Intelligent cutting and sizing method for continuous casting billet

An intelligent cutting and continuous casting billet technology, applied in the field of steelmaking, can solve the problems of low labor productivity, cutting damage of billet rollers, frequent replacement, etc., and achieve the effect of higher equipment cost, optimized cutting accuracy and low equipment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

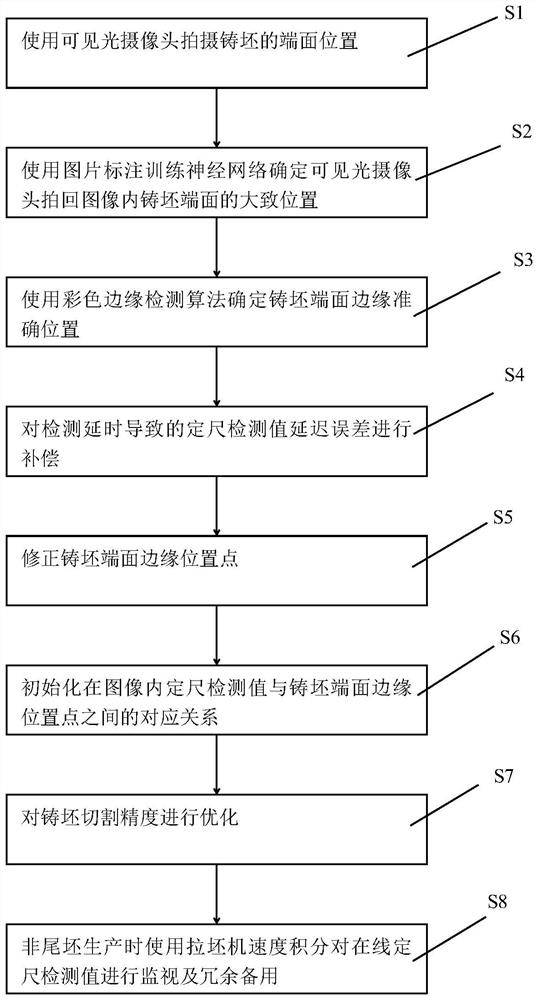

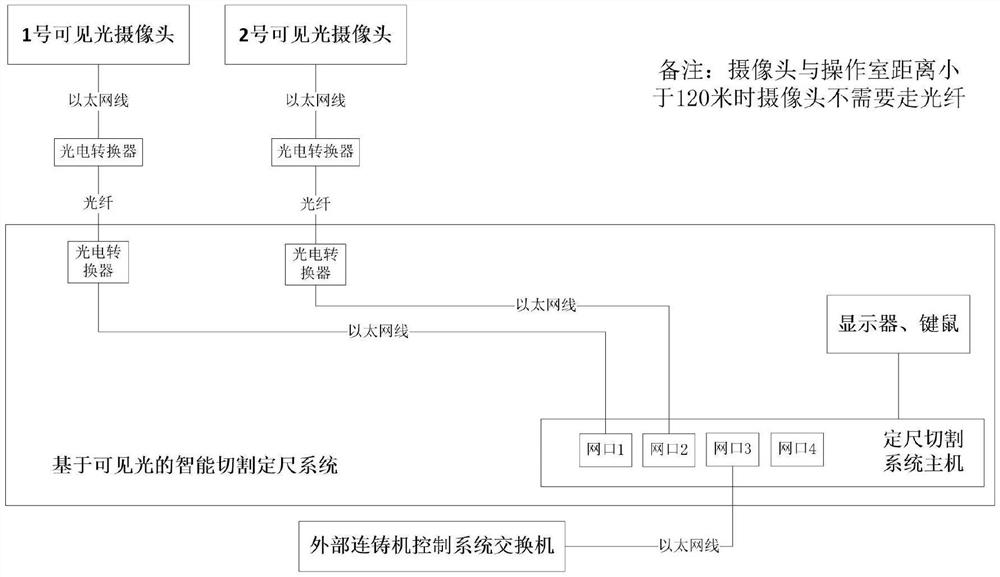

Method used

Image

Examples

example

[0055] Real vehicle cutting verification: No. 3 continuous casting machine of No. 1 steelmaking branch of Wuhan Iron and Steel CSP strip plant has the problem that the continuous casting slab has a large cross-sectional specification, which leads to the low temperature of the continuous casting slab surface and cannot use the traditional infrared sizing method. By using the continuous casting slab proposed by the present invention The method of intelligent cutting and sizing of slabs is proved by experiments on the online actual vehicle cutting of continuous casting slabs of the continuous casting machine. Image 6 with Figure 7 It is a screenshot of the online real car cutting experiment process. exist Image 6 with Figure 7 Among them, the set target cutting length is PS, the cutting signal sent by the sizing system is DQ, and the slab length detected by the sizing system is YBS. from Figure 7 It can be seen that when the slab target cutting length PS=5560.0 mm, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com