Method for preparing manganese sulfate solution by removing high-concentration SO2 in flue gas by using manganese carbonate ore

A manganese sulfate solution, manganese carbonate ore technology, applied in the directions of manganese sulfate, separation method, chemical instrument and method, can solve the problems of high production cost and low oxidation efficiency, and achieve low production and operation cost, removal and oxidation conversion efficiency High, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

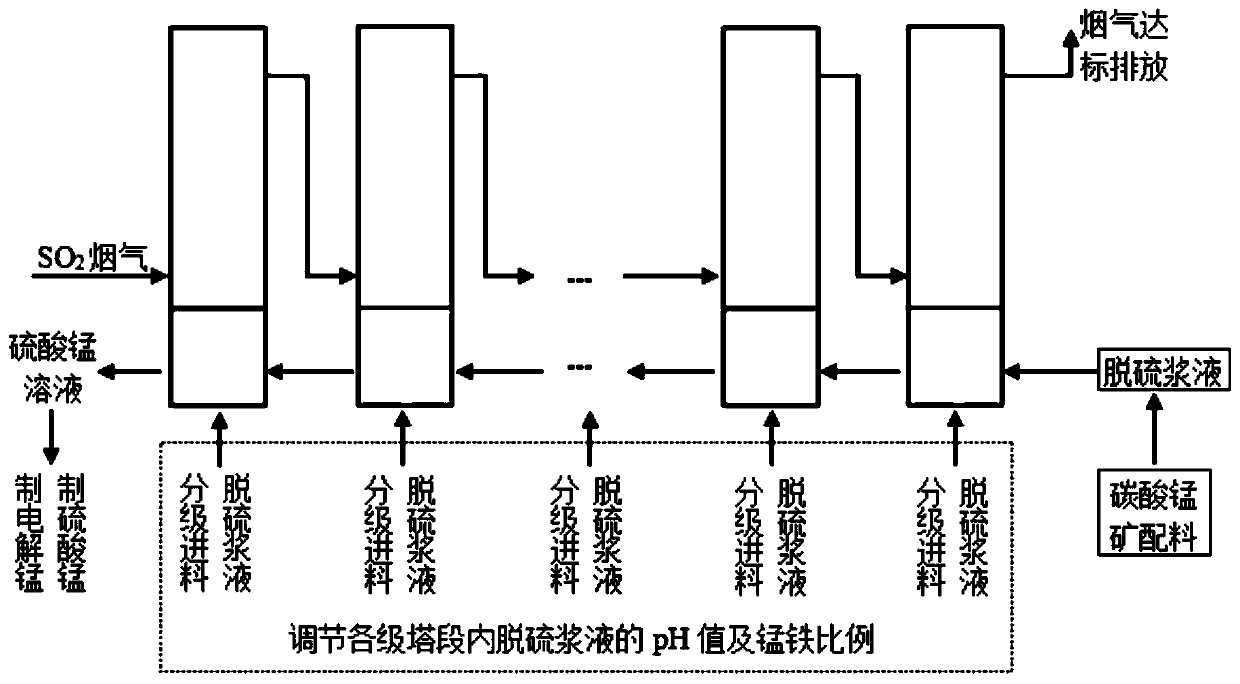

Image

Examples

Embodiment 1

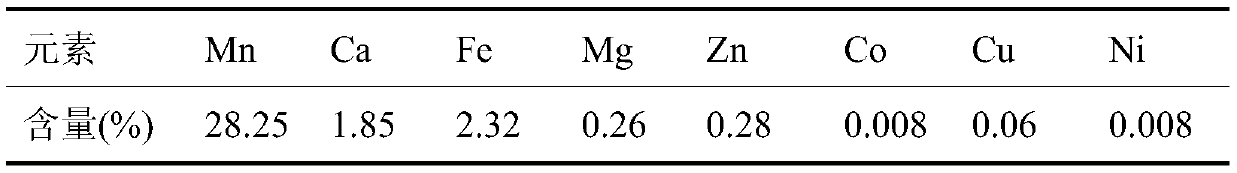

[0031] The manganese carbonate ore used in this example is produced in Ghana, and the composition analysis of the manganese carbonate ore is shown in Table 1. Iron ore is used as the iron-containing auxiliary agent. The manganese carbonate slurry was prepared with the electrolytic manganese anolyte. The concentration of manganese sulfate in the electrolytic manganese anolyte was 39.8 g / L and the acid concentration was 34 g / L. The flue gas adopts laboratory simulation flue gas, and the specific composition is 5% SO 2 , 12% oxygen, the balance is nitrogen.

[0032] Table 1 Composition analysis of manganese carbonate ore

[0033]

[0034] Specific steps are as follows:

[0035] (1) Blending

[0036] ① The manganese carbonate ore is crushed and passed through a 100 mesh sieve to obtain manganese carbonate ore powder, and the iron-containing auxiliary agent is crushed and passed through a 100 mesh sieve.

[0037] ②Prepare desulfurization slurry for the feed of the final tower section: mix...

Embodiment 2

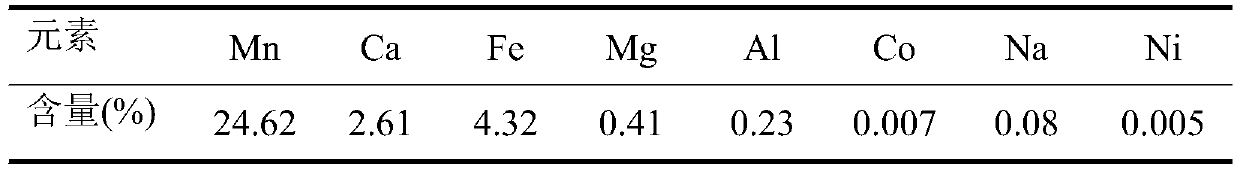

[0044] The manganese carbonate ore used in this example is produced in Guangxi, and the composition analysis of the manganese carbonate ore is shown in Table 2. High-speed iron waste slag is used as the iron-containing auxiliary agent. The manganese carbonate slurry was prepared with the electrolytic manganese anolyte. The concentration of manganese sulfate in the electrolytic manganese anolyte was 39.8 g / L and the acid concentration was 34 g / L. The flue gas adopts laboratory simulation flue gas, and the specific composition is 7% SO 2 , 12% oxygen, the balance is nitrogen.

[0045] Table 2 Composition analysis of manganese carbonate ore

[0046]

[0047] Specific steps are as follows:

[0048] (1) Blending

[0049] ① The manganese carbonate ore is crushed and passed through a 100 mesh sieve to obtain manganese carbonate ore powder, and the iron-containing auxiliary agent is crushed and passed through a 100 mesh sieve.

[0050] ②Preparation of desulfurization slurry for the feed of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com