Adhered self-lifting highrise operation platform

An aerial work platform and self-elevating technology, which is applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of large number of attachment devices, poor stability of hanging baskets, high technical requirements, etc., to achieve convenient operation, The effect of improving the level of construction mechanization and reducing the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

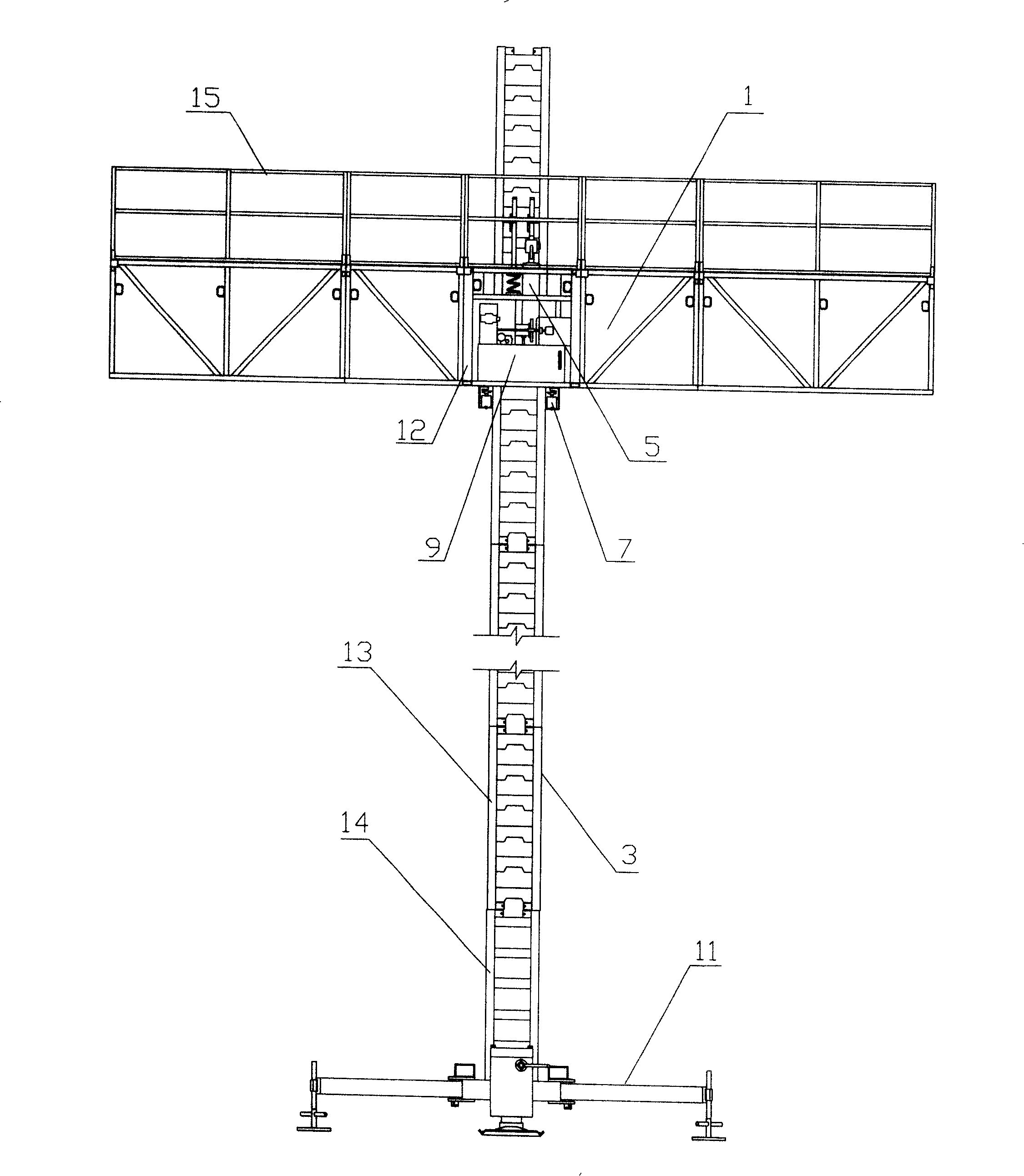

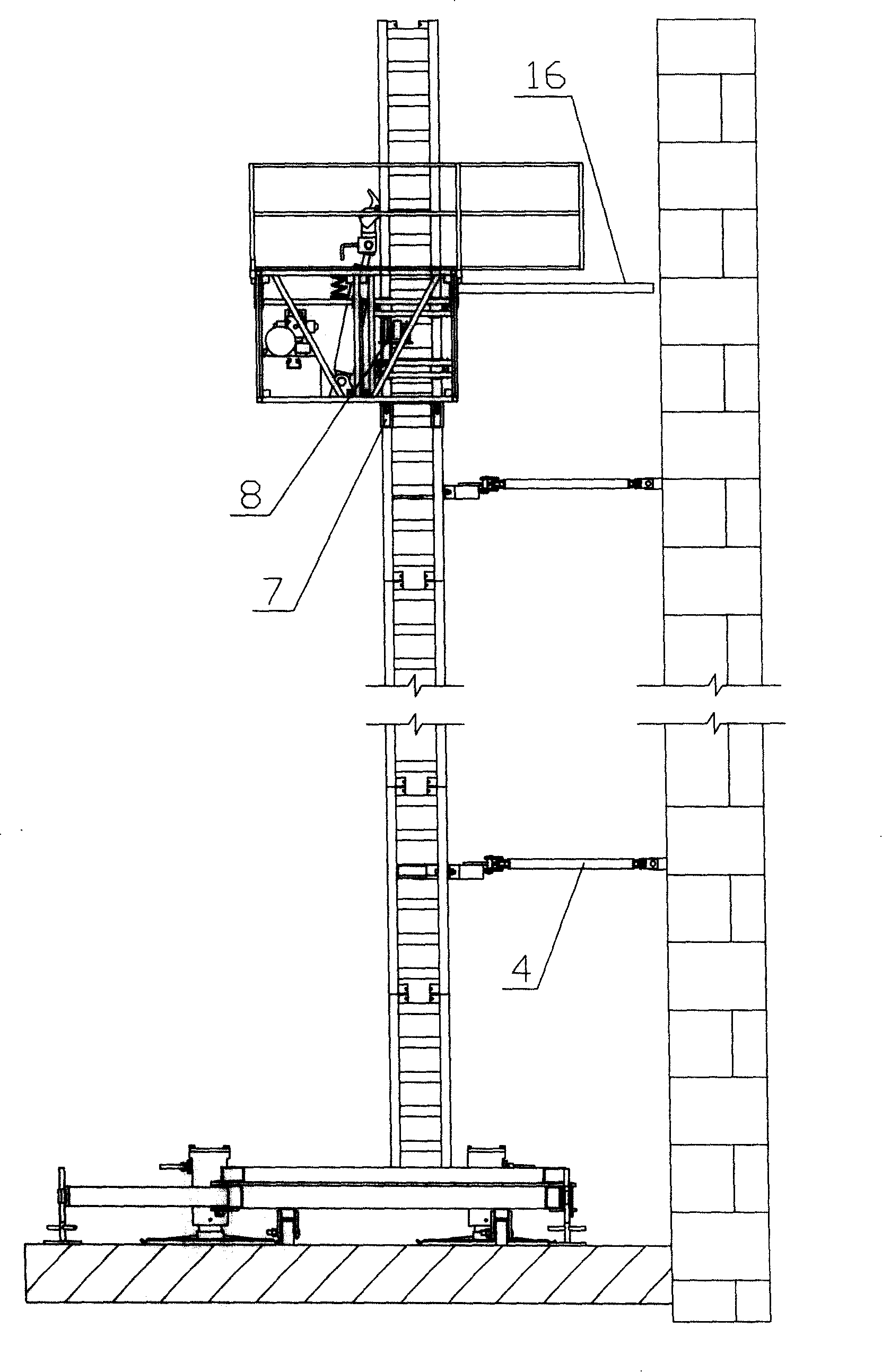

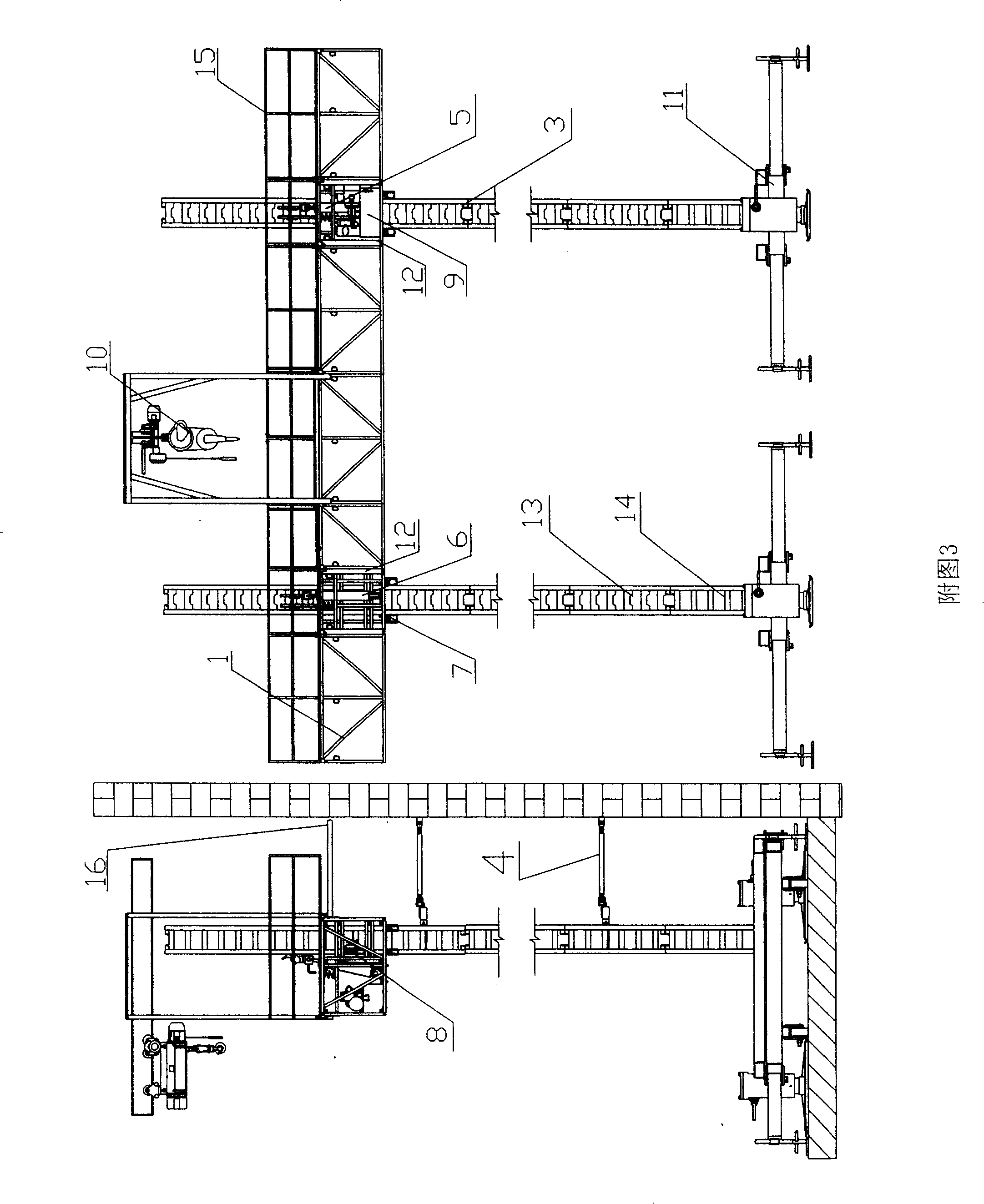

[0036] As shown in Figure 5, this embodiment is an attached self-elevating aerial work platform in the form of four attachment brackets, including an operating platform, attachment bracket 3, attachment rod 4, lifting device, wedge safety device, hydraulic system, lifting The device 10 and the stand base 11. among them:

[0037] Operating platform. The operating platform is assembled into a basic platform 1 from various platform standard sections and control platform sections. The standard sections of each platform are 1m platform standard section, 2m platform standard section, 1 / 2m platform standard section, all of which are space truss structures, and are equipped with multiple diagonal braces to increase the rigidity of the standard section; the two ends of the platform are welded with eight pieces The connecting ear plate is provided with a connecting hole in the center, and each platform unit is connected to each other through a connecting piece. In this embodiment, high-stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com