Excavation and construction method of underground cavity ball coronary dome

A construction method and underground cavern technology, which is applied in underground caverns, earthwork drilling, wellbore lining, etc., can solve the problems of lack of engineering precedents, and achieve the effects of convenient and accurate work, high construction efficiency, and increased construction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

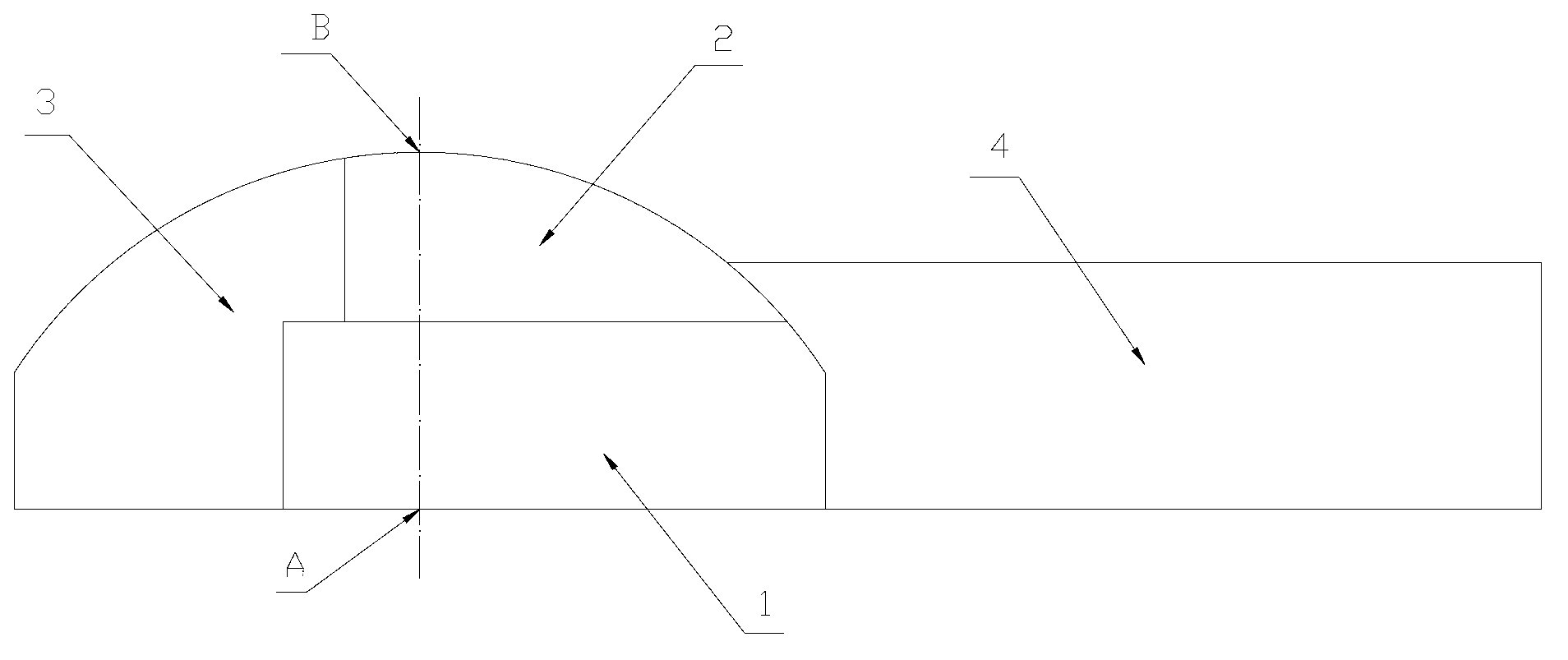

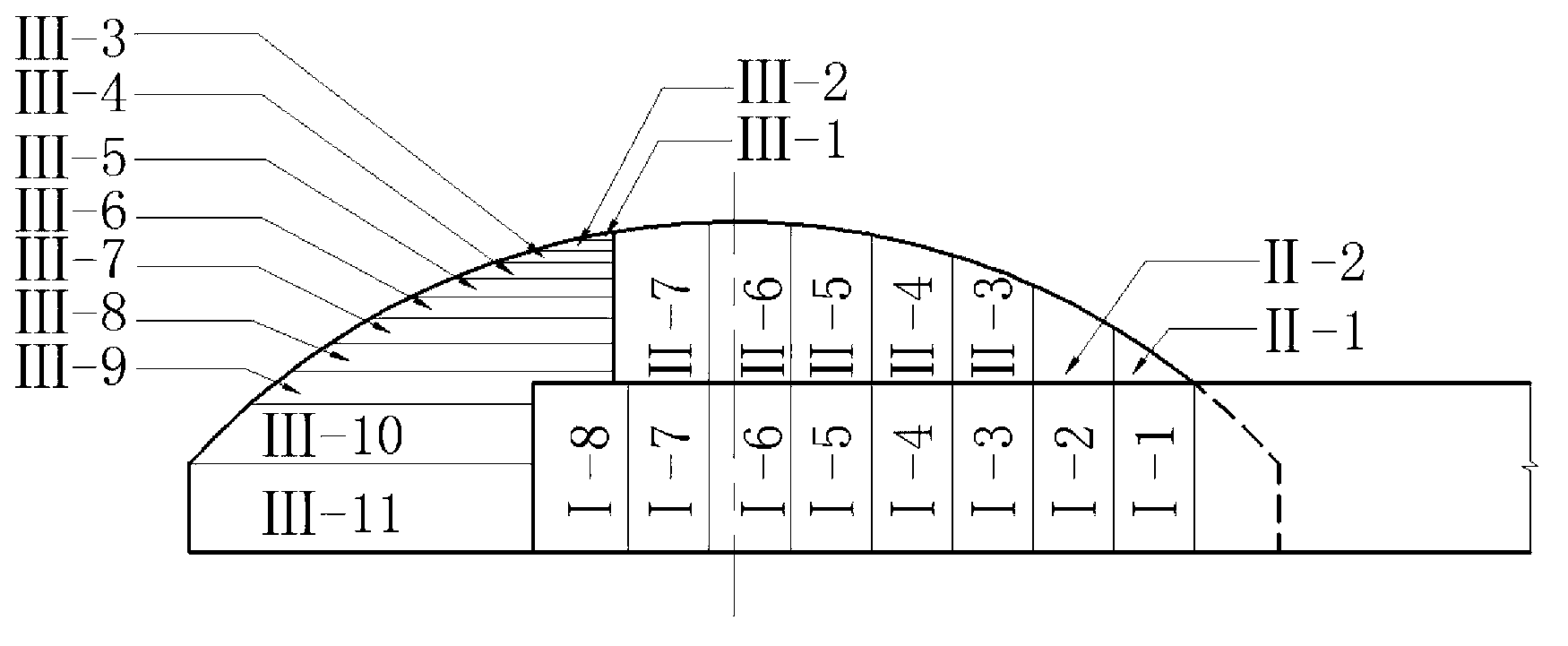

