Woven bag cutting method

A cutting method and woven bag technology, applied in metal processing and other directions, can solve the problem of large incision in woven bags, and achieve the effects of high cutting speed, reducing impact and accelerating cutting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below by means of specific embodiments:

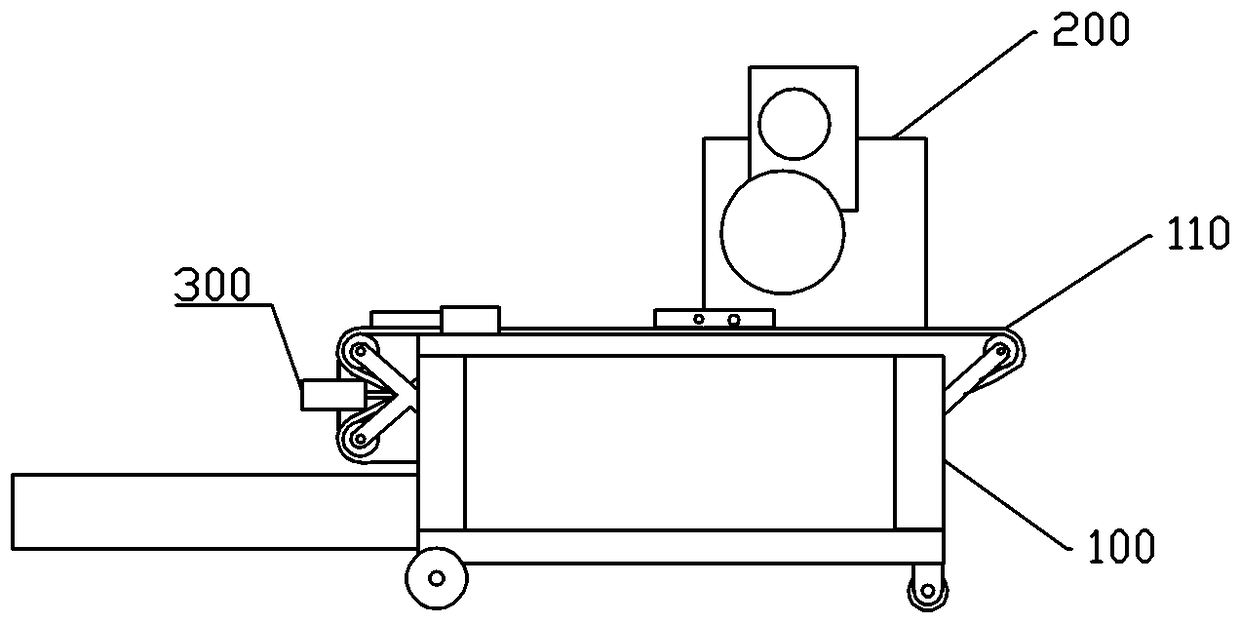

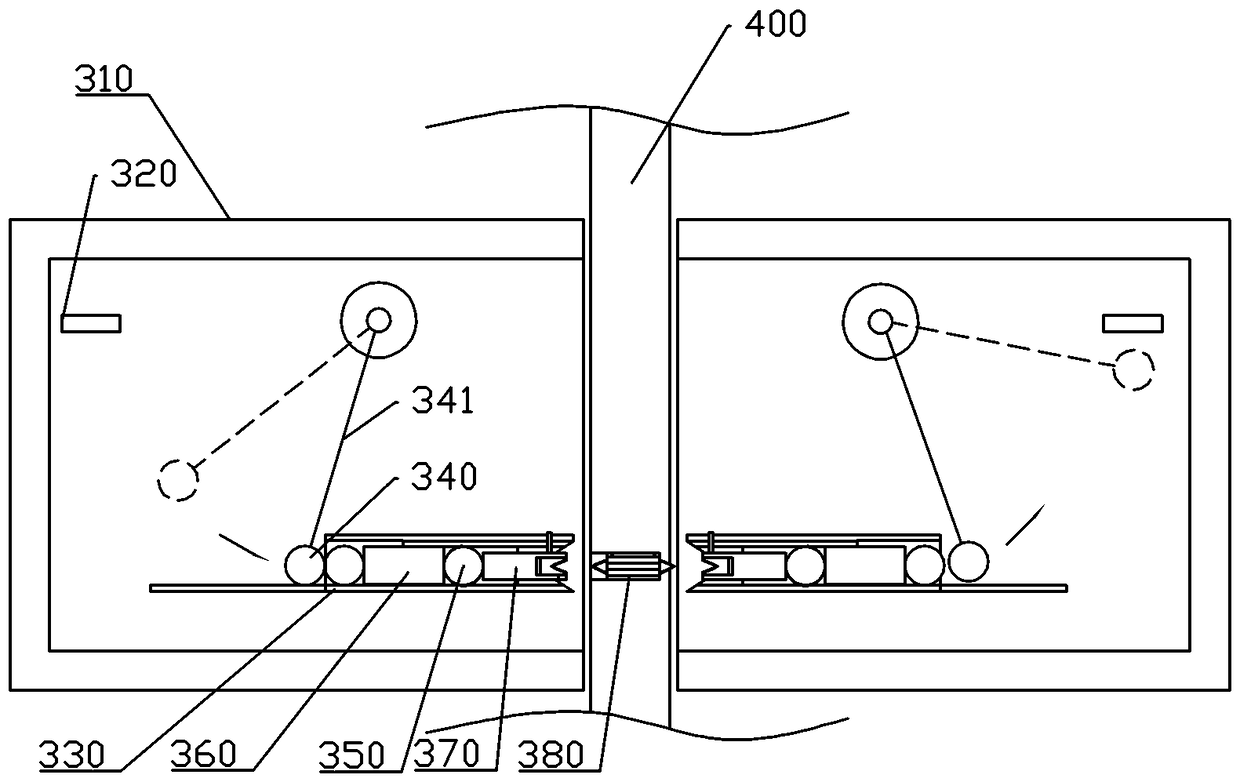

[0028] Woven bag cutting methods such as figure 1 As shown, the following device is used to implement the method. The cutting device includes a frame 100, a strip cutting mechanism 200 arranged on the horizontal plane of the frame 100, and a quick cutting mechanism 300 arranged on a vertical plane. Mechanism 110, strip cutting mechanism 200 cuts woven bag 400 into strips according to the delivery line; quick cutting mechanism 300 includes housing 310, electromagnetic block 320, slide rail 330, billiard ball 340, two transfer balls 350, magnetic column 360, excitation Block 370 and cutting block 380; the quick-cutting mechanism 300 is centered on the woven bag 400 as a mirror image, the electromagnetic block 320 is fixed on the inner wall of the housing 310, the electromagnetic block 320 is located above the slide rail 330, and the billiard ball 340 is pivotally connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com