Friction feeder

A feeding device and friction-type technology, which is applied in the field of friction-type yarn feeding devices, can solve problems such as complex adjustment of yarn delivery, inaccuracy or error in knitting processing, and error in fabric products, and achieve the effect of reducing friction interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

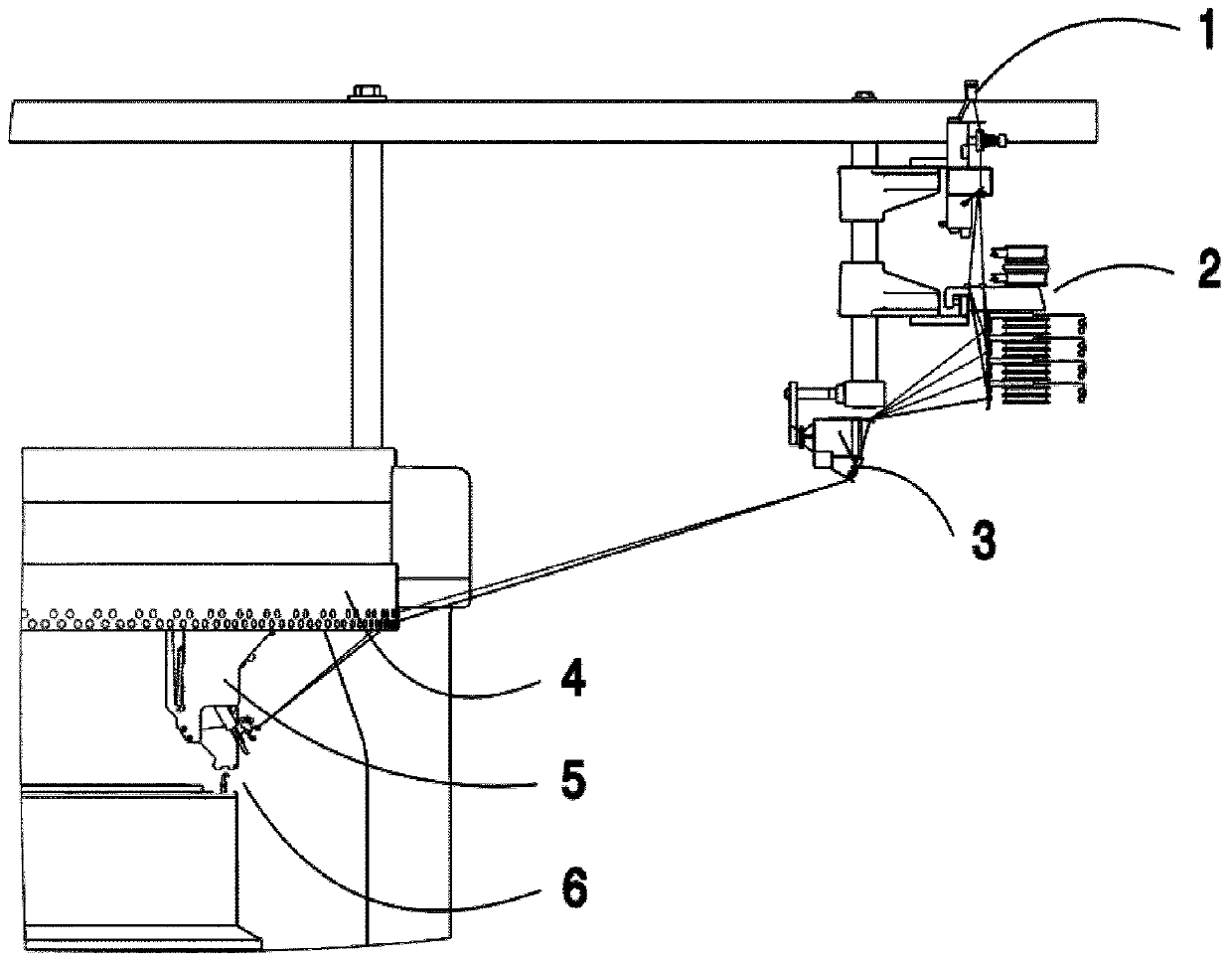

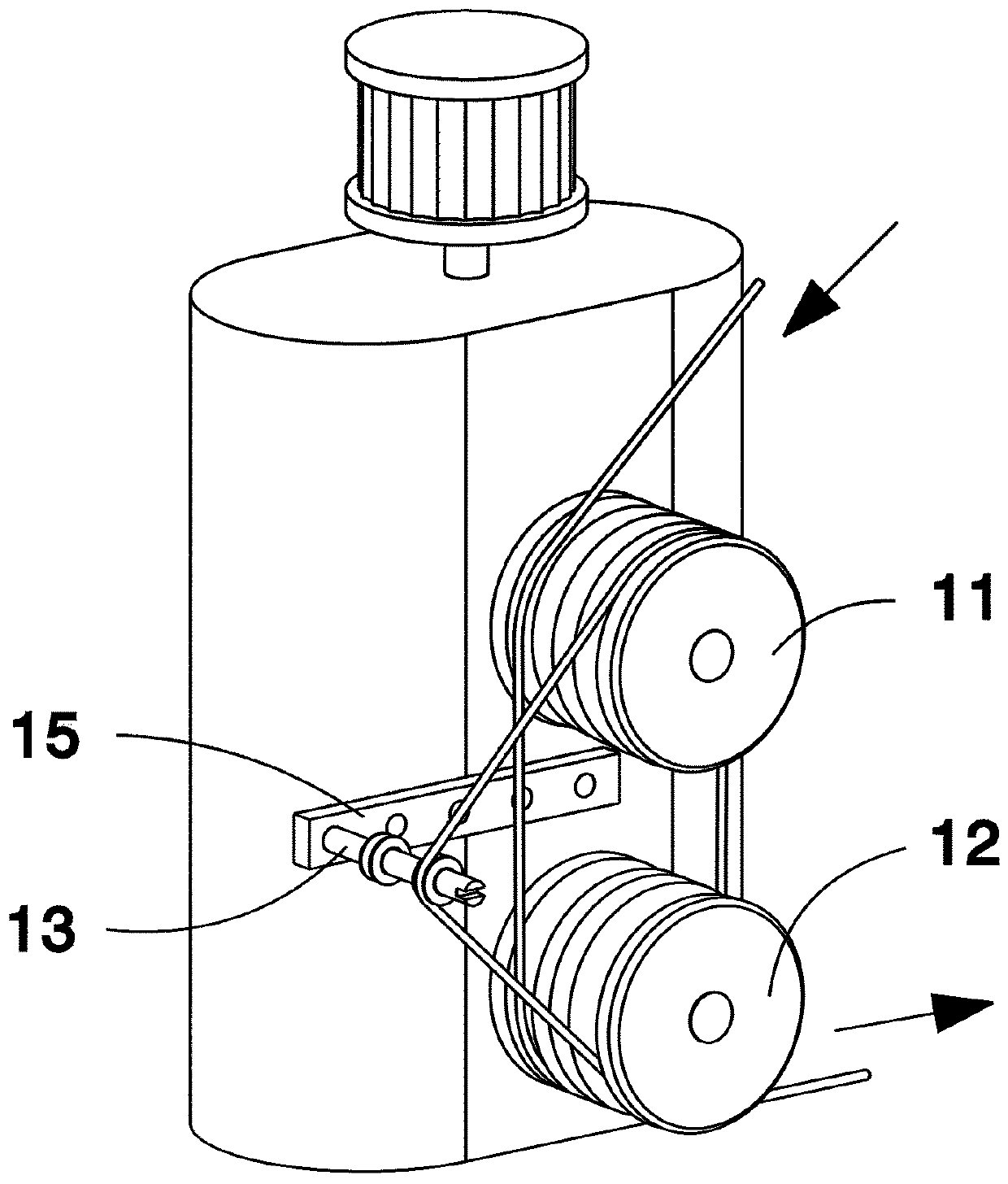

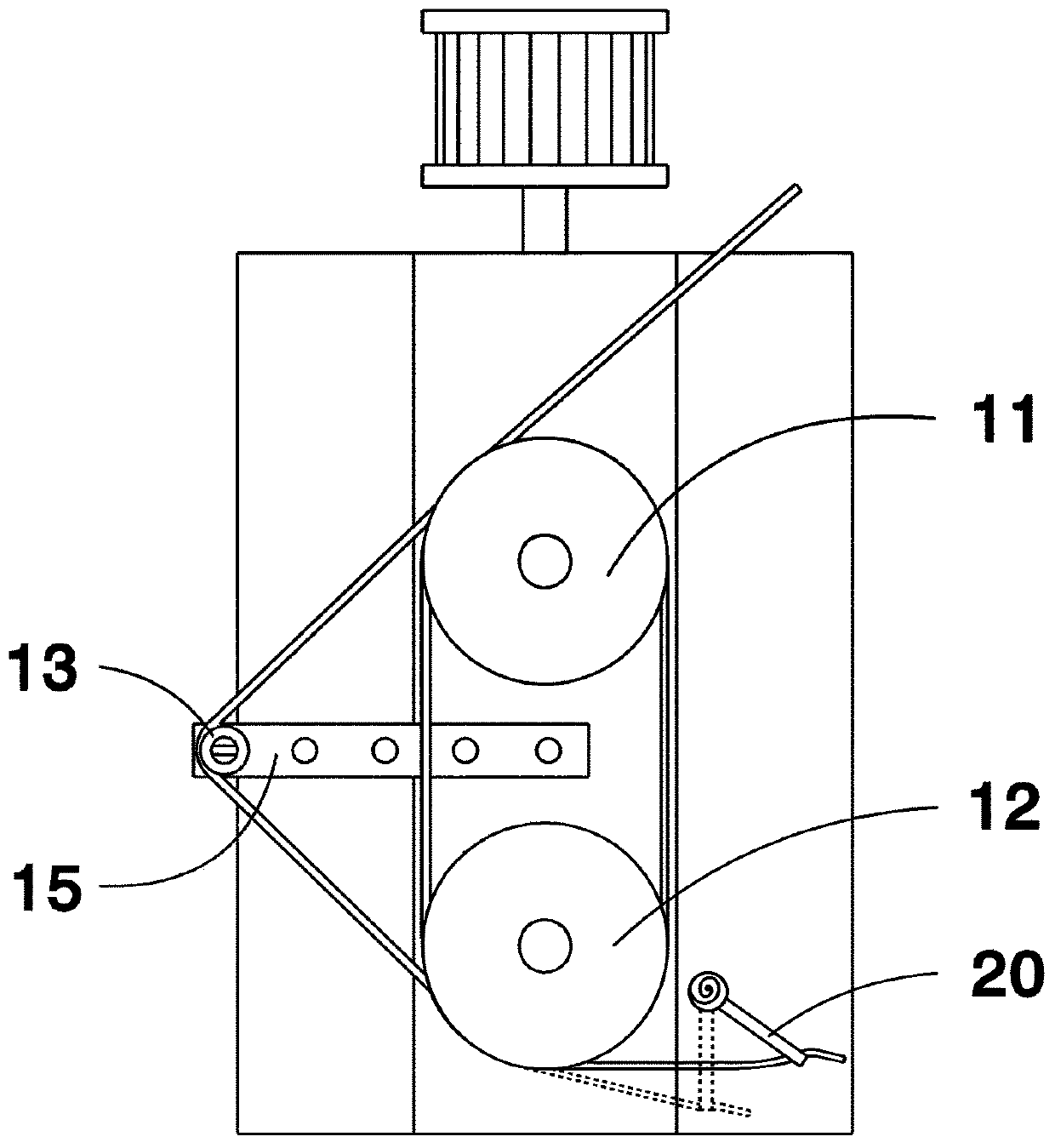

[0033] In circular knitting machines with pick-up devices, several (for example four or six) yarns pass through each yarn feeder under the control of yarn selection on the pick-up device, but at each time Only one yarn is processed on each point, while the other yarns are disconnected. In this regard, figure 2 and image 3 (in which only one yarn passes through the yarn feeder to illustrate the yarn path in the frictional yarn feeder according to the invention) shows only a sub-aspect of an embodiment of the frictional yarn feeder according to the invention, which Friction Yarn Feed Replacement figure 1 Shown is a conventional friction yarn feeding device in a conventional circular knitting machine with yarn picking function.

[0034] The frictional yarn feed device according to the invention has two delivery rollers 11 , 12 which are held in a recumbent manner (ie with a horizontal axis) and parallel to each other. The conveying rollers are preferably arranged one above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com