Composite wear-resistant part preparation method

A technology of composite wear-resistant parts and wear-resistant parts, which is applied in the field of preparation of ball mill liners and composite wear-resistant parts. problems, to achieve the effect of facilitating mechanized operation, simplifying the production process and improving the service life of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the composite wear-resistant part of the present invention comprises the following steps:

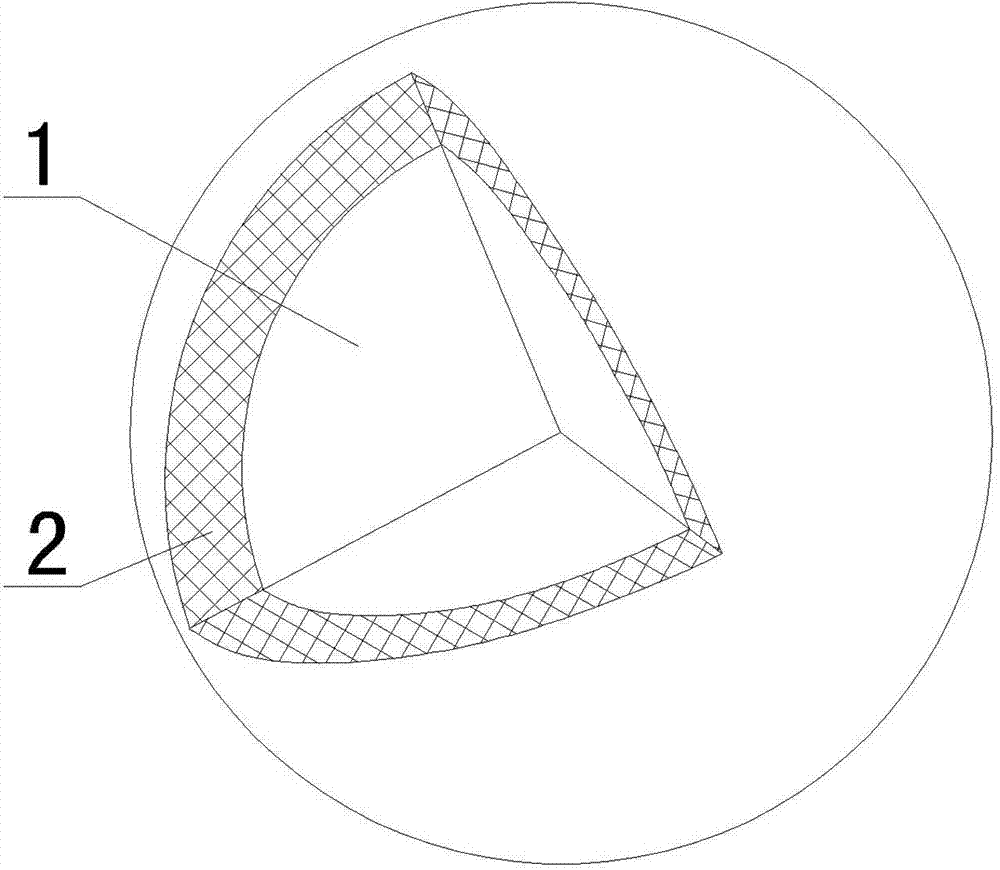

[0033] 1) Determine the wear surface and failure mode under the working conditions of the wear-resistant parts, and design the configuration of the ceramic reinforcement: the thickness of the configuration is 3-80mm, and the configuration can be strip-shaped, plate-shaped or porous, etc. It is necessary to ensure the instant ceramic The absolute distance from any point in the reinforcing body to the molten metal is less than 10mm;

[0034] 2) Design and manufacture molds according to the designed ceramic reinforcement configuration;

[0035] 3) Surface nickel-plated ceramic particles with a particle size of 0.1-7mm;

[0036] 4) Mix the treated ceramic particles with a binder with a weight percentage of 0.5-2%, fill them in a mold, and adopt a method of warm pressing to make a ceramic reinforcement green body with a certain strength;

[0037] 5) Remove ...

