Beef slicing device

A technology for slicing and beef, which is applied in the direction of meat processing equipment, processed meat, and meat clamping devices, etc. It can solve the problems that seasonings cannot be stirred evenly, cannot achieve the effect of stirring, and have inconsistent flavors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

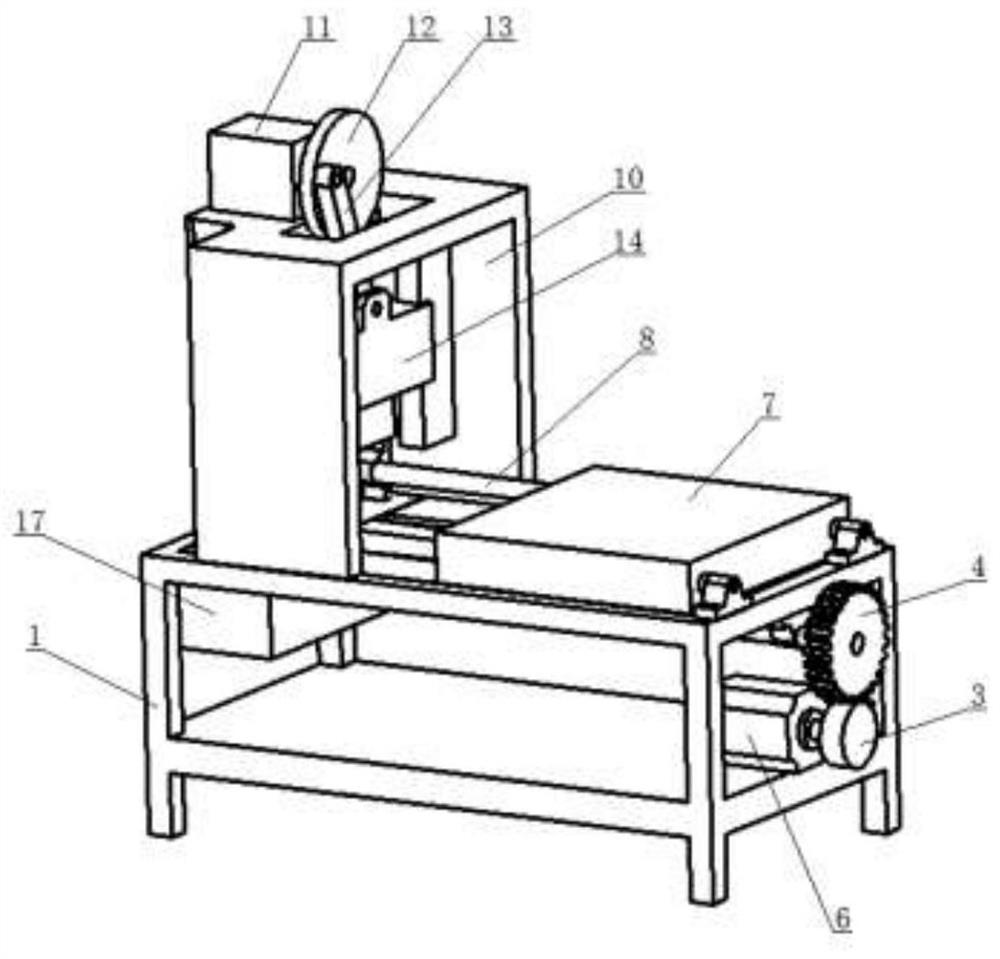

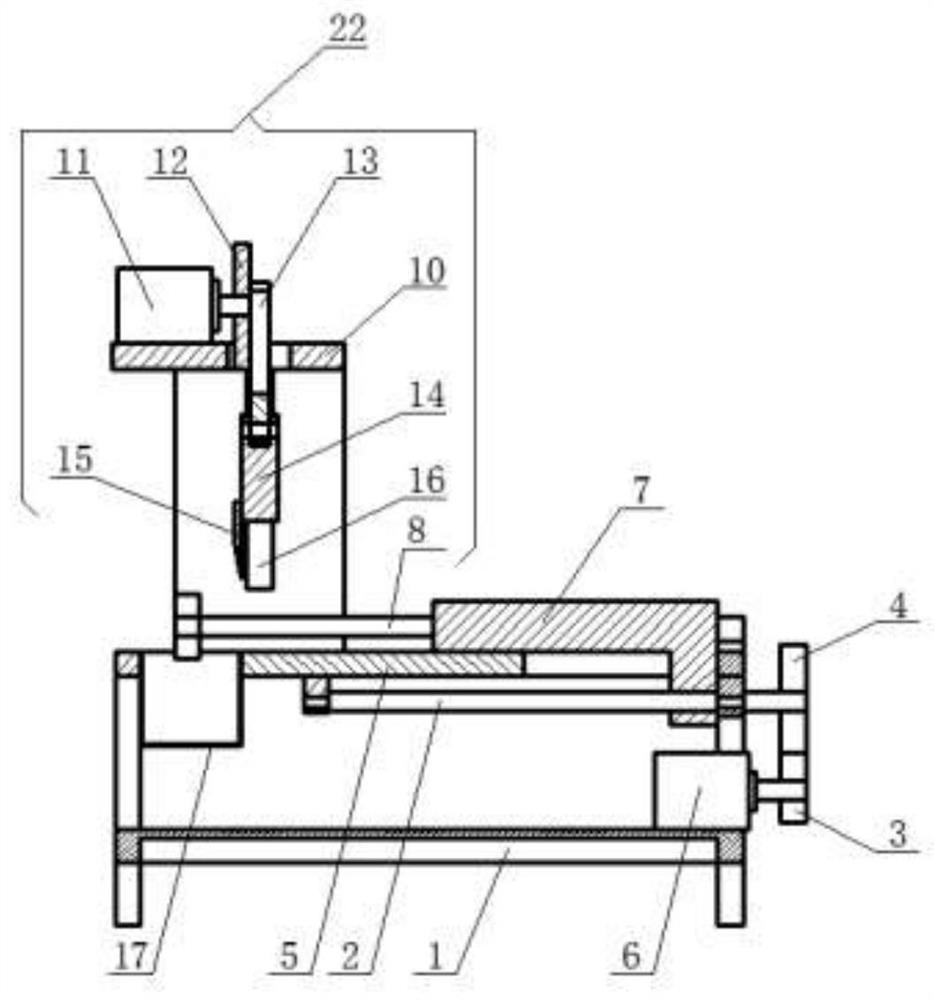

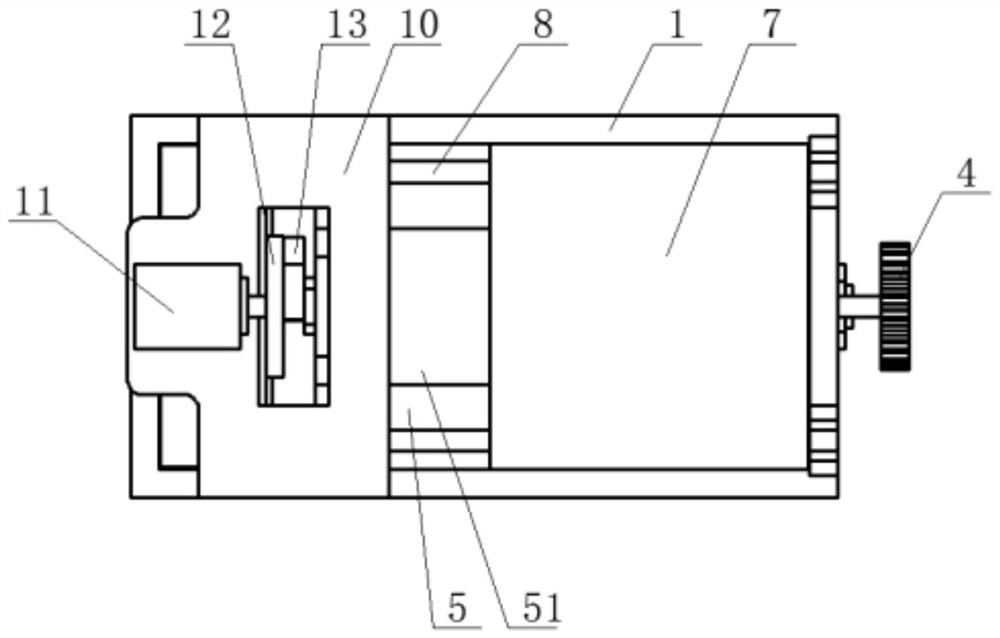

[0024] Such as Figure 1 to Figure 4 As shown, a kind of beef slicing equipment of the present invention comprises frame 1, push screw mandrel 2, driving gear 3, driven gear 4, driving motor 6 and slicing mechanism 22, is fixedly connected with cutting board 5 on frame 1, The slicing mechanism 22 and the driving motor 6 are all fixedly installed on the frame 1. The slicing mechanism 22 is used to cut the beef into thin slices when the beef is in a static state relative to the cutting board 5. The output shaft of the driving motor 6 The top is fixedly connected with a driving gear 3, and one end of the push screw rod 2 is installed on the lower surface of the cutting board 5 through a bearing seat, and the other end of the push screw rod 2 is fixedly connected with a coaxial driven gear 4, and the push screw rod 2 is also screwed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com