Patents

Literature

133results about How to "Avoid error rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

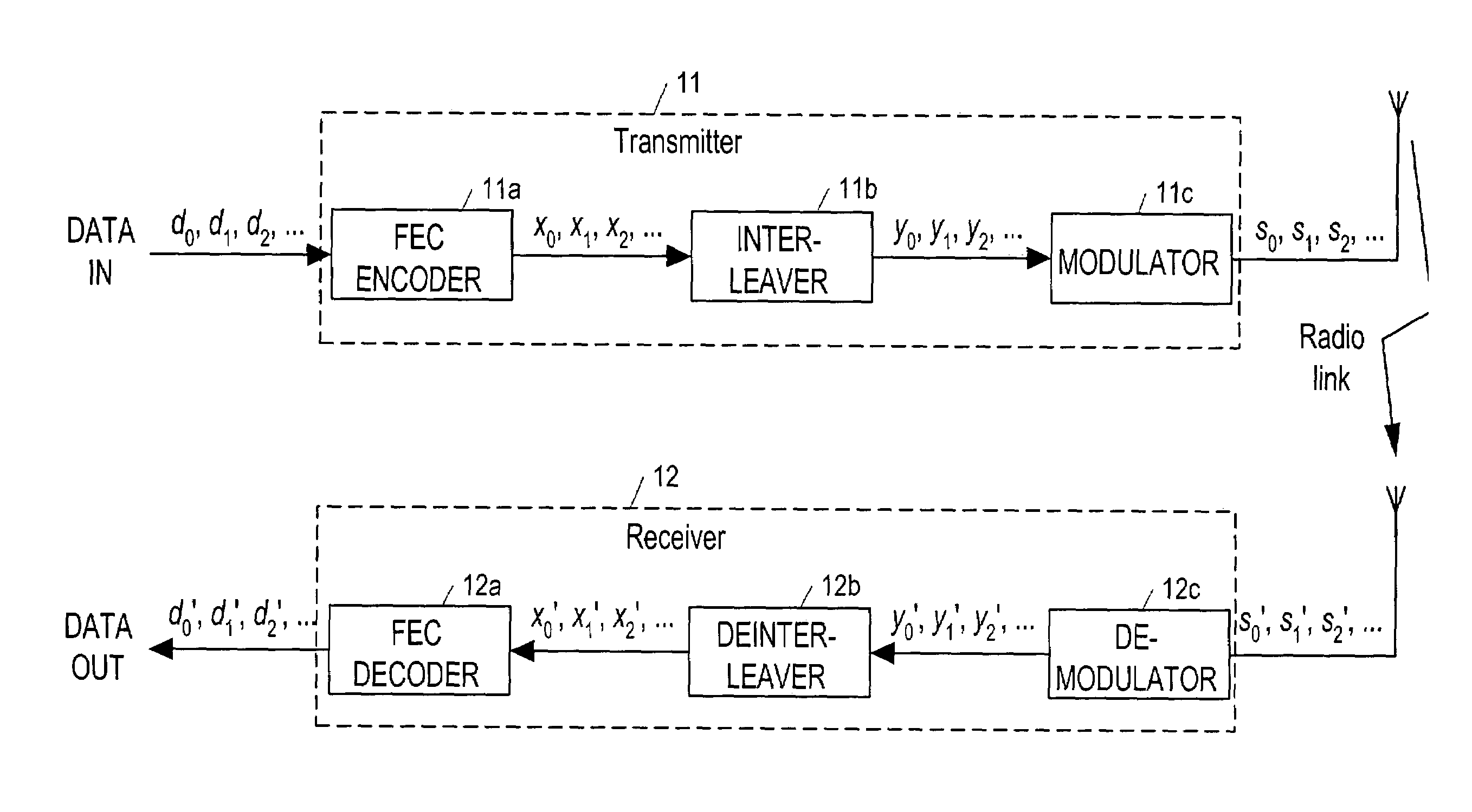

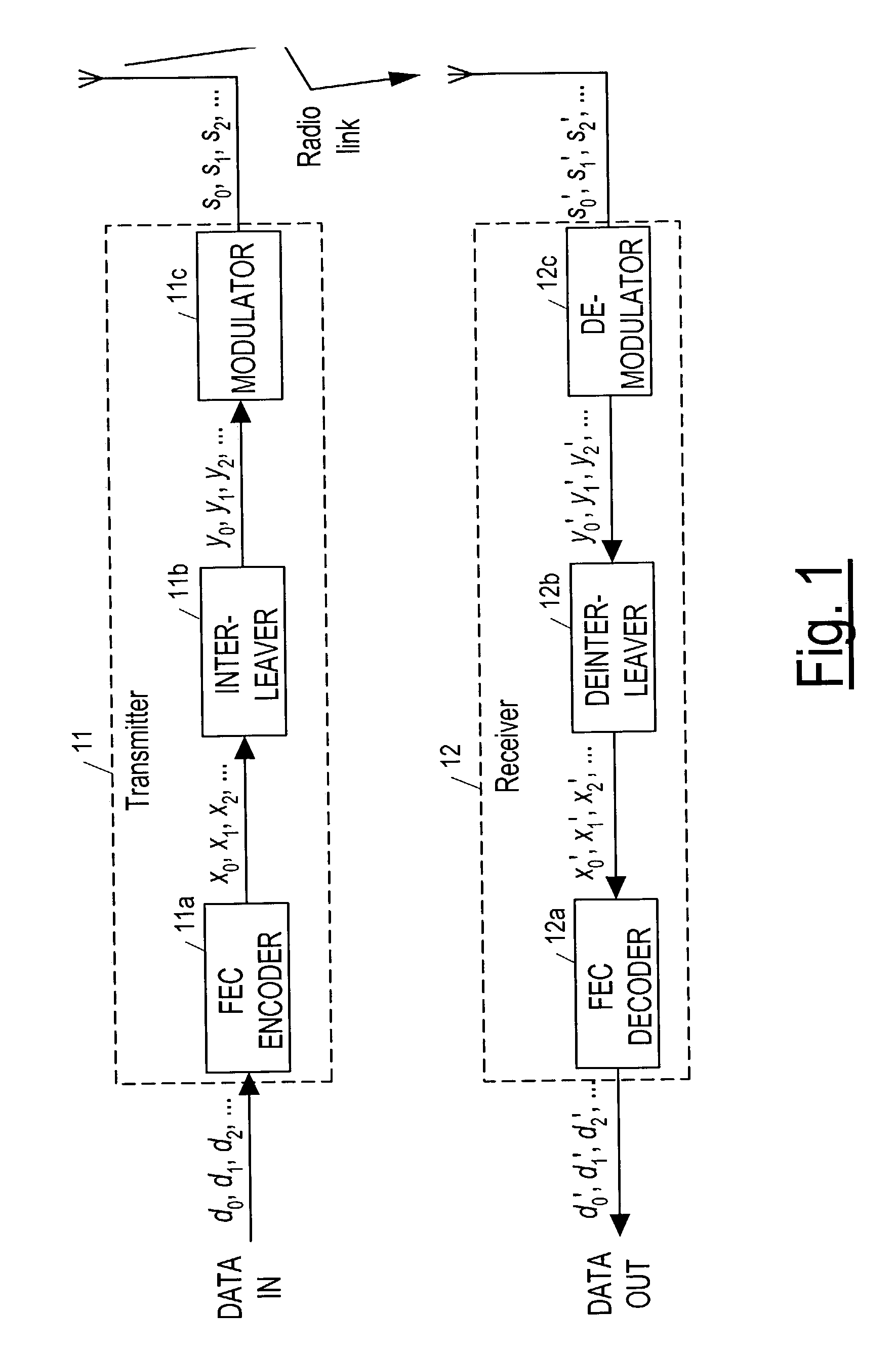

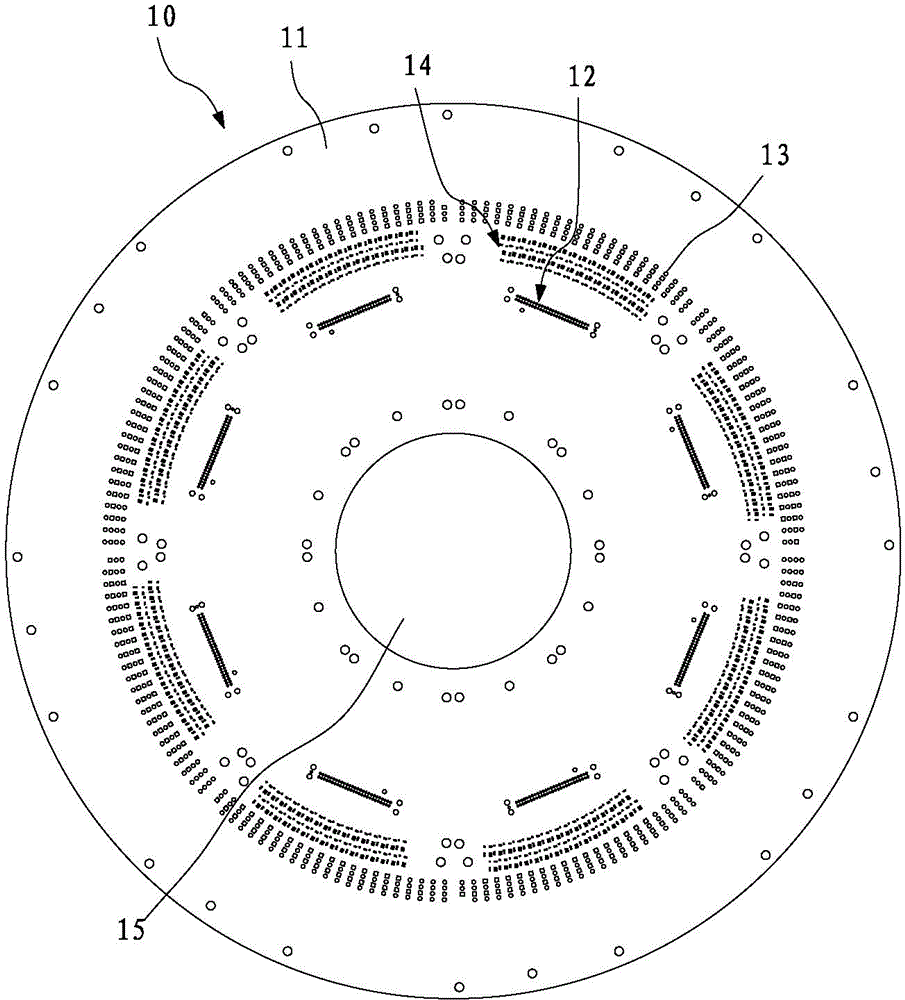

Partially filling block interleaver for a communication system

InactiveUS7028230B2Avoid error rateData representation error detection/correctionDigital data processing detailsCommunications systemNetwork packet

An interleaver (11b) for filling an interleaver matrix (51) used in interleaving a packet of bits for transmission as symbols via a wireless communication channel in a wireless communication system (11 12) including a modulator (11c), the interleaver (11b) having a number of rows (or columns, depending on whether bits are pulled column-wise or row-wise for encoding as symbols by the modulator) that is not divisible by the number of bits in a symbol, but having at least as many bits as in a packet, and so having, unavoidably, more elements than there are bits in a packet.

