Express item special-shaped part automatic sorting equipment

A technology for automatic sorting and special-shaped parts, which is applied in the field of logistics and can solve problems such as large physical and mental requirements and increased error rate of staff.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

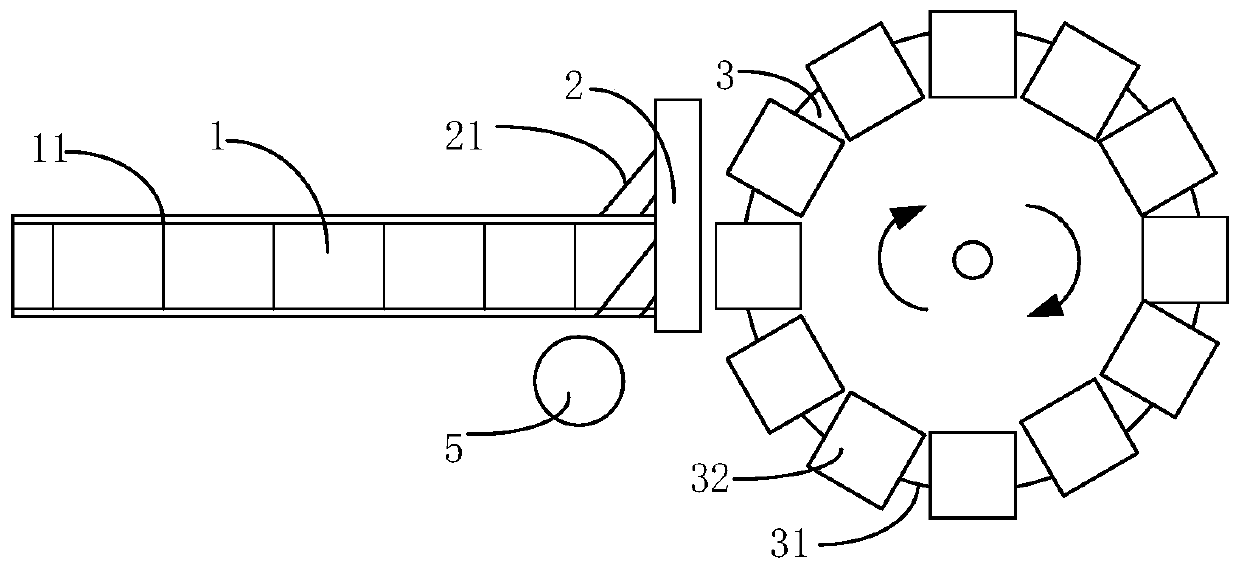

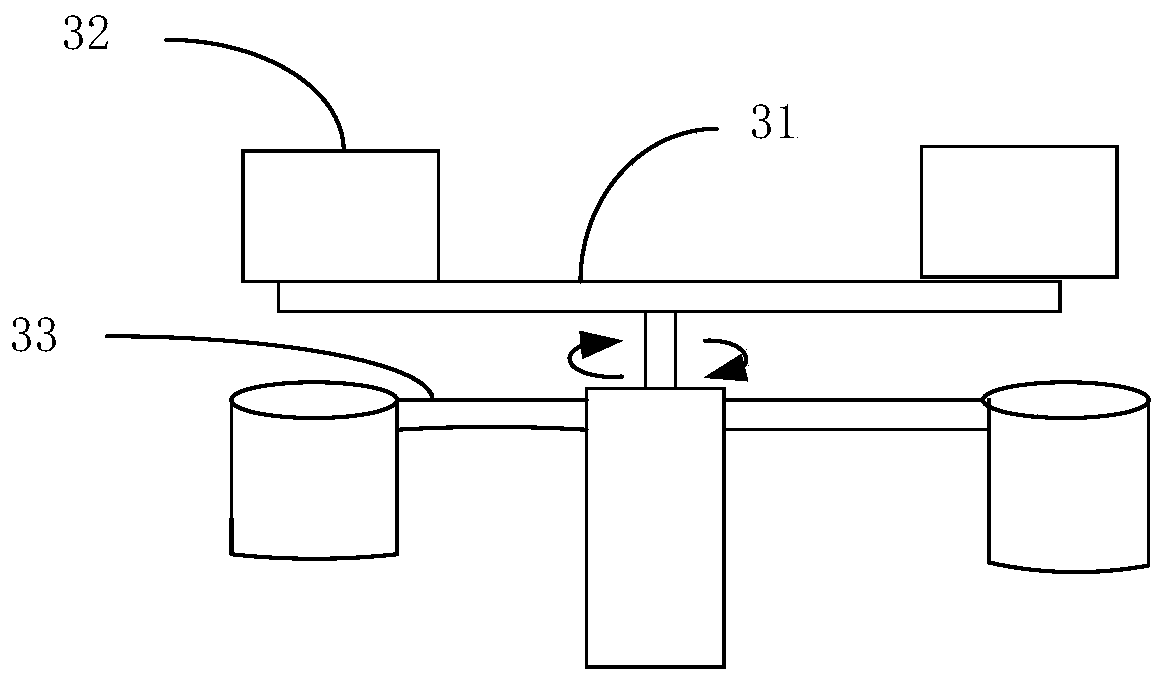

[0043] figure 1 It is a schematic structural diagram of an automatic sorting device for special-shaped express mail provided by the embodiment of the present invention; figure 2 It is a partial structural schematic diagram of an automatic sorting device for special-shaped express mail provided by the embodiment of the present invention; refer to figure 1 with figure 2 , the automatic sorting equipment for special-shaped express mail provided by this application includes:

[0044] Conveyor belt 1 for conveying special-shaped parts;

[0045] A top-scanning camera 2 arranged above the conveyor belt 1 for scanning the information of special-shaped parts;

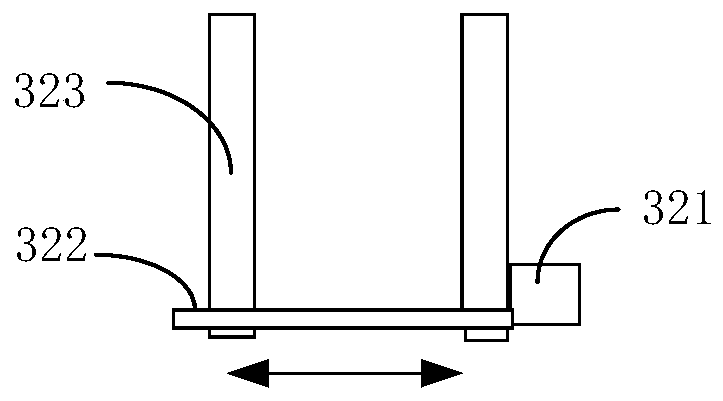

[0046] The disc sorter 3 arranged at the end of the conveyor belt 1 is used to sort the special-shaped parts based on the information scanned by the top scanning camera 2; wherein, the disc sorter 3 includes: a support 31, multiple A sorting trolley 32 and a plurality of telescopic hanging bag devices 33; the support 31 fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com