Bucket cylinder

A technology for oil cylinders and buckets, applied in the field of oil cylinder development, can solve the problems of increased processing difficulty, poor buffering effect, and difficult processing of parts, etc., and achieve the effects of low coaxiality requirements, easy processing, and good buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

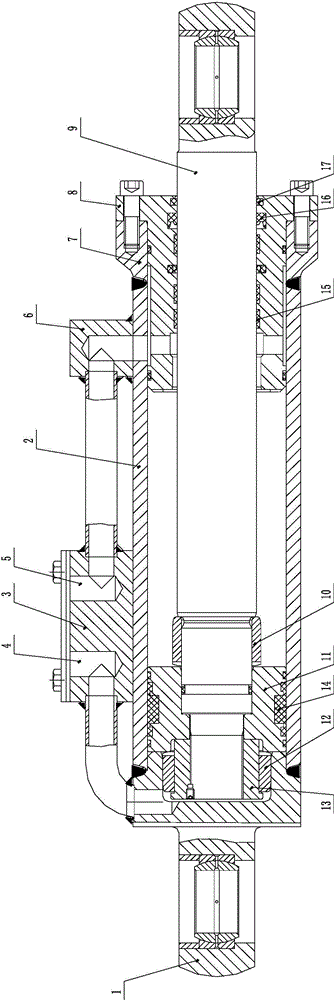

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

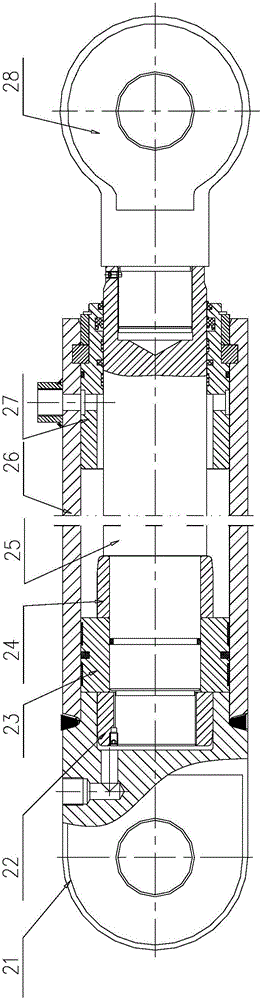

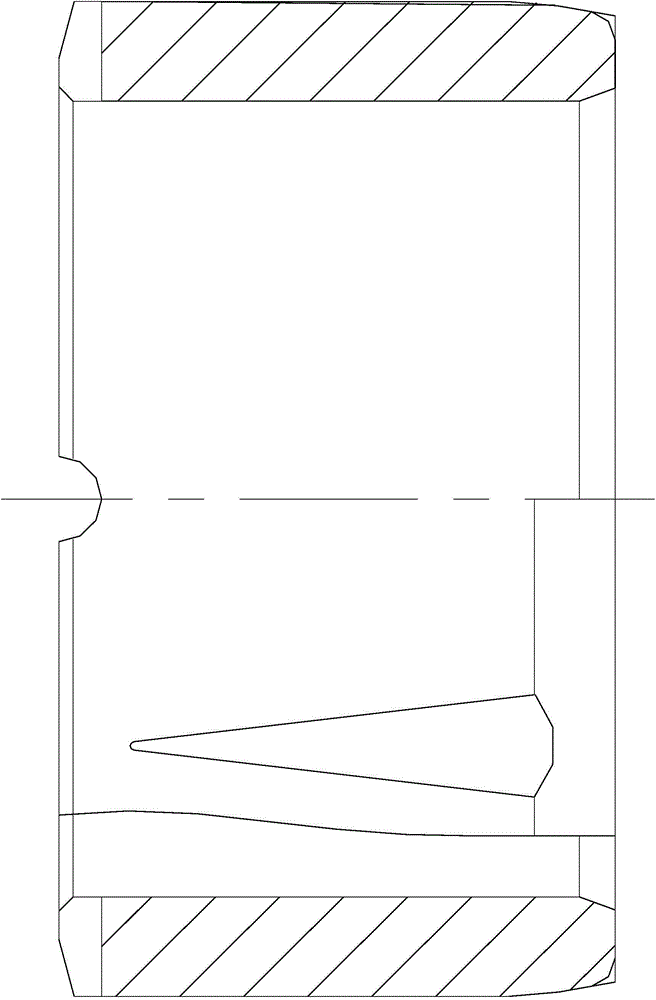

[0028] For the cylinder assembly, refer to the attached figure 2 , including: cylinder bottom 1, cylinder barrel 2, valve seat 3, bend through 6, cylinder head 7, guide sleeve 8, guide ring 15, rod seal 16 and dust seal 17; see attached Figure 5 , 6, the cylinder bottom 1 is divided into a cylindrical part and a connecting head part, a blind hole is opened along the axial direction of the cylindrical part, and a radial through hole connected with the blind hole is provided along the peripheral surface of the cylindrical part; the cylinder barrel 2 It is a cylinder with an axial through hole, and a radial through hole connected with the axial through hole is provided on the peripheral surface of the cylinder; the valve seat 3 is provided with two L-shaped through holes, which are oil holes respectively. A4 and oil hole B5; the bend 6 is provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com