Owner:WSOU INVESTMENTS LLC

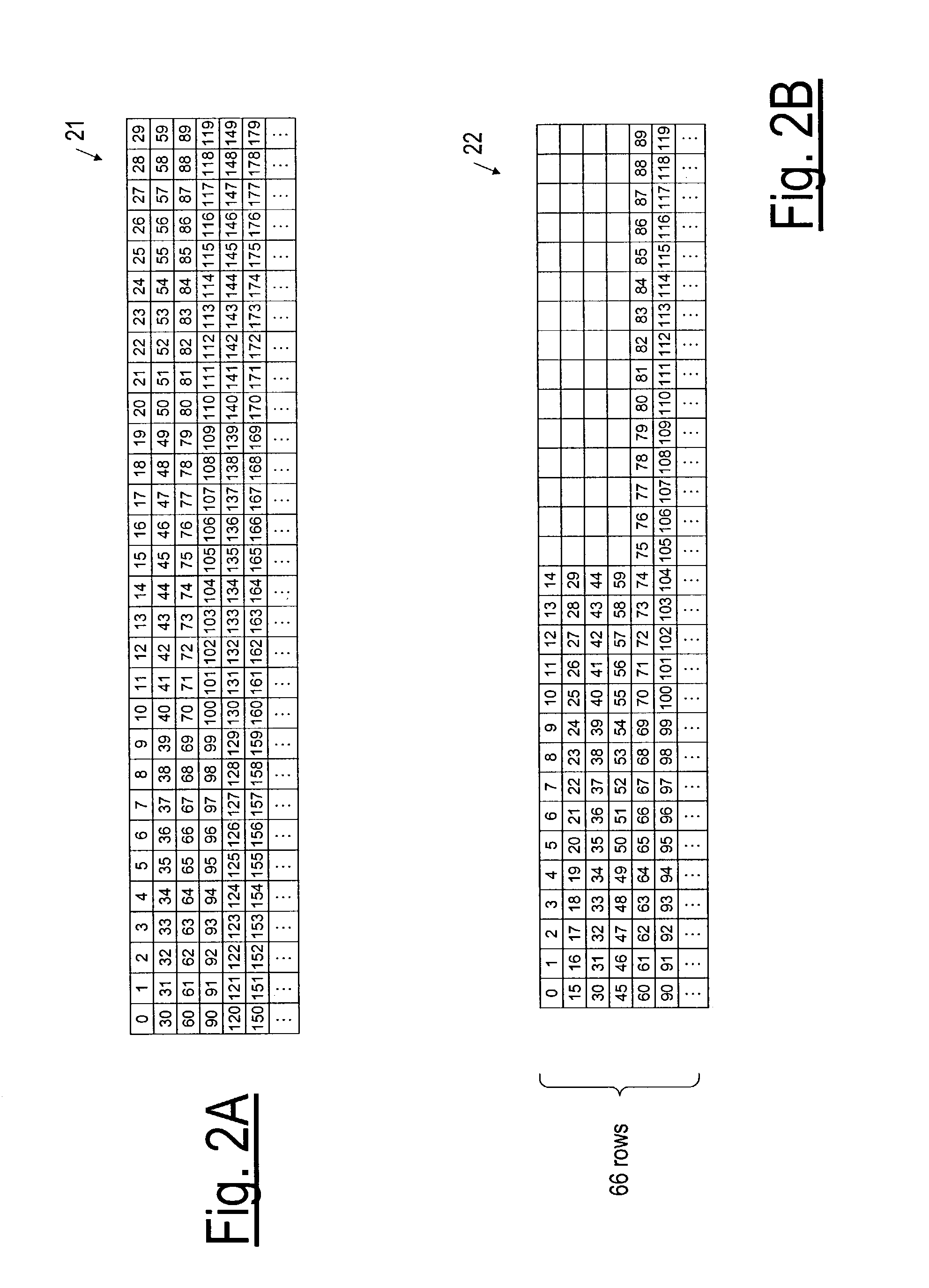

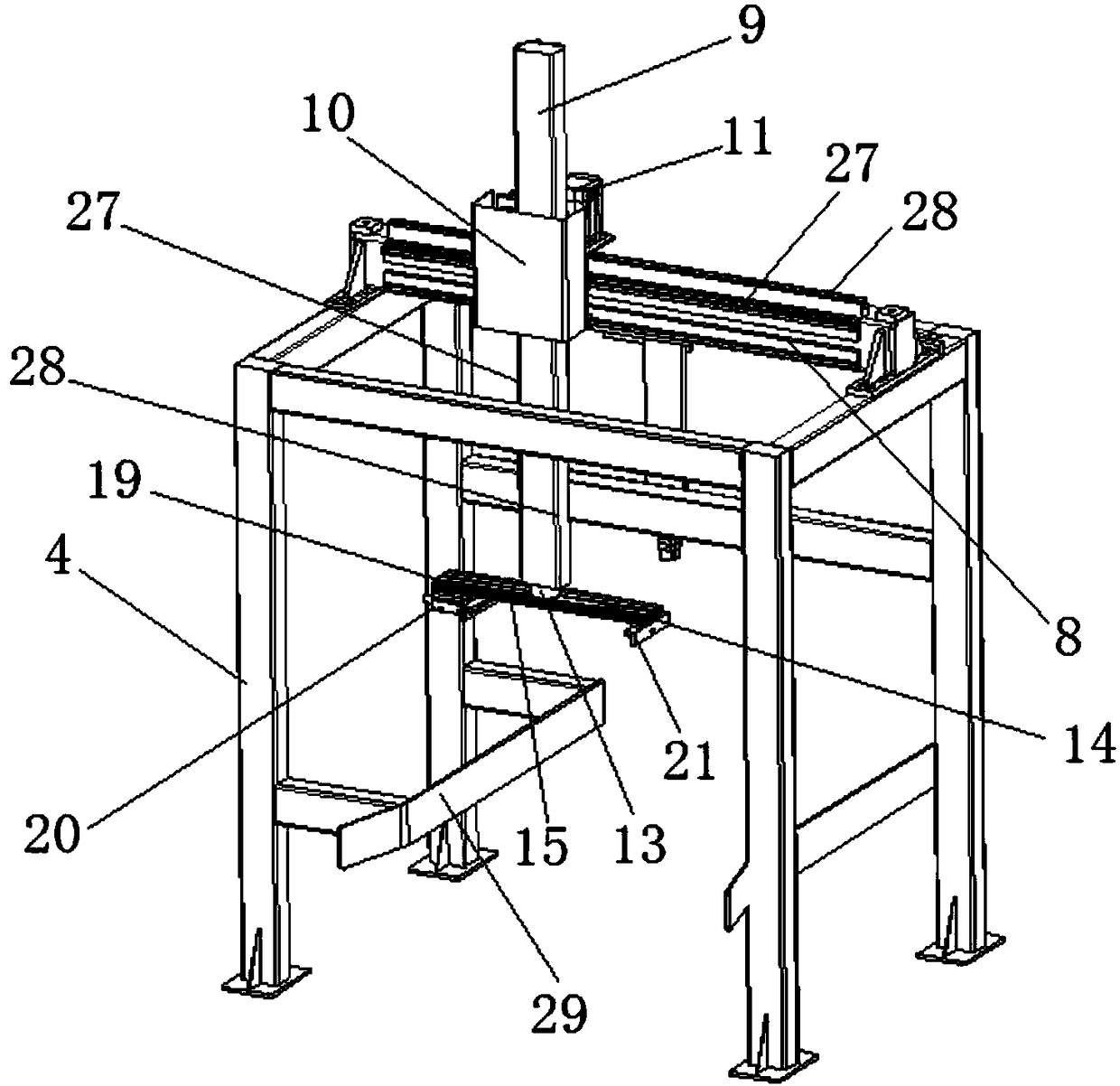

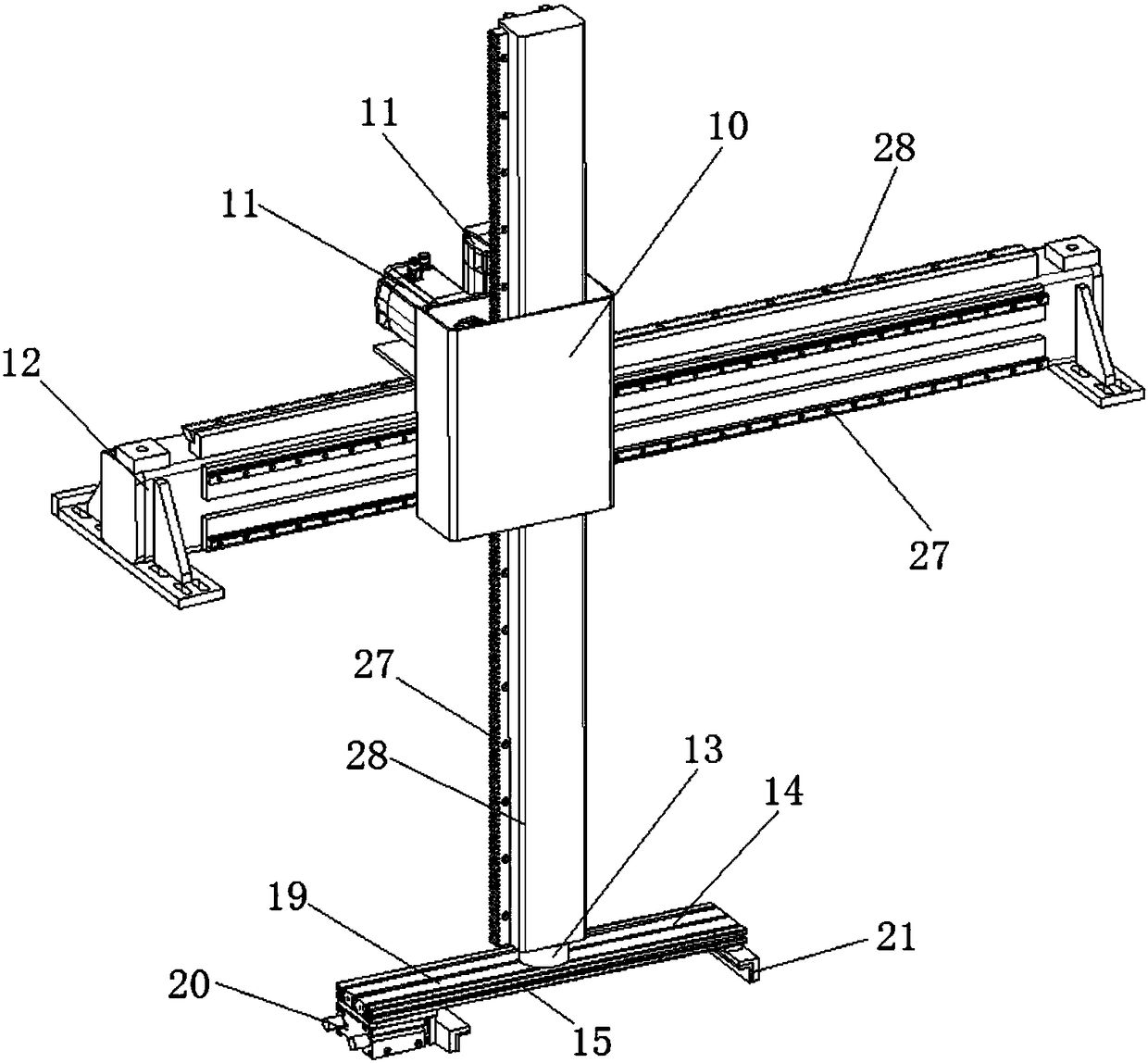

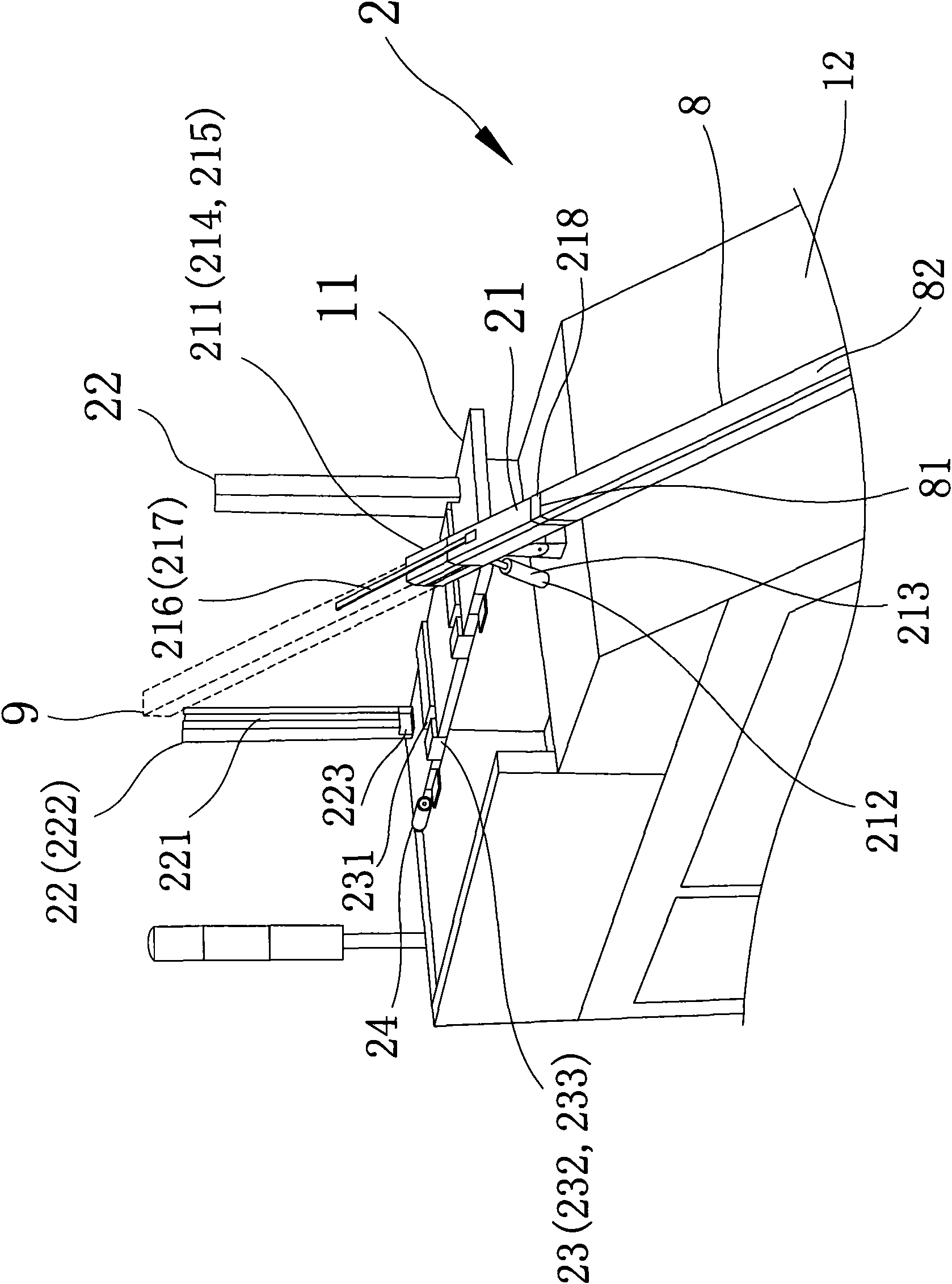

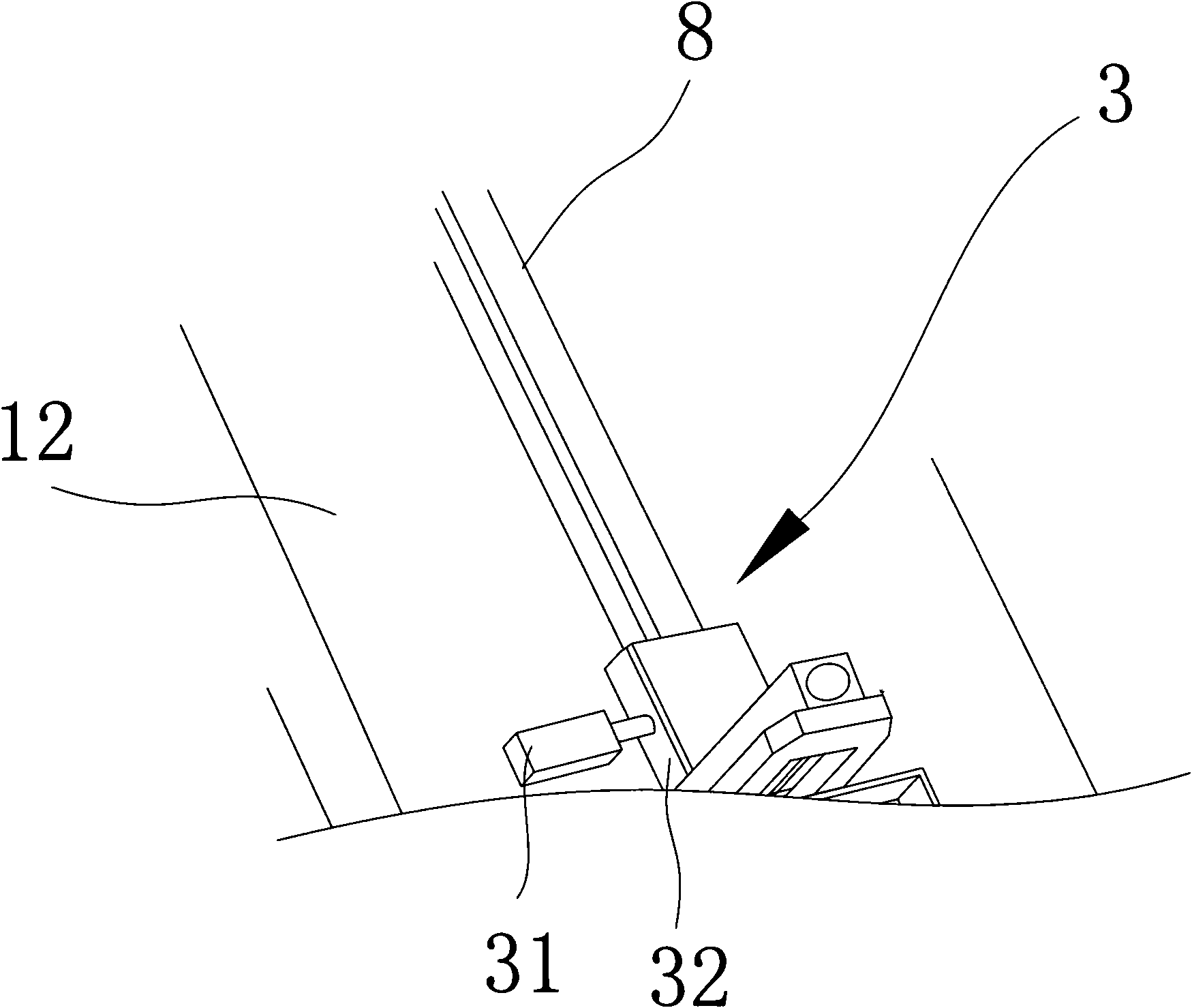

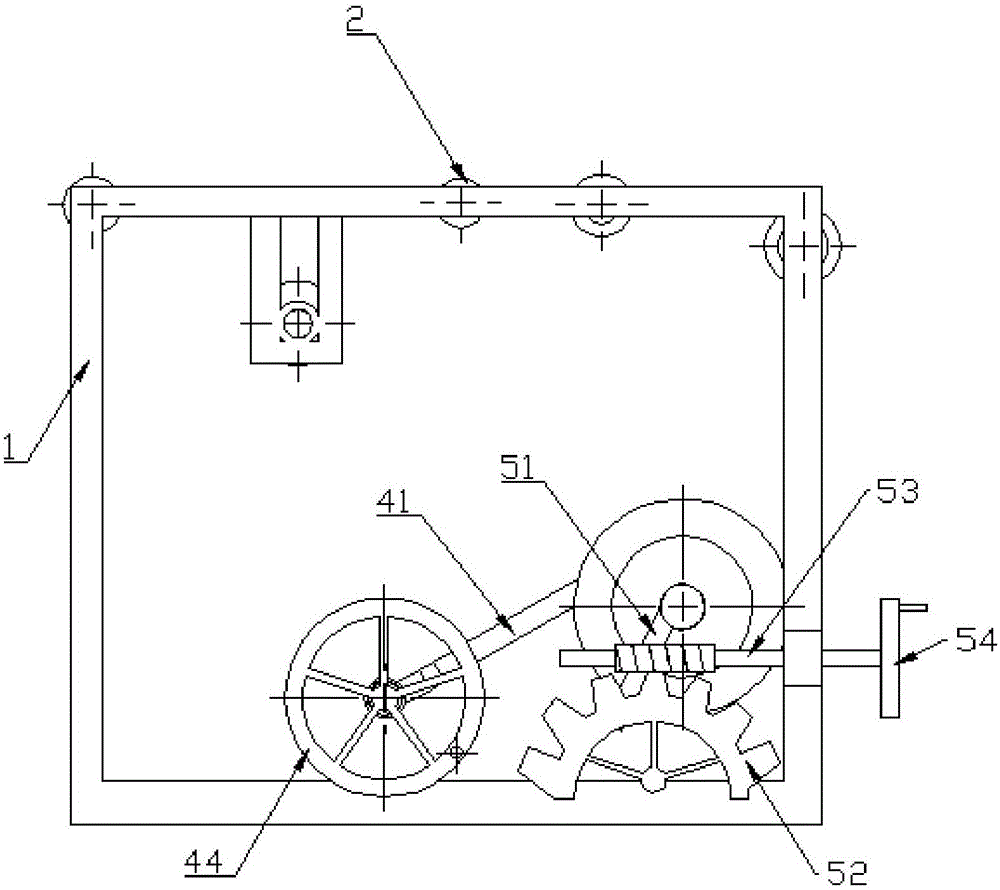

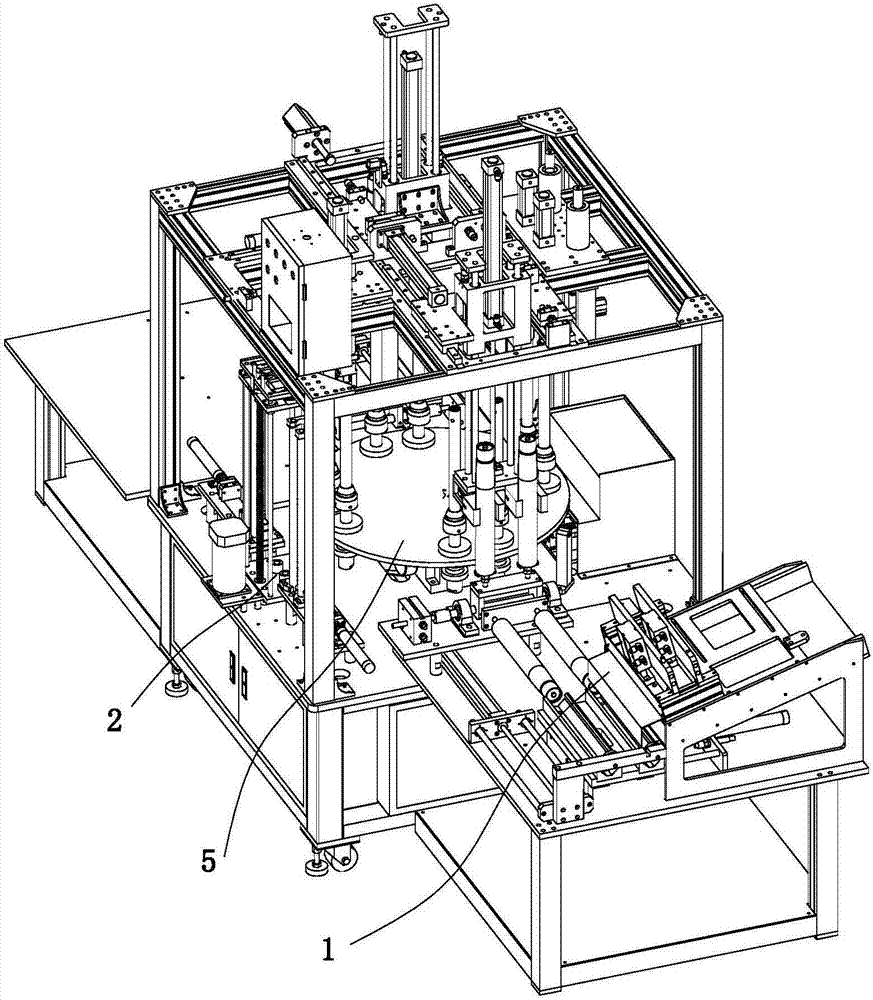

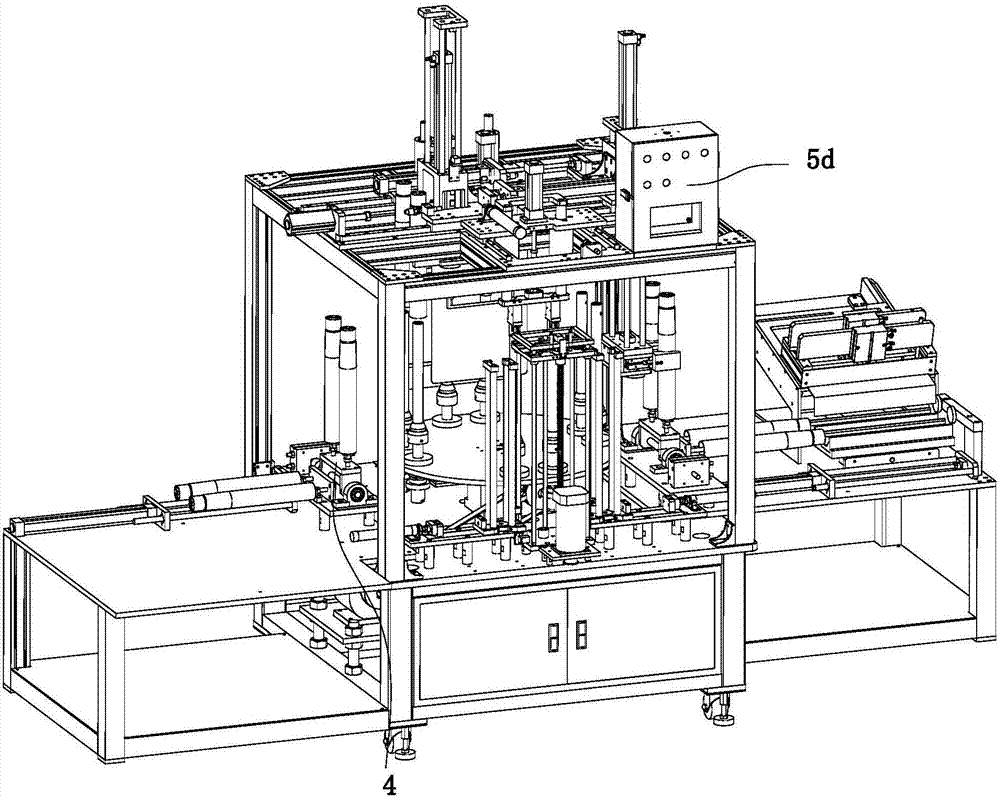

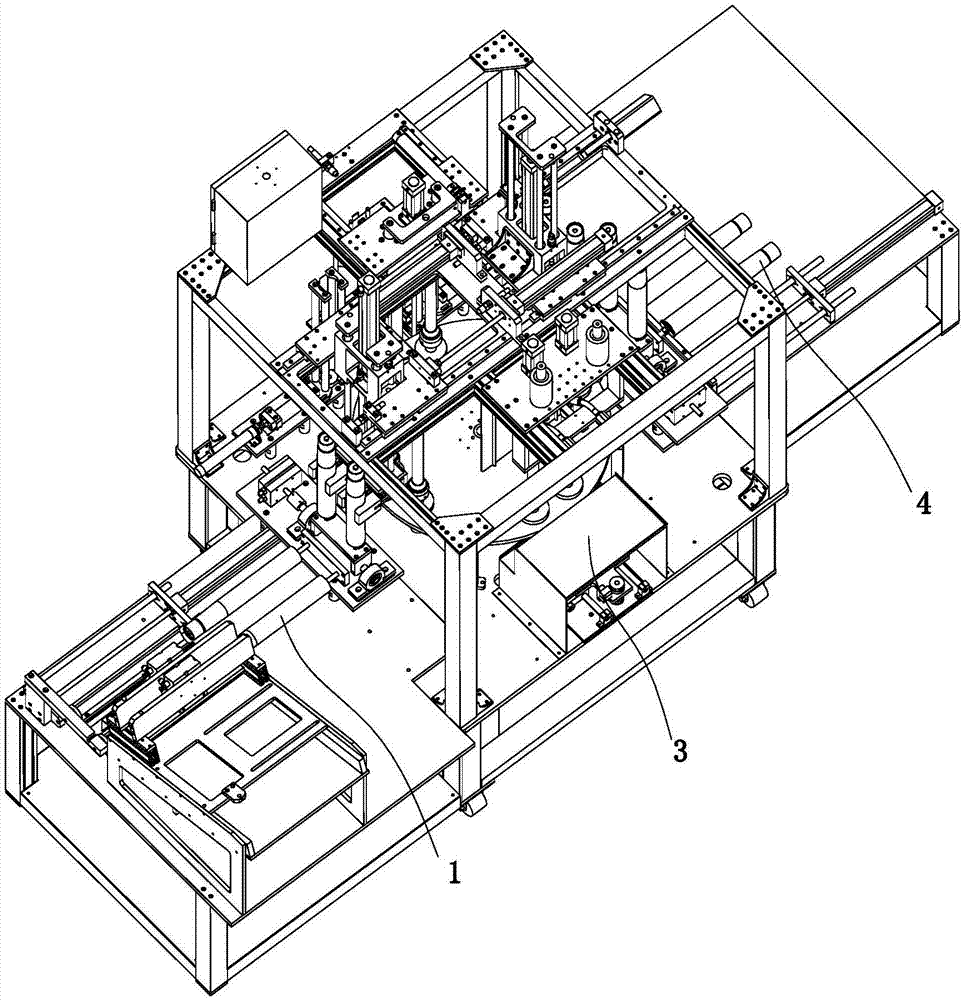

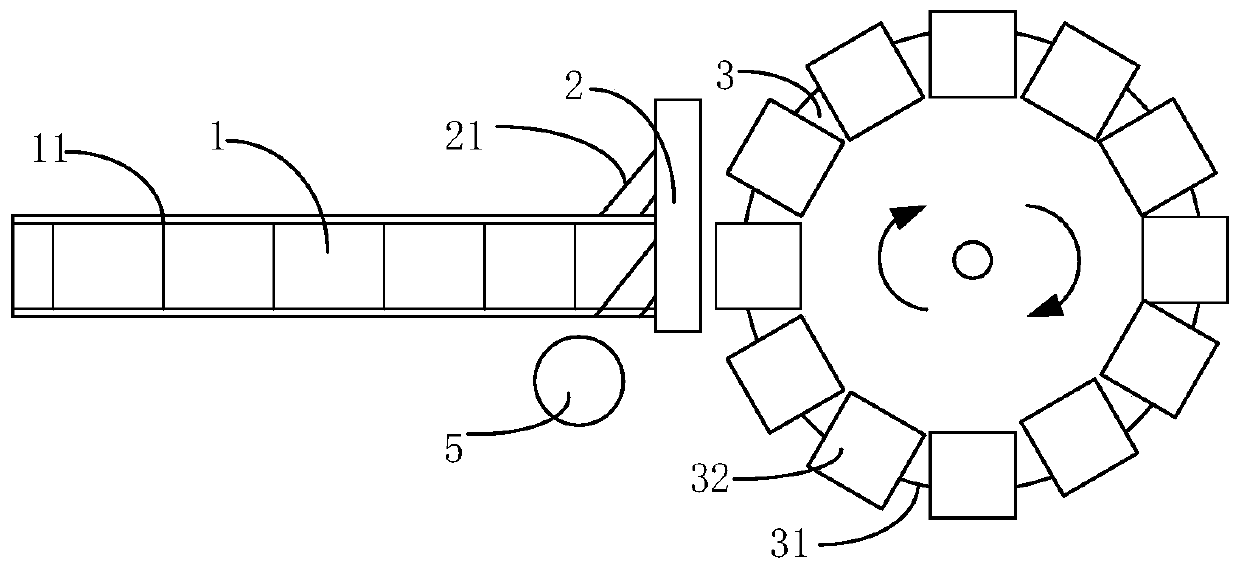

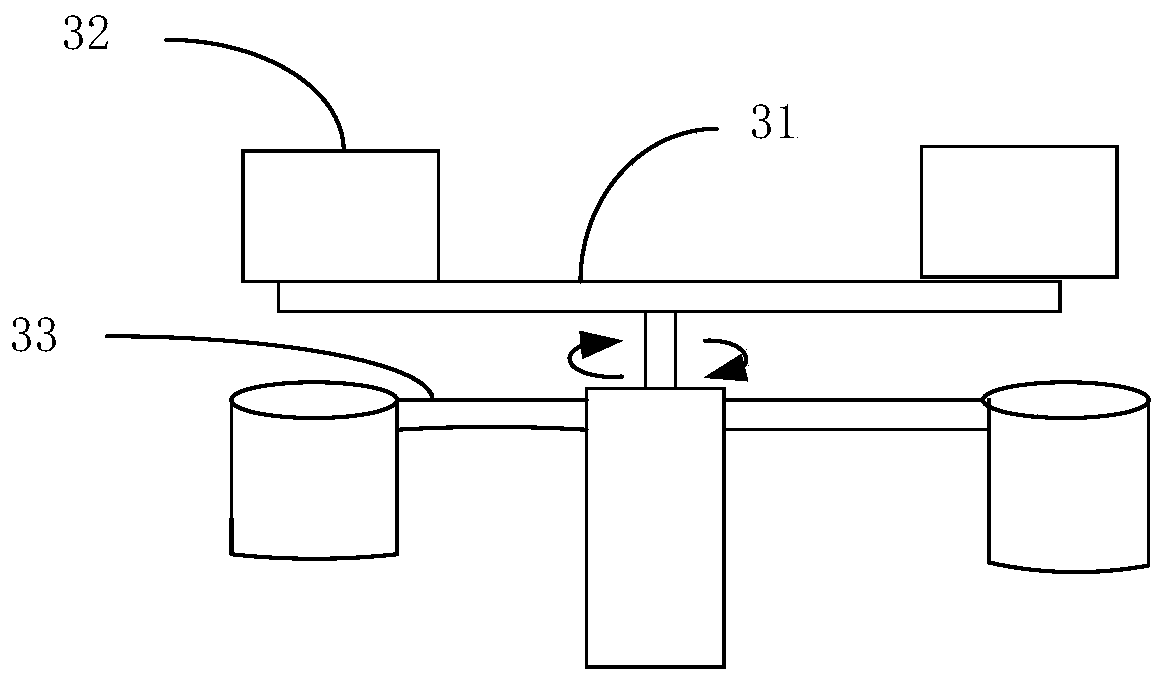

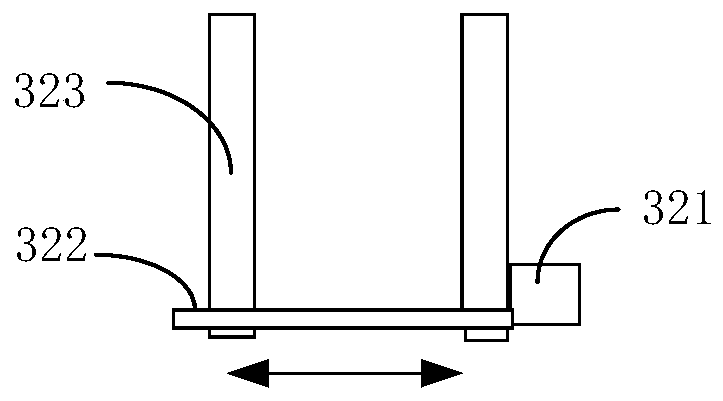

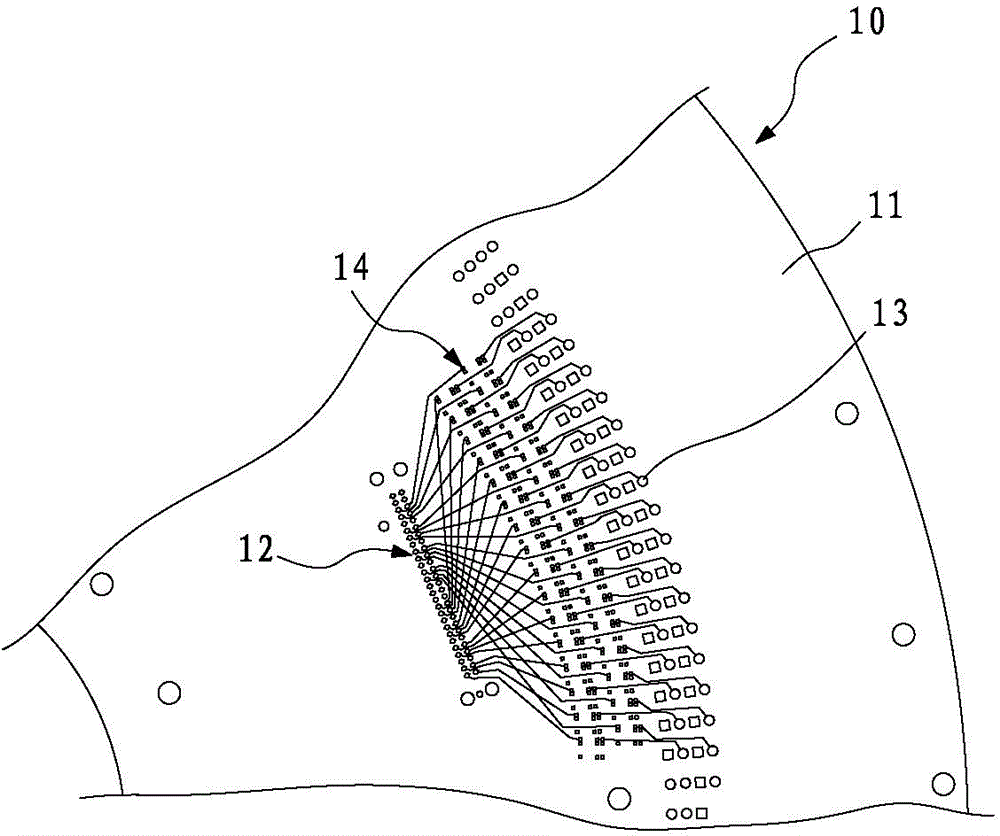

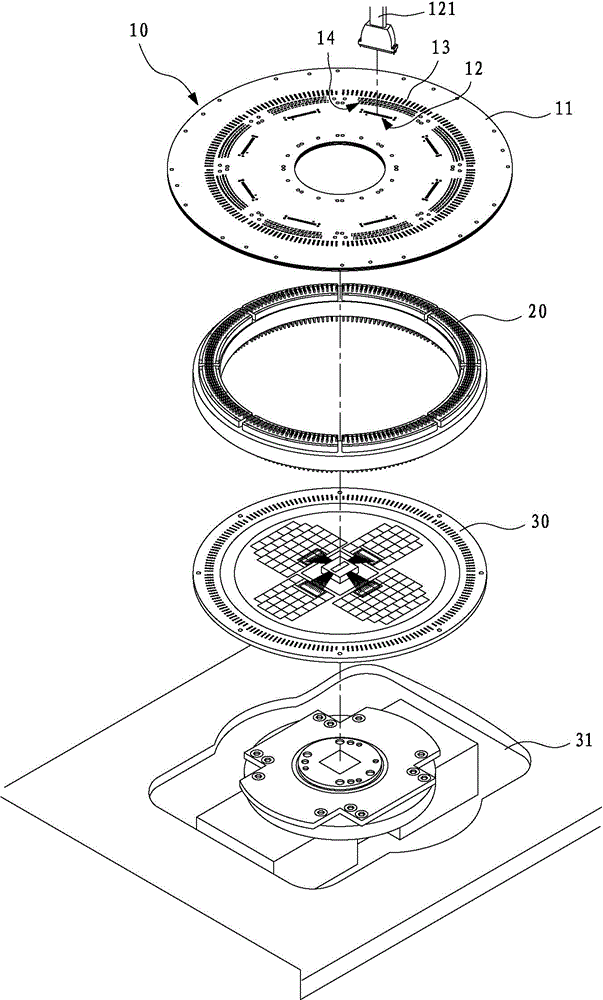

Automatic detecting and unstacking device for condensers

PendingCN108082927ANo need to manually moveFree to useConveyorsControl devices for conveyorsElectricityElectric machine

Owner:INST OF INTELLIGENT MFG TECH JITRI

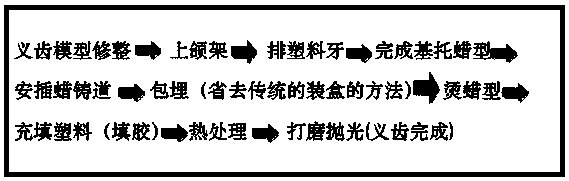

Manufacturing method of removable dentures

ActiveCN107854187AAvoid Coitus HeighteningAvoid Shrinkage Bubble PhenomenonArtificial teethWater bathsDental cast

The invention relates to a manufacturing method of removable dentures. Currently, the removable-denture manufacturing methods in all countries in the world are a thermos-coagulation packing method, need steps such as casing, filling, squeezer pressurizing and water bath polymerization (dental cast cooking pot), are complex in process, time-consuming and labor consuming, are non-uniform in moldingcase pressurizing and are difficult in precise mastering and control of heating speed and heating maintaining time during heat processing. The method has the advantages that the manufacturing flow oftraditional removable dentures is improved, joint height increasing and contraction bubbles of the removable dentures manufactured by the traditional manufacturing process are avoided, and the base-material filling of the partial removable dentures and attachment dentures can be performed; the models of the attachment dentures does not need to be pressurized on a squeezer, and the subfissure or deformation of the fixing-part porcelain teeth of the attachment dentures is avoided.

Owner:程昕

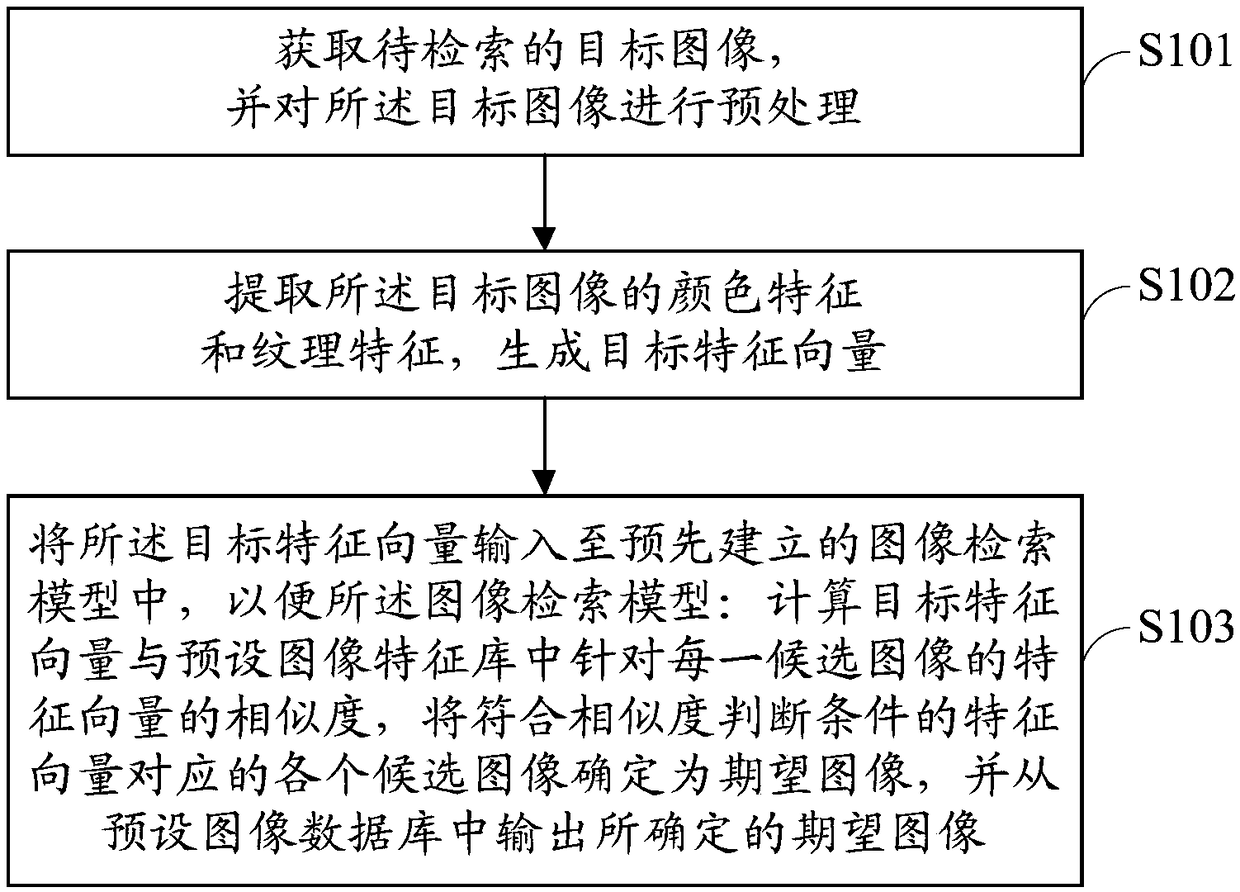

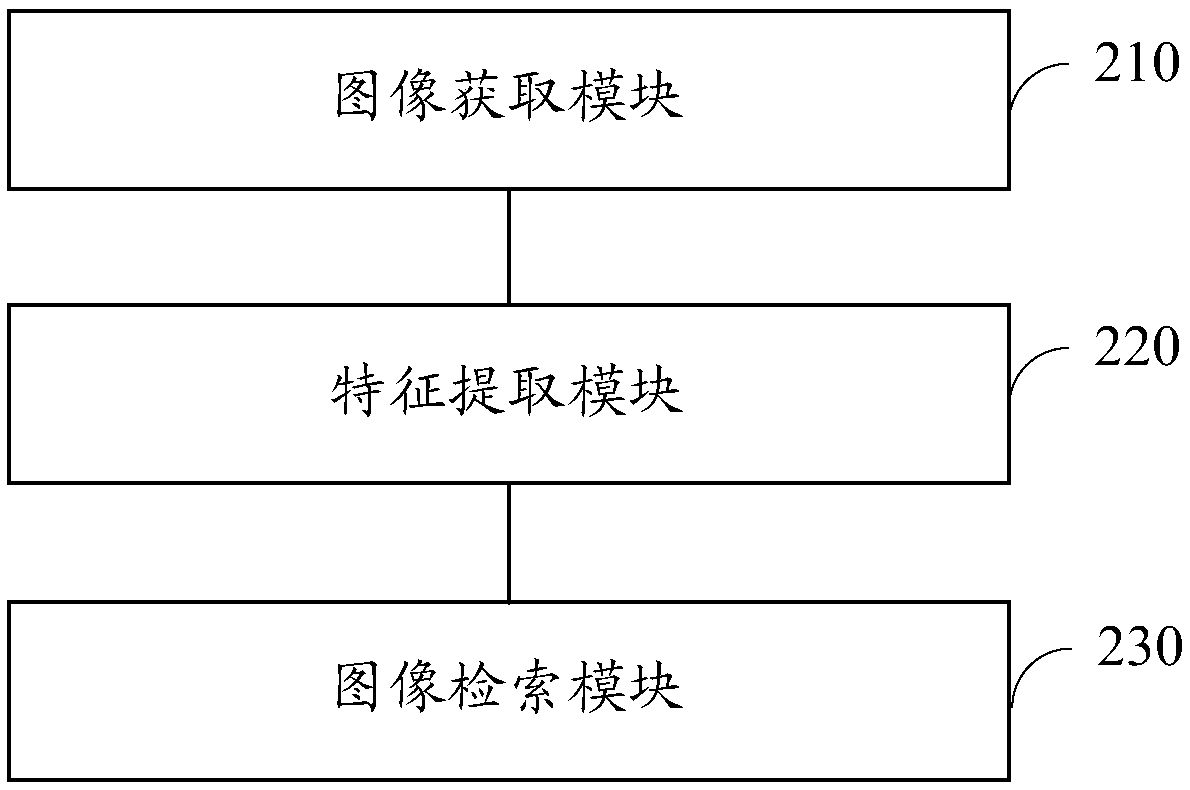

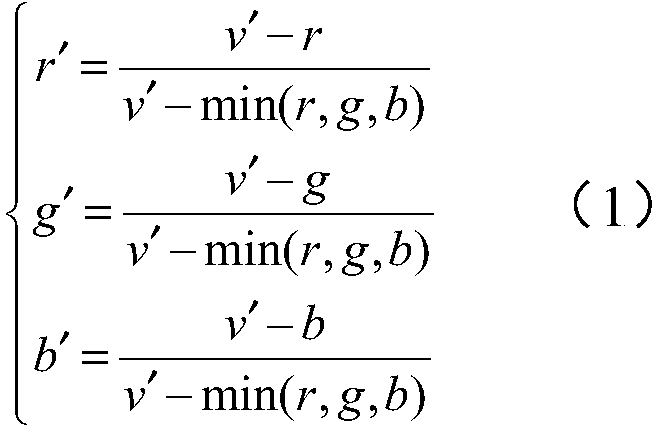

A method and apparatus for image retrieval

InactiveCN109033308AImprove accuracyAvoid error rateCharacter and pattern recognitionSpecial data processing applicationsFeature vectorImage name

