Thread combining machine

A textile thread and thread passing roller technology, which is applied in the field of textile production, can solve problems such as delaying production efficiency, increasing production workload, and affecting efficiency, and achieves the effects of ensuring quality, reducing damage, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples.

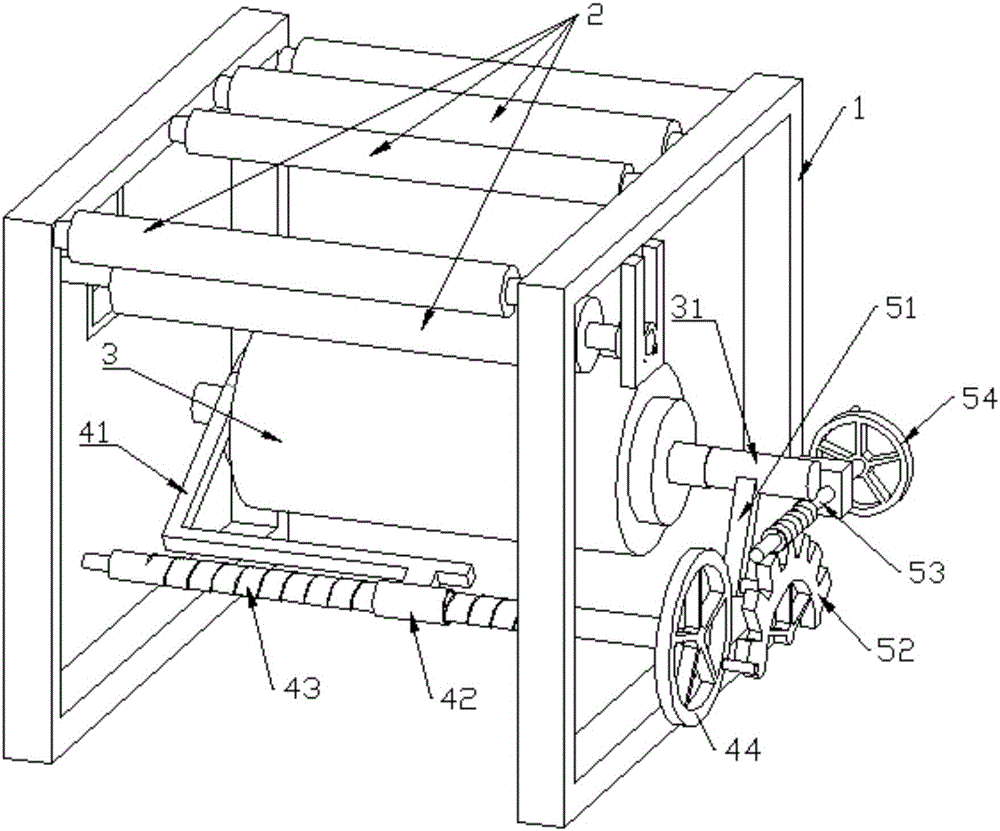

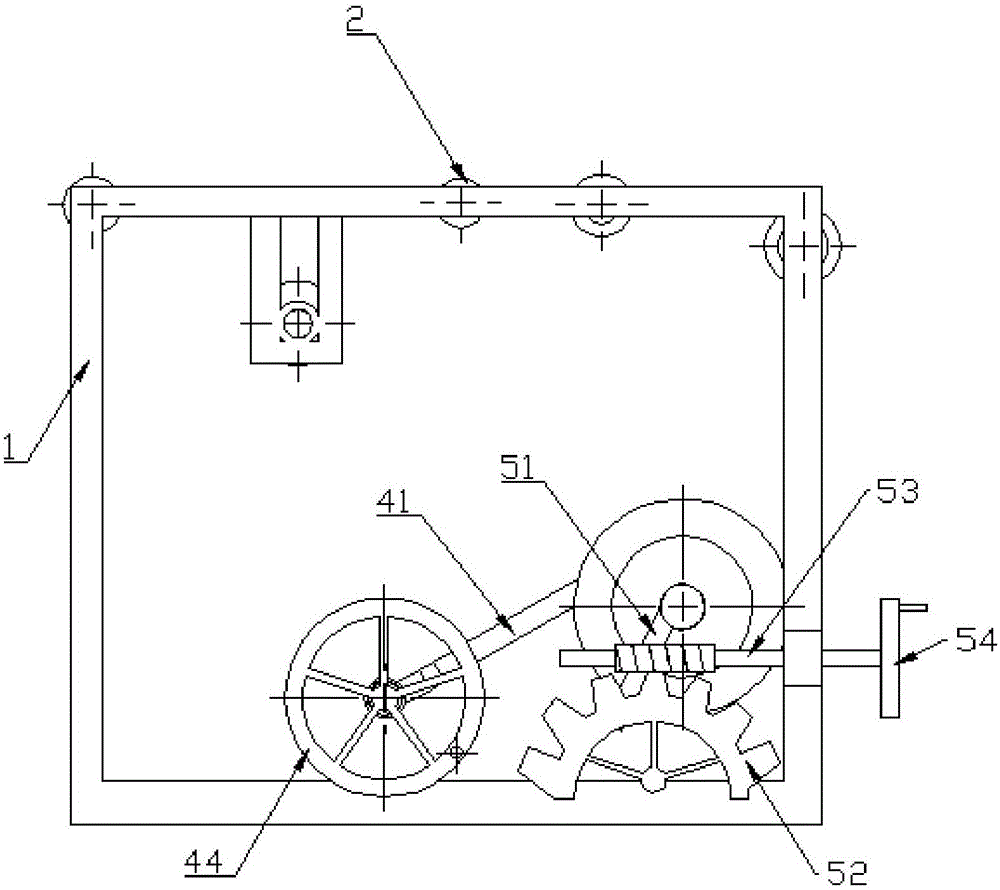

[0029] Such as figure 1 with 2 As shown, the textile line integration machine includes a support 1, a wire passing roller 2, a carding needle, an integration roller 3, and a left support mechanism and a right support mechanism;

[0030] A plurality of wire passing rollers 2 are arranged obliquely above the integration roller 3, wherein carding needles are arranged between two adjacent wire passing rollers 2, and several carding needles are arranged along the axial direction of the wire passing rollers 2, Moreover, several carding needles are set up in a staggered manner, which can ensure that the trajectories of the wire bundles do not overlap, and can be evenly and smoothly wound on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com