Roof-contacted method for mine gob-side entry paste filling wall body

A technology of paste filling and roadway retention, which is applied to filling materials, mining equipment, earth cube drilling and mining, etc. It can solve the problems of cumbersome operation, long support time and damage of filling body, etc., and achieve simple operation procedures and low filling cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

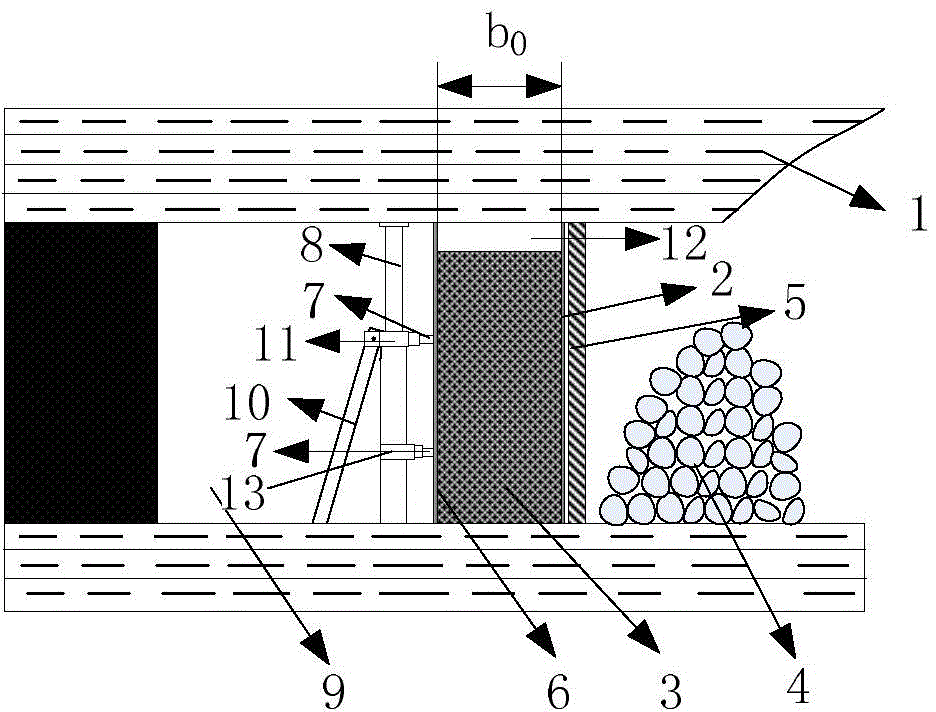

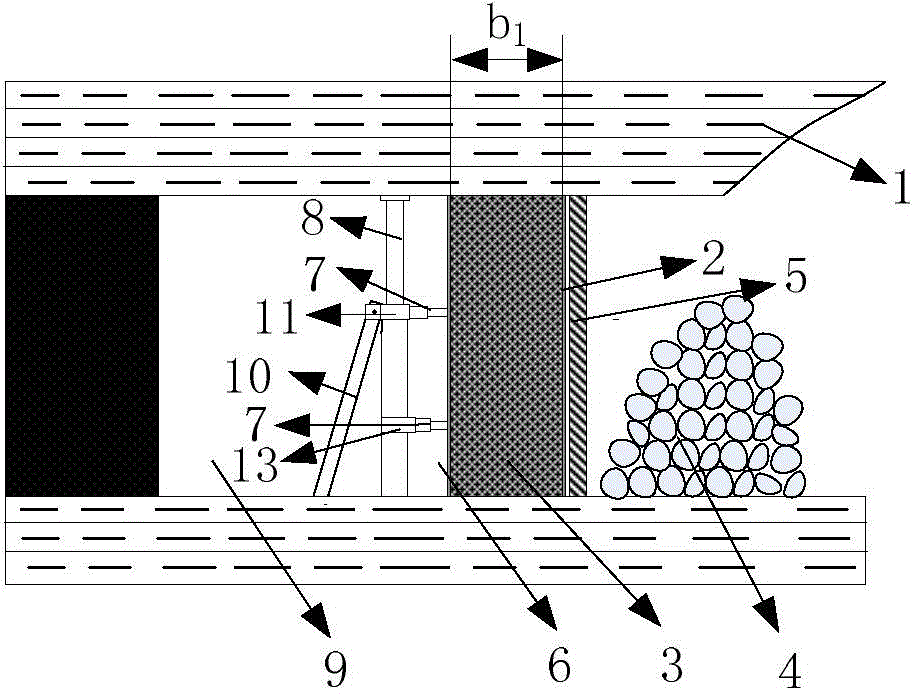

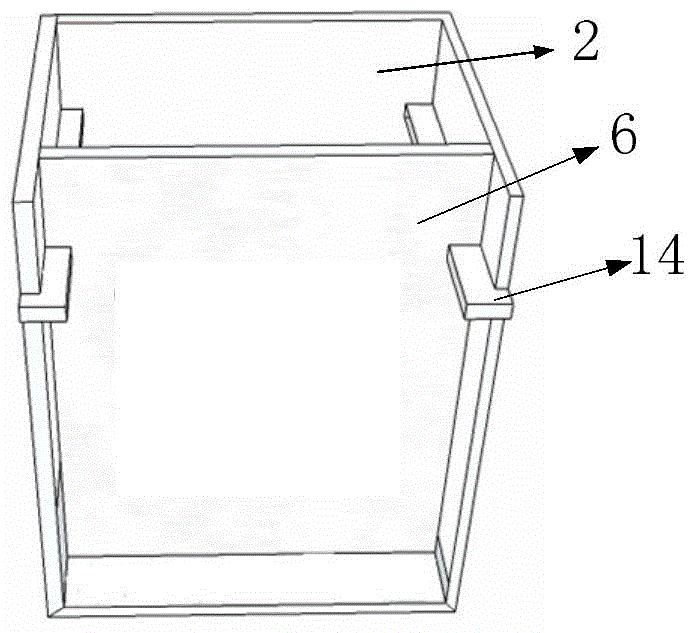

[0023] like Figure 1 ~ Figure 3 As shown in the figure, a method for side push and roof connection of gob-side filling and gob-side entry retaining, the specific steps are:

[0024] 1. First calculate the erection width b of the filling formwork 0 , the width is the design width b of the filling body 1 Add the reduction value Δh of the width after pressing the filling body to the top; b 0 =b 1 +Δh

[0025] Δh can be calculated according to the principle that the volume of the filling body does not change before and after the top is connected. The formula is as follows:

[0026] Δh=b 0 -b 1 =b 1 / η-b 1

[0027] In the formula: η—filling rate;

[0028] 2. When the coal seam in the pre-filled section of the working face is mined for one working cycle and the frame is moved, a row of wooden pillars 5 with a spacing of 0.8m should be supported on the side of the pre-filled section near the goaf in time, and the spacing between the other sections should be installed. It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com