The embodiment of the invention provides a method and apparatus for image retrieval. The image retrieval method comprises the following steps: acquiring a target image to be retrieved, and preprocessing the target image; extracting color features, texture features and image names of target images to generate target feature vectors; inputting the target feature vector into a pre-established image retrieval model, so that the image retrieval model calculates the similarity between the target feature vector and the feature vector of each candidate image in the preset image feature library, determines each candidate image corresponding to the feature vector that meets the similarity judging condition as a desired image, and outputs the determined desired image from the preset image database. When the method provided by the embodiment of the invention is used for image retrieval, the subjectivity problem similar to that of adding keywords in the traditional image retrieval mode by the manual identification mode is not involved, so that the error probability in feature matching can be avoided, and the accuracy of the image retrieval result is greatly improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

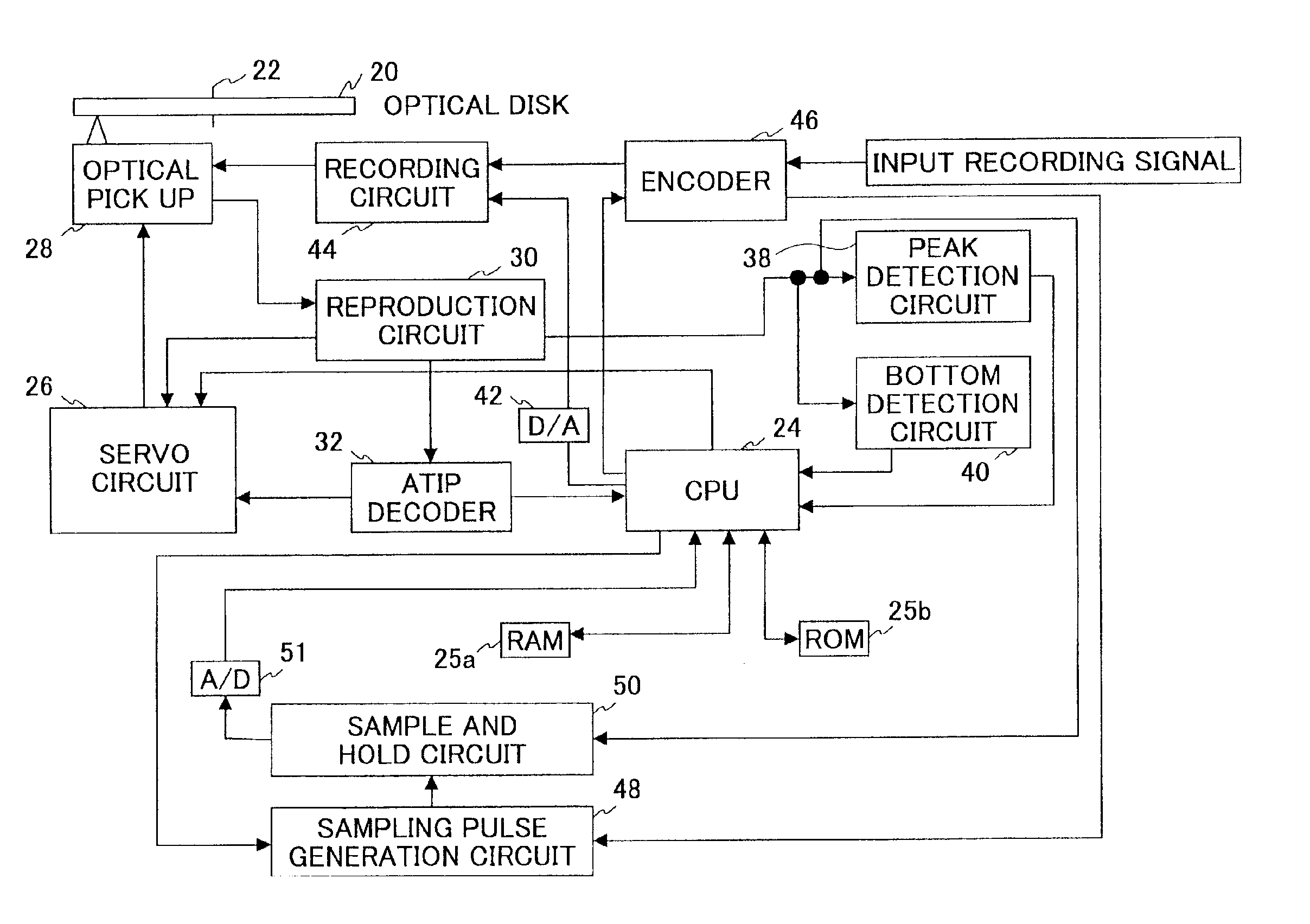

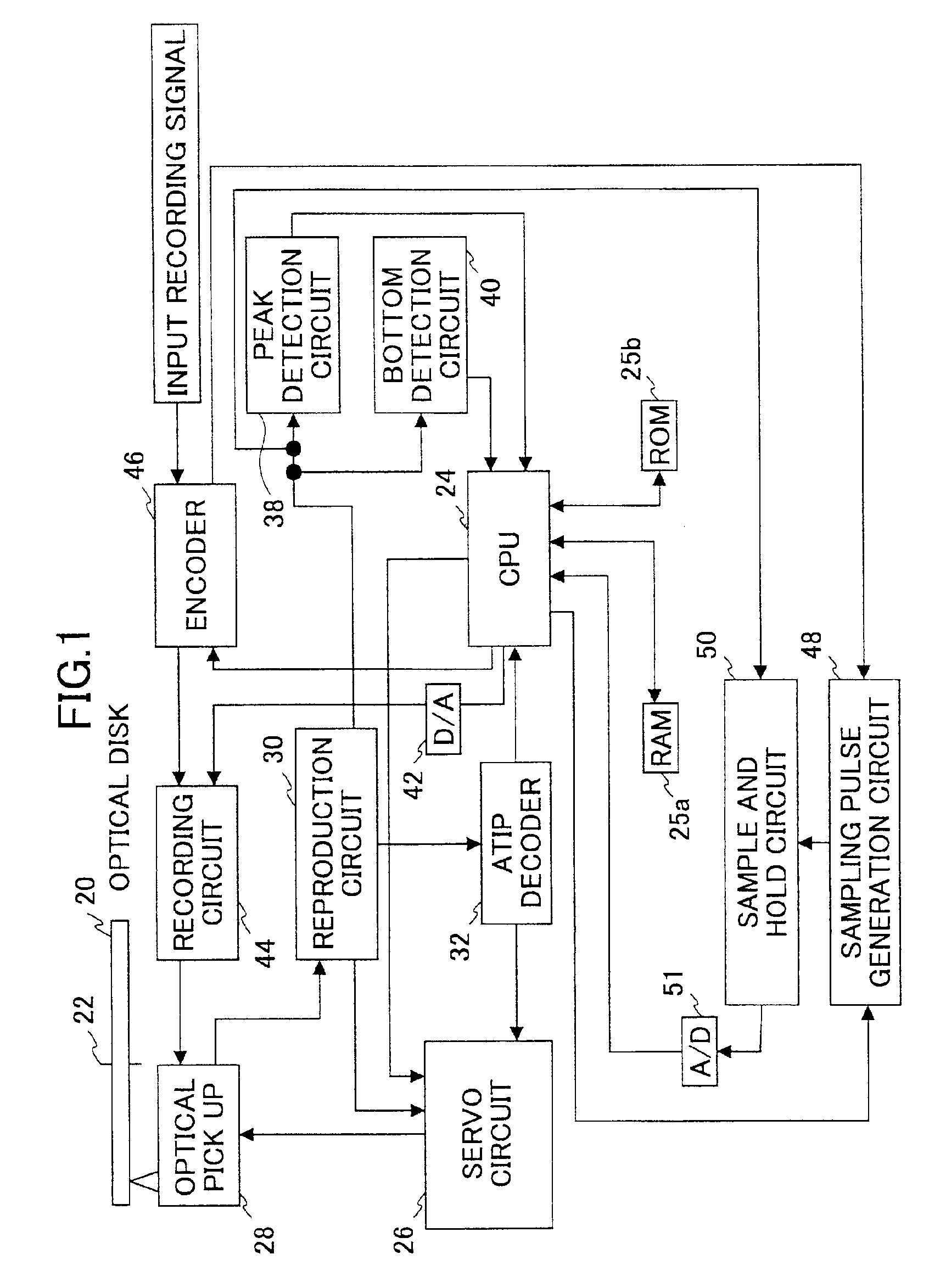

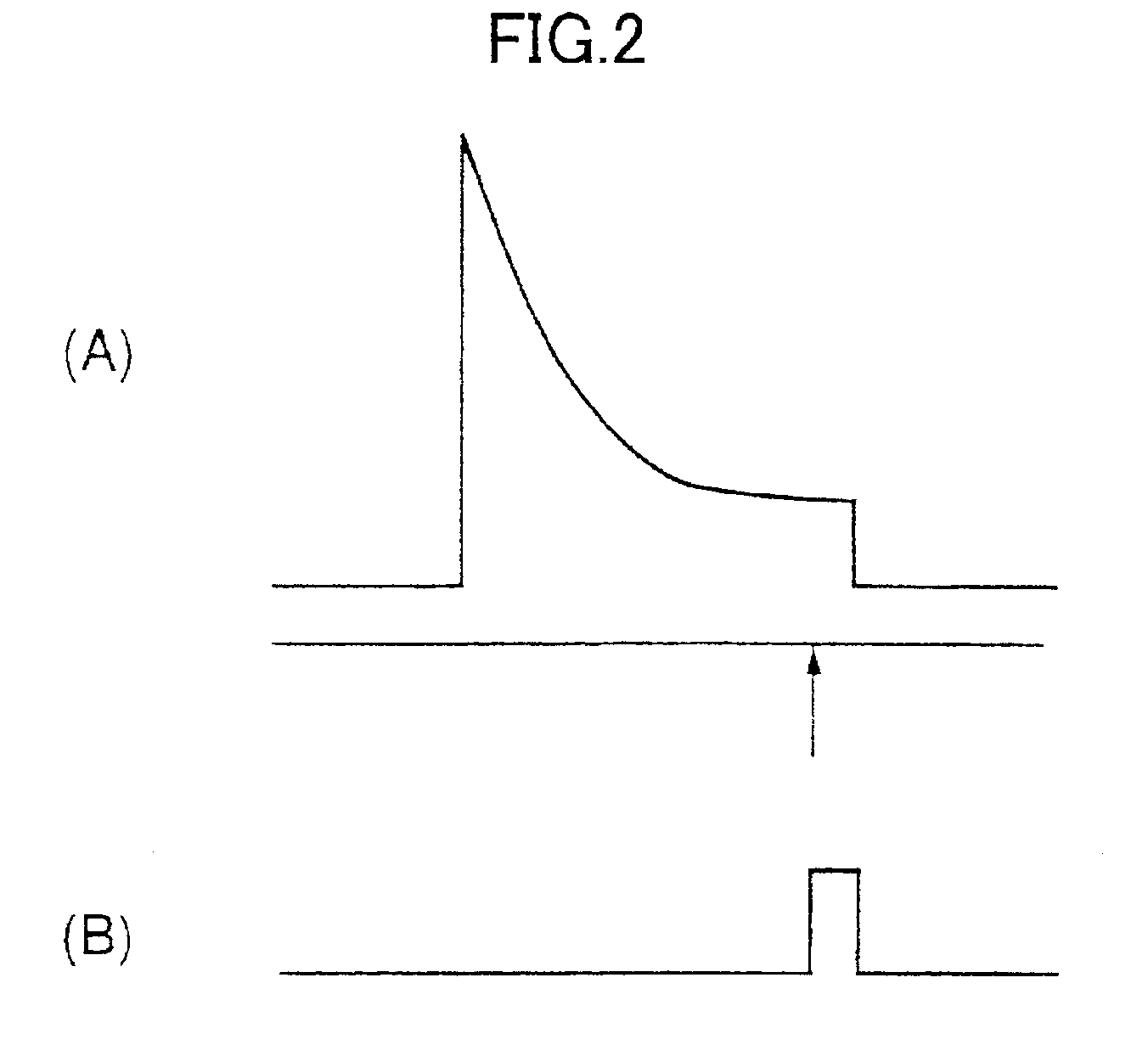

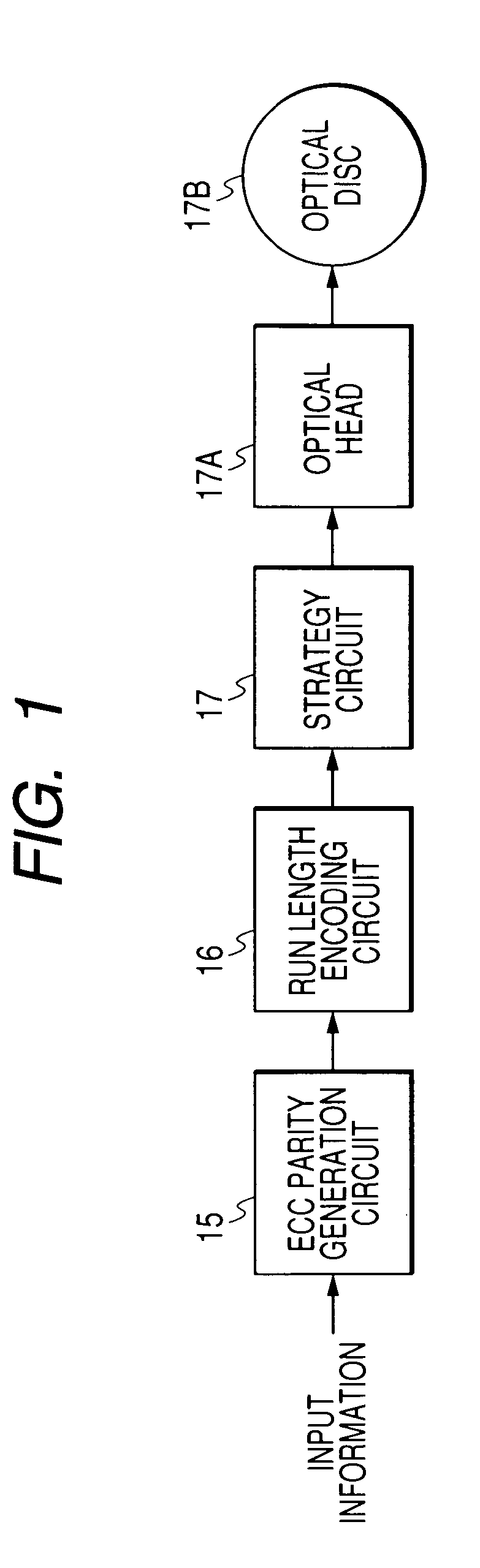

Optical disc drive having OPC control unit for controlling the level of power of the laser beam for recording and reading data from an optical disc

InactiveUS7085210B2Improve accuracyError rate of the reproduced signal are kept lowCombination recordingDisposition/mounting of recording headsPower overEngineering

An optical disc drive has an OPC control unit that records the signal to a plurality of frames in the predetermined test area on the optical disc using a plurality of recording power values and repeatedly records the signal to another plurality of frames in the predetermined test area on the optical disc using the plurality of recording power values, and calculates an average strength value of the reflected light of the plurality of strength values of the reflected lights from the plurality of frames in which frames the signal is recorded with the same recording power value, and the average strength value of the reflected light corresponding to the optimum recording power value is determined as an optimum strength value of the reflected light , during the OPC operation, and a recording power control unit that modifies the recording power value by a predetermined value in order to make the strength value of the reflected light from the pit portion during recording move toward the optimum strength value of the reflected light, during the running OPC operation. As a result, the present invention provides the optical disc drive, in which data can be recorded with an optimum recording power over the whole disc and both a jitter and an error rate of the reproduced signal are kept low.

Owner:TEAC CORP

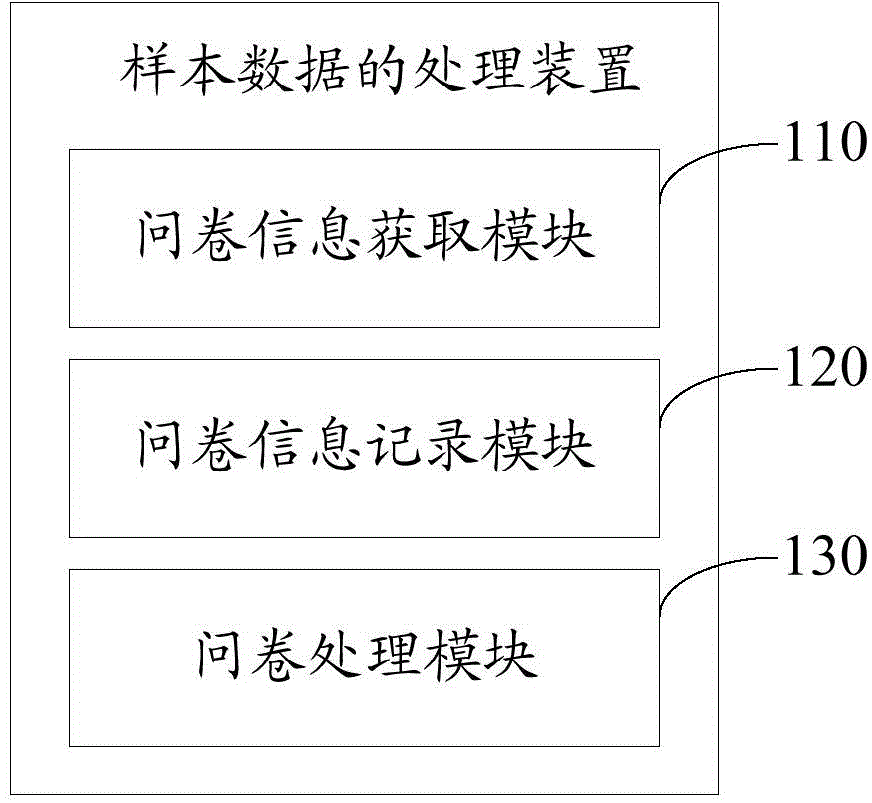

Sample data processing method and device

ActiveCN104699798ARealize automatic judgmentAvoid error rateOther databases retrievalSpecial data processing applicationsSimulationData processing

The invention discloses a sample data processing method and device. The sample data processing method includes that when an electronic questionnaire request is detected, acquiring the requested questionnaire information, and displaying the questionnaire information; gathering the finished situation of a user for the electronic questionnaire; judging whether the finished situation of the user for the displayed electronic questionnaire satisfies a preset valid judgment rule, and processing the electronic questionnaire according to the judgment result. The sample data processing method and device realize the automatic electronic questionnaire judgment, the error rate of the manual judgment is avoided, and the manpower cost is saved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

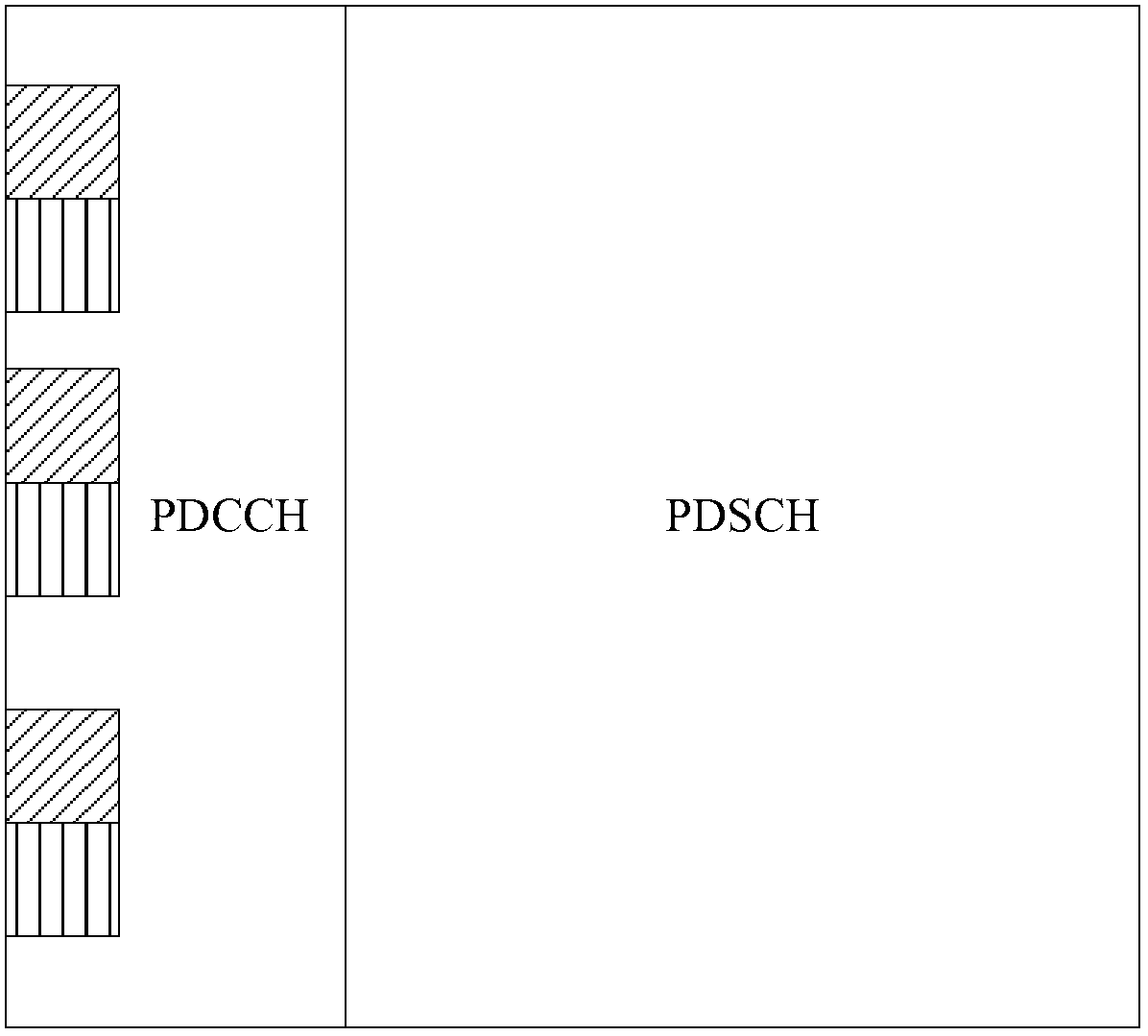

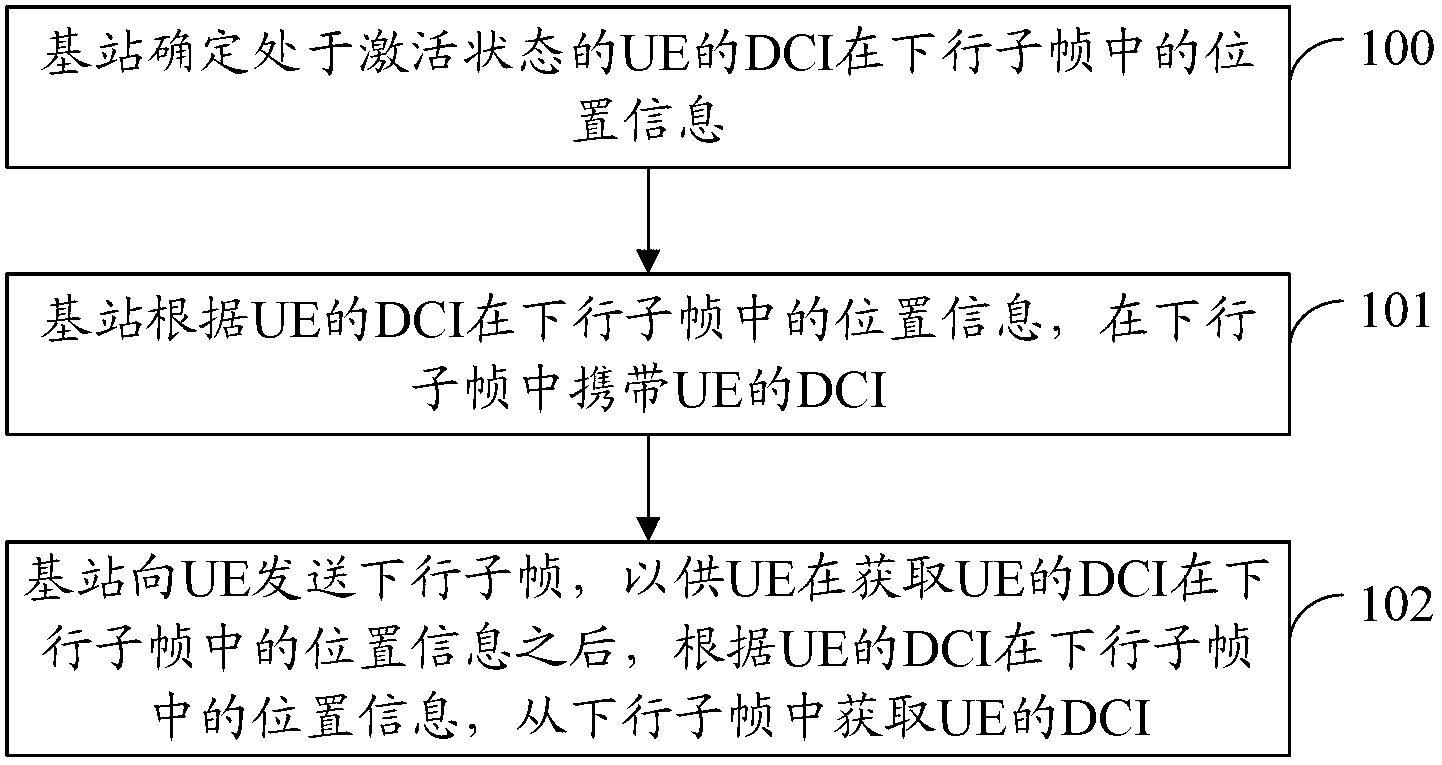

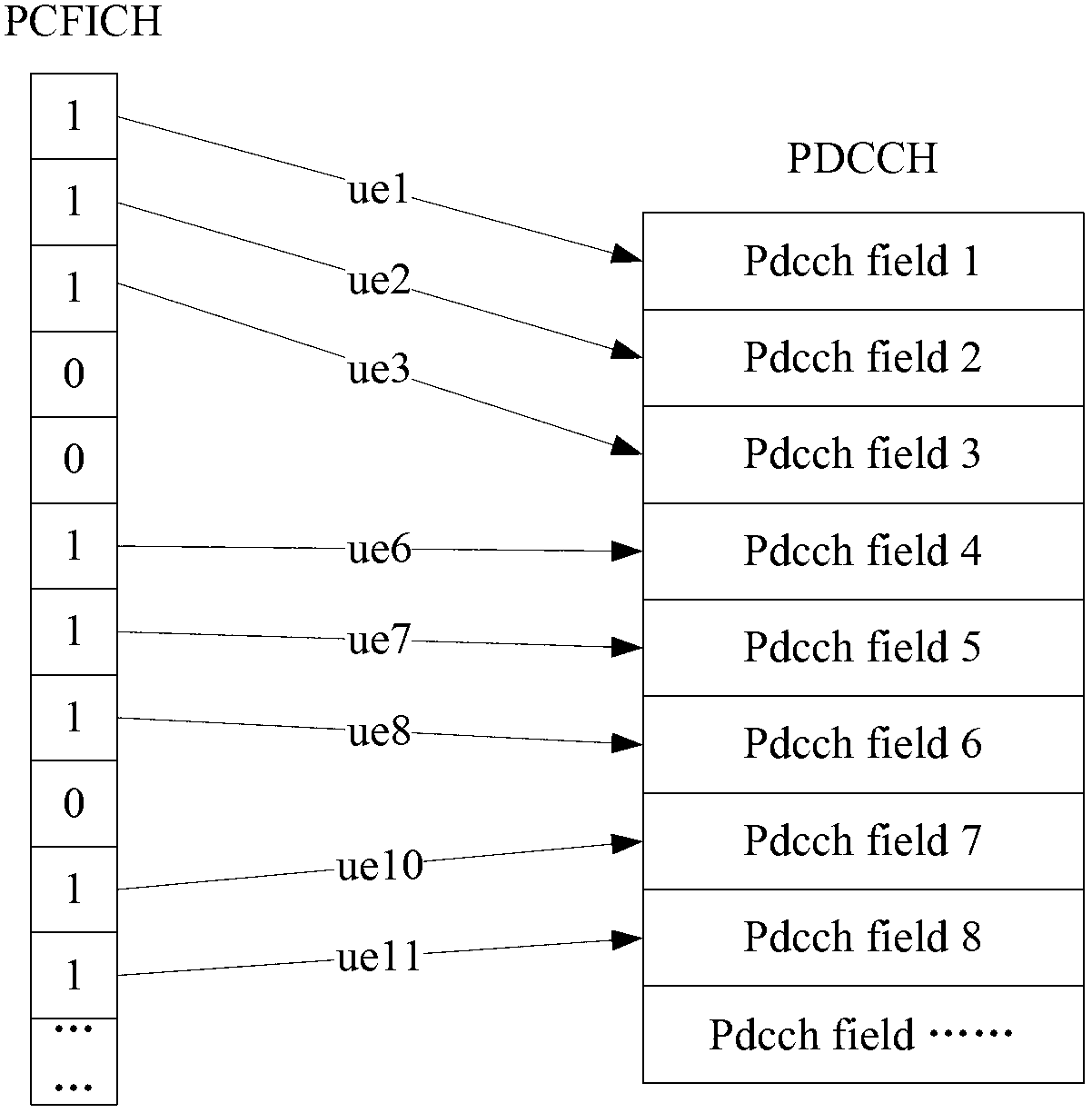

Processing method and system for downlink control information, base station and user equipment

InactiveCN102710405AImprove acquisition efficiencyReduce operational complexitySignal channelsUser equipmentFalse detection

The invention provides a processing method and a system for downlink control information (DCI), a base station and user equipment, wherein the method comprises the following steps: the base station confirms the position information of the downlink control information of the active user equipment in a downlink subframe; the base station takes along the downlink control information of the user equipment in the downlink subframe according to the position information of the downlink control information of the user equipment in the downlink subframe; the base station sends the downlink subframe to the user equipment so as to enable the user equipment to acquire the position information of the downlink control information of the user equipment in the downlink subframe, and the user equipment acquires the downlink control information of the user equipment from the downlink subframe according to the position information of the downlink control information of the user equipment in the downlink subframe. With the adoption of the technical proposal provided by the invention, probability of false detection does not exist, the implement is easy, and the DCI acquiring efficiency is improved.

