Groove machining blade

A technology for grooving and inserting, applied in cutting inserts, metal processing equipment, manufacturing tools, etc., can solve the problems of chipping of cutting edges, difficulty in chip breaking, poor quality of machined surface, etc., and achieve the effect of reducing cutting impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

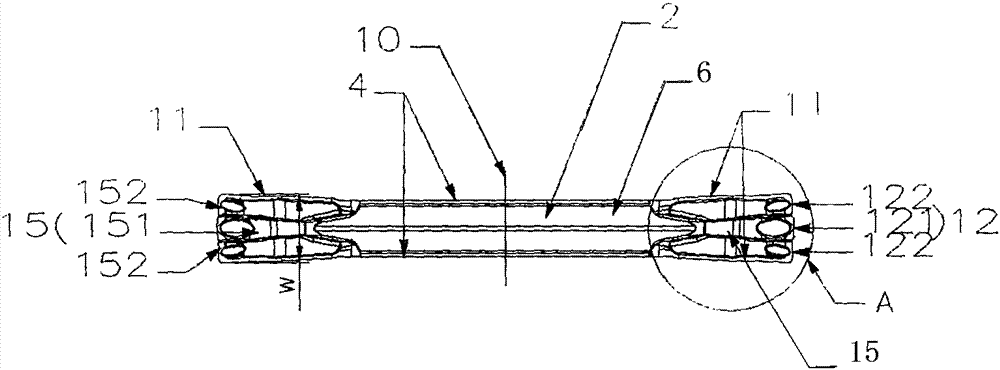

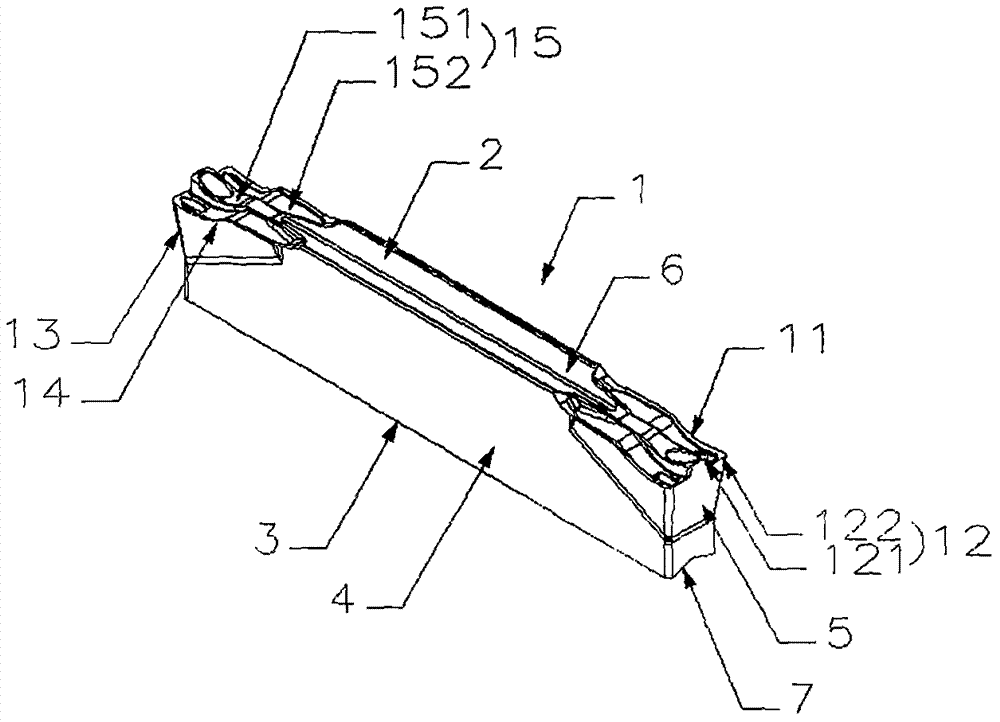

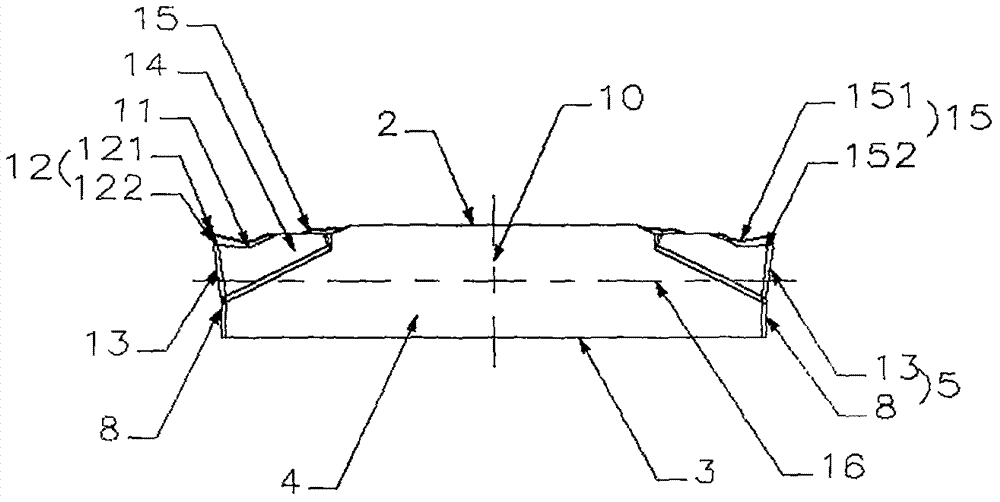

[0032] Figure 1 to Figure 6 An embodiment of the grooving blade of the present invention is shown, the blade 1 is surrounded by an upper positioning surface 2, a lower positioning surface 3, two side surfaces 4 and two end surfaces 5 connecting the upper and lower positioning surfaces, the The upper positioning surface 2 is provided with an upper positioning slope group 6, and the lower positioning surface 3 is provided with a lower positioning slope group 7. In order to facilitate manufacture and installation, the upper positioning slope group 6 and the lower positioning slope group 7 have symmetrical cross-sectional shapes. Between the two end surfaces 5 and the upper positioning surface 2, a rake surface 15 connecting the upper surface 2 and the end surface 5 is respectively provided, and two side flank surfaces 13 are provided between the rake surface 15 and the adjacent end surface 5 and the side surface 4, The two end faces 5 are all composed of an end positioning face ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com