Equipment and method for multi-interface test of electronic product

An electronic product and multi-interface technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of mismatching action and thought rhythm, no machine-assisted operation, and increased operation time, etc., to achieve the solution of taking the signal line Joint error rate, efficiency improvement, and the effect of reducing resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

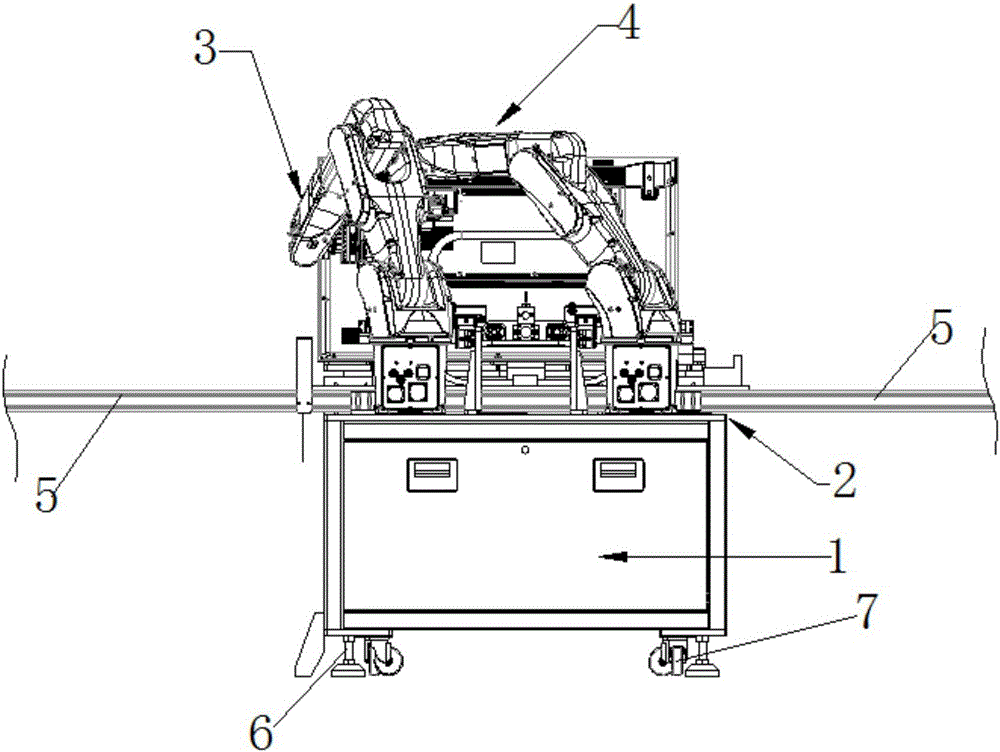

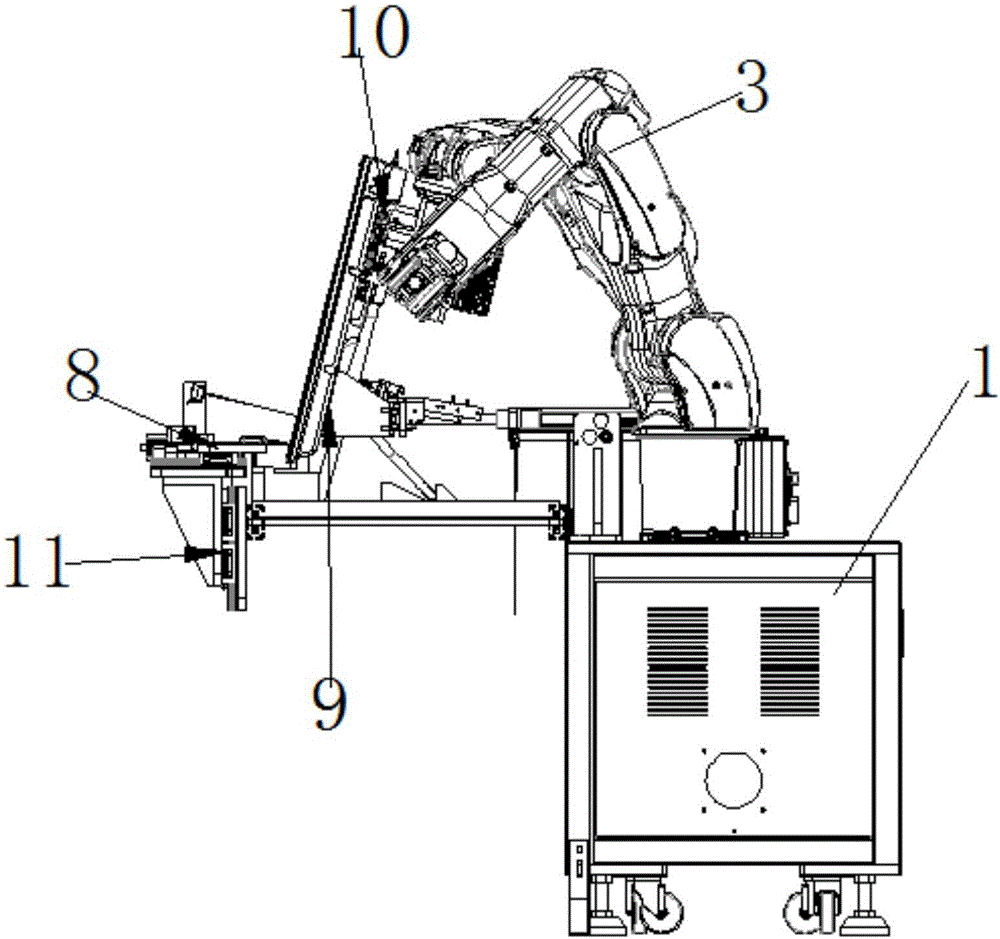

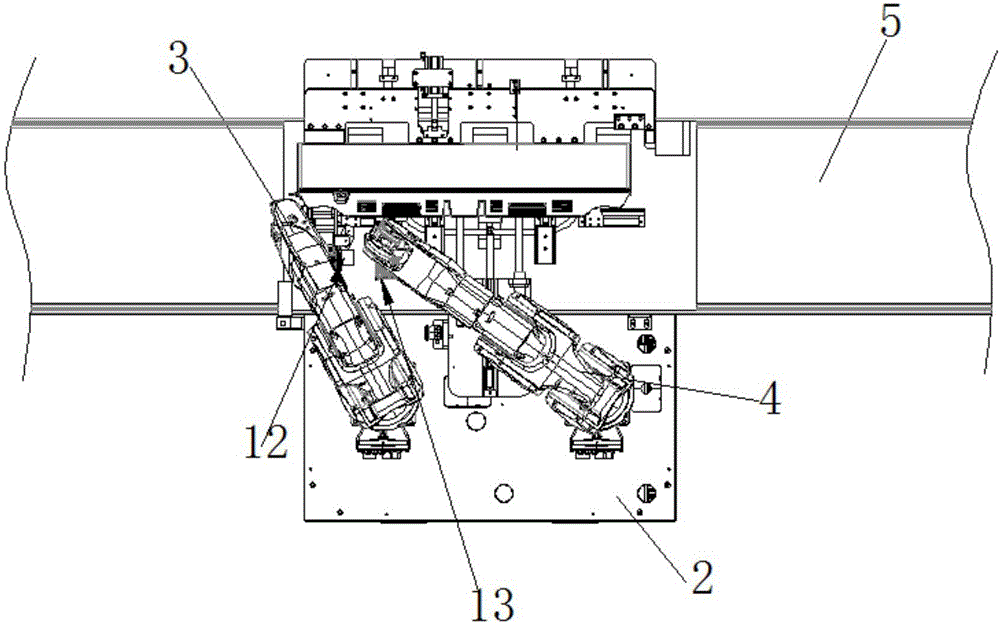

[0027] Implementation case 1: When the test product enters the other position of the test station, the sensor will detect that the product is in place. The PLC will control the positioning device to lift the product for rough position correction S1; then the PLC control notifies the robot to move to the top of the interface, and the PLC controls the trigger The camera takes pictures, and the camera takes pictures and analyzes the coordinates and sends the position compensation data back to the PLC S2; the PLC sends the received data coordinates to the robot for position correction S3 before the interface is inserted; the robot automatically corrects the signal according to the position coordinates The plug is inserted into the interface S4; the PLC notifies the test software to start the test, and the test software sends the test result to the PLC S5; the PLC notifies the robot to pull out the plug S6; the robot pulls out the plug and goes to the second test station S7.

Embodiment example 2

[0028] Implementation Case 2: If Figure 6 As shown, at the beginning, the plug is inserted into the HDMI-1 interface, and the software signal source is switched. The test software detects and judges the HDMI-1 interface. After the test, it detects and judges the AV-IN interface. HDMI-2 interface, USB interface, HDMI-3 interface, high-definition image and computer P card image are detected and judged, among which HDMI-1 interface, AV-IN interface, HDMI-2 interface, USB interface, HDMI-3 interface, high-definition image It is qualified when the left side of the computer P card image is tested at 1Khz, and the right side is tested at 200hz.

[0029] The time for automatic plugging + unplugging of 7 interfaces is 21 seconds, the output is increased from the original 1600 machines / person / day to 1800 machines / station / day, and the production rate is increased by 12.5% / (for a single station production rate), which can be improved Yield. However, the missed test rate of the machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com