Automobile body tracing system for automobile production workshop

A production workshop and traceability system technology, applied in the direction of instruments, electrical program control, data processing applications, etc., can solve the problems affecting production efficiency, production site confusion, limited human ability and energy, etc., to achieve automatic management and avoid mistakes. rate, the effect of collecting a large amount of information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0021] The invention proposes a vehicle body traceability system in an automobile production workshop, in which a read-write head identification system is added, and the car model information is written or read through the read-write head, and the collection of information is strengthened in the real-time production stage, so that the specific details of the car body can be clarified. The location thus consolidates the supply of materials.

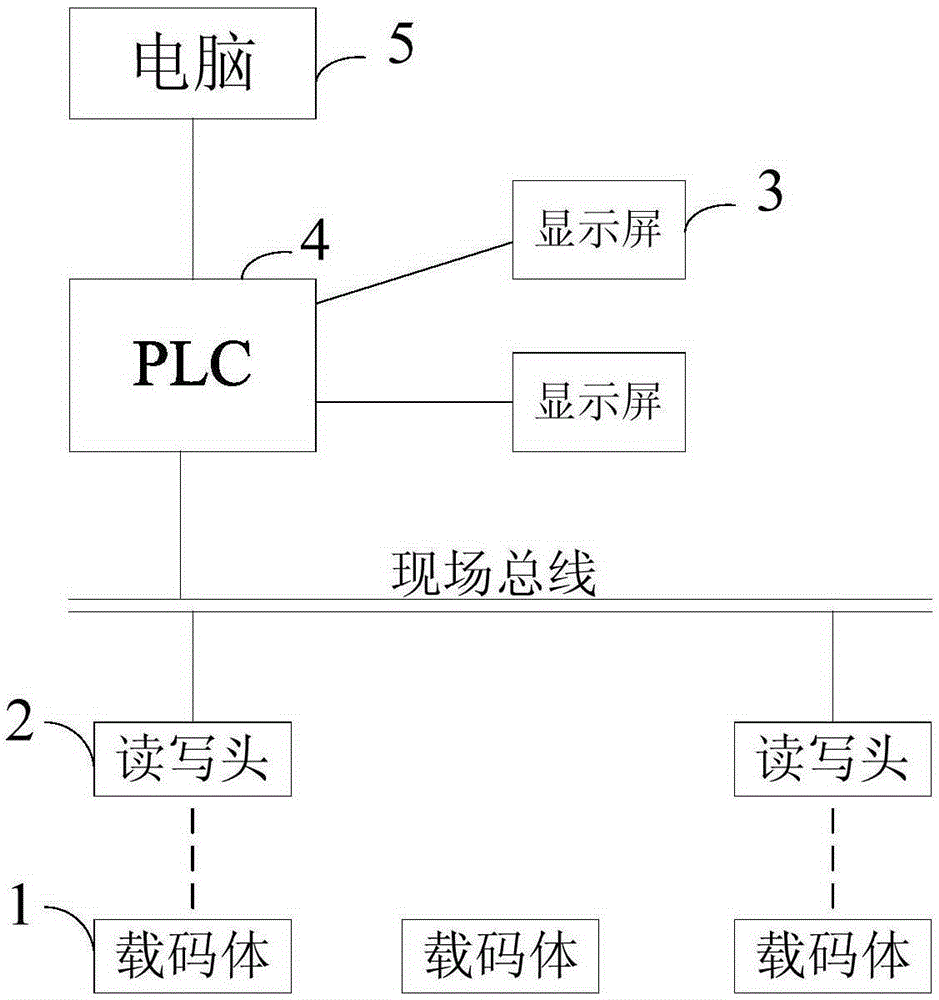

[0022] The car body traceability system of the automobile production workshop includes a code carrier 1, a read-write head 2, a display screen 3, a PLC 4 and a computer 5; each code carrier 1 and the read-write head 2 constitute a read-write head identification system.

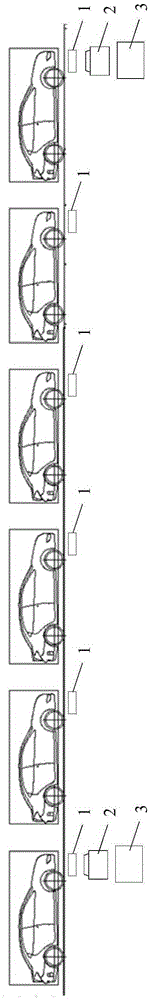

[0023] Such as figure 1 As shown, one or more code carriers 1 are installed on the production conveying mechanism, and the code carriers 1 move together w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com