Owner:이노피데이인코포레이티드 +1

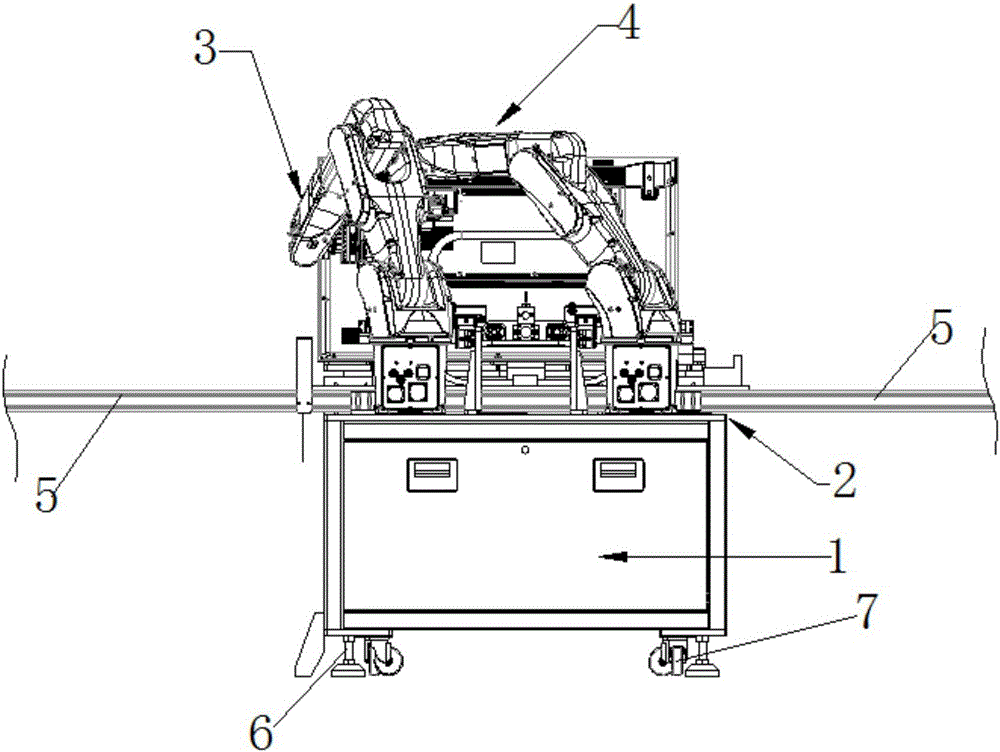

Chip issuing equipment and chip issuing system

ActiveCN102486835ARealize the whole process of automatic feedingFast releaseDigitally marking record carriersConveying record carriersComputer softwareEmbedded system

The invention discloses chip issuing equipment and a chip issuing system, wherein the chip issuing equipment comprises a chip loading device, a chip transmission passage, a chip writing device and a chip sorting device, wherein the chip loading device is used for loading chips to be issued into the chip transmission passage, the chip transmission passage is used for transmitting the chips to be issued to the chip writing device through the self weight of the chips to be issued, the chip writing device is used for writing issuing data into the chips to be issued, detecting issued chips and outputting detection results, and the chip sorting device is used for sliding the issued chips into successfully issued chip loading tubes or unsuccessfully issued chip loading tubes according to the detection results. The chip issuing equipment and the chip issuing system disclosed by the invention have the advantages that pneumatic transmission and infrared sensing detection modes are adopted, the computer software control is matched for completing the whole-process automatic feeding, the issuing, the detection and the loading of the chips, the issuing speed is high, and in addition, the issuing accuracy is high.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +2

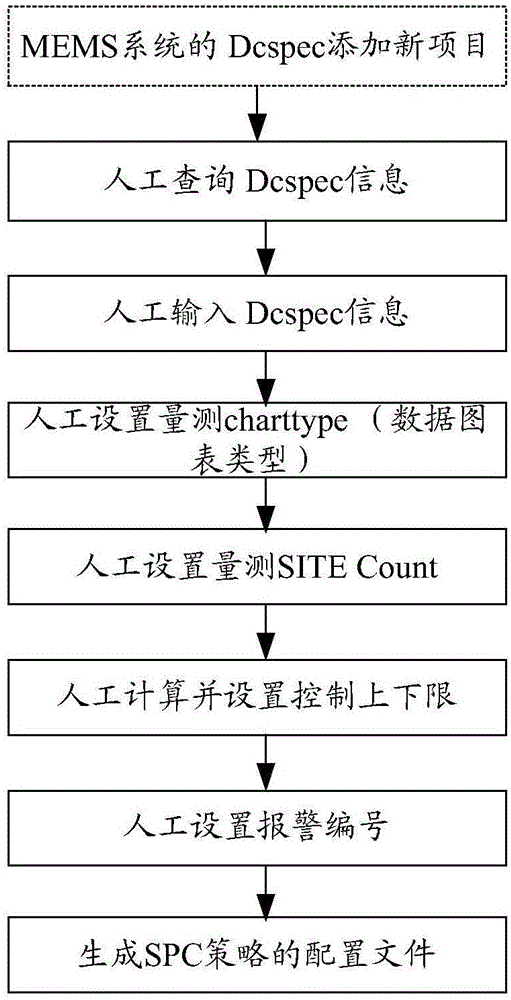

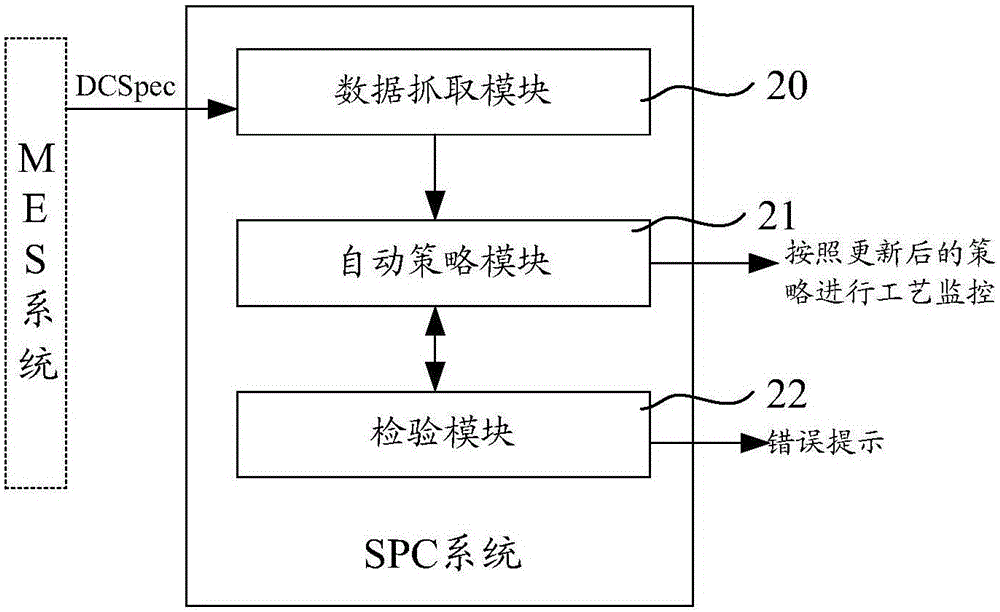

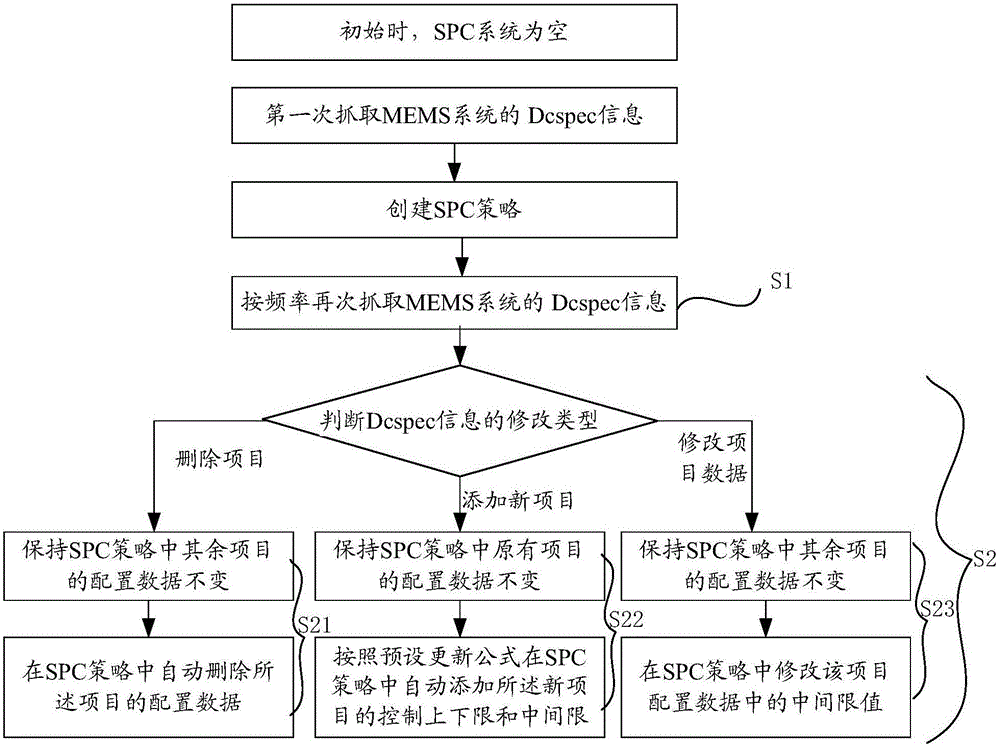

Method for automatically updating SPC strategy and SPC automatic strategy system

ActiveCN105159239AImprove reliabilityImprove stabilitySemiconductor/solid-state device manufacturingTotal factory controlData acquisitionDependability

The invention provides a method for automatically updating a SPC strategy and a SPC automatic strategy system. The method may directly acquire data acquisition specification information from a MES system, automatically adds, deletes, and modifies the SPC strategy on the basis of an original SPC strategy and according to the modification type of the data acquisition specification information so as to fast update the SPC strategy. The method greatly reduces computing, querying and inputting workload and time when an engineer manually updates the SPC strategy, decreases maloperation generated by manual updating, and prevents an error rate caused by manual updating. A subsequent process for detecting the correctness of the modification of the SPC strategy may further reduce the strategy updating error rate and improve strategy reliability and stability.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

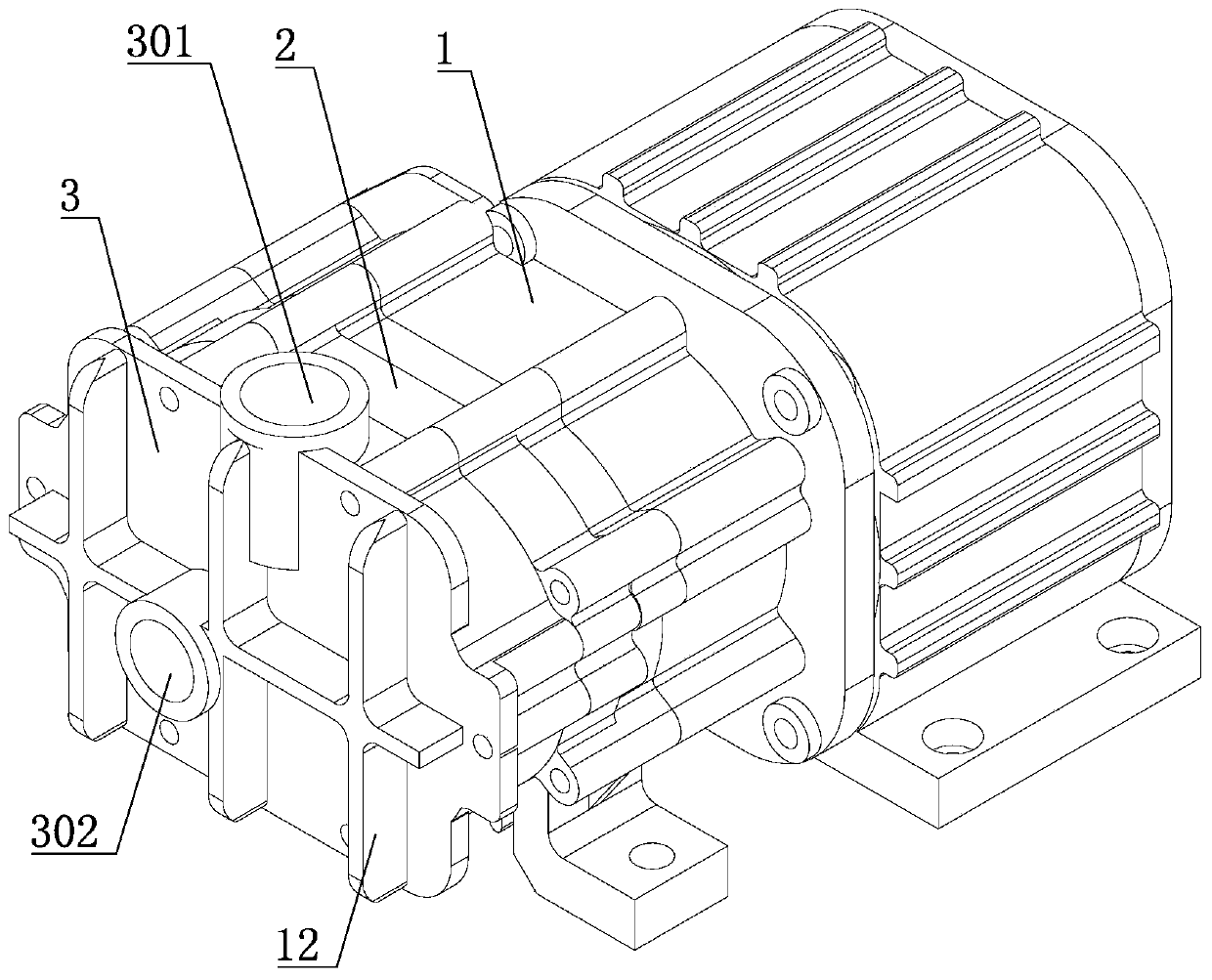

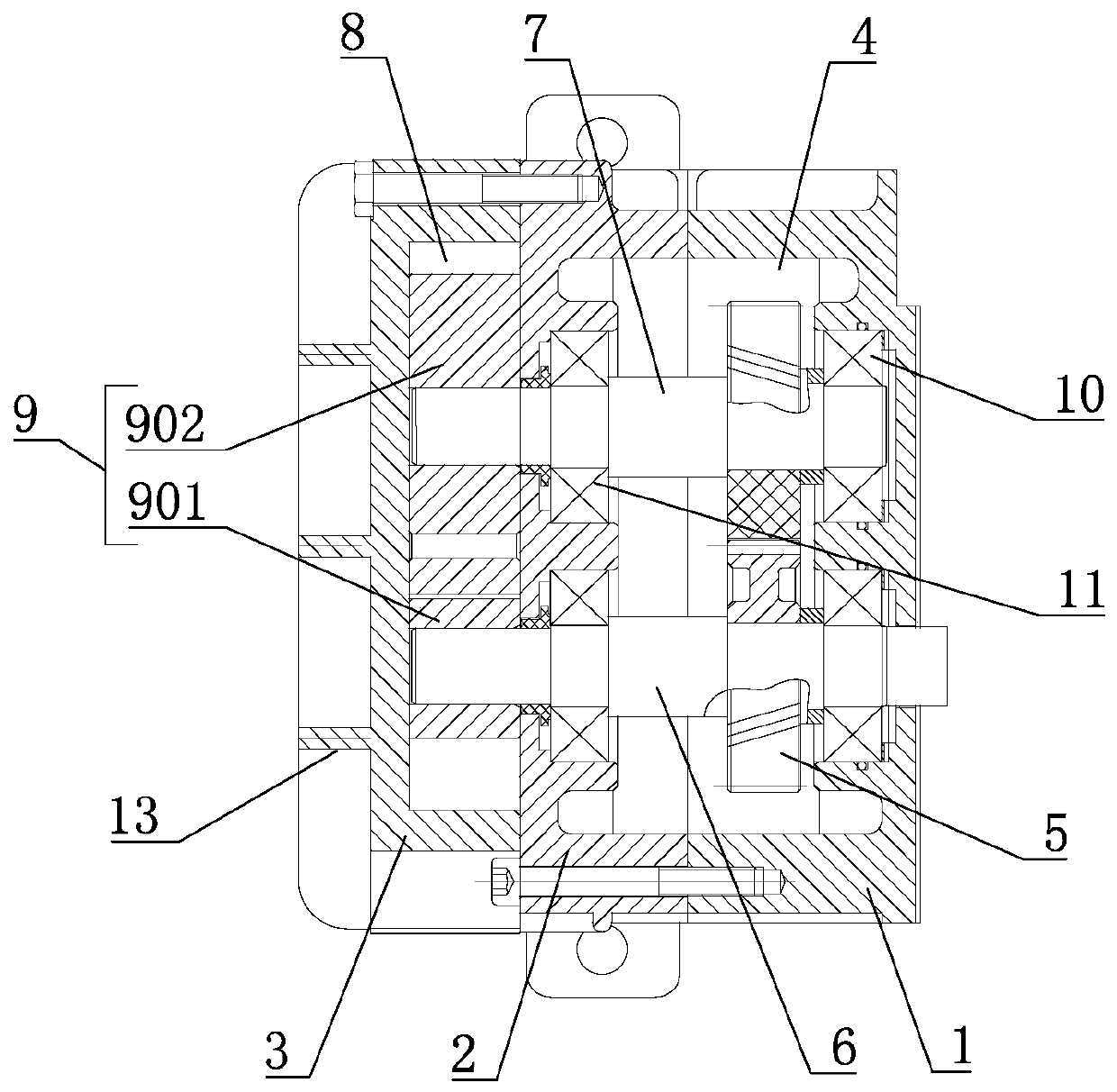

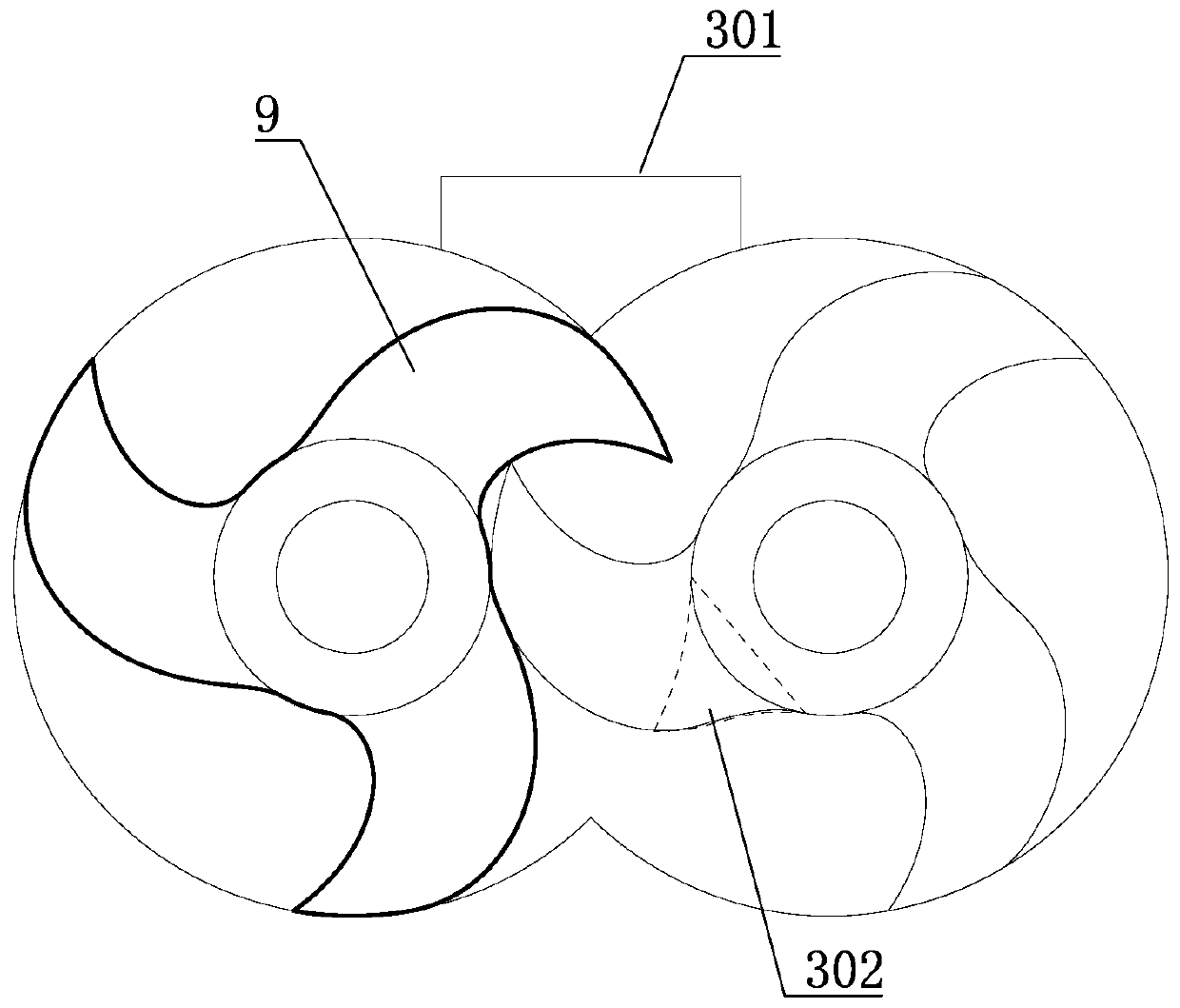

Claw type hydrogen circulating pump

PendingCN110319004AReasonable structural designReduce noiseRotary piston pumpsRotary piston liquid enginesLow noiseHydrogen

The invention relates to a claw type hydrogen circulating pump. The claw type hydrogen circulating pump comprises a first shell body, a bearing end cover connected with the first shell body, and a second shell body connected with the bearing end cover, wherein a gear chamber is formed between the first shell body and the bearing end cover, two self-lubricating gears which are meshed with each other are arranged in the gear chamber, and no lubricating oil exists in the gear chamber; the two self-lubricating gears are correspondingly connected with a driving shaft and the driven shaft; a rotor chamber is formed between the bearing end cover and the second shell body, and two mutually matched three-jaw rotors are arranged in the rotor chamber. According to the claw type hydrogen circulating pump, the synchronous gears of the rotors adopt a novel technology of non-metal self-lubricating, and has the characteristics of high temperature resistance and no need of lubrication, therefore, lubricating oil does not need to be added in the gear chamber, the oil-free operation of the hydrogen circulating pump is realized, and the problem of the lubricating oil leakage is fundamentally solved; and moreover, the self-lubricating gears of non-metal material further has the advantages of wear resistance and low noise, the replacement maintenance of the lubricating oil is not needed, and equivalently, the maintenance-free of the gears is realized.

Owner:烟台东德氢能技术有限公司

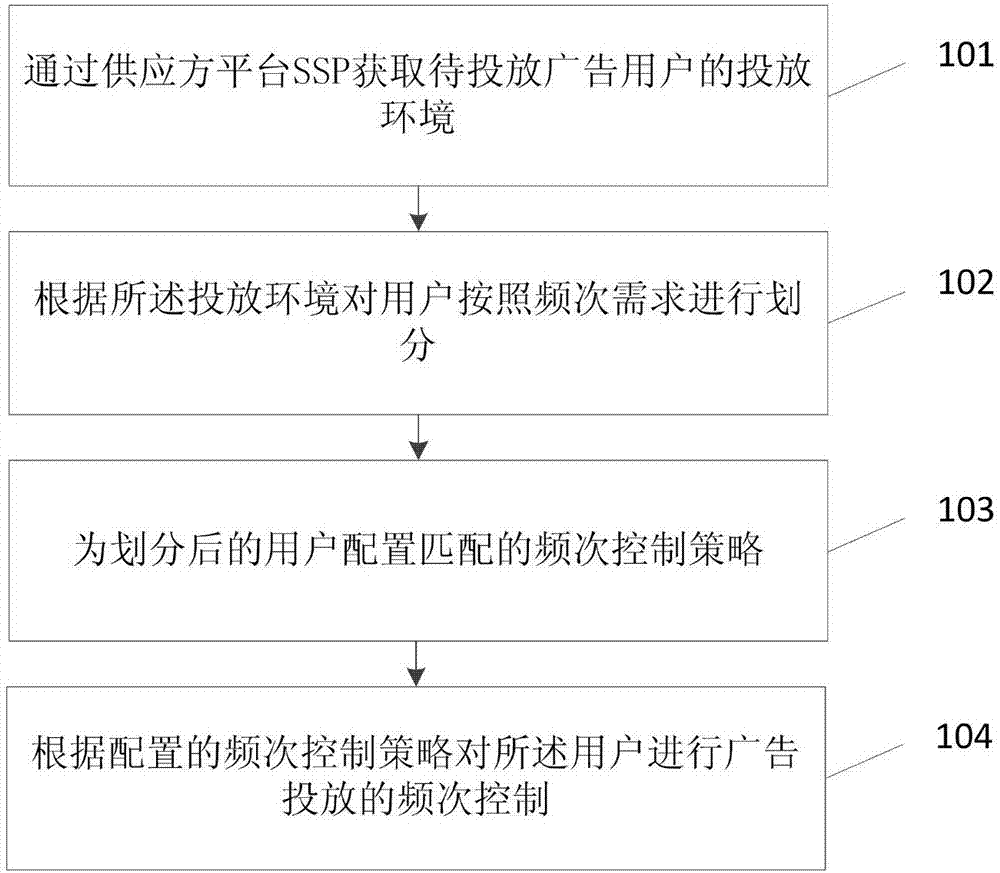

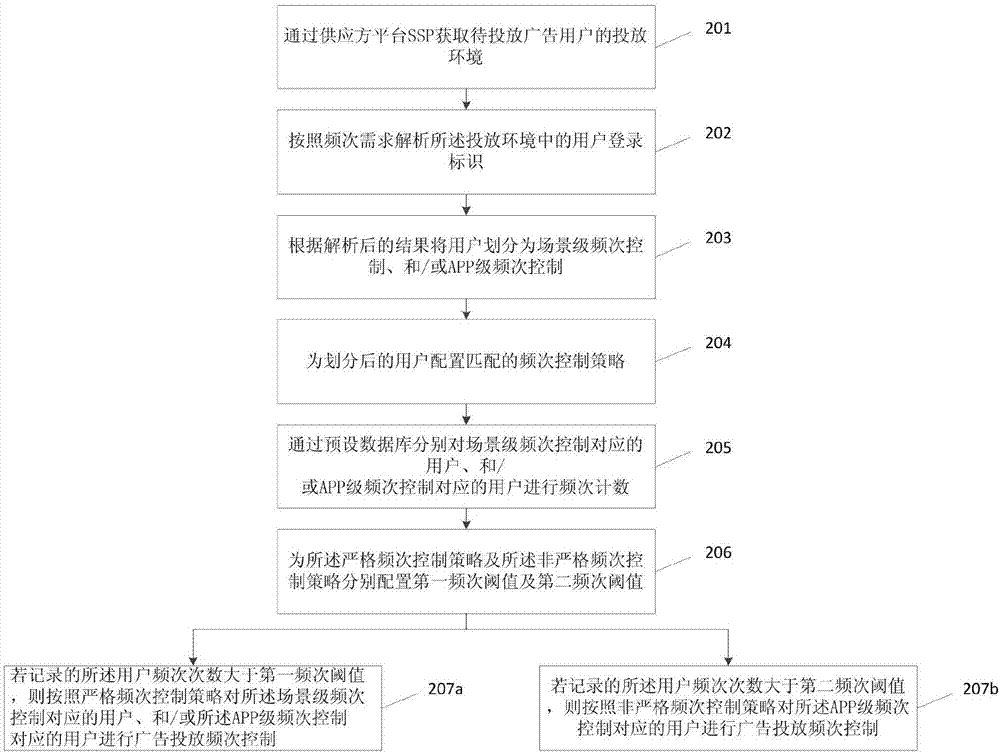

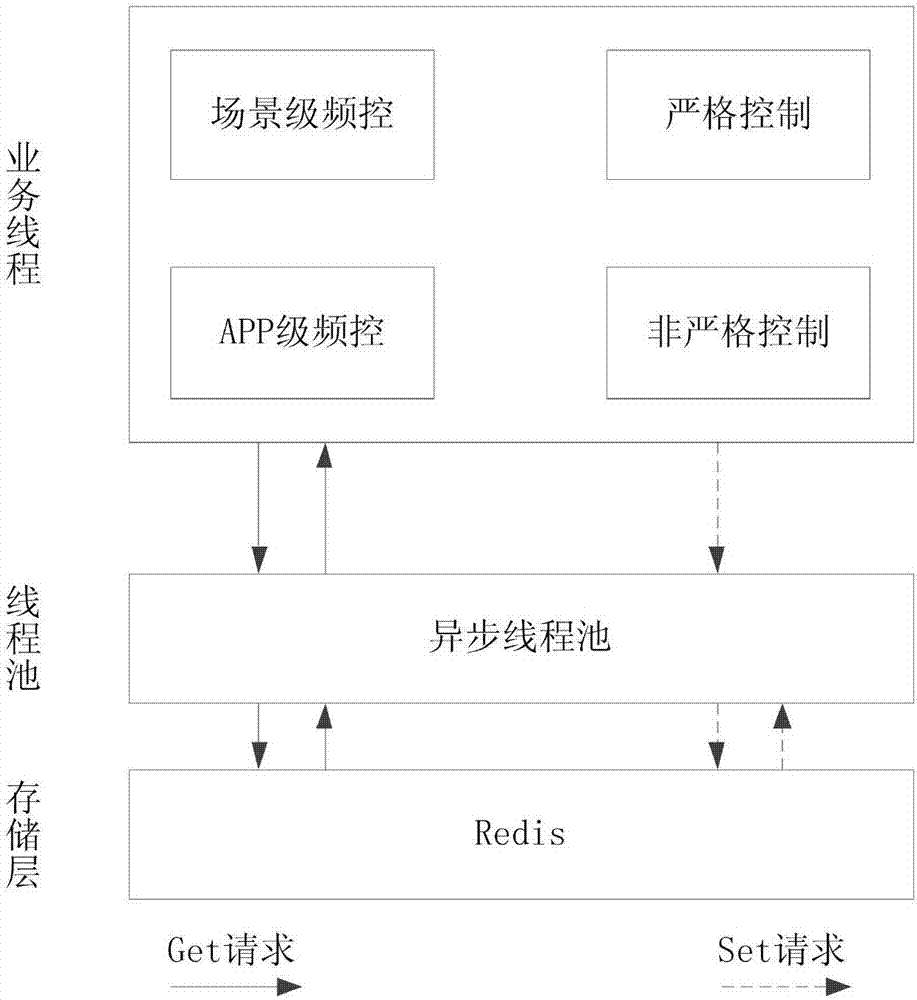

Method and device for controlling advertisement injecting frequency

ActiveCN107578287AImprove the efficiency of frequency controlAvoid error rateMarketingThe InternetComputer science

The invention discloses a method and a device for controlling advertisement injecting frequency, relates to the technical field of internets, and mainly aims to solve the problem that when the frequency of super-large-scale advertisement injecting is controlled, consumed time of manually set frequency control is long, mistakes of control strategies are easily caused, and advertisement injecting effects are affected. The technical scheme mainly includes that injecting environments of users with advertisements to be injected are acquired by the aid of an SSP (supply side platform), the users aredivided according to frequency requirements and the injecting environments, the frequency requirements are used for responding the requirements of the users for the advertisement injecting frequencyin different injecting environments, matched frequency control strategies are configured for divided users, the matched frequency control strategies are advertisement injecting frequency control methods applicable to the users with different frequency requirements, and the advertisement injecting frequency for the users is controlled according to the matched frequency control strategies. The method and the device are mainly used for controlling the advertisement injecting frequency.

