Patents

Literature

58results about How to "Surrounding rock stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double-medium decoupling fracture damage blasting control method and auget

InactiveCN101363701AHighlight substantive featuresHigh static pressure resultant forceBlasting cartridgesBlastingEngineeringExplosive power

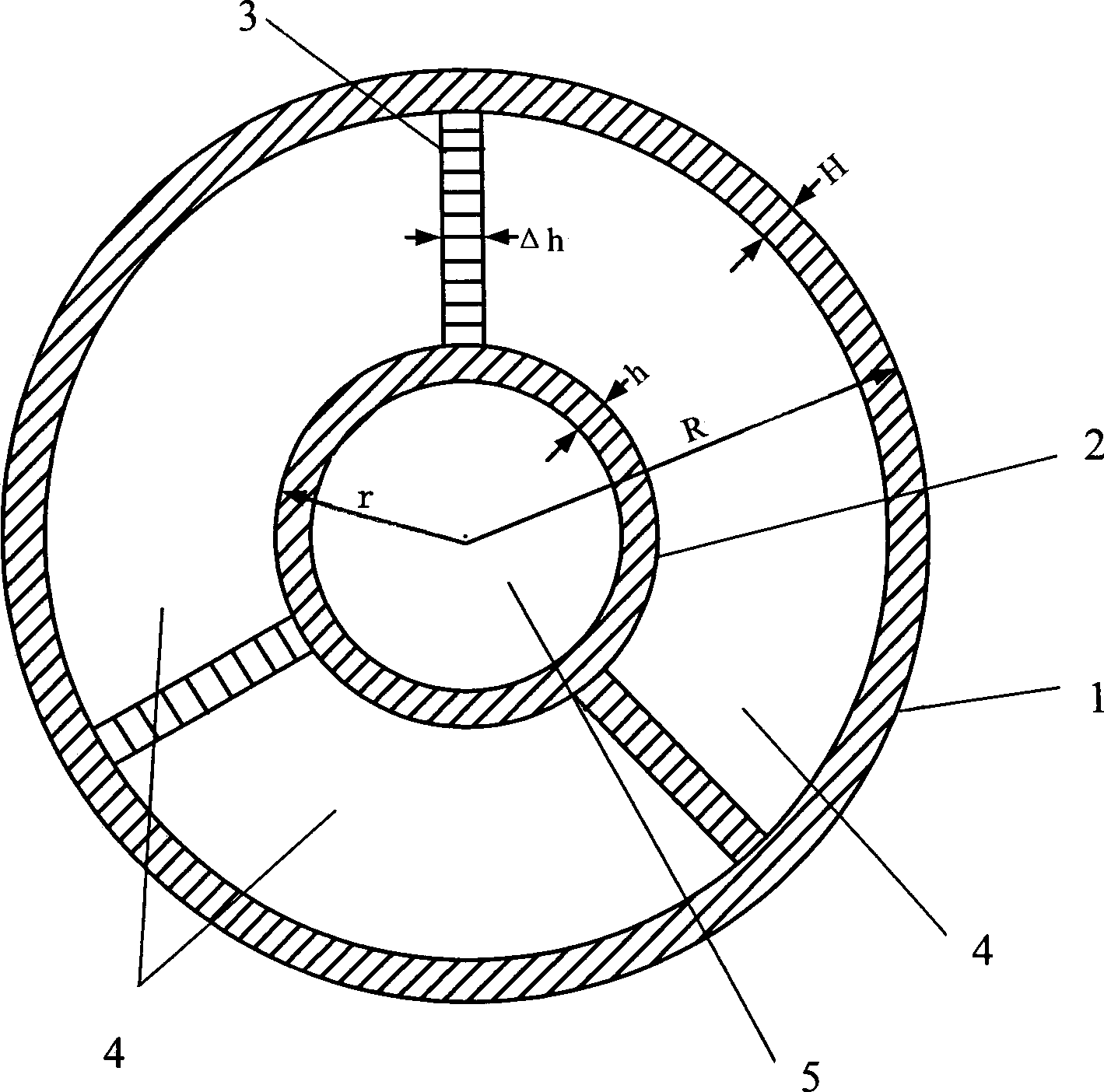

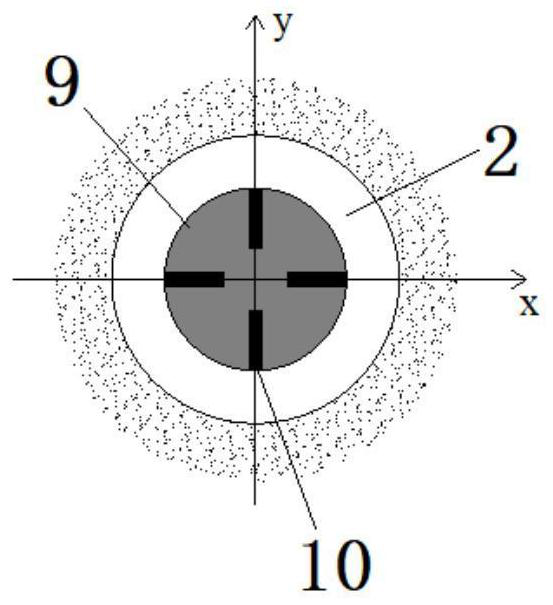

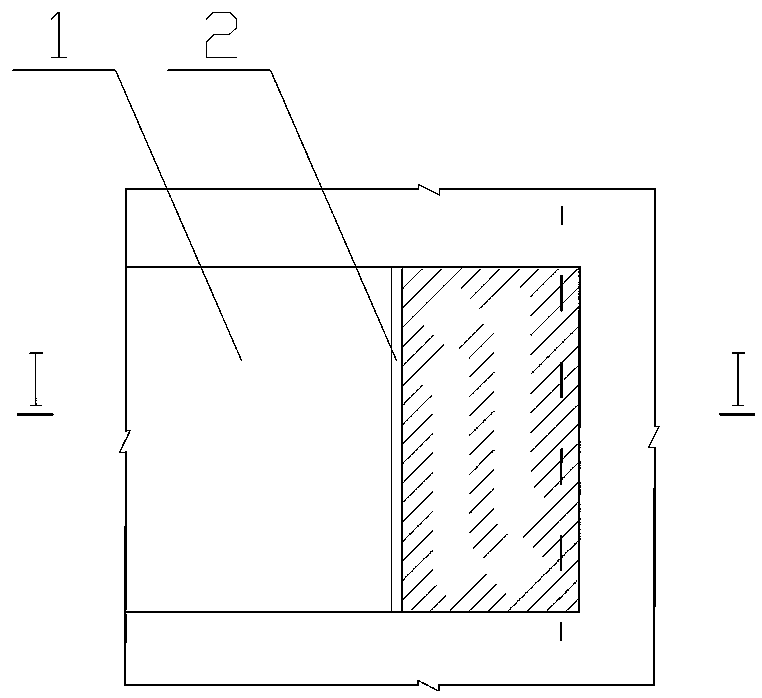

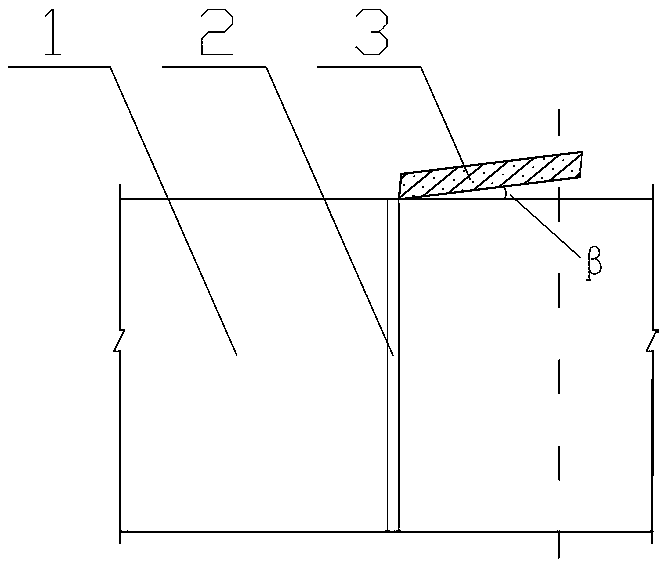

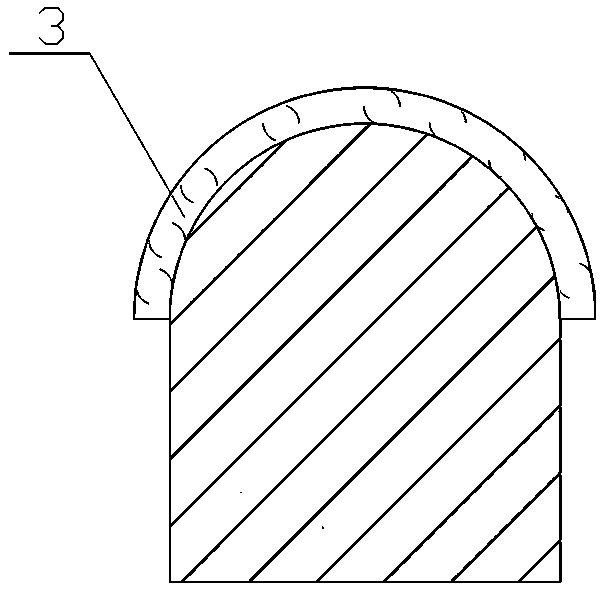

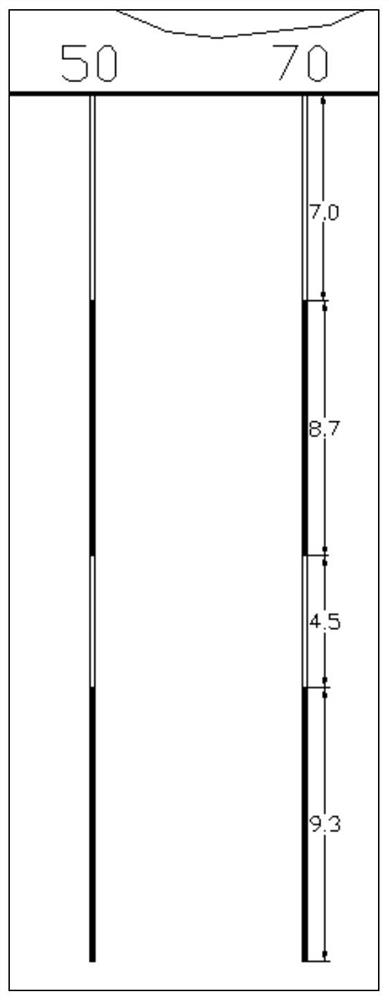

The invention relates to a method for controlling blasting by double-medium decoupling fracture and damage and a blasting cartridge