Embodiment 1

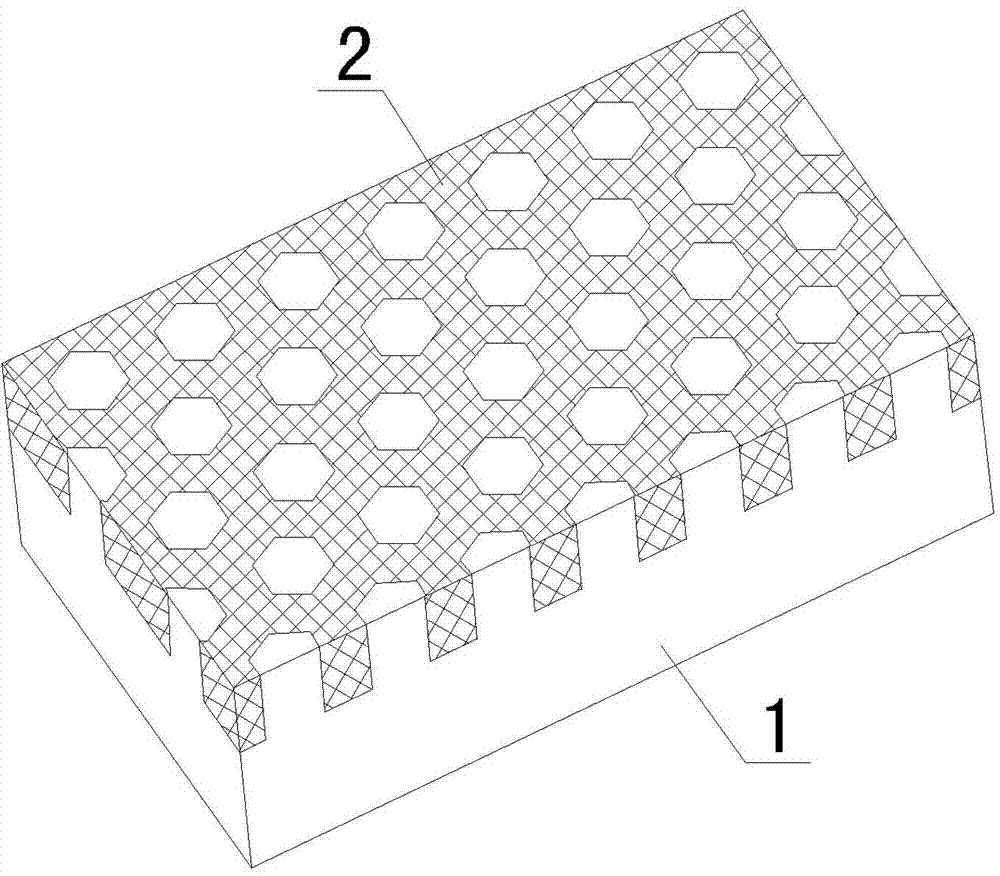

[0042] 1) Determine the wear surface and failure mode of the liner of the ball mill, and design the configuration of the ceramic reinforcement, such as figure 1 As shown, the thickness of the configuration is 40mm, and the configuration is porous (hexagonal honeycomb holes). It is necessary to ensure that the absolute distance from any point in the ceramic reinforcement to the molten metal at the moment of casting is less than 10mm;

[0043] 2) Design and manufacture molds according to the designed ceramic reinforcement configuration;

[0044] 3) Surface nickel-plated ceramic particles with a particle size of 4-7 mm;

[0045] 4) Mix the processed ceramic particles with 2% by weight binder, fill them in the mold, and use warm pressing to make a ceramic reinforcement green body with a certain strength;

[0046] 5) Remove the mold, put it into the atmosphere furnace for degreasing and sintering, and obtain a ceramic reinforcement with three-dimensional multi-scale interconnected...

