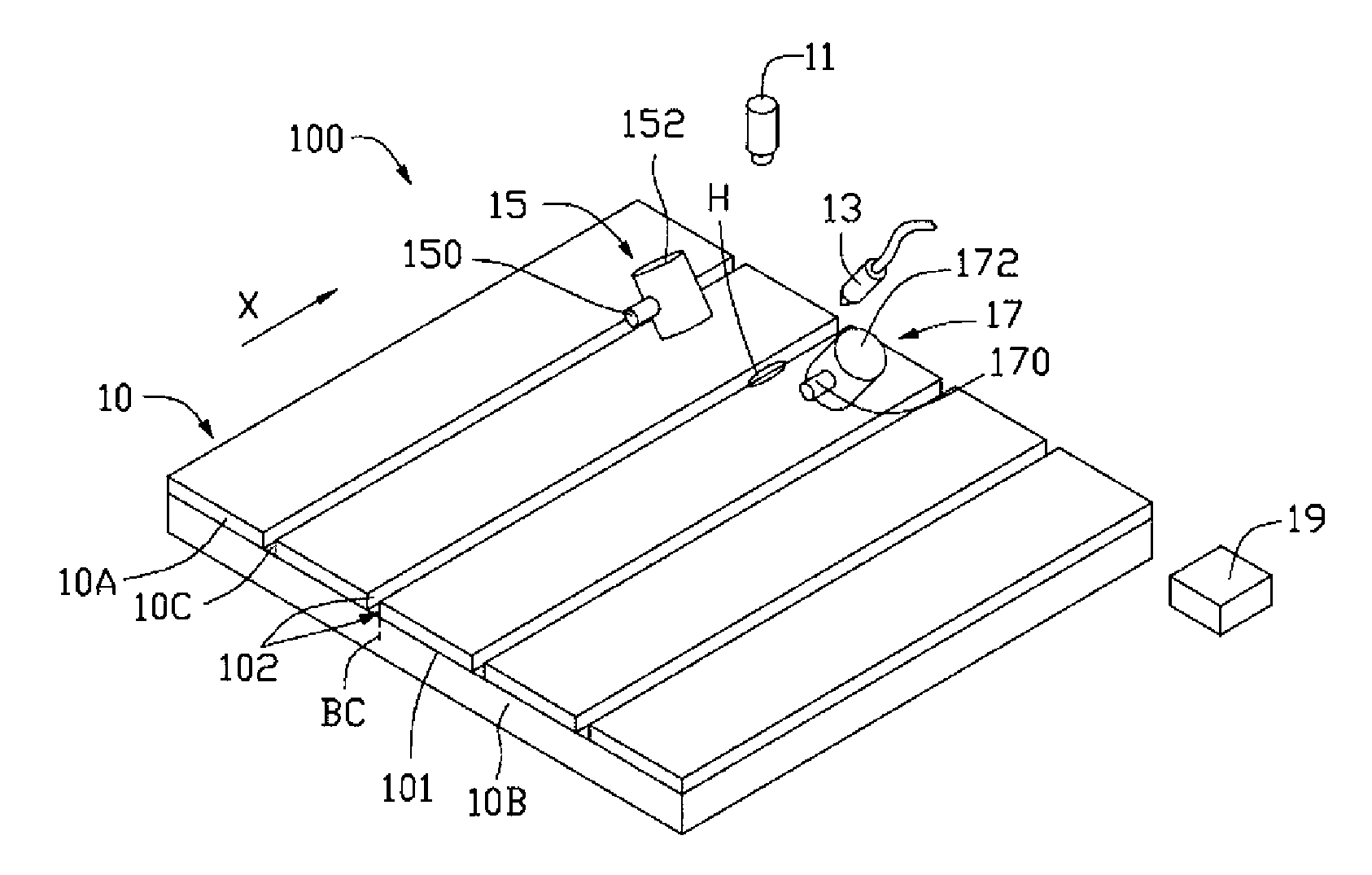

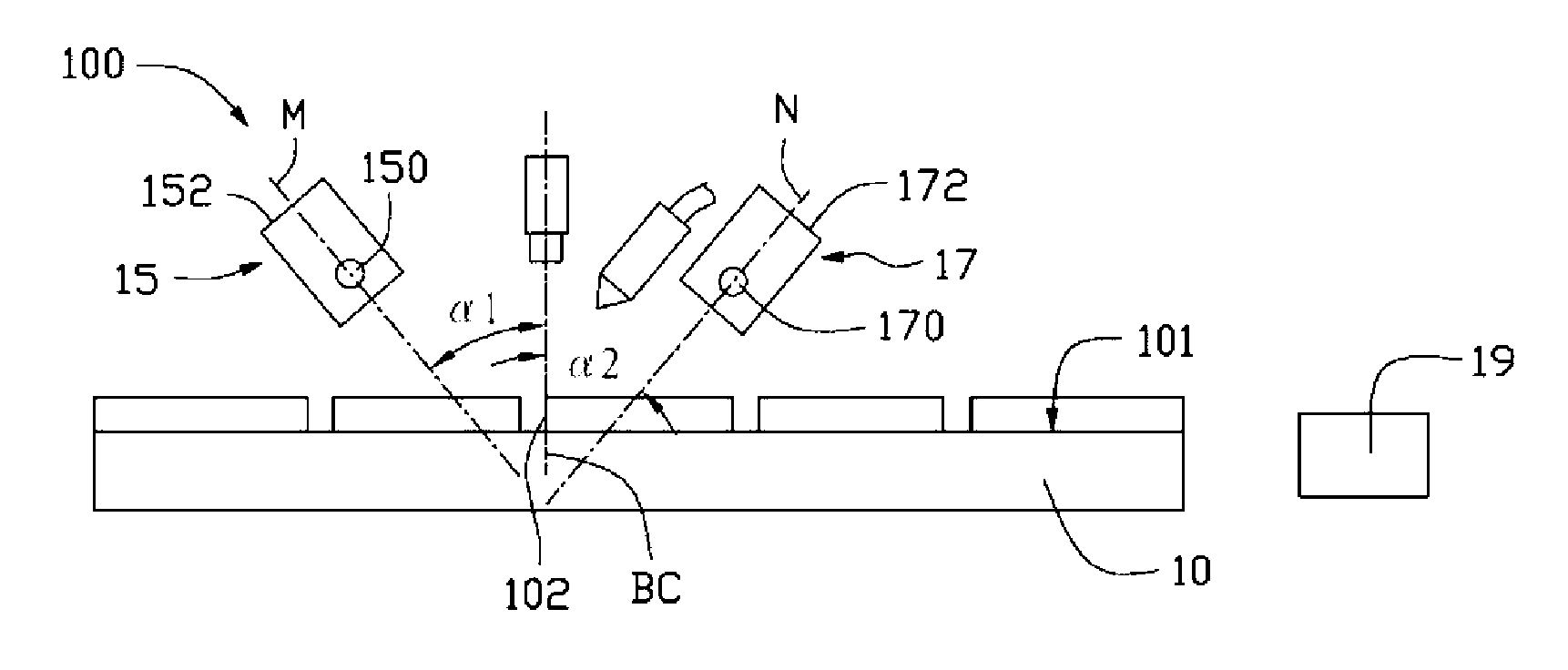

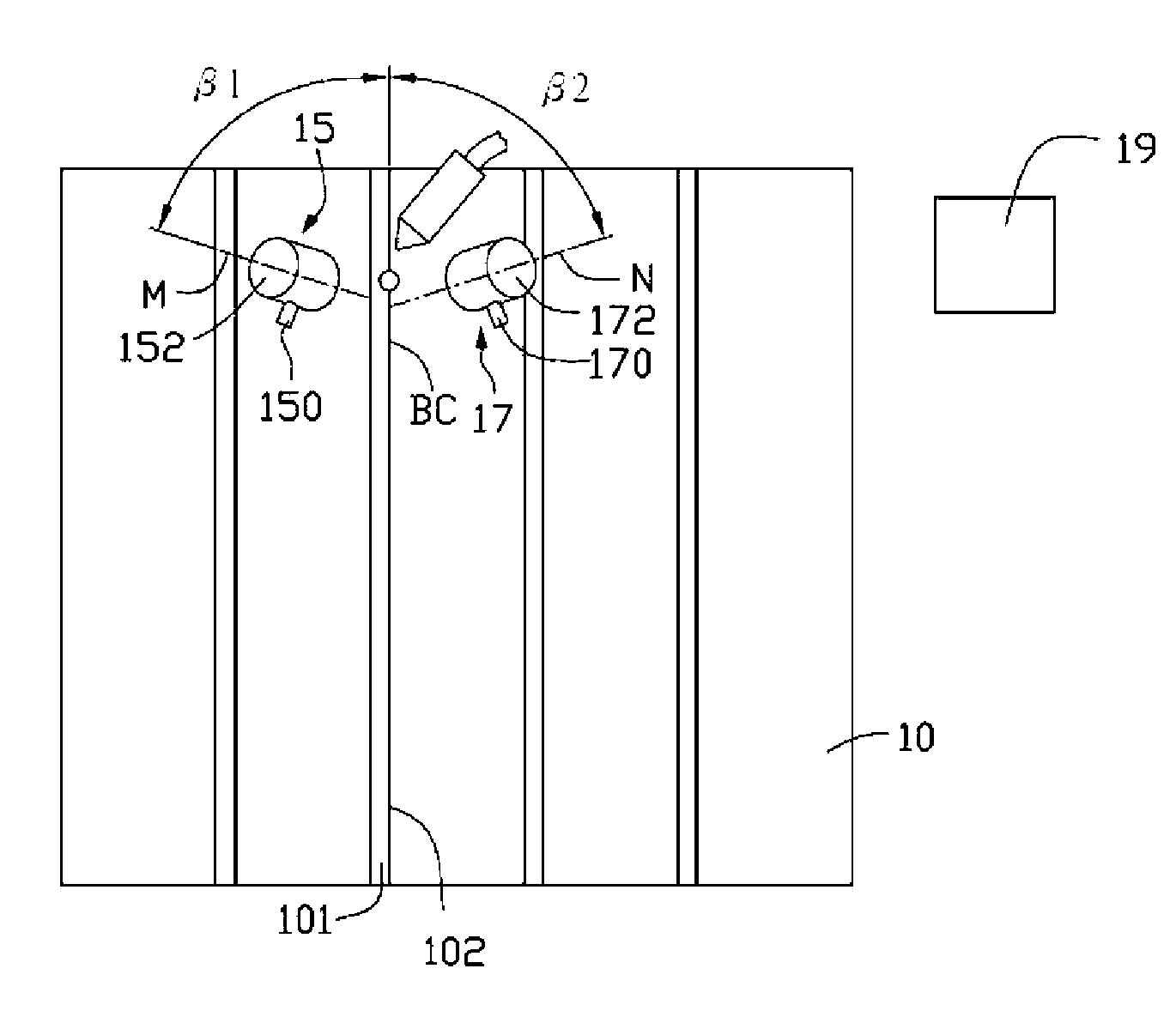

[0017] see figure 1 , a laser cutting device 100 provided by the first embodiment of the present invention is used to generate blind cracks BC on a panel 10 to be processed, so as to separate a plurality of substrates 10B from the blind cracks BC of the panel 10 . The panel 10 includes a substrate 10B, and a plurality of filter layers 10A distributed at intervals. Specifically, the substrate 10B has a surface to be processed 101, the plurality of filter layers 10A are formed on the surface 101 to be processed, the substrate 10B can be a glass substrate, and the plurality of filter layers 10A can be color filter layers respectively. Optical layer 10A. In addition, a cutting line 10C is formed between two adjacent filter layers 10A, and the two filter layers have two opposite sides 102 corresponding to the cutting line 10C, and the two side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com