Railway side dump car

A self-rollover and railway technology, which is applied to railway car body parts, dump trucks, transport passenger cars, etc., can solve the problems of low stability of rollover and small volume of self-rollover, so as to improve the economic benefits of transportation, increase the volume of carriages, The effect of reducing the weight of the side door

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

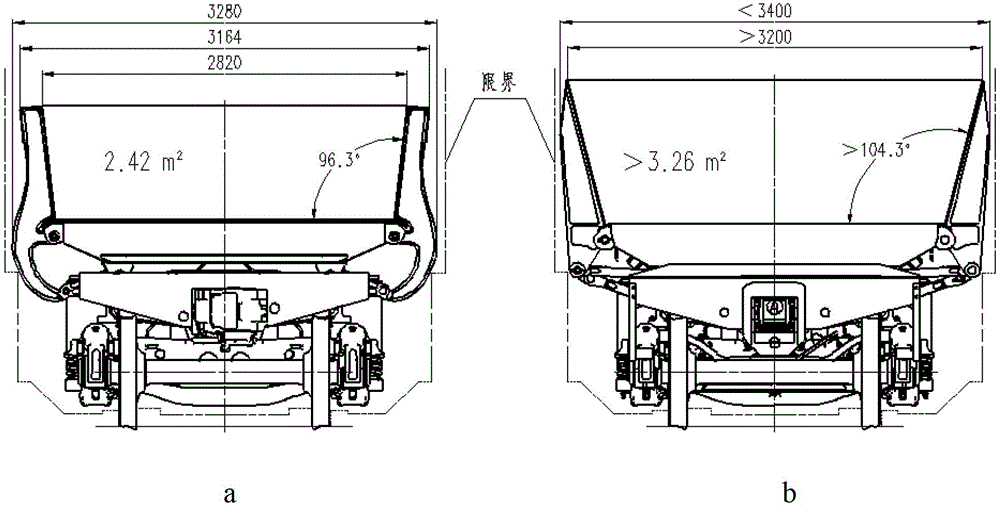

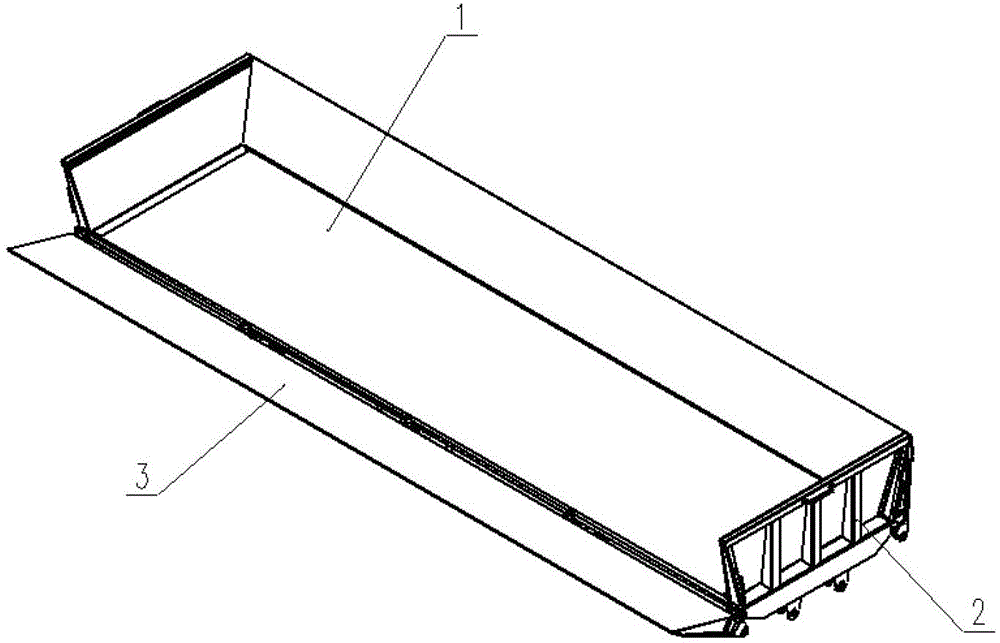

[0043] like figure 1 As shown, since the length of the existing self-dumping truck loading and unloading supporting facilities has been fixed, the length of the vehicle should not be changed in order to be used in conjunction with the existing facilities.

[0044] Since the maximum width of the dump truck with a load of 60t is 3280mm, the outer width of the lower part of the compartment is already close to the limit, and it is difficult to widen it. However, the maximum outer width of the top is 3164mm, and each side has a distance of 118mm from the limit, and there is a small amount of room for increase in the width direction. .

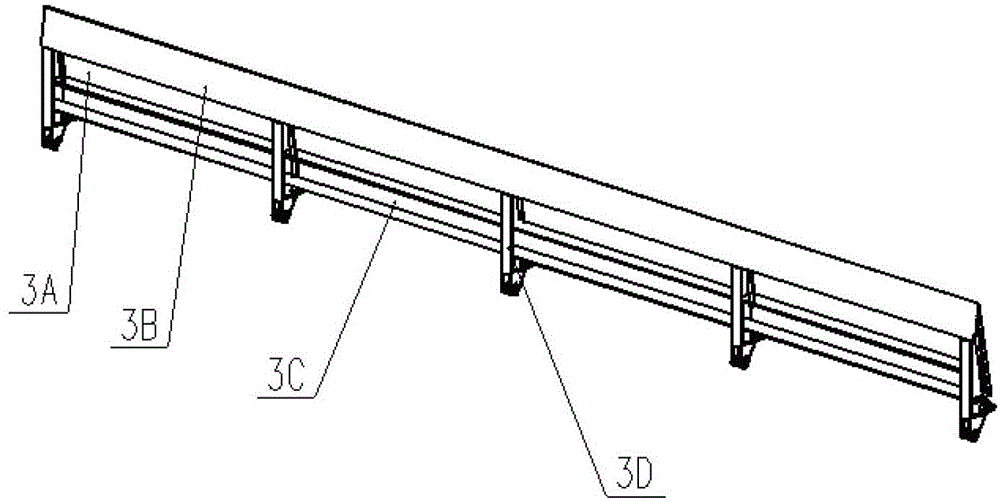

[0045] After analysis, the load of the upper side beam of the side door is small, and the section size can be reduced. In order to make full use of the lateral space, the transverse section size of the upper side beam of the side door is reduced, and the section size of the lower side beam with large load is increased. When the interior length of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com