Circuit board laser cutting machine capable of slowly falling finished products

A laser cutting machine, circuit board technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of harmful gas pollution, circuit boards bumping against each other, and low circuit board yield, etc., to avoid damage. , reduce vibration, improve efficiency and the effect of cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

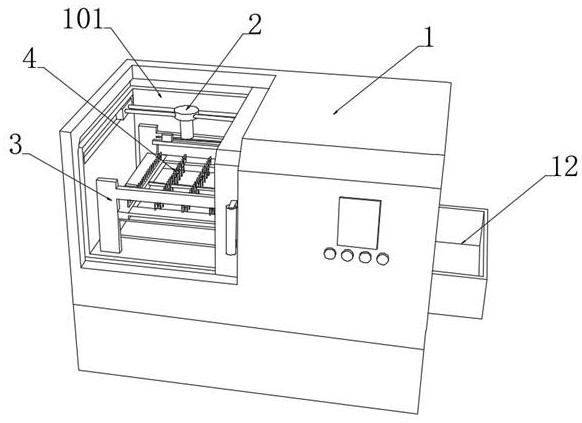

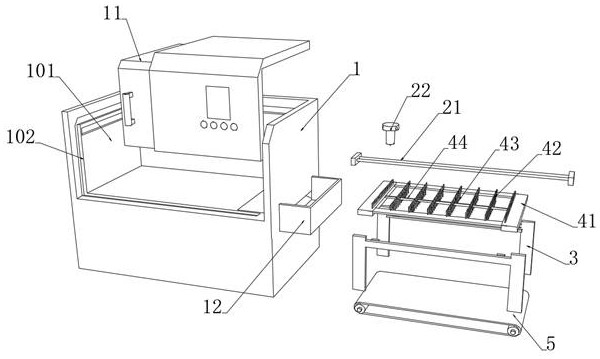

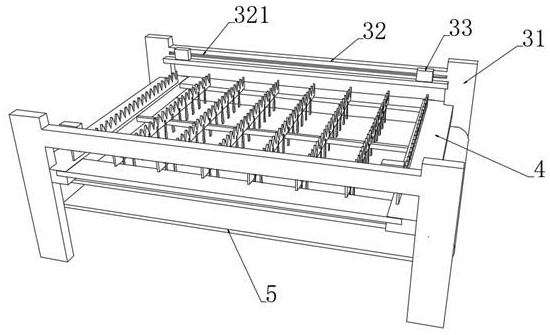

[0045] see Figure 1-Figure 6 , a circuit board laser cutting machine whose finished product is slowly falling, including a main body 1 and a working cabin 101 opened at the upper end, the lower end of the main body 1 is provided with a ventilation pipe 6, a cutting assembly 2 is arranged inside the working cabin 101, and the cutting assembly 2 includes a sliding rod 21 and the cutting head 22 slidably connected to the sliding rod 21. A pair of fixing frames 3 are arranged inside the working cabin 101. The fixing frame 3 includes a cross bar 32 and a vertical bar 31 fixedly connected to the left and right ends thereof. The opposite sides of the cross bar 32 are provided with The displacement groove 321, the electric clamping block 33 is slid inside the cross bar 32, the bottom end of the cross bar 32 is provided with a material bearing bar, the inside of the working cabin 101 and located in the middle of the pair of fixing frames 3 is provided with a buffer suction component 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com