Owner:BEIJING QIHOO TECH CO LTD

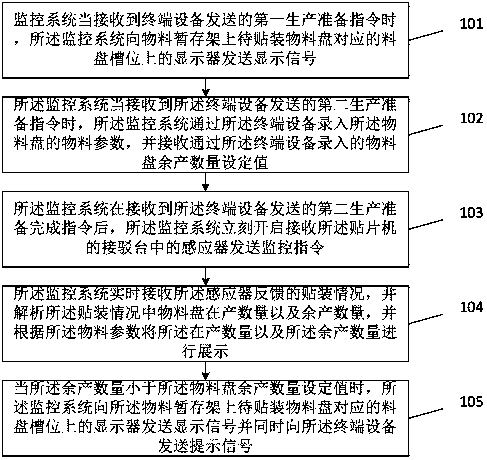

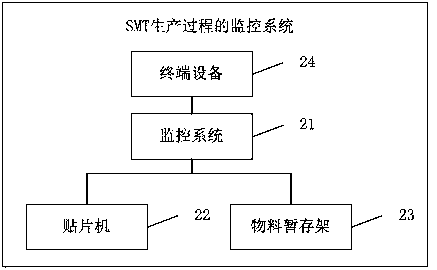

Monitoring method and system of SMT production process

ActiveCN108762175AImprove fully automated proceduresImprove monitoring efficiencyProgramme controlComputer controlSurface mountingTerminal equipment

The application discloses a monitoring method and system of an SMT production process, relates to the technical field of SMT production, and is capable of freely reading the process of surface mounting and realizing intelligence of surface-mounted production. The method includes steps: when a first production preparation instruction transmitted by a terminal device is received, a display signal istransmitted to a display on a material tray slot position corresponding to a to-be-mounted material tray on a material temporary storage rack; material parameters of the material tray are input through the terminal device, and a material tray residual production quantity set value input through the terminal device is received; the mounting condition fed back by an inductor is received in real time, the in-production quantity and the residual production quantity of the material trays in the mounting condition are analyzed, and the in-production quantity and the residual production quantity aredisplayed according to the material parameters; and when the residual production quantity is less than the material tray residual production quantity set value, the display signal is transmitted to the display on the material tray slot position corresponding to the to-be-mounted material tray and a prompt signal is transmitted to the terminal device.

Owner:浙江华企正邦自动化科技有限公司

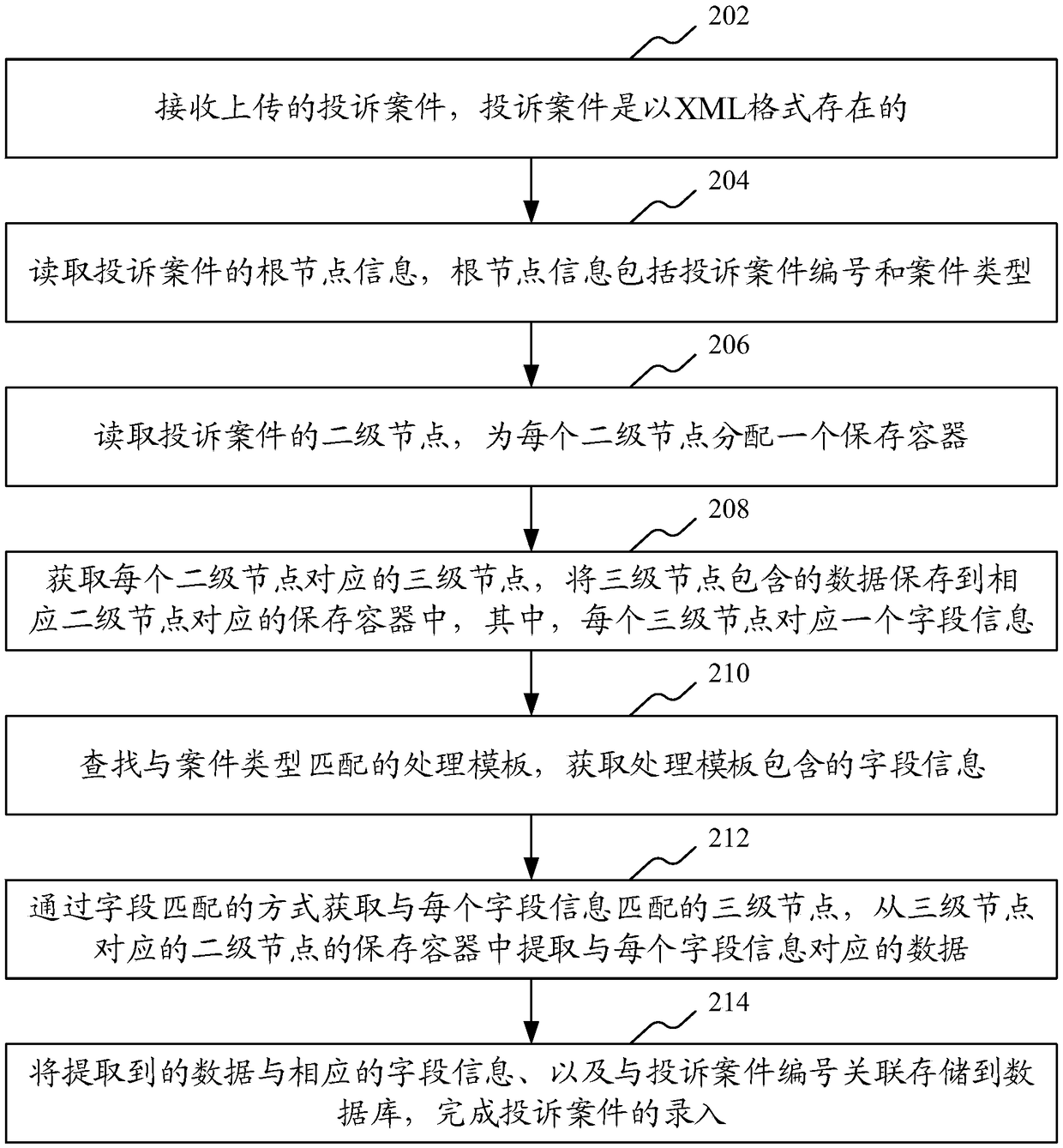

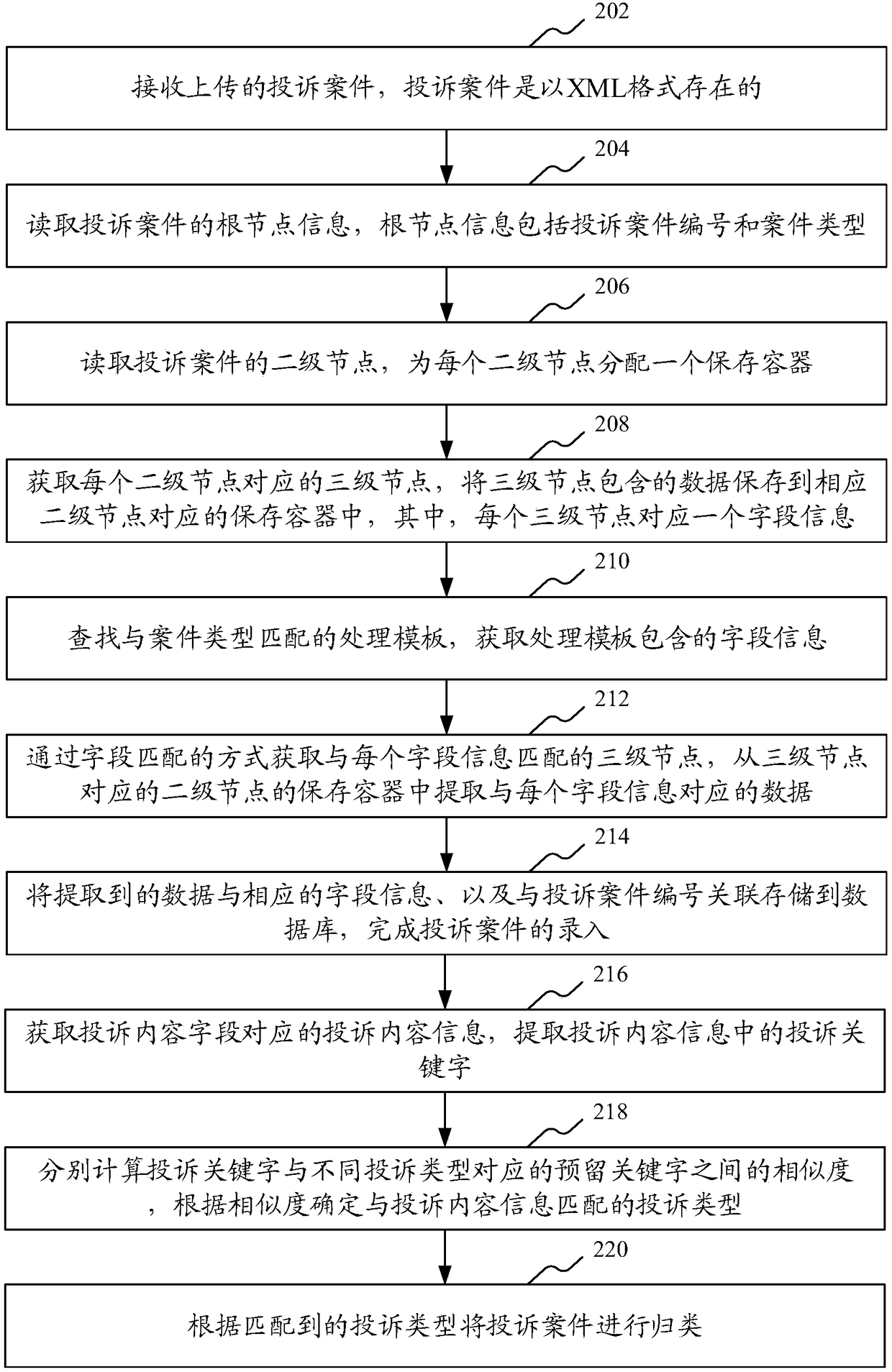

Complaint case processing method and device, computer equipment and storage medium

ActiveCN108170759AImprove entry efficiencyAvoid error rateFinanceSemi-structured data retrievalComputer equipmentData library

The invention provides a complaint case processing method. The method comprises the steps that an uploaded complaint case is received, and root node information of the complaint case is read, whereinthe root node information comprises a complaint case number and a case type; second-level nodes of the complaint case are read, and corresponding saving containers are allocated according to the number of the second-level nodes; data of third-level nodes are saved into the saving containers corresponding to the second-level nodes; a processing template matched with the case type is found, and field information contained in the processing template is acquired; the saving container matched with each piece of field information is acquired, and data corresponding to each piece of field informationis extracted from the corresponding saving container; and the extracted data, the corresponding field information and the complaint case number are stored into a database in an associated mode to complete input of the complaint case. Through the complaint case processing method, input efficiency is greatly improved. Besides, a complaint case processing device, computer equipment and a storage medium are furthermore provided.

Owner:PING AN PENSION INSURANCE

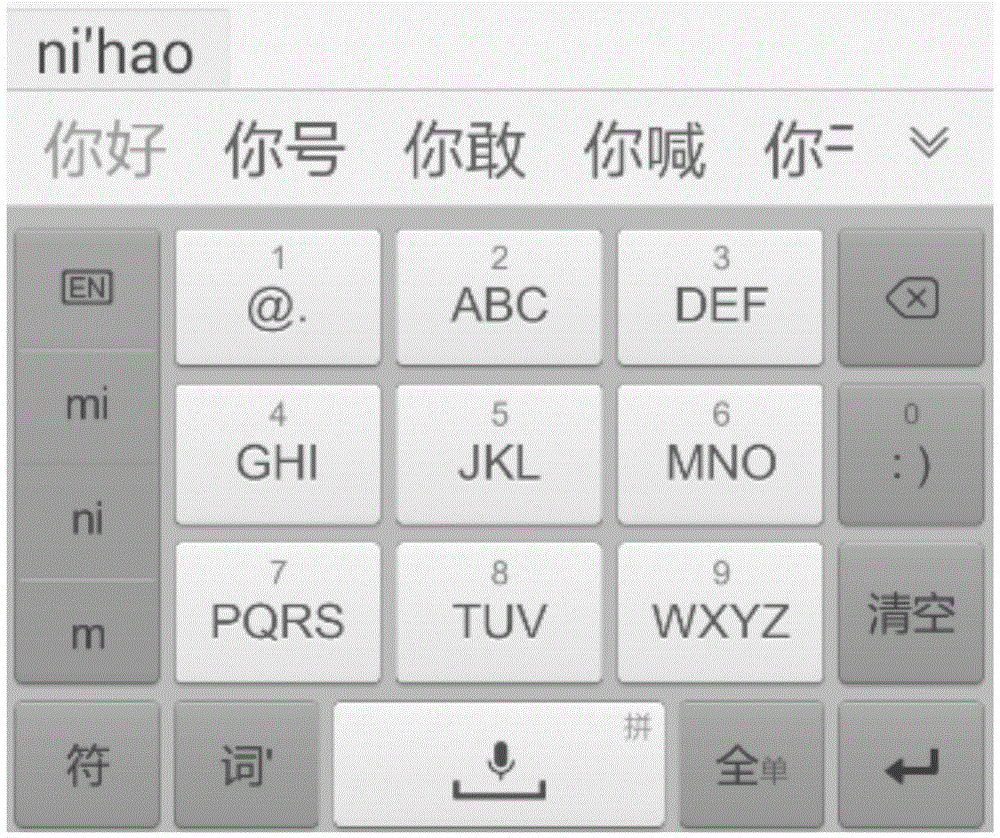

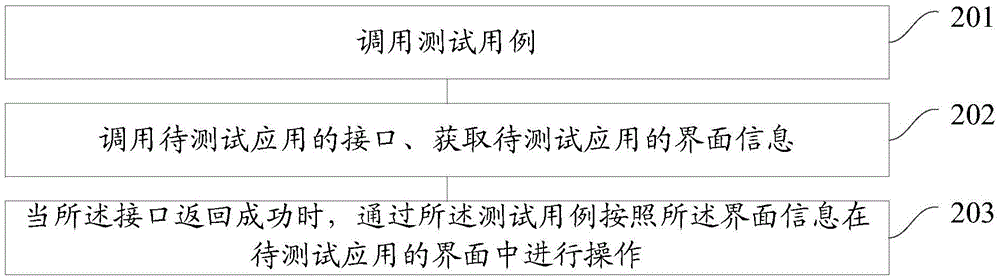

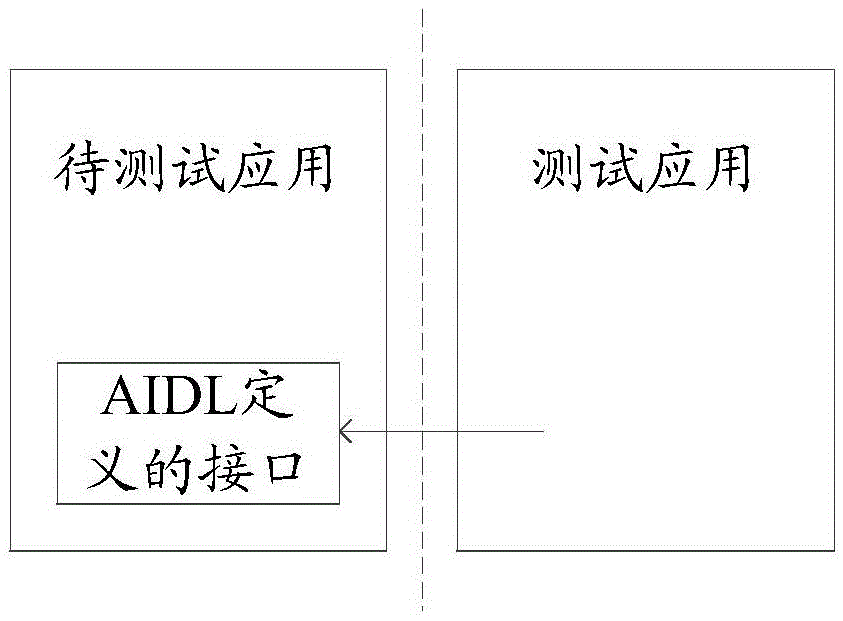

Test method and device capable of aiming at interface

InactiveCN105630674AGet value in real timeAvoid resolution issuesSoftware testing/debuggingTest efficiencyManual testing

The embodiment of the invention provides a test method and device capable of aiming at an interface. The method comprises the following steps: calling a test case; calling the interface of an application to be tested, and obtaining the interface information of the application to be tested; and when the interface succeeds in returning, operating through the test case in the interface of the application to be tested according to the interface information. The embodiment of the invention lowers test complexity, in addition, an automatic test is realized through the interface information fed back from the application to be tested, a manual test is avoided, an error probability is lowered, and test efficiency is improved.

Owner:BEIJING QIHOO TECH CO LTD +1

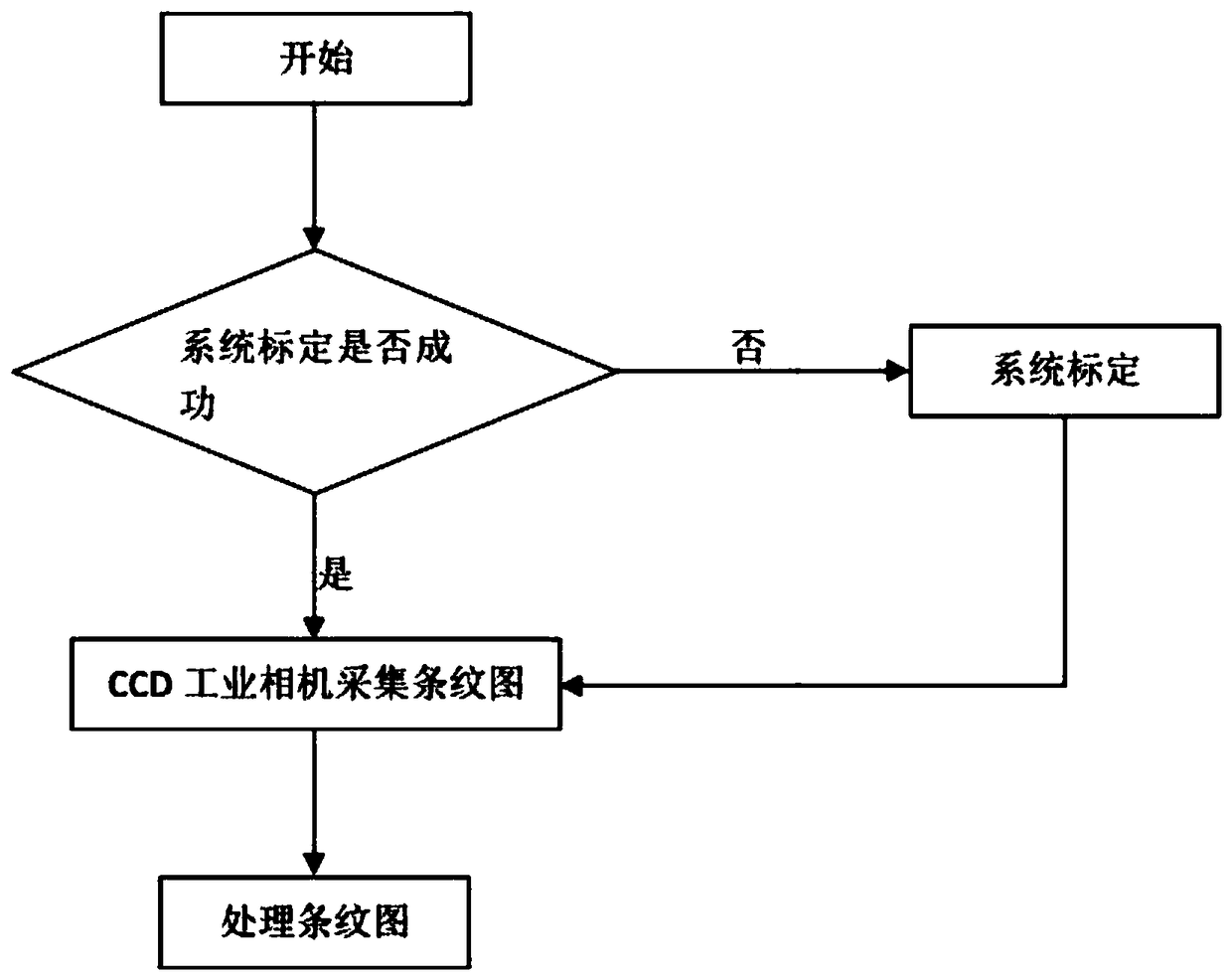

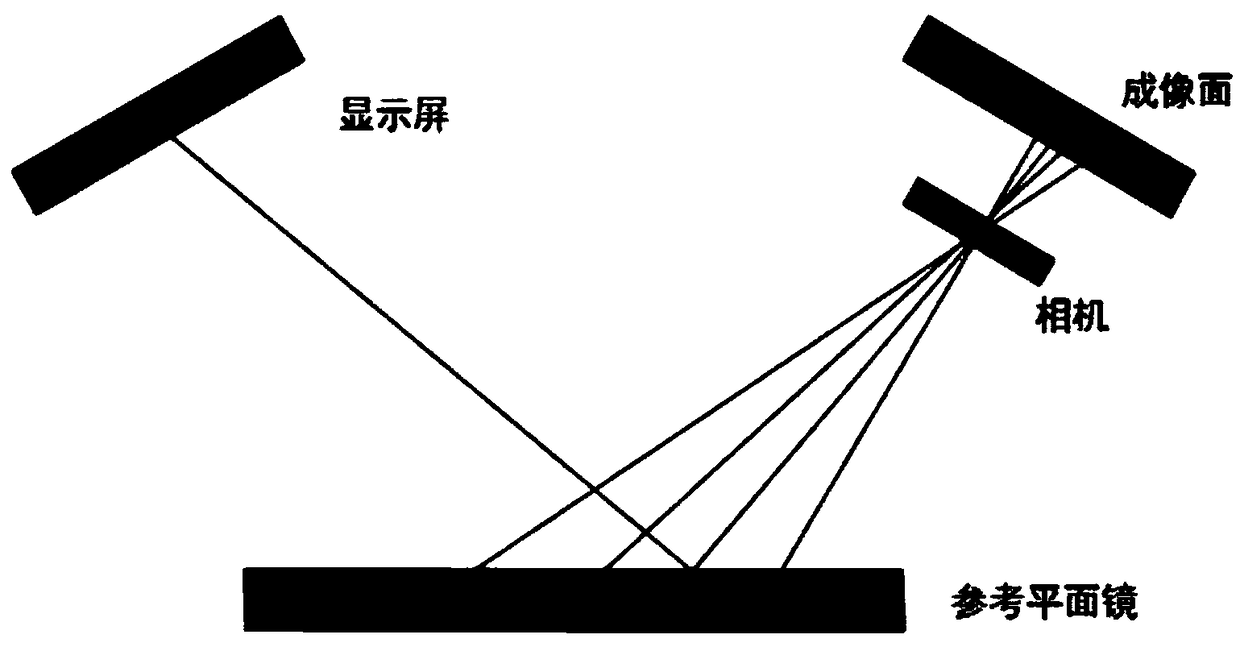

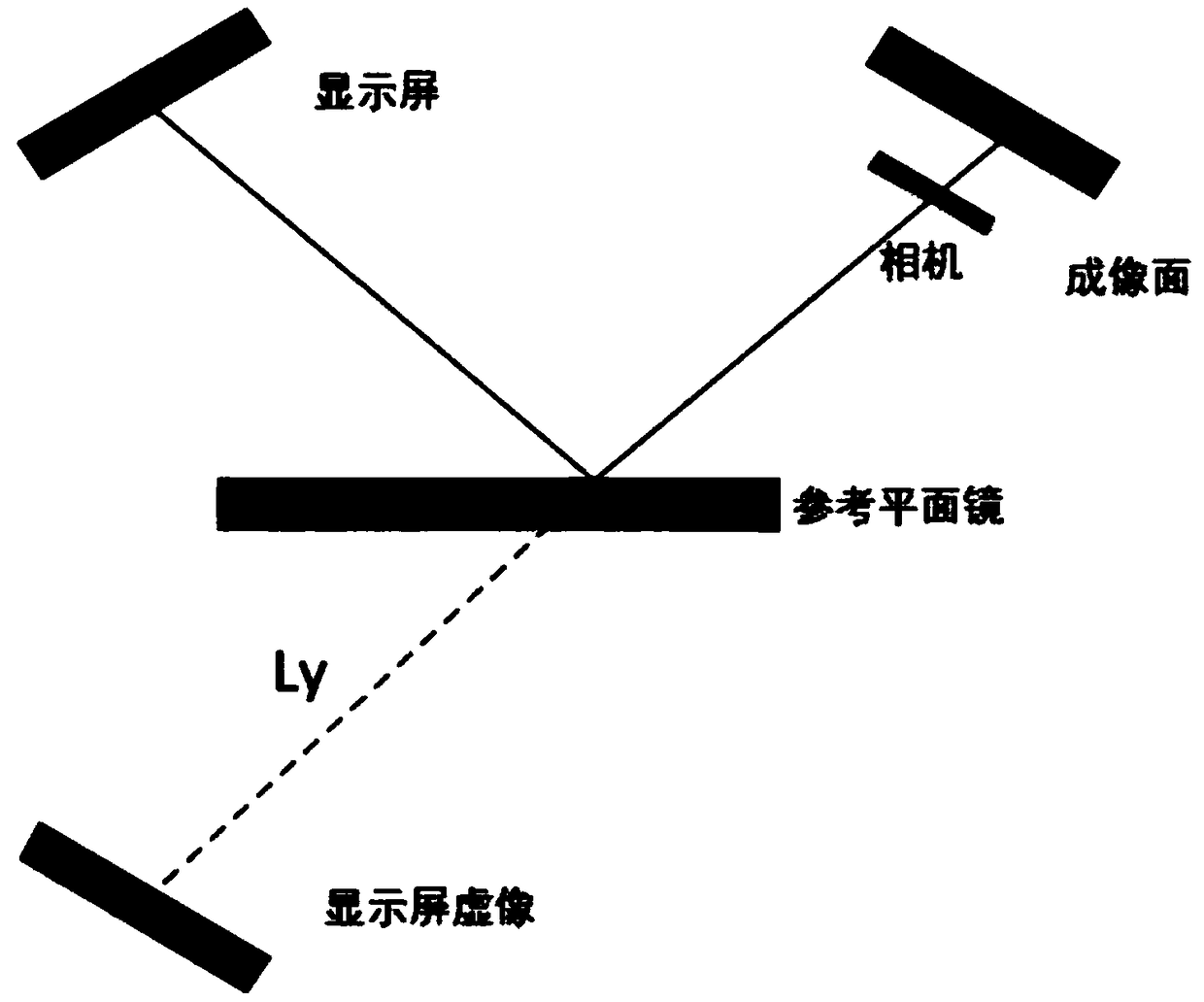

3D curved glass defect detection method based on stripe reflection

InactiveCN108645871AImproving the Efficiency of Detecting 3D Curved Glass DefectsAvoid error rateMaterial analysis by optical meansComputer sciencePattern processing

The invention discloses a 3D curved glass defect detection method based on stripe reflection. The 3D curved glass defect detection method comprises system calibration, stripe pattern acquisition basedon a CCD industrial camera, and stripe pattern processing. The method utilizes the non-contact, high-speed and high-efficiency characteristics of the reflection stripe, greatly improves the efficiency of detecting the 3D curved glass, and prevents the error rate of manual detection. The accuracy of the method can reach the sub-micron level, meet the production testing requirements and help to improve the automation degree of the factory.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

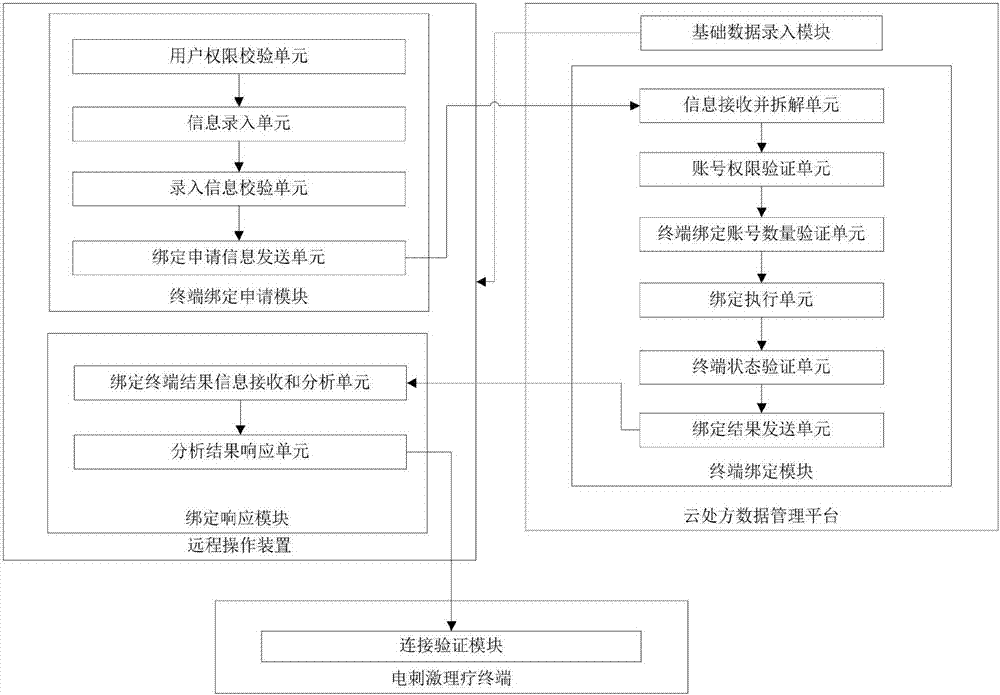

User and terminal binding system and method applied to electrical stimulation physiotherapy system

PendingCN106934227AEasy retrievalClear processElectrotherapyData processing applicationsPhysical medicine and rehabilitationPhysical therapy

The invention relates to a user and terminal binding system and method applied to an electrical stimulation physiotherapy system. The system comprises an electrical stimulation physiotherapy terminal, a remote operation apparatus and a cloud prescription data management platform which are connected mutually, wherein the electrical stimulation physiotherapy terminal comprises a connection verification module; the remote operation apparatus comprises a terminal binding application module and a binding response module; and the cloud prescription data management platform comprises a terminal binding module and a basic data input module used for inputting basic information of the electrical stimulation physiotherapy terminal. According to the system and the method, user information is bound with the electrical stimulation physiotherapy terminal; prescription data is easier to manage; the security of the electrical stimulation physiotherapy terminal is guaranteed; the permission of a remote operation terminal is higher; and the operation error rate is better prevented.

