Preparation method and application method of titanium dioxide nanosheet supported MIL-100 (Fe) composite photocatalysis material

A composite photocatalysis and titanium dioxide technology, which is applied in the field of titanium dioxide photocatalysis and titanium dioxide nanosheet-supported porous metal-organic framework composite materials, can solve the problems of high energy consumption, cumbersome methods, and unspecified visible light responsiveness, and achieves improved separation efficiency, The effect of good repeatability and easy control of preparation parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

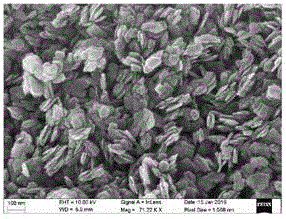

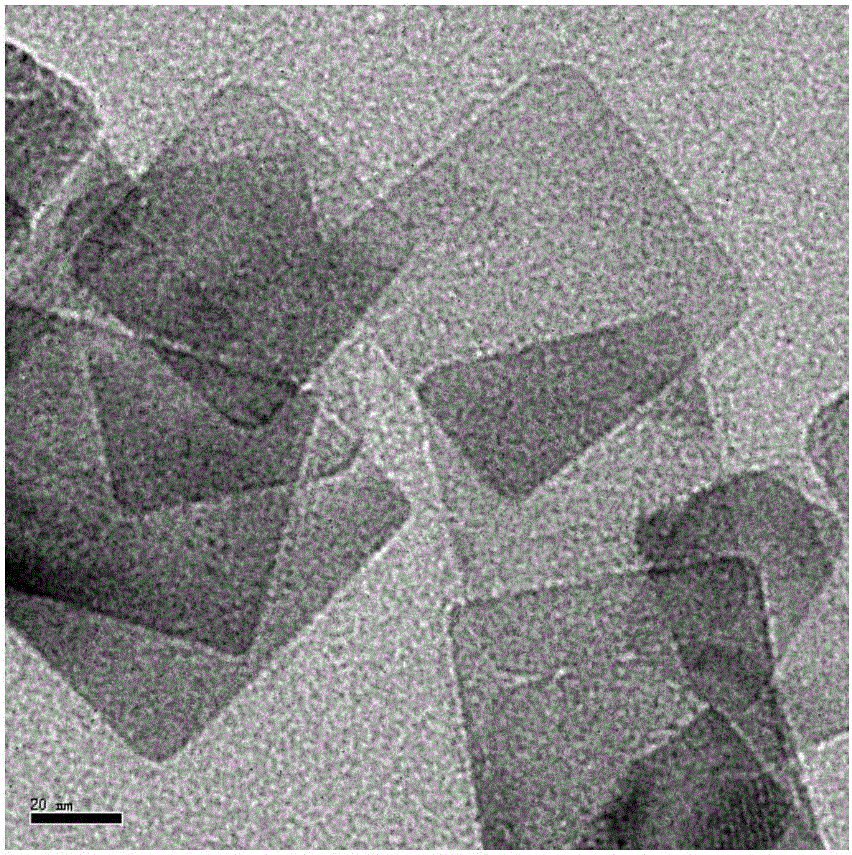

[0026] (1) Add 5ml of hydrofluoric acid with a mass fraction of 40% to 25ml of tetrabutyl titanate, stir evenly at 25°C, put it into a 100ml autoclave, and react at 200°C for 20h. After the reaction is finished, it is washed to neutrality with deionized water and ethanol, and dried to obtain titanium dioxide nanosheet powder.

