Manufacturing method of removable dentures

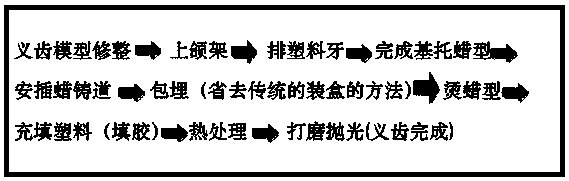

A denture and process technology, applied in the field of removable denture manufacturing, can solve the problems of long manufacturing cycle, complicated operation, cumbersome steps, etc., and achieve the effects of reducing the need for many personnel, simple operation, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A removable denture manufacturing process and method, characterized in that: the method includes the following steps:

[0060] (1) Model trimming process:

[0061] First, use a model trimmer to trim the bottom and surroundings of the model. The thickness from the trimmed bottom to the gums is 0.9-1.2 cm. During the trimming process, the abutment teeth and the corresponding opposing teeth must not be damaged, and the occlusal relationship and the required dissociation can be determined. important part of the end;

[0062] (2) Upper jaw frame:

[0063] Carry out processing according to the specific requirements on the design sheet, and accurately bite the jaw position according to the doctor's biting wax, and then rest the upper jaw, pay attention to the alignment of the midline when the upper jaw is rested, the model should be soaked first, and then the lower jaw and then the upper jaw;

[0064] (3) Row of plastic teeth:

[0065] Fill the undercut. The depth of the ti...

Embodiment 2

[0082] According to the production and method of the removable denture described in Example 1, according to step 5, three wax castings are inserted for the complete denture, and two are placed at the back of the wax base near the back of the teeth, which are auxiliary castings. The one inserted in the anterior tooth area is the main casting channel;

[0083] Partial dentures: three to nine, according to the location of the missing teeth to insert the sprue;

[0084] Single missing tooth: Two wax injection channels, one on each buccal and lingual surface.

Embodiment 3

[0086] According to the manufacture and method of the removable denture described in embodiment 1 or 2, filling the plastic according to step 7 is to convert the wax base into a plastic base, and after the materials are blended, the base water gradually penetrates into the base powder, and The infiltration process is divided into the following six stages:

[0087] (1) Wet sand stage: the tray water has not yet penetrated into the tray powder, and exists between the tray powder particles. It looks like there is less water and more powder. At this time, the reconciliation resistance is small, non-sticky, and it feels like wet sand to the touch;

[0088] (2) Paste stage: the surface of the tray powder is gradually swollen by the tray water, the particles are squeezed tightly, the intergranular gaps disappear, the surface of the mixture appears to have more tray water, and there is no resistance during blending;

[0089] (3) Silk sticking period: the tray water continues to swell ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com