Owner:成都华信高科医疗器械有限责任公司

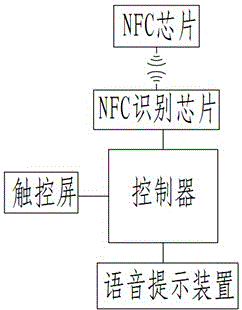

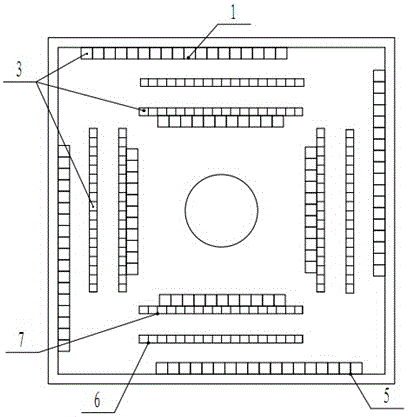

Mahjong table capable of calculating Guiyang mahjong tiles and use method thereof

PendingCN105709414AQuick calculationImprove computing efficiencyIndoor gamesAlgorithmComputer science

The invention discloses a mahjong table capable of calculating Guiyang mahjong tiles and a use method thereof. The mahjong table comprises a tabletop and multiple mahjong blocks, wherein each side of the mahjong table is respectively provided with an operation region, a mahjong tile selection region and a mahjong tile showing region which are provided with multiple NFC recognition chips; the operation region is used for placing pung, kong, first one dick tile and turned dick tiles; the NFC recognition chips are connected with a controller; the controller is connected with a touch screen; and one NFC chip is embedded in each mahjong block. After each round of mahjong game is over, mahjong tiles are set and intelligently recognized by virtue of the NFC chips and the NFC recognition chips, the recognized mahjong tiles are sent to the controller for calculation, and meanwhile, points and kong numbers of Hu cards are calculated, so that the calculation efficiency can be greatly improved, the calculation error rate is avoided, new learners can conveniently and rapidly learn the use of the mahjong table, and the learning efficiency is greatly improved. The mahjong table also has the characteristics of simple structure, convenience and quickness in control and low price.

Owner:GUIZHOU UNIV

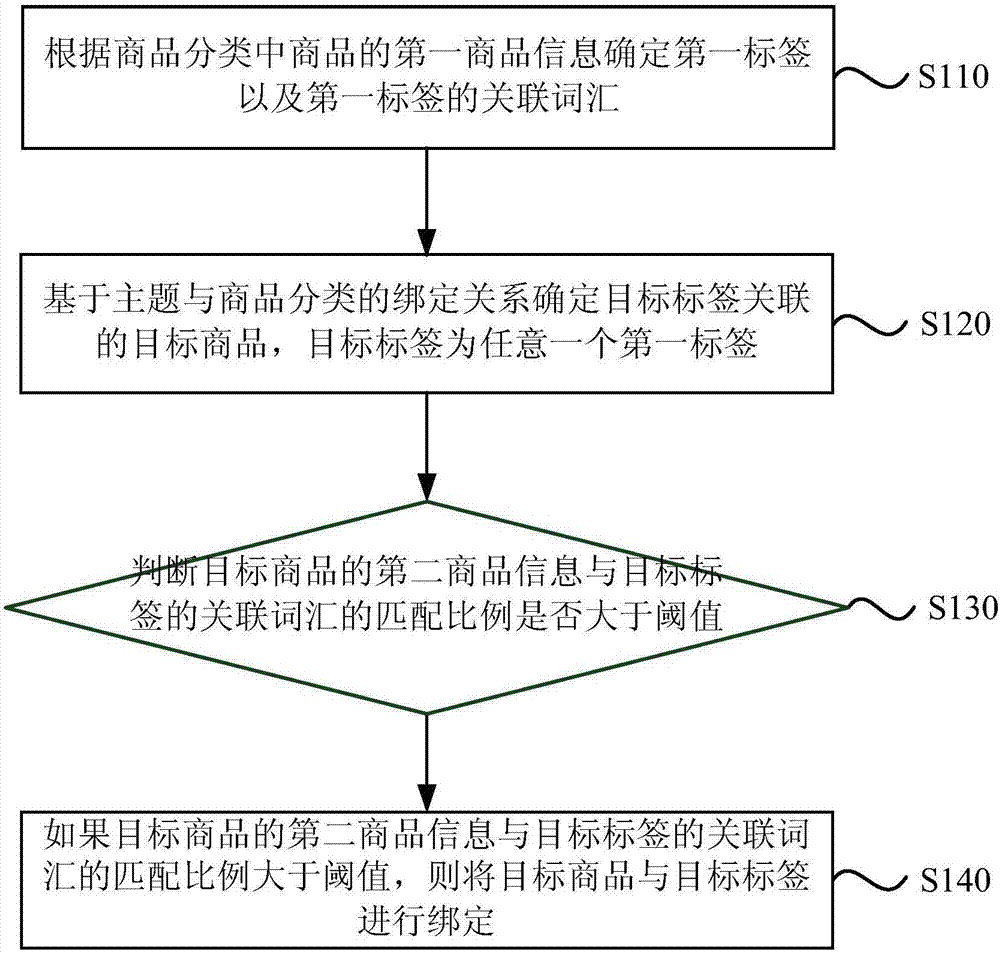

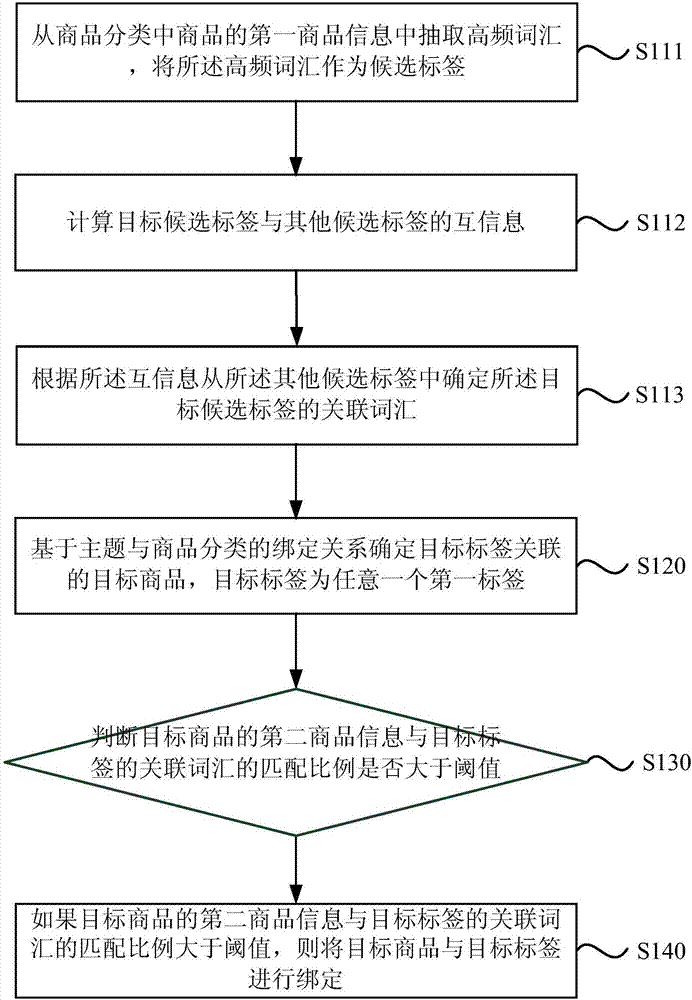

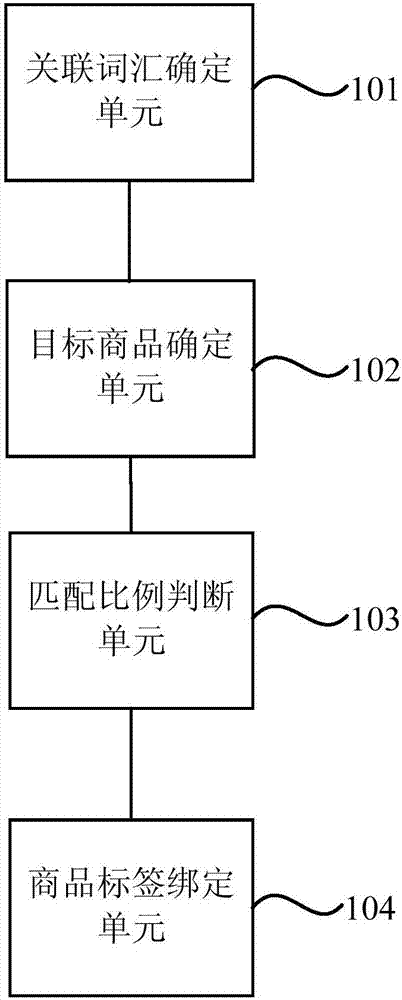

Product tag binding method, apparatus and equipment, and computer readable storage medium

ActiveCN107292365ALow operating efficiencyImprove binding efficiencyImage selection/retrieval using associated code-marksComputer science

The invention discloses a product tag binding method, apparatus and equipment, and a computer readable storage medium. The product tag binding method includes the steps: according to the first product information of a product in classification of products, determining the first tag and the related vocabulary of the first tag; based on the binding relationship of the theme and classification of products, determining the target product associated with the target tag which is any one first tag; determining whether the matching proportion between the second product information of the target product and the related vocabulary of the target tag is greater than the threshold; and if the matching proportion between the second product information of the target product and the related vocabulary of the target tag is greater than the threshold, and binding the target product with the target tag. The product tag binding method can accurately add a tag for the target product, can save the manual operation cost of an operator and also avoid the error rate caused manual work at the same time, and can improve the binding efficiency of the product tag.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

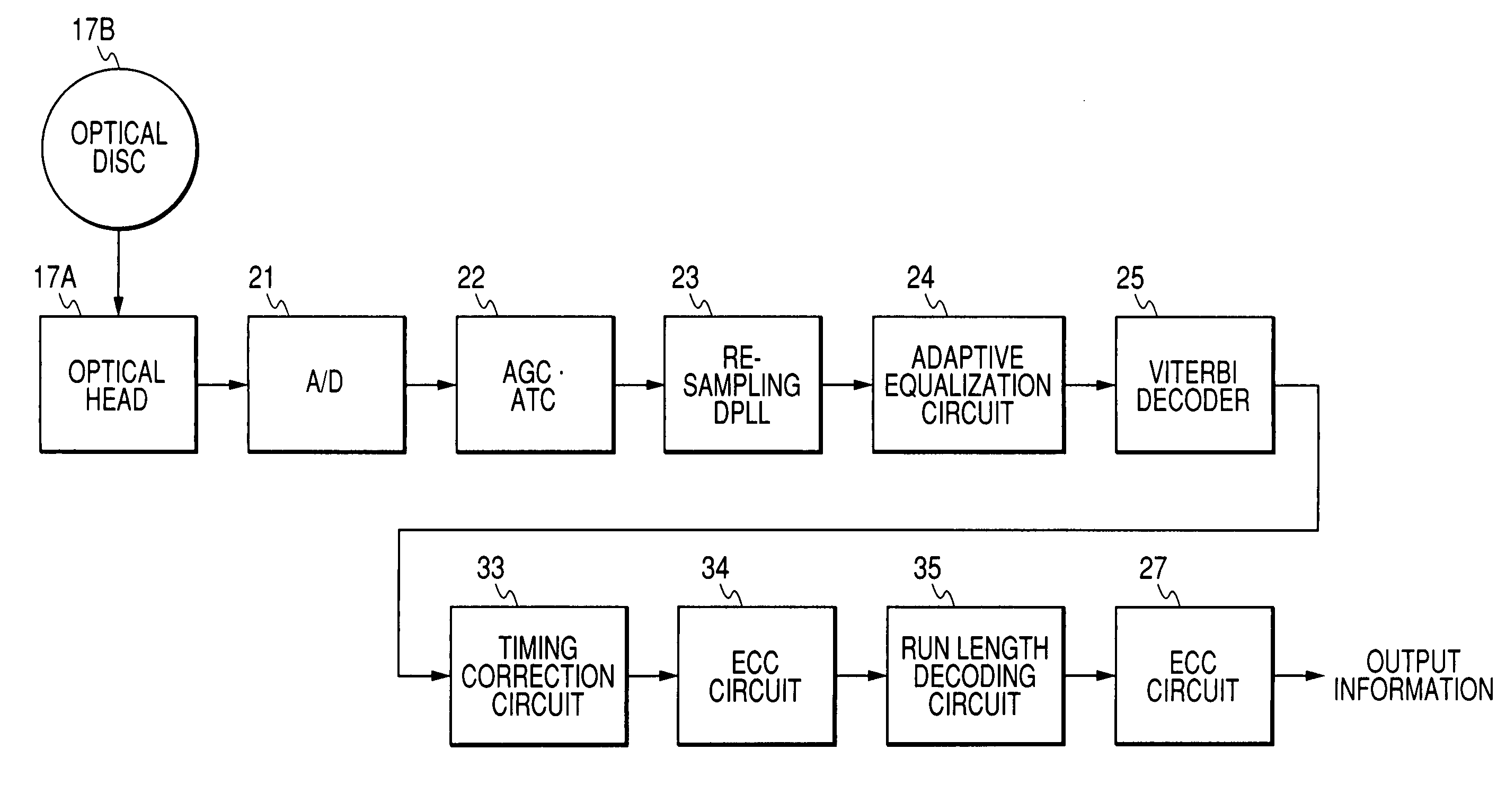

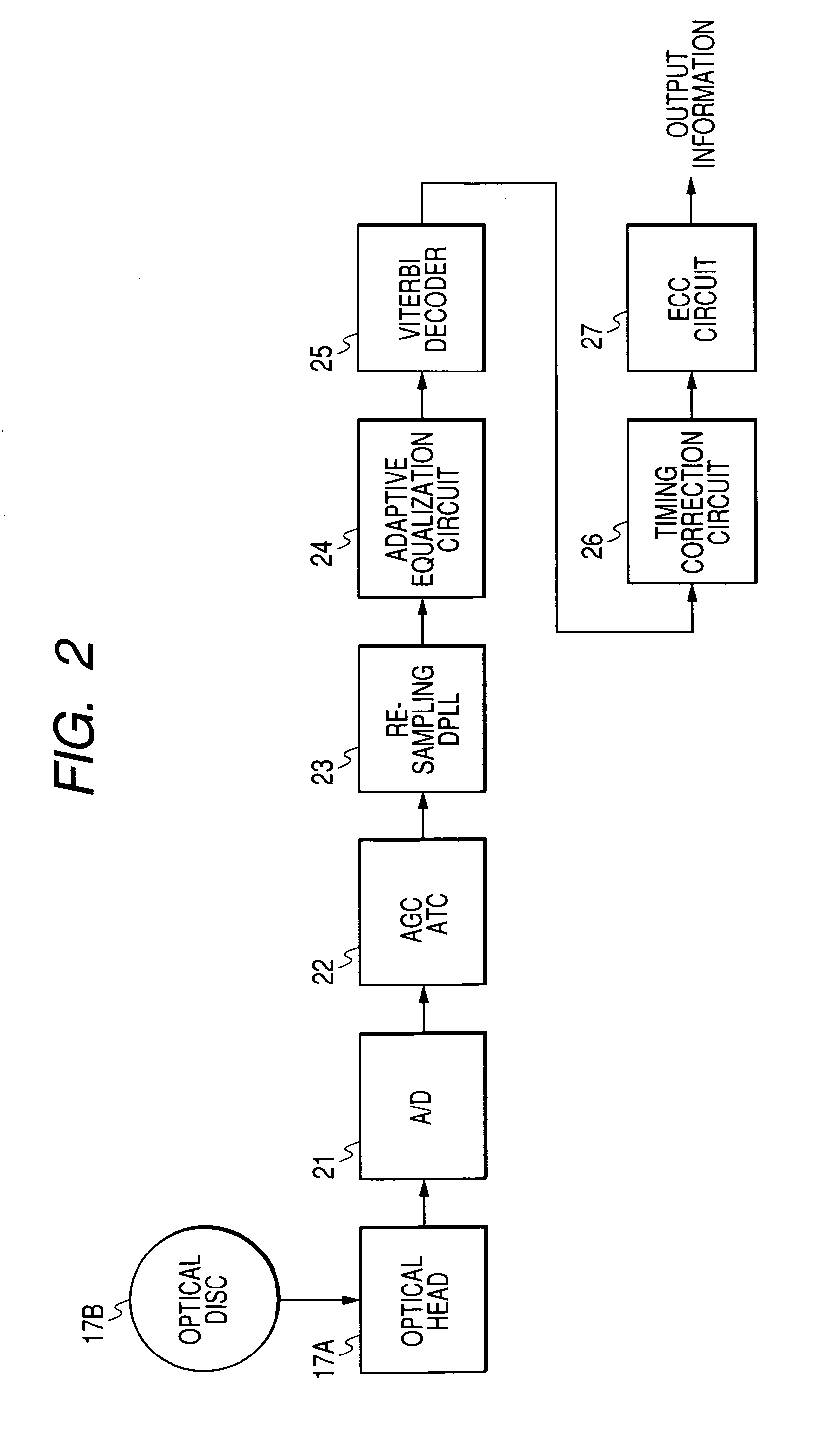

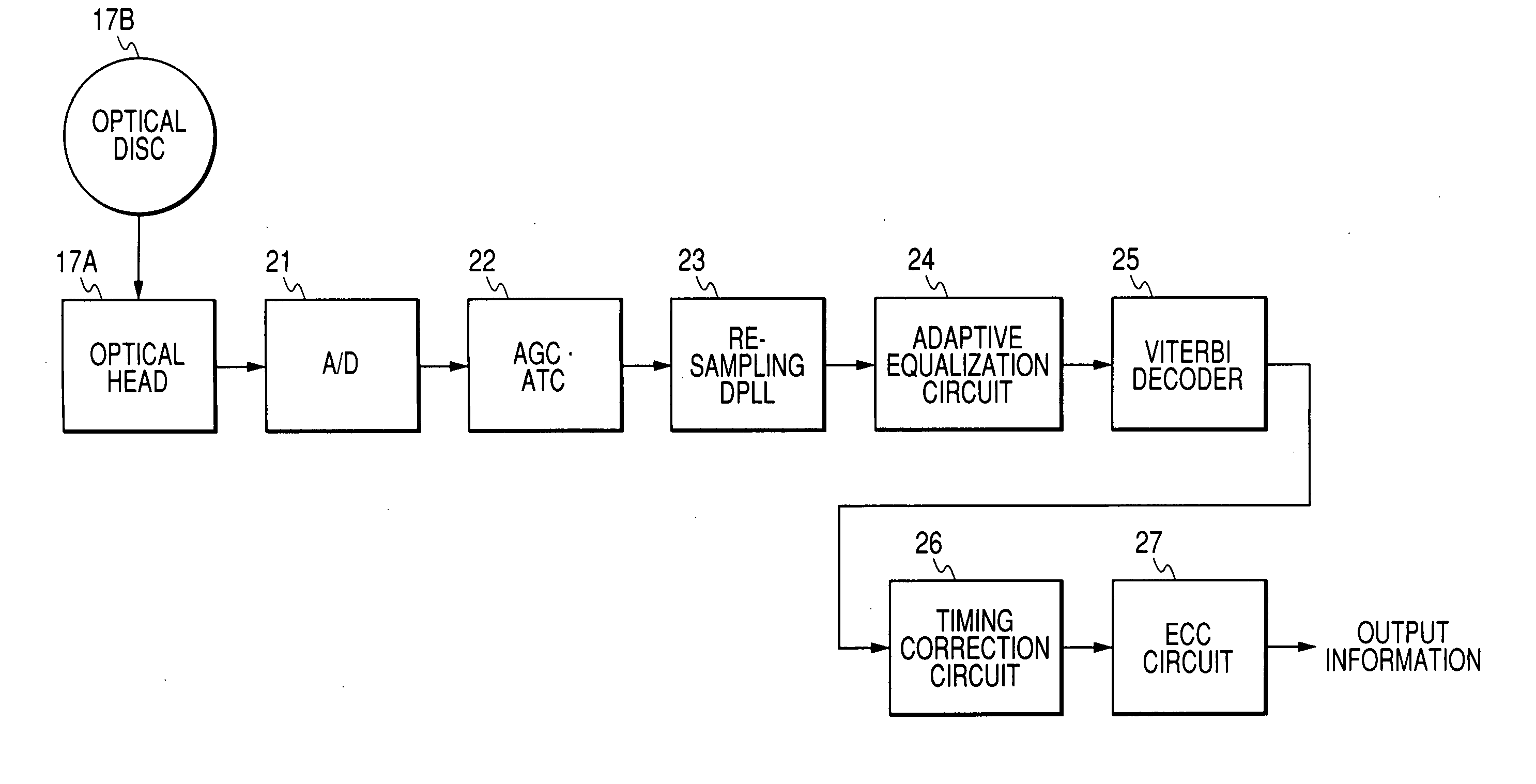

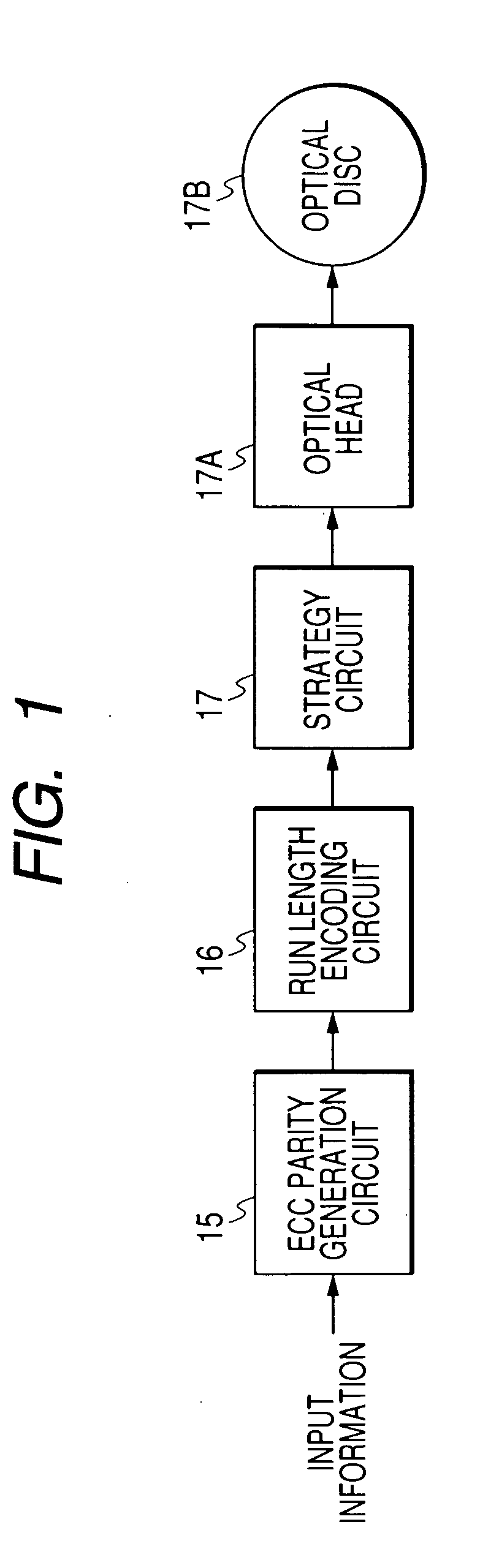

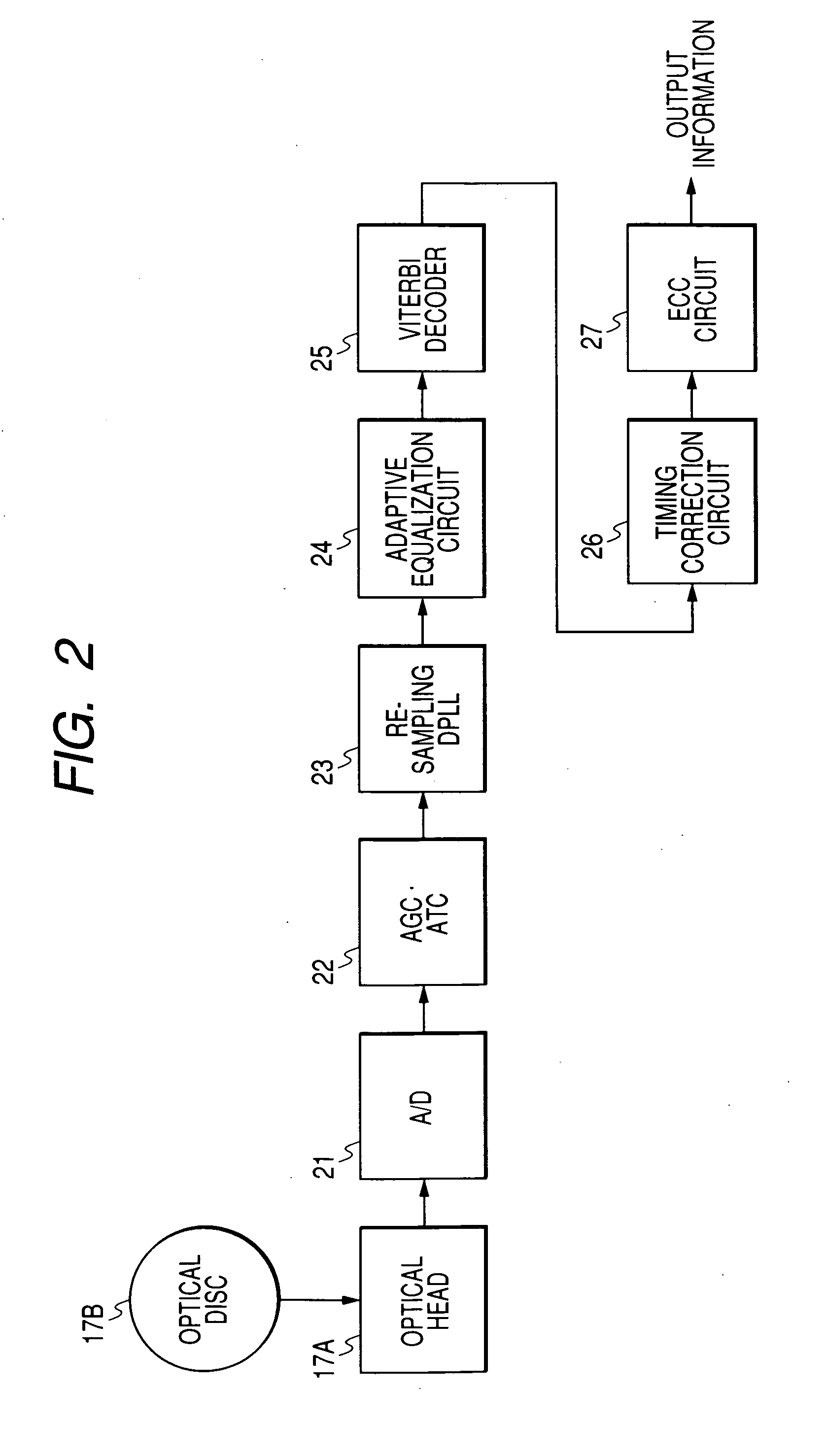

Reproducing apparatus and method, and recording and reproducing apparatus

ActiveUS7423949B2Avoid error rateTelevision system detailsRecord information storageComputer hardwareDigital signal

A signal of a run-length-limited code is read out from a recording medium. The read-out signal is converted into a reproduced digital signal. A decoder subjects the reproduced digital signal to first decoding different from run length decoding to get a first decoded signal. Information bit streams are generated from the first decoded signal. The information bit streams are different in timing by 1-bit-correpsonding intervals. Run length decoders subject the information bit streams to run length decoding to get run-length-decoded bit streams respectively. Each of the run-length-decoded bit streams undergoes one of error correction and error detection. A decision is made as to which of the run-length-decoded bit streams is the smallest in error number on the basis of results of the one of error correction and error detection. The run-length-decoded bit stream being the smallest in error number is selected and outputted as a likeliest information bit stream.