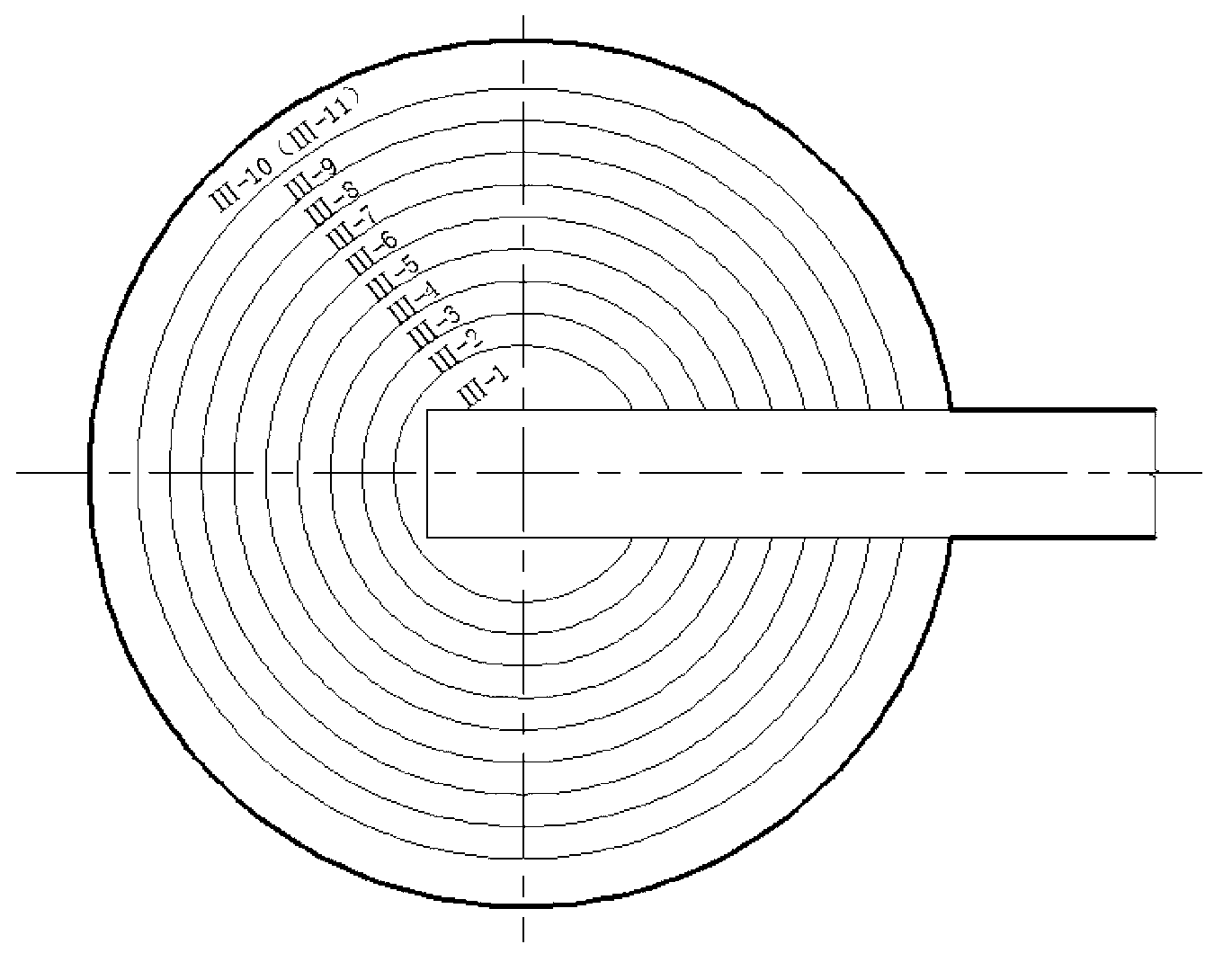

[0022] Such as Figure 1-3 Shown, be 27.5m with transverse span, height is the underground cavern spherical crown dome of 8.3m as an example and introduces the excavation construction method of underground cavern spherical crown dome provided by the present invention, is provided with a width and is 3.9m, and height is A 4.3m channel is connected to it. The surrounding rock has well-developed joints and faults, and the faults are rich in groundwater. The integrity of the surrounding rock is poor, and the construction risk is high. In order to solve the difficult problem of excavation construction of the spherical crown dome under poor geological conditions, the excavation construction method provided by the present invention is adopted.

[0023] (1) Construction of channel 4, providing access for construction personnel, materials and machinery to enter and exit.

[0024] (2) The excavation construction of part 1 of the dome uses plain sprayed concrete as the initial support....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com