Mechanical and electrical integration plate burr-free treatment cutting process

A cutting process and edge processing technology, applied in the field of electromechanical integrated plate burr-free edge processing cutting process, can solve problems such as the influence of the service life of the plate, the loose structure at the section, and the broken edge, etc., to prolong the service life, reduce burrs, improve the The effect of cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

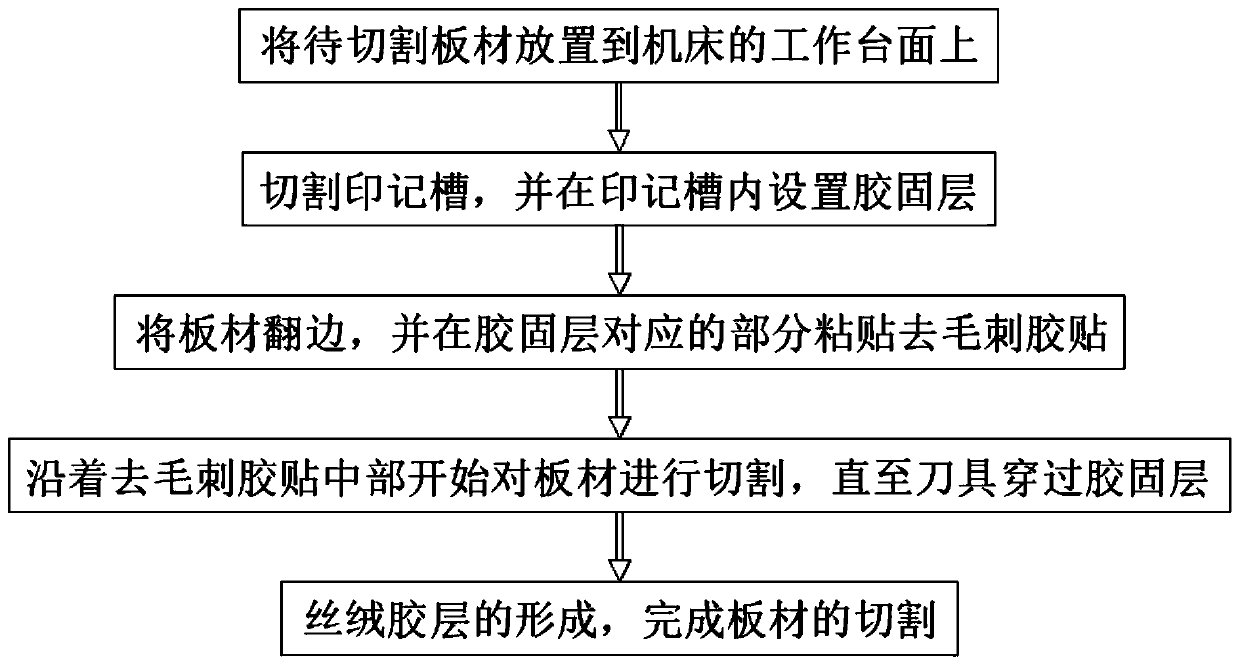

[0047] see Figure 1-2 , a kind of mechanical and electrical integration plate without thorn edge processing cutting process, comprising the following steps:

[0048] S1. First, wipe off the obvious attached impurities on the surface of the plate to be cut, and place it on the working table of the machine tool;

[0049] S2. Cut an imprint groove at the part to be cut of the plate, and fill PVC glue into the imprint groove, after drying and curing, a glue layer is formed in the imprint groove;