Owner:JVC KENWOOD CORP A CORP OF JAPAN

Method and device for deploying application programs and storage medium

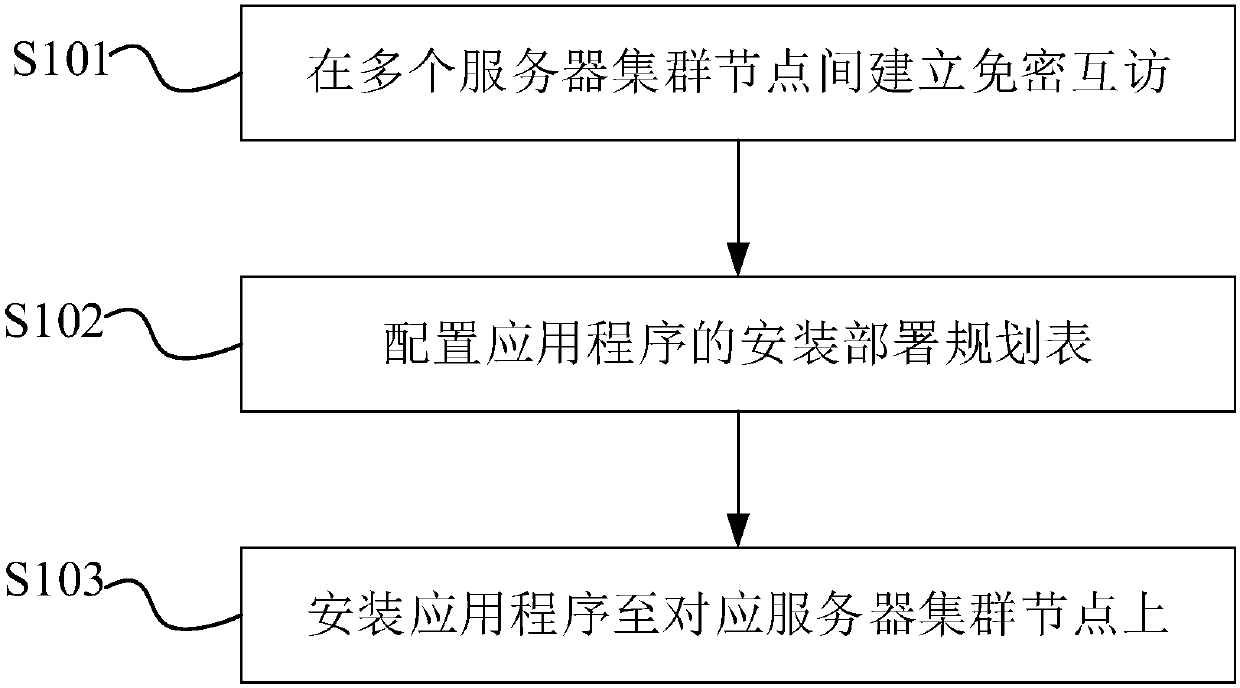

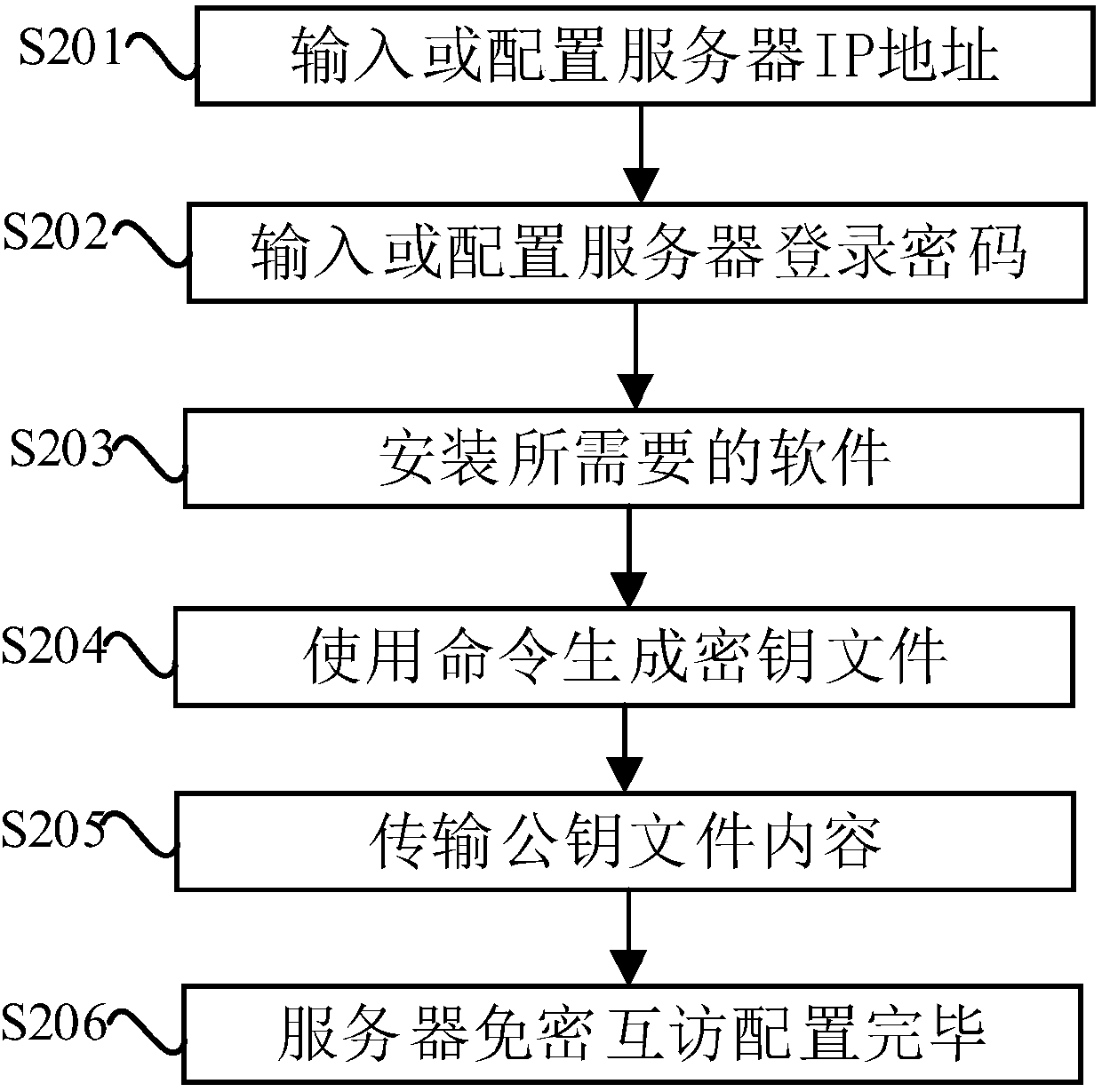

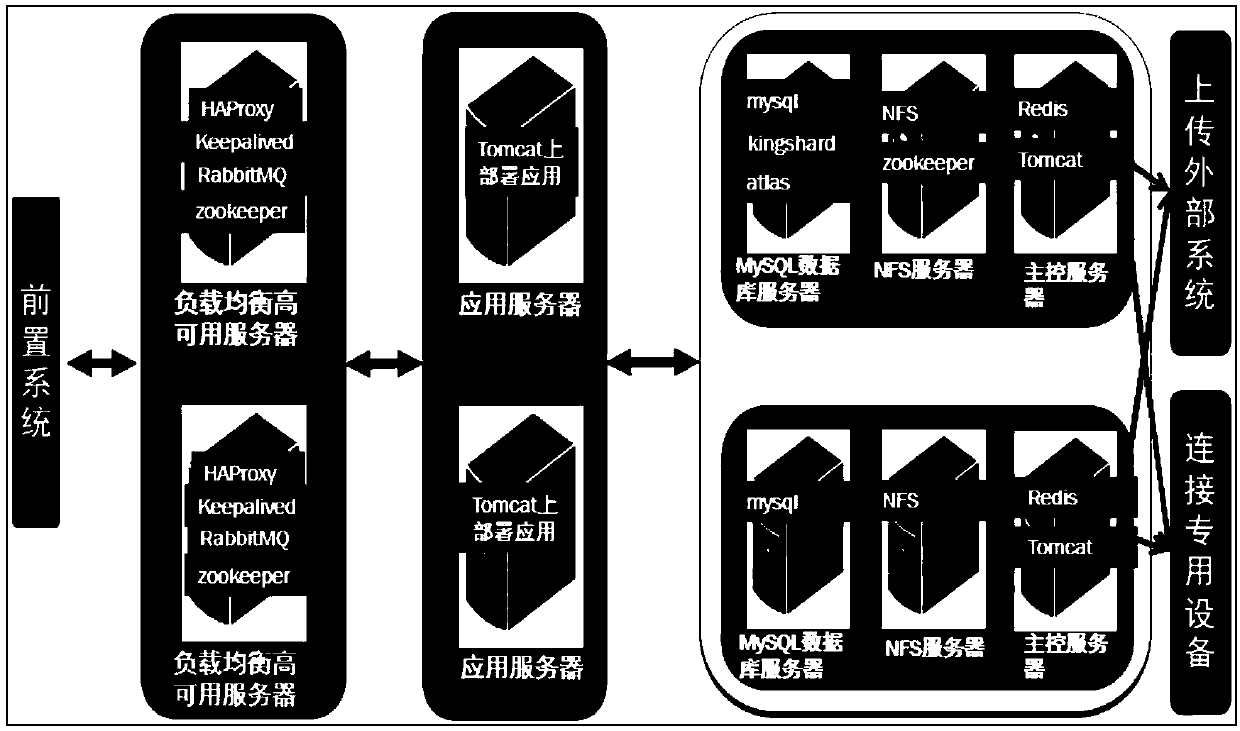

InactiveCN109814876ARealize free combinationImprove installation and deployment efficiencySoftware deploymentPasswordApplication software

The embodiment of the invention provides a method and device for deploying an application program and a storage medium, and belongs to the field of computers. The method comprises the steps of establishing password-free mutual access among a plurality of server cluster nodes, configuring an installation and deployment planning table of application programs, and installing the application programsto the corresponding server cluster nodes through automatic installation and deployment scripts of the application programs according to the installation and deployment planning table. By installing and deploying the application program through the method, the installation and deployment efficiency can be improved, the problem that errors are prone to occurring in manual deployment is avoided, a large number of human resources are released, and the personnel and time investment cost in the implementation stage is saved.

Owner:AEROSPACE INFORMATION

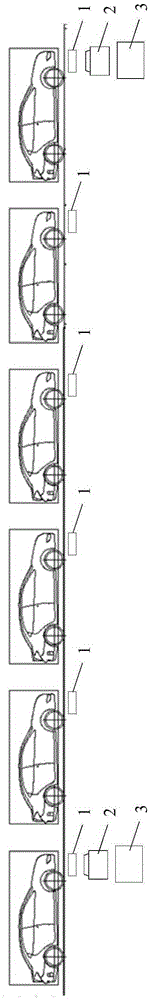

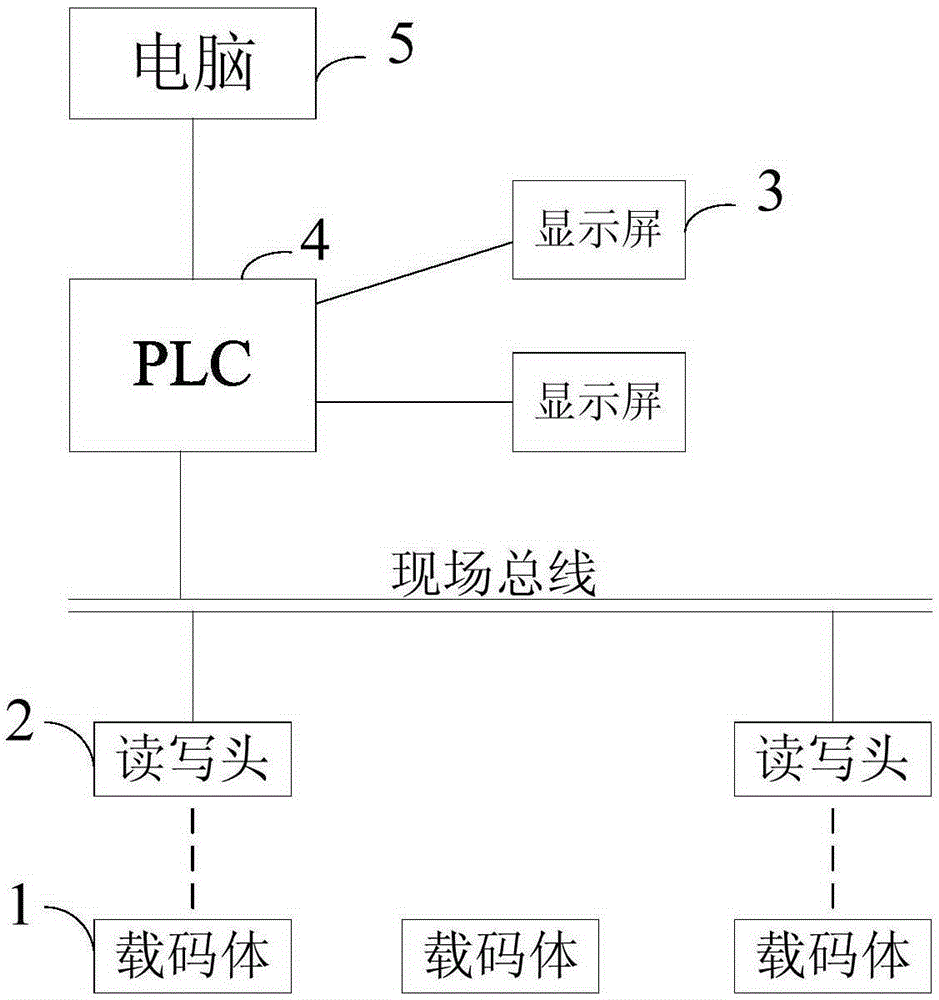

Automobile body tracing system for automobile production workshop

InactiveCN105335823AAvoid error rateA large amount of information is collectedCo-operative working arrangementsResourcesEngineeringBody positions

The invention provides an automobile body tracing system for an automobile production workshop, comprising code carriers, read / write heads, display screens, a PLC, and a computer. One or more code carriers are installed on a production conveying mechanism, and one code carrier corresponds to one automobile body position on the production conveying mechanism. The first read / write head is installed on a start station corresponding to the production conveying mechanism, and the other read / write heads are installed on operation stations needing a read / write head. The start station and the operation stations are each equipped with one display screen, and the display screens correspond to the read / write heads on the stations in a one-to-one mode. The PLC is used as a controller. The computer pre-stores the information of all models. The PLC is connected with the computer. The PLC is connected with the read / write heads on the stations and the corresponding display screens. The read / write heads and the code carriers communicate based on radio frequency. According to the invention, the positions of automobile bodies can be known in real time, and part information needed for operation on the stations can be displayed.

Owner:WUXI TIANQI INFORMATION TECH CO LTD

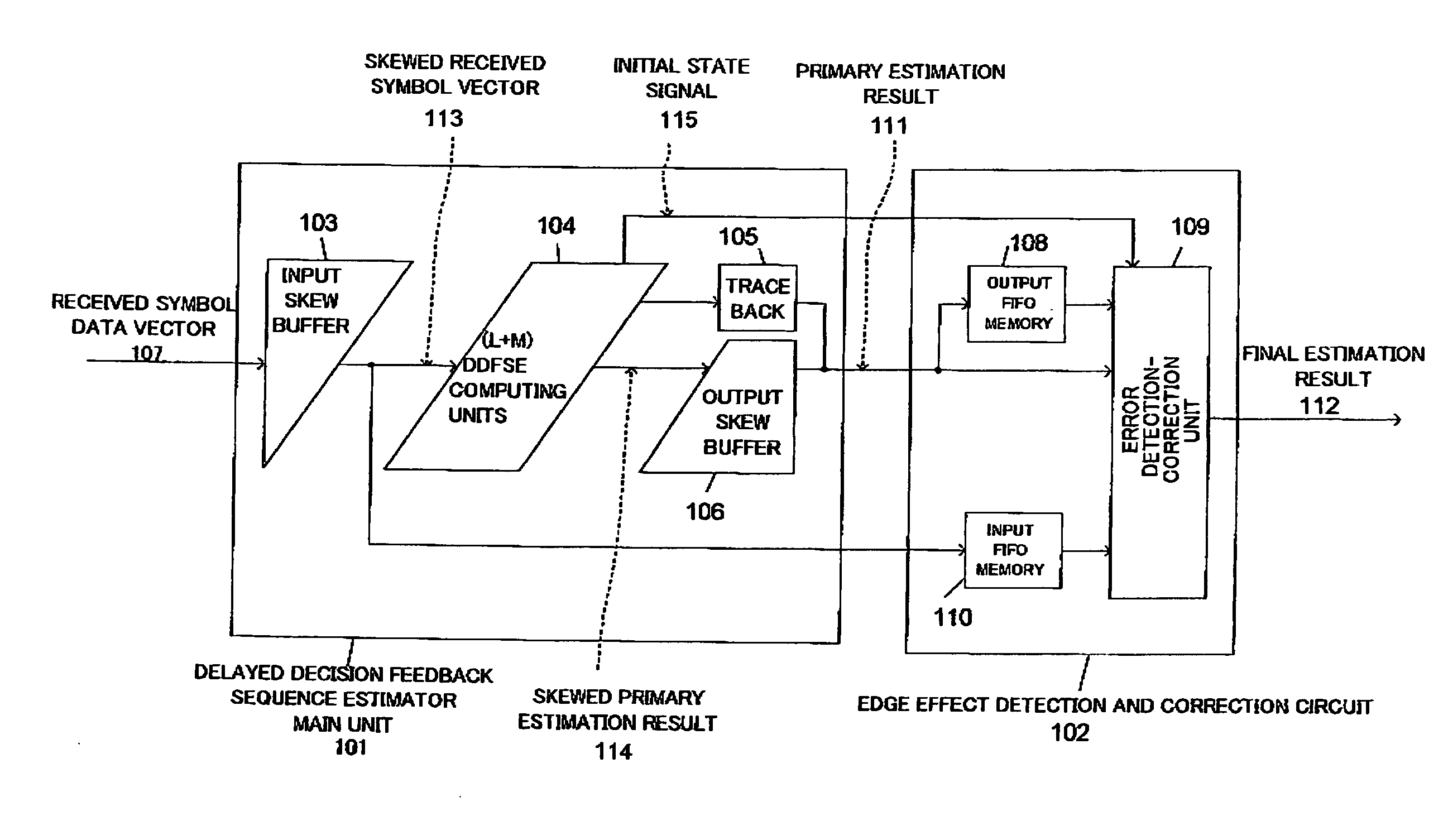

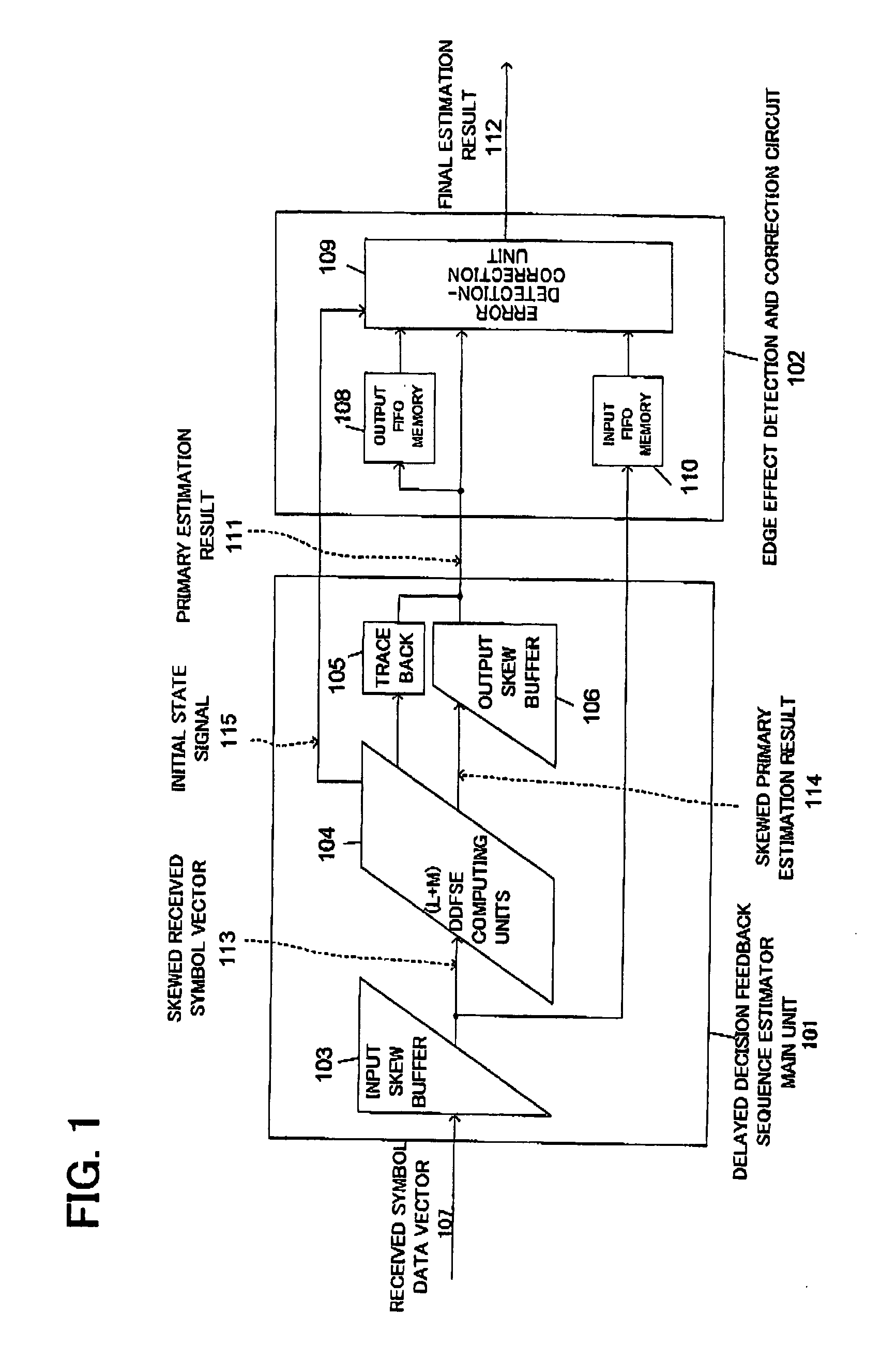

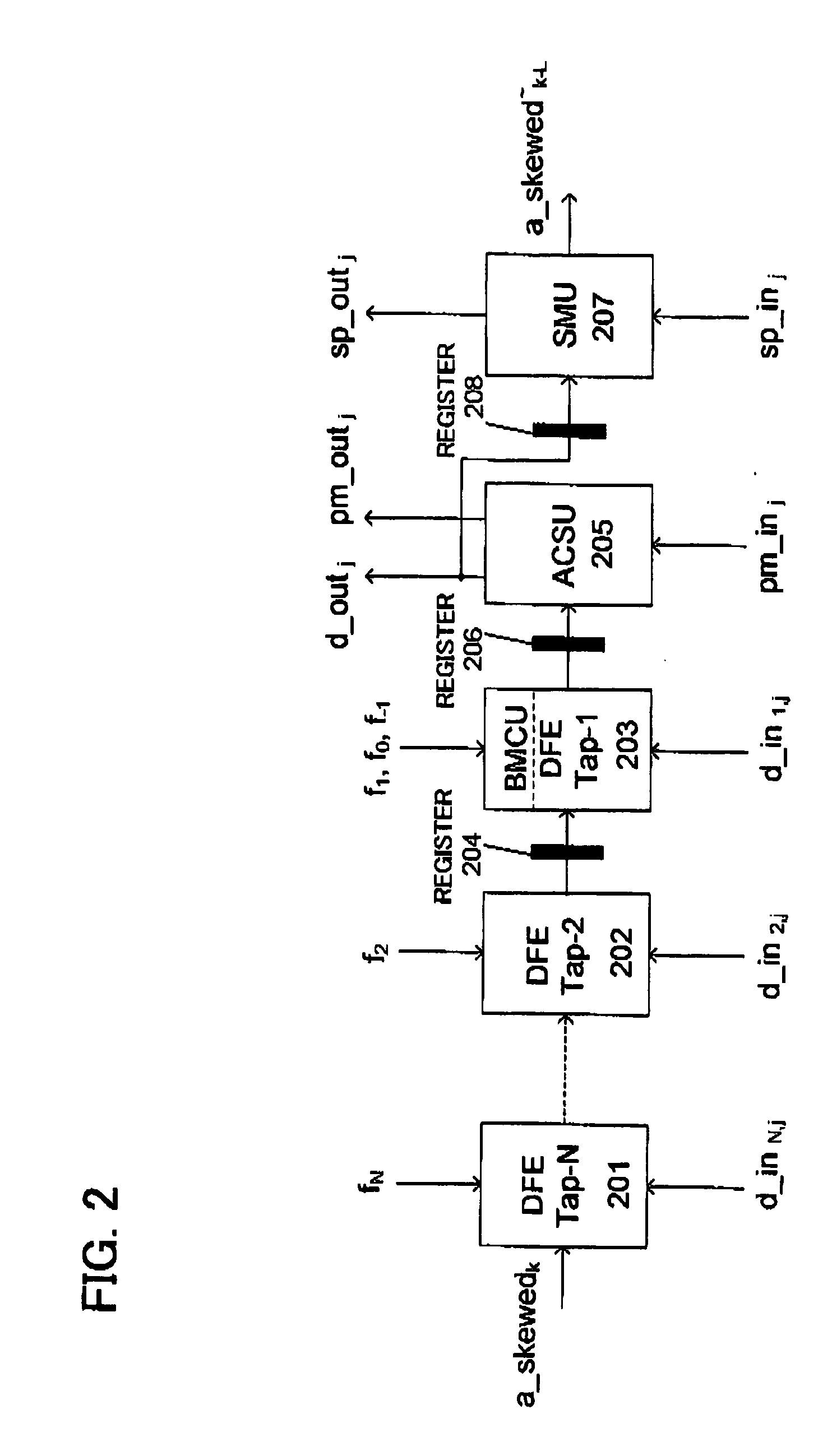

Delayed decision feedback sequence estimator

ActiveUS20090268804A1Improve processing throughputAvoid error rateMultiple-port networksDelay line applicationsAlgorithmUnit group

Disclosed is a delayed decision feedback sequence estimator comprising a delayed decision feedback sequence estimator main unit including DDFSE computing unit group including (L+M) DDFSE computing units, equal in number to a length of each of plurality of blocks into which a received data symbol sequence is divided; wherein (L+M) DDFSE computing units are connected in a pipeline configuration to execute delayed decision feedback sequence estimation of the blocks in parallel; and an edge effect detection and correction circuit that detects an edge effect due to processing the delayed decision feedback sequence estimation of the separated block and corrects a relevant bit error.