thereof. The method adopts cylindrical explosive, detonator or primacord to explode a hole on a blasted rock body. The method is characterized in that water and air are simultaneously used in the hole to separate explosive, wherein, the water medium is aligned to the side of a free surface, while the air medium is aligned to the side of a reserved surface; the uniform distributing state of explosive energy can be changed by using the characteristics that the two media have different efficiencies of transmitting energy, thereby achieving the function of completely destroying one side and protecting the reserved surface during blasting, and forming a flat fracture surface. The blasting cartridge consists of an outer tube, an inner tube and a separating wall, wherein, the separating wall separates a cavity formed between the outer tube and the inner tube into a medium chamber for containing the water medium and a medium chamber for containing the air medium; and an explosive chamber for placing the cylindrical explosive is arranged in the inner tube. The invention has the advantages of easily operating, improving explosive power and agglomerating rate, protecting stability of wall rock, reducing harm of dust and noise, and the like, and can be widely applied to smooth blasting projects such as tunnels, side slopes, water conservancies, mining, and the like.

Owner:TAIYUAN UNIV OF TECH

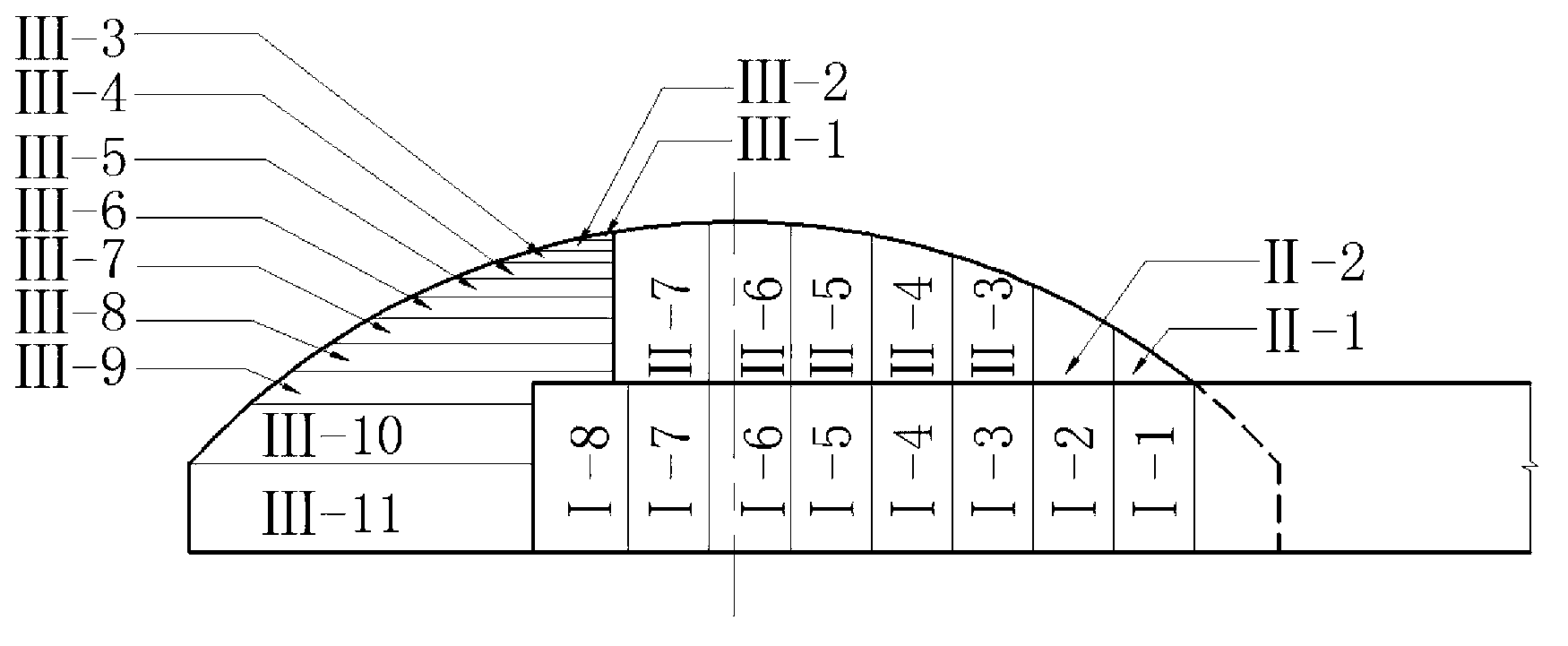