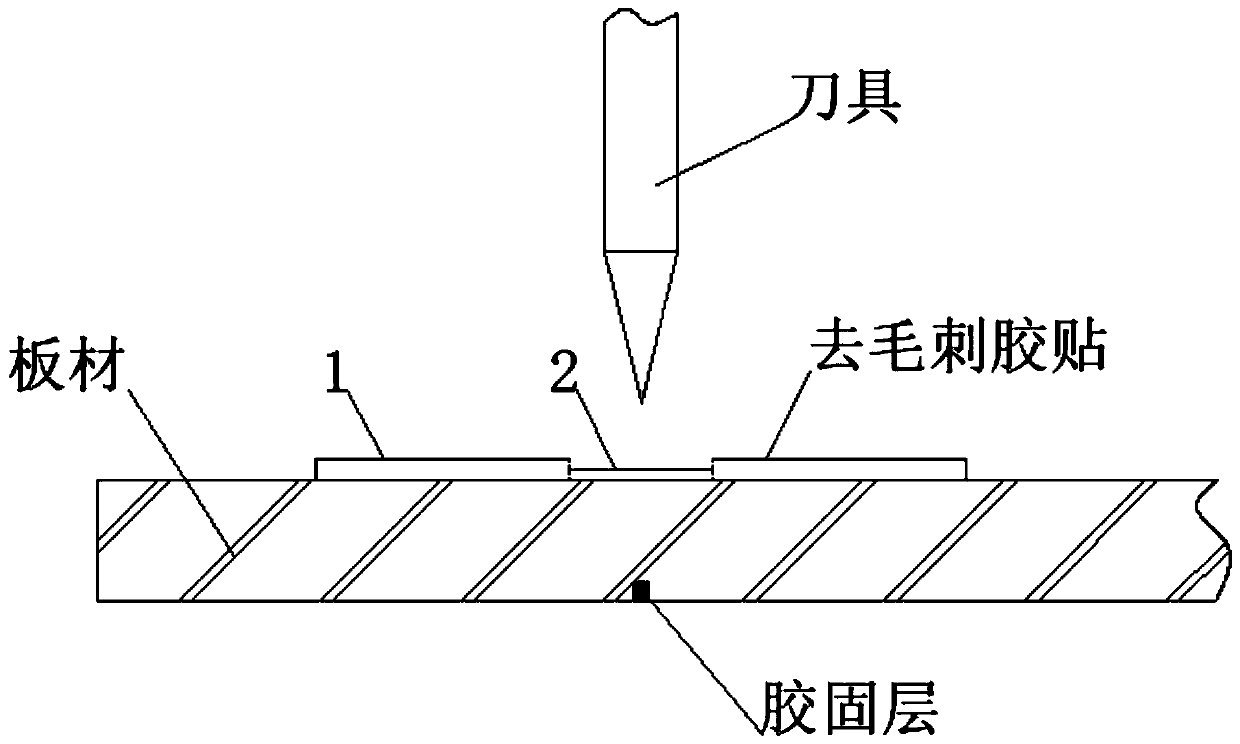

[0050] S3, flanging the plate, and pasting the deburring sticker on the corresponding part of the glue layer;

[0051] S4. The tool is controlled by the machine tool to start cutting the plate along the middle part of the deburring sticker until the tool passes through the glue layer;

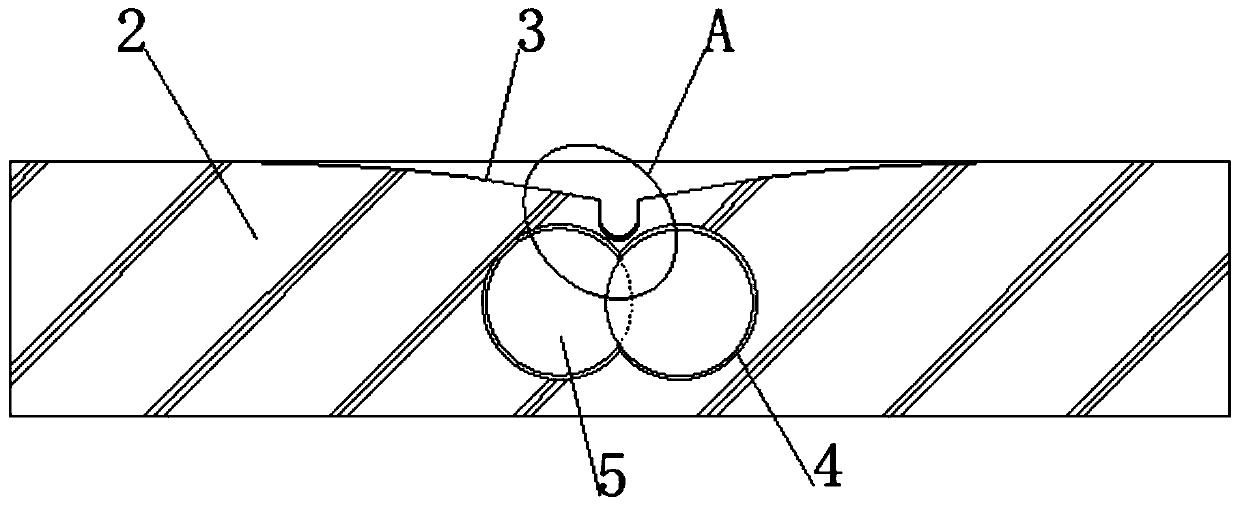

[0052] S5. The deburring glue is pasted on the end faces of the two cut boards to form a velvet glue layer, so as to wrap the cutting edges of the boards, realize the wrapping and elimination of burrs,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com