Owner:RENESAS ELECTRONICS CORP +1

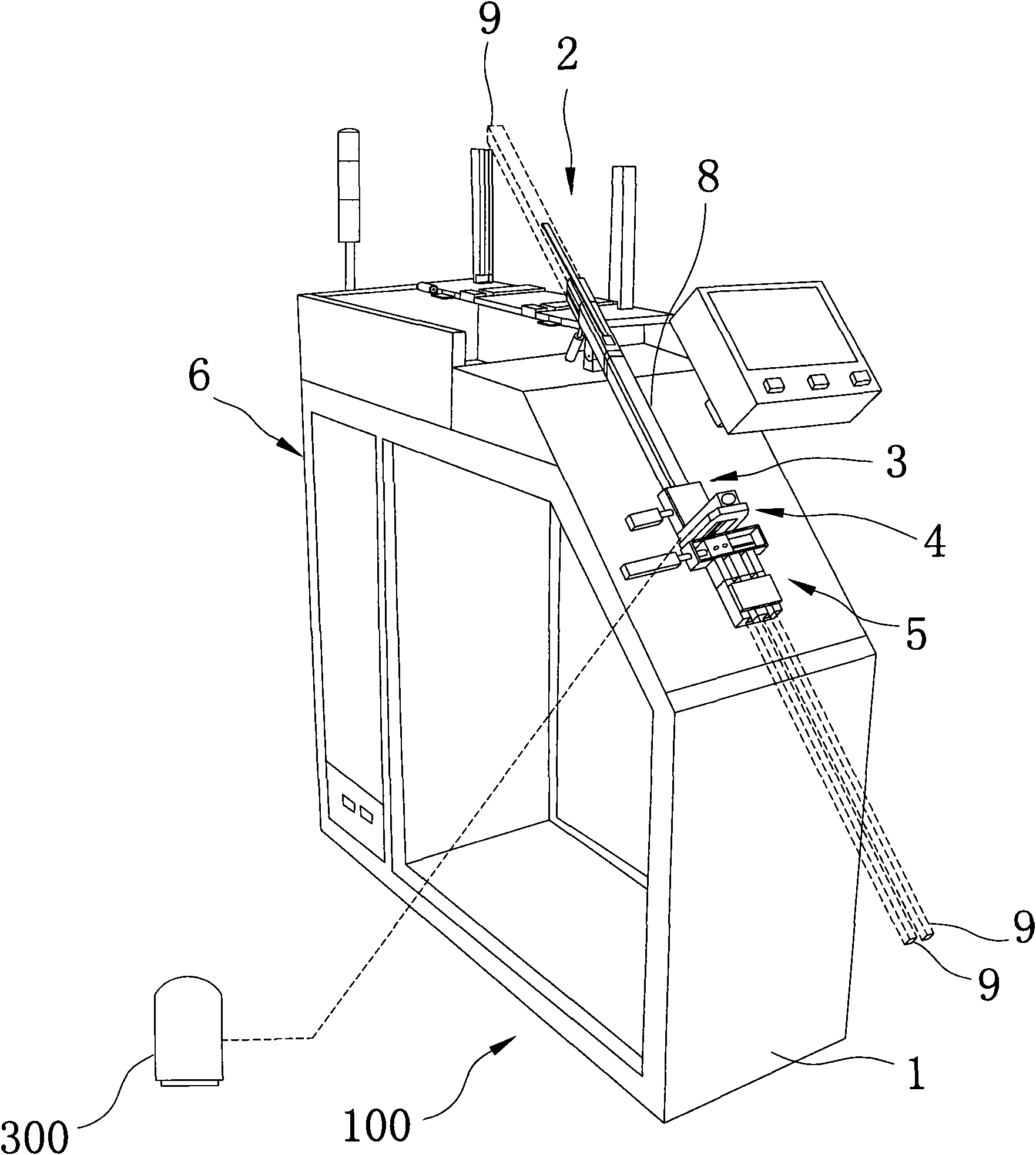

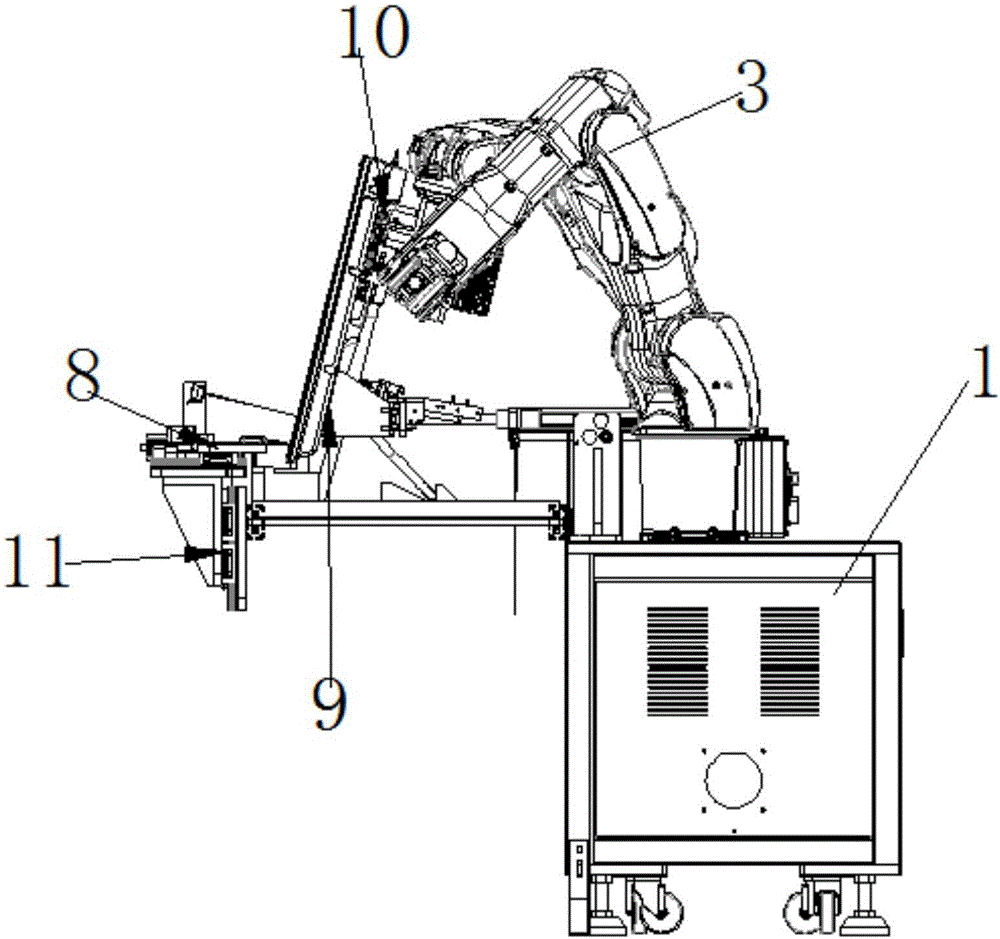

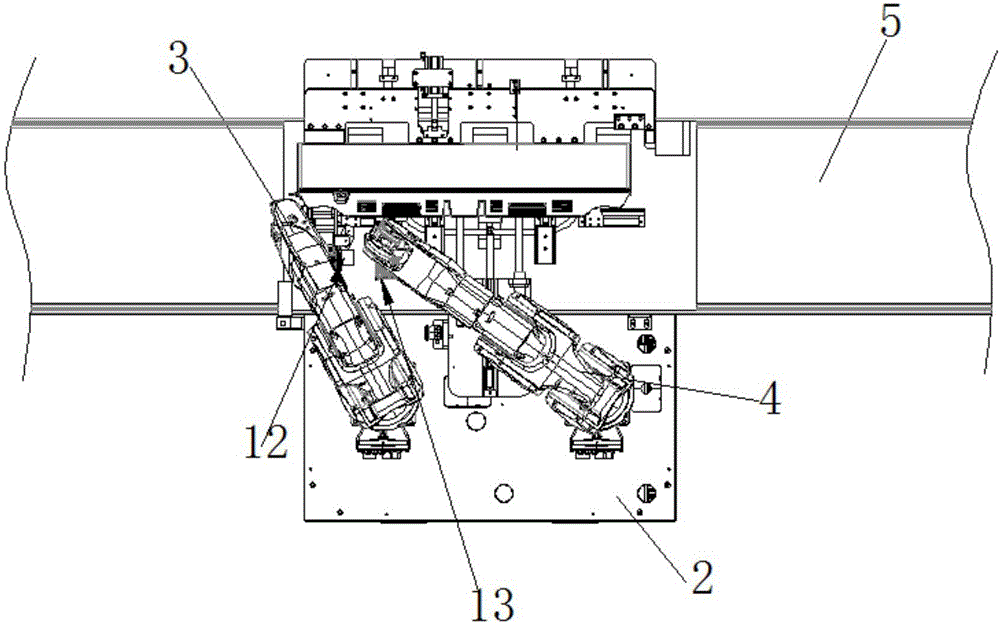

Equipment and method for multi-interface test of electronic product

InactiveCN106291206ASolve the error rate of taking the signal line connectorAvoid error rateElectrical testingComputer moduleEngineering

The invention discloses equipment and a method for a multi-interface test of an electronic product. The equipment comprises a control case cabinet; a bearing overload platform is arranged on the end surface of the control case cabinet; a left plugging / unplugging robot is fixedly mounted at the left side part of the bearing overload platform; a right plugging / unplugging robot is fixedly mounted at the right side part of the bearing overload platform; a supporting device is arranged at the rear part of the control case cabinet; a product angle correcting device is arranged between the supporting device and the control case cabinet; a multi-signal plug plugging / unplugging module is arranged at the upper part of the angle correcting device; a lifting device is arranged at the lower part of the supporting device; a product existence detecting sensor is arranged in the central position of the upper end surface of the lifting device. According to the equipment and the method for the multi-interface test of the electronic product, manpower is replaced by adopting intelligent robots and the equipment, so that the labour force can be reduced; therefore, the error rate of taking signal wire connectors by an operator and the error rate of plugging signal interfaces by mistake are reduced; the yield is improved; the quality rate is improved; the plugging / unplugging precision is improved; the efficiency is improved; processes are integrated and optimized; the operation is more convenient; resource waste is effectively reduced.

Owner:江苏拓科起航智能科技有限公司

Thread combining machine

InactiveCN105133121AReduce harmImprove work efficiencyWarping machinesTextiles and paperAcute angleEngineering

The invention provides a thread combining machine. The thread combining machine comprises thread passing rollers, combing needles, a combining roller, a left supporting mechanism and a right supporting mechanism. The right supporting mechanism comprises a right end movable frame fixedly connected with a right bearing. The included angle between the axis of the right end movable frame and the axis of a supporting shaft is an acute angle. A right lead screw rotating around the axis of the right lead screw is arranged in the direction perpendicular to the axis of the supporting shaft. Conical teeth are turned on the outer wall of the right lead screw. An arc-shaped displacement gear is arranged below the right lead screw. A rack meshed with the conical teeth on the right lead screw is turned on the displacement gear. The plane where the centering angle of the displacement gear is located is parallel to the plane where the end face of the supporting shaft is located. By means of the arrangement of the combing needles, it is guaranteed that tracks are not crossed in the thread harness winding process, and quality of wound thread harnesses is guaranteed.

Owner:TIANJIN JINBAO TEXTILE

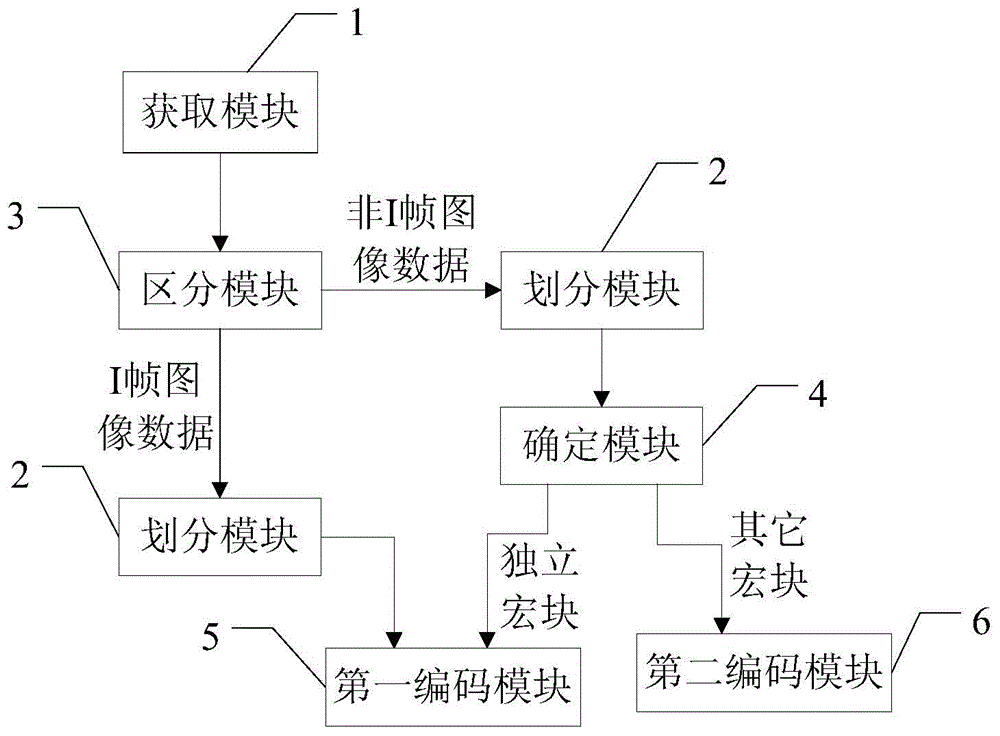

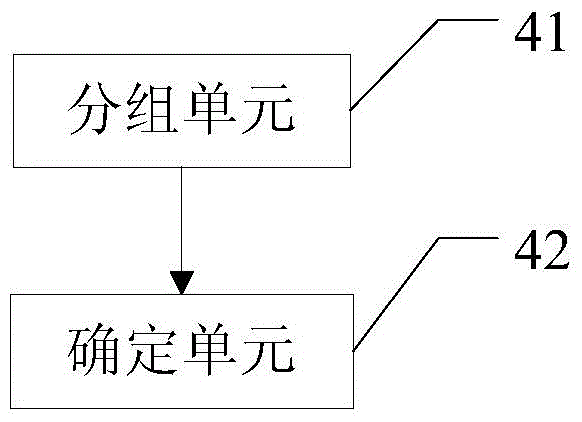

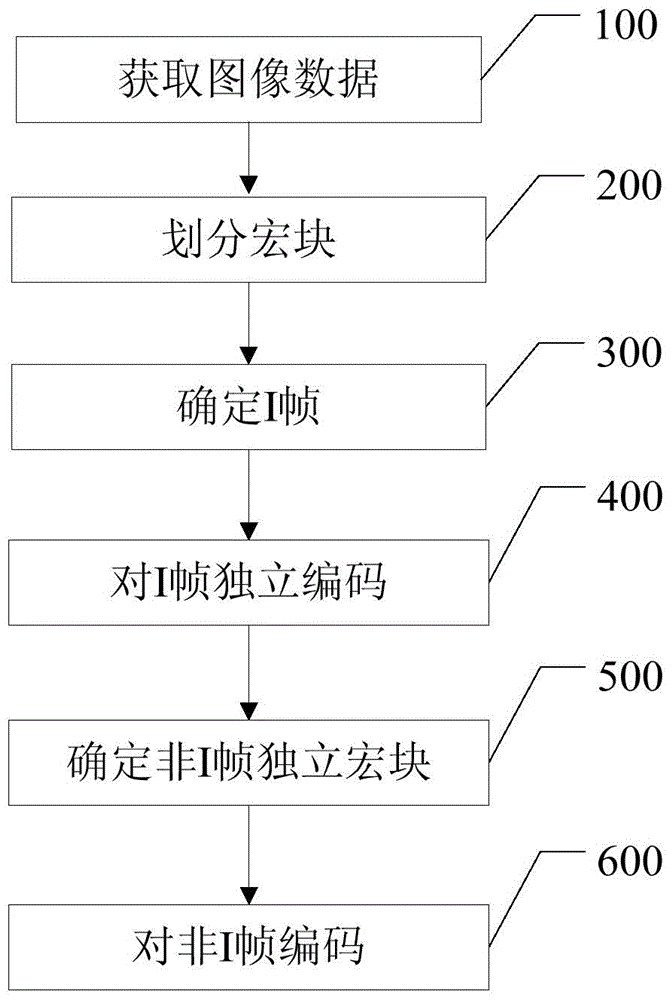

Video coding method and device

InactiveCN104796706AReduce error accumulationReduce to avoidDigital video signal modificationTraffic volumeImaging data

The invention discloses a video coding method comprising the steps of acquiring a plurality of frames of image data representing a video image, determining independent macro blocks from the non-Ith frames of image data, and independently coding the image data on the independent macro blocks during coding. By the method, image error accumulation can be reduced, and the probability of image error can be lowered. Moreover, as the independent coding macro blocks are distributed in the frames of image, the traffic can be taken into consideration while the fluency is improved. The invention further discloses a video coding device.

Owner:SHENZHEN WISION TECH HLDG

Reproducing apparatus and method, and recording and reproducing apparatus

ActiveUS20060028749A1Avoid error rateTelevision system detailsRecord information storageComputer hardwareDigital signal

A signal of a run-length-limited code is read out from a recording medium. The read-out signal is converted into a reproduced digital signal. A decoder subjects the reproduced digital signal to first decoding different from run length decoding to get a first decoded signal. Information bit streams are generated from the first decoded signal. The information bit streams are different in timing by 1-bit-correpsonding intervals. Run length decoders subject the information bit streams to run length decoding to get run-length-decoded bit streams respectively. Each of the run-length-decoded bit streams undergoes one of error correction and error detection. A decision is made as to which of the run-length-decoded bit streams is the smallest in error number on the basis of results of the one of error correction and error detection. The run-length-decoded bit stream being the smallest in error number is selected and outputted as a likeliest information bit stream.

Owner:JVC KENWOOD CORP A CORP OF JAPAN

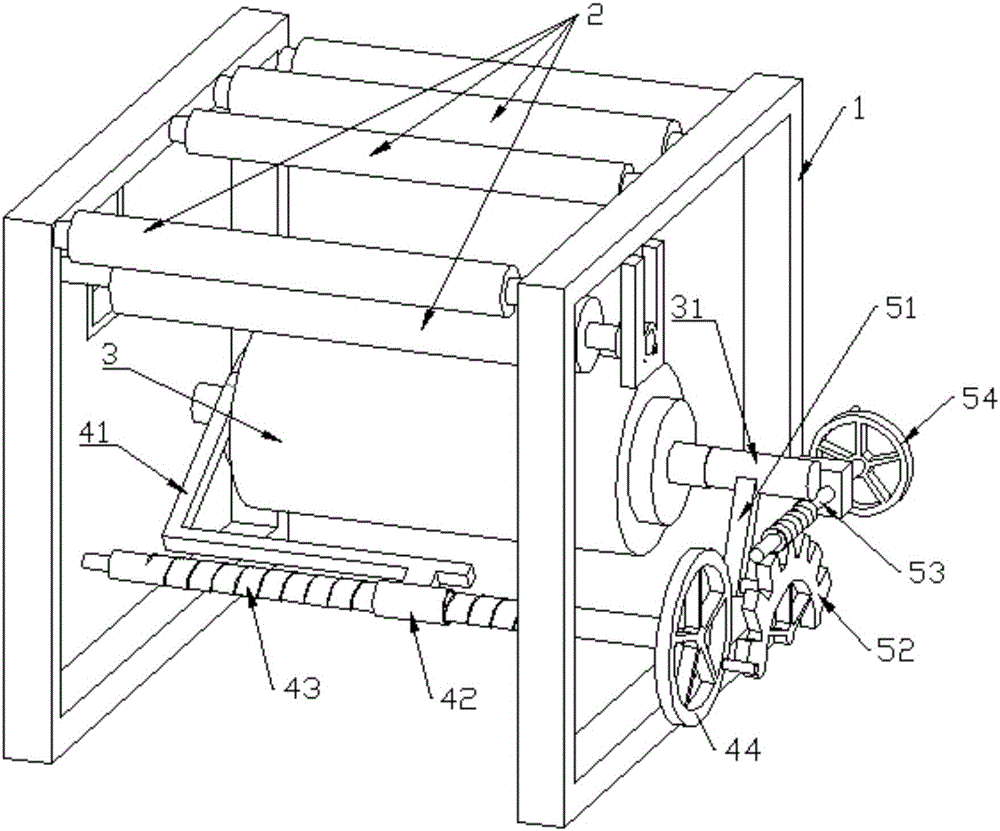

Welding accessory feeding device for full-automatic welding machine

ActiveCN107470799AAssembly precisionAvoid error rateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention relates to the field of welding equipment, in particular to a welding accessory feeding device for a full-automatic welding machine. The welding accessory feeding device comprises a welding accessory limiting device, a lifting platform, a first driving mechanism driving the lifting platform to ascend and descend, and a push device used for pushing welding accessories to the lifting platform. A round rotary disc is arranged on the side of the first driving mechanism, and multiple carrying rods used for being sleeved with materials are arranged on the edge of the top of the rotary disc. A welding accessory moving device used for moving the welding accessories to the top ends of the carrying rods is arranged over the lifting platform. The first driving mechanism comprises a first driving motor, a screw rod vertically arranged and a first fixing plate. A belt wheel is arranged at the bottom end of the screw rod, and an output shaft of the first driving motor penetrates the first fixing plate to be arranged under the first fixing plate. The screw rod is sleeved with a sliding block in transmission fit with the screw rod so that assembling between a welding pipeline and the welding accessories before welding is more accurate, and the error rate that welding is not accurate is avoided.

Owner:安徽成泰化学科技有限公司

Express item special-shaped part automatic sorting equipment

Owner:SHANGHAI ZHONGTONGJI NETWORK TECH CO LTD

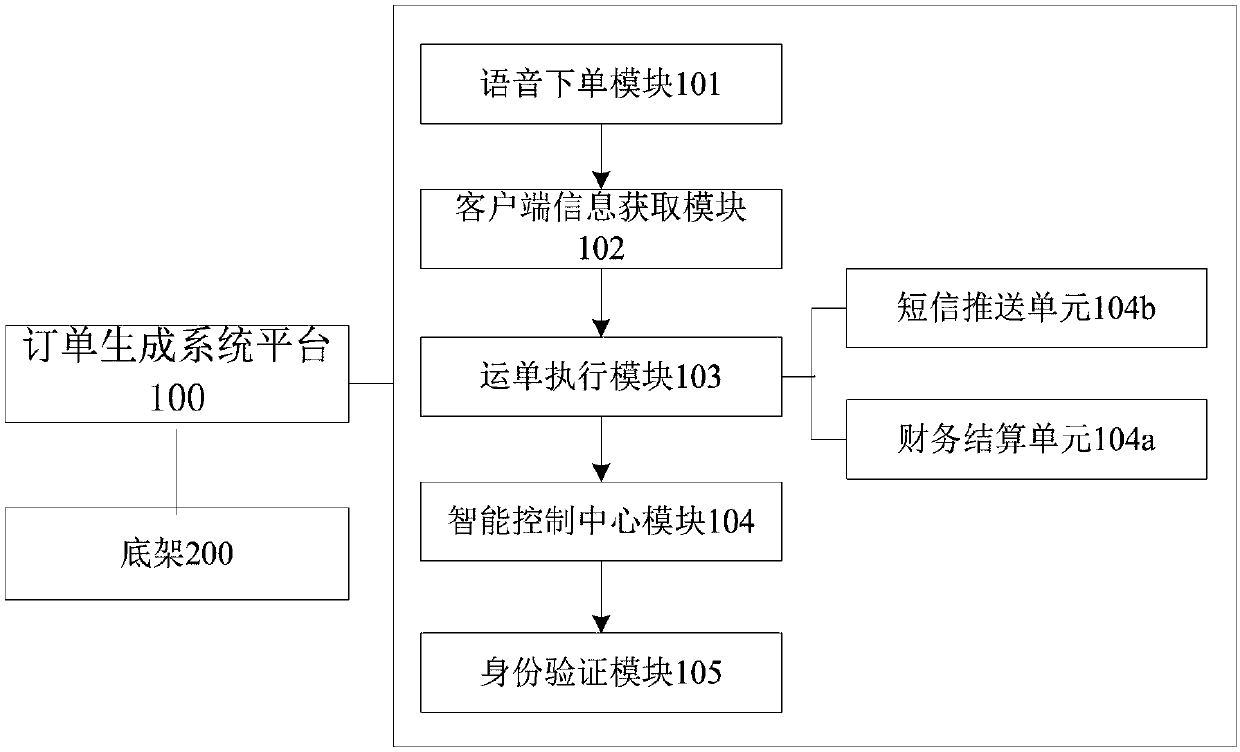

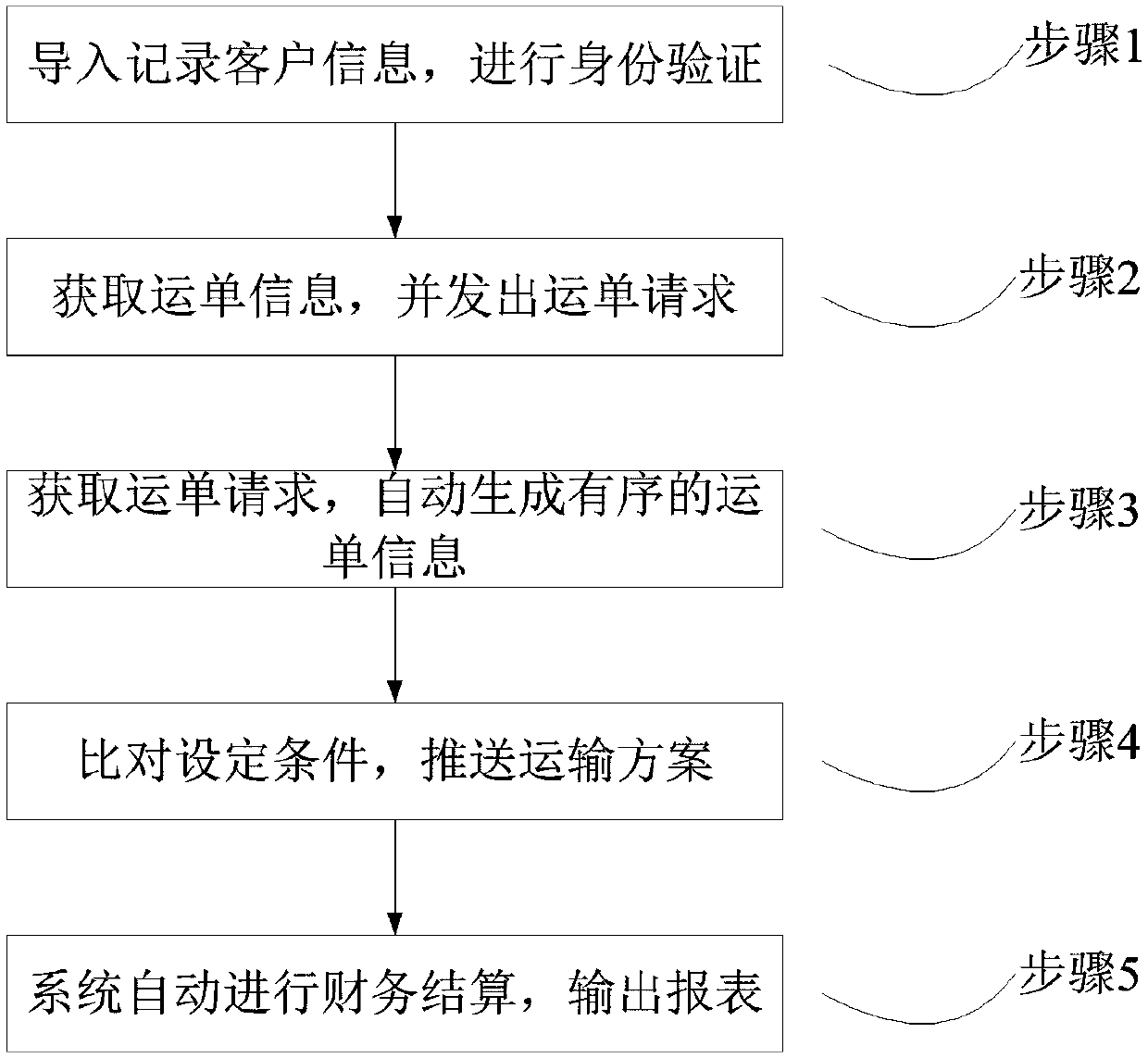

Operation system and order generation method for fast logistics informatization

InactiveCN107808219AAvoid mistakesReduced computer skill level requirementsForecastingSpeech recognitionInformatizationOperational system

The invention provides an operation system and an order generation method for fast logistics informatization. The operation system is used for providing a system platform for a client to generate an order, and comprises an order generation system platform and a bottom frame; during operation, the bottom frame is used for supporting hardware of the order generation system platform; when the clientor a biller fills waybill information, a client information obtaining module automatically obtains an order generation condition set for a cargo waybill by the client or the biller and sends a waybillrequest to a waybill execution module; the waybill execution module receives the waybill request sent by the client information obtaining module and automatically generates ordered waybill information; and an intelligent control center module screens out an optimal transportation scheme according to the waybill information and performs pushing. An original manual waybill issuing mode is convertedinto a mode of filling the waybill in a system platform by the biller or the client in a self-service manner, so that the accuracy of logistics information is guaranteed, the informatization threshold of logistics staffs is lowered, the biller operation is simplified, and the billing efficiency is improved.

Owner:广州智远信息技术服务有限公司

Conversion card for testing probe card

InactiveCN105092925AAvoid error rateReduce inventory rateElectrical measurementsTime-domain reflectometerProbe card

Provided is a conversion card for testing a probe card. The conversion card comprises a plate body, and a plurality of first transmission units, a plurality of second transmission units and a DC / AC conversion circuit; and the first transmission units, the second transmission units and the DC / AC conversion circuit are disposed on the plate body. The first transmission units are electrically connected with a test instrument. The second transmission units are electrically connected with interfaces of the probe card. The DC / AC converting circuit is electrically connected with the first transmission units and the second transmission units. AC signals are transmitted by the first transmission units, and the AC signals are transmitted to the DC probe card through the DC / AC conversion circuit, the second transmission units and the interfaces of the probe card. By using principles of an AC circuit and a transmission line, the conversion card cooperates with AC signal test instruments of a logic analyzer, an oscilloscope, a time-domain reflectometer, a frequency domain network analyzer, an error code generator, an eye pattern analyzer and the like. An AC method is used to perform error analysis and improvement on the DC probe card, thereby preventing the misjudging error rate of the probe card, reducing the card changing rate and the pin removing rate, and reducing the inventory ratio of the DC probe card.

Owner:詹定叡

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com