Method for producing metal and diamond composite body

A manufacturing method and diamond technology, applied in metal rolling, manufacturing tools, metal processing equipment, etc., can solve problems such as low density, particle surface layer oxidation, and composite quality that cannot meet the requirements, so as to improve product quality and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

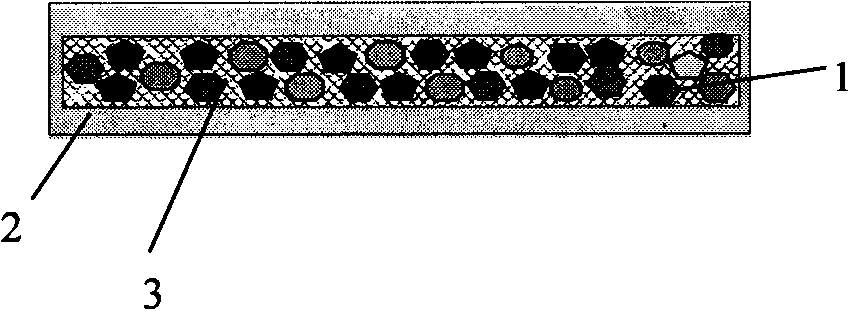

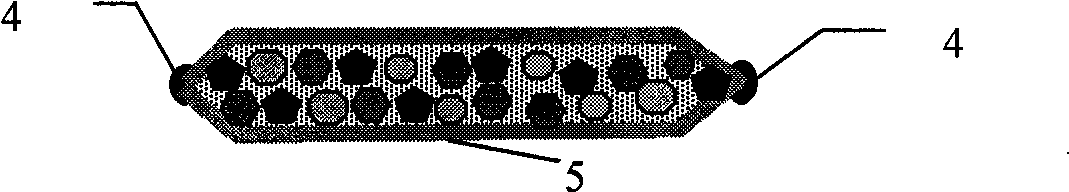

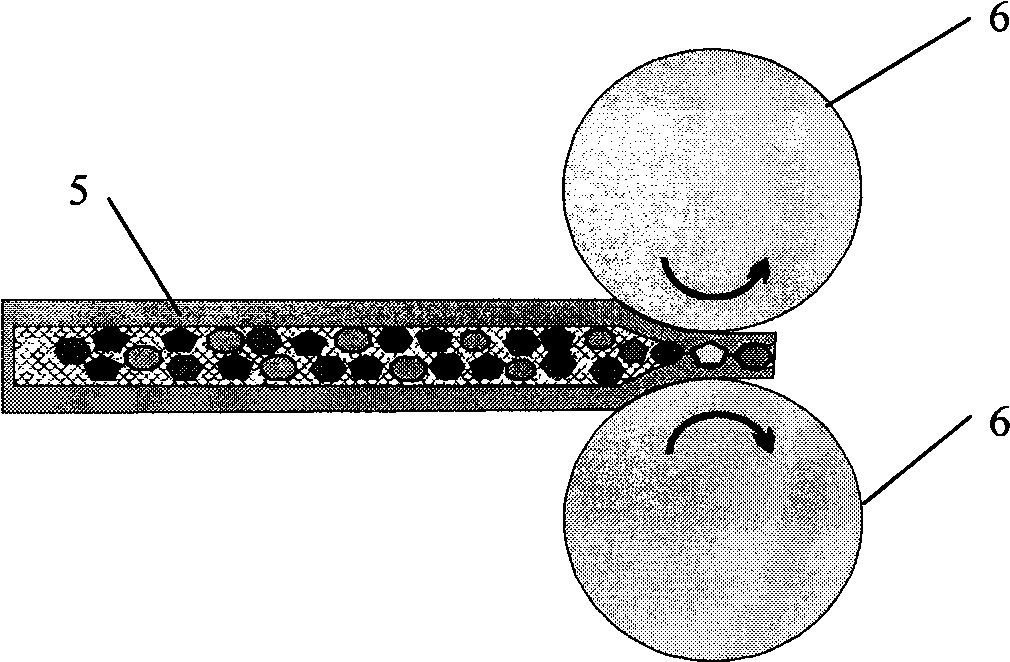

[0024] (1) Take a section of copper tube with a wall thickness of 1 mm and an inner diameter of 6 mm; (2) Flatten it on a press to leave a cavity of 2 to 3 mm; (3) The inner wall of the tube is washed with alkali, pickled and soaked in acetone to remove oil , rust and attachments, dry for later use; (4) fill the calculated amount of diamond with a particle size of 0.3mm and metal powder for brazing into the cavity of the flattened copper tube, and the metal for brazing The volume of the powder is 8% of the complex, and the composition is (Wt.%) 20% Sn+80% Cu. The calculated amount is estimated that the volume occupied by diamond in the composite body after rolling is 40%; (5) after shaking, one end is pressed and placed at the stick gap of the two-roll rolling mill, and rolled at a speed of 0.2m / min; (6 ) after each pass to measure the thickness; (7) rolling after three passes to obtain a composite body of 0.4 mm, and no diamond exposed on the surface. (8) Then the obtained c...

Embodiment 2

[0026] (1) get 08F steel plate, thickness 1.2mm, wide 10mm, according to embodiment 1 (1), (3) step process, by (4) same diamond and metal powder are evenly distributed on the steel plate, get another same steel plate Overlay on it, process by (5), (6), (7), (8) step in embodiment 1, the composite body that obtains is wide 11.5mm, thickness 0.48mm, after grinding off flashing, width is 9.6mm, The hardness is HRB106.

[0027] The method of the present invention can also carry out multi-layer composite rolling after softening annealing and surface treatment of the monolithic composite body obtained after rolling, so as to obtain a multi-layer composite body. This method abandons the shortcomings of the traditional method, greatly reduces the metal cost, improves the production efficiency, simplifies the manufacturing process of the diamond-metal composite, improves the quality of the product, and its economic and social benefits are very significant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com