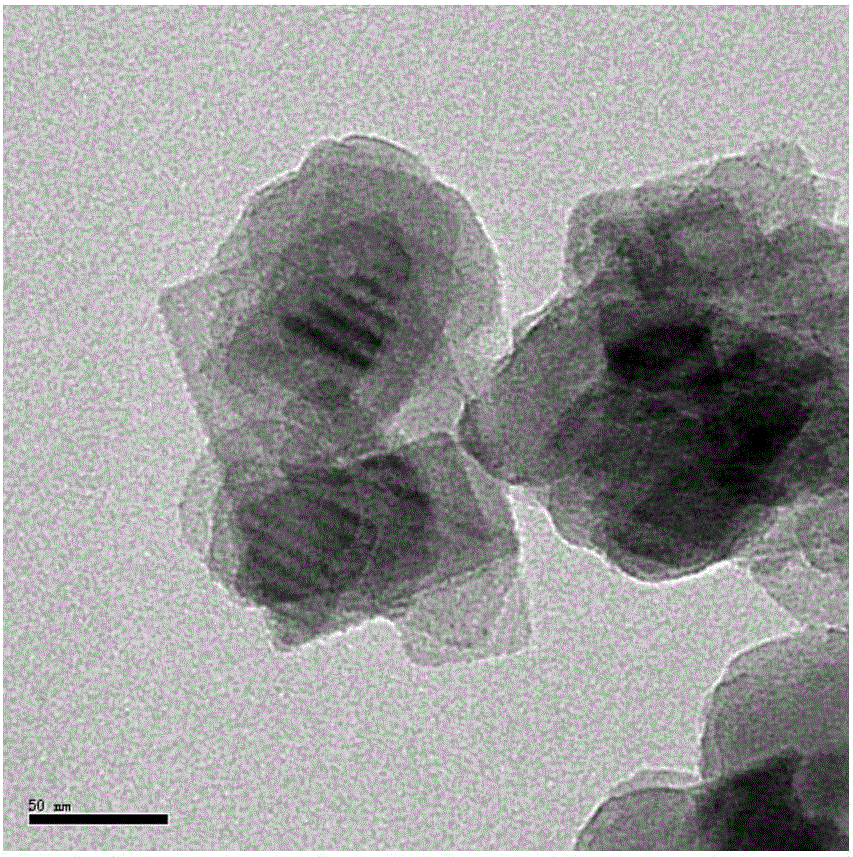

[0027] (2) Weigh 0.027g of ferric trichloride hexahydrate and dissolve it in 10m of ethanol, ultrasonically dissolve it fully, and then disperse 0.10g of prepared titanium dioxide nanosheets into the above solution, after ultrasonic dispersion is uniform, magnetic force at room temperature After stirring for 15min, the Fe 3+Adsorbed titanium dioxide nanosheets; weigh 0.021g trimesic acid and dissolve it in 10m ethanol, and ultrasonically dissolve it fully, and the adsorbed Fe 3+ The titanium dioxide nanosheets were dispersed into the ethanol solution of trimesic acid, dispersed evenly, placed in a water bath at 70°C for 30 minutes, and then separated b...

Embodiment 2

[0032] The preparation method of the MIL-100 (Fe) loaded titanium dioxide nanosheet composite catalyst, the steps are the same as in Example 1, the difference is: the titanium dioxide nanosheets are coated with MIL-100 (Fe) 5 times

[0033] Weigh 20 mg of the above-prepared MIL-100(Fe)-loaded titanium dioxide nanosheet catalyst to carry out the experiment of visible light catalytic degradation of high concentration methylene blue, the concentration of methylene blue is 50 mg L -1 , the degradation rate of methylene blue was 71.5% after visible light irradiation for 80min.

Embodiment 3

[0035] The preparation method of MIL-100 (Fe) loaded titanium dioxide nanosheet composite catalyst, the steps are the same as in Example 1, the difference is: titanium dioxide nanosheets are coated MIL-100 (Fe) 10 times

[0036] Weigh 20 mg of the above-prepared MIL-100(Fe)-loaded titanium dioxide nanosheet catalyst to carry out the experiment of visible light catalytic degradation of high concentration methylene blue, the concentration of methylene blue is 50 mg L -1 , the degradation rate of methylene blue was 84.2% after visible light irradiation for 80min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com