Embodiment 2

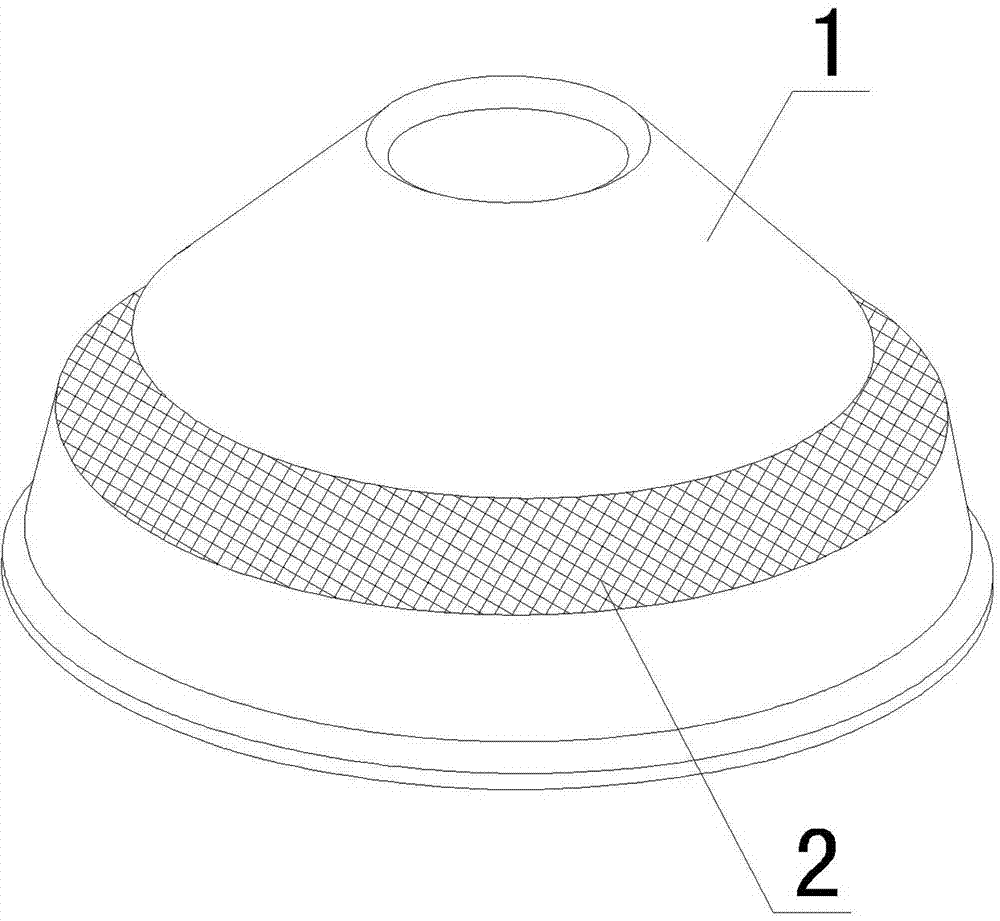

[0051] 1) Determine the wear surface and failure mode under the working condition of the broken wall of the crusher, such as figure 2 As shown, the ceramic reinforcement is designed to be strip-shaped, and the thickness of the configuration is 60mm. It is necessary to ensure that the absolute distance from any point in the ceramic reinforcement to the molten metal at the moment of casting is less than 10mm;

[0052] 2) Design and manufacture molds according to the designed ceramic reinforcement configuration;

[0053] 3) Surface nickel-plated ceramic particles with a particle size of 0.5-3mm;

[0054] 4) Mix the treated ceramic particles with 0.8% by weight of binder, fill them in the mold, and use the method of warm pressing to make a ceramic reinforcement green body with a certain strength;

[0055] 5) Remove the mold, put it into the atmosphere furnace for degreasing and sintering, and obtain a ceramic reinforcement with three-dimensional multi-scale interconnected pores;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com