Control method for reducing length of surface scratch caused by coiling machine auxiliary coiling device on aluminum strip

A technology of a machine coiler and a control method, which is applied to the rolling mill control device, metal rolling, manufacturing tools, etc., can solve the problem that the operation time of the equipment cannot be further shortened, the shape and thickness of the aluminum strip head are affected, and the scratch length effect. Not ideal, etc., to reduce the length of surface scratches, ensure the stability of the belt, and reduce the length of scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0026] The invention provides a control method for reducing the scratch length of the surface of the aluminum strip by the coiler of the coiler, such as figure 1 As shown, the method includes the following steps:

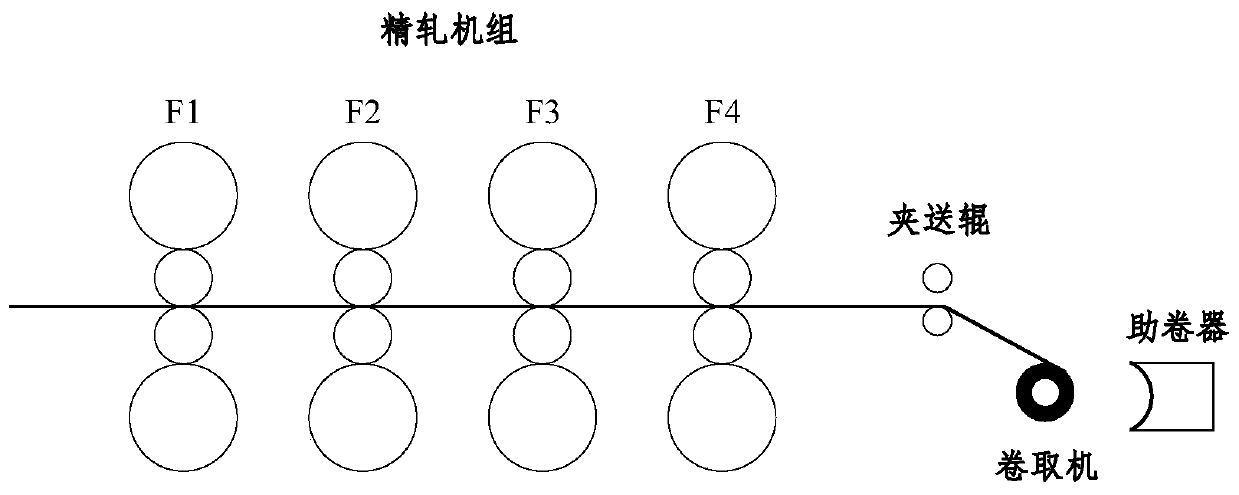

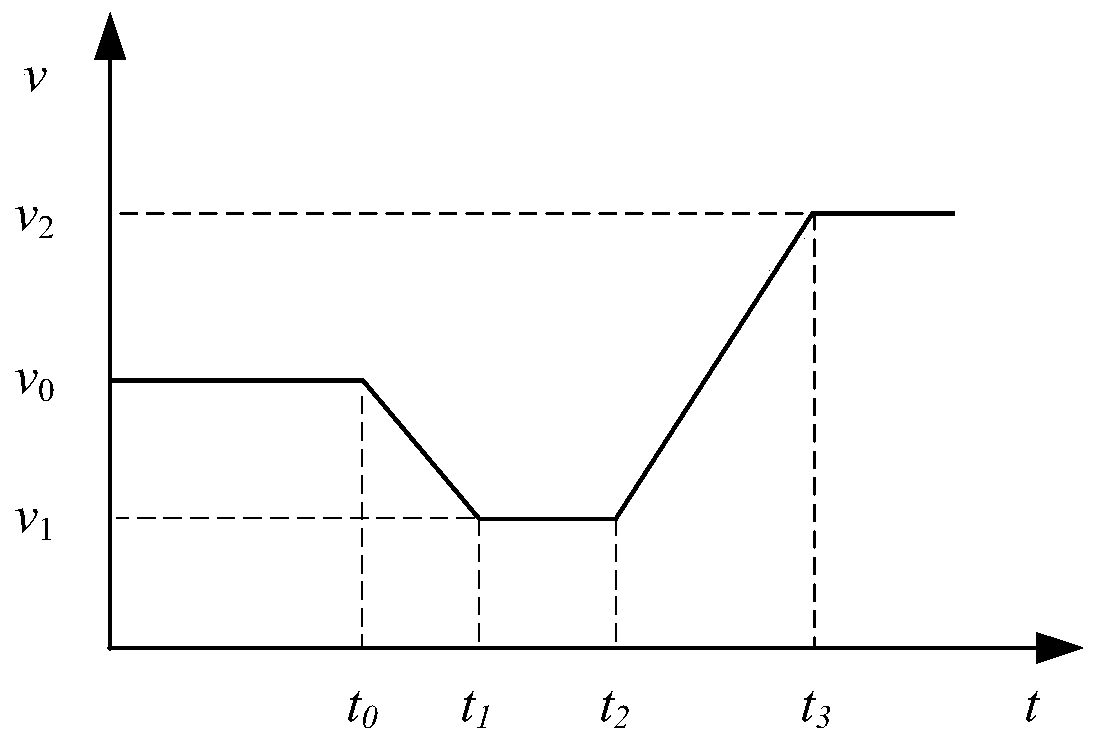

[0027] S1: When the finishing rolling unit starts rolling, the strip threading speed v 0 Conduct strip rolling; the finish rolling unit takes the line speed of the last stand rolling mill as the reference speed;

[0028] S2: When the head of the aluminum strip enters the last stand rolling mill to generate a biting signal, start to track the position of the head of the aluminum strip; the tracking of the head position of the aluminum strip uses the line speed of the last stand rolling mill and the forward slip coefficient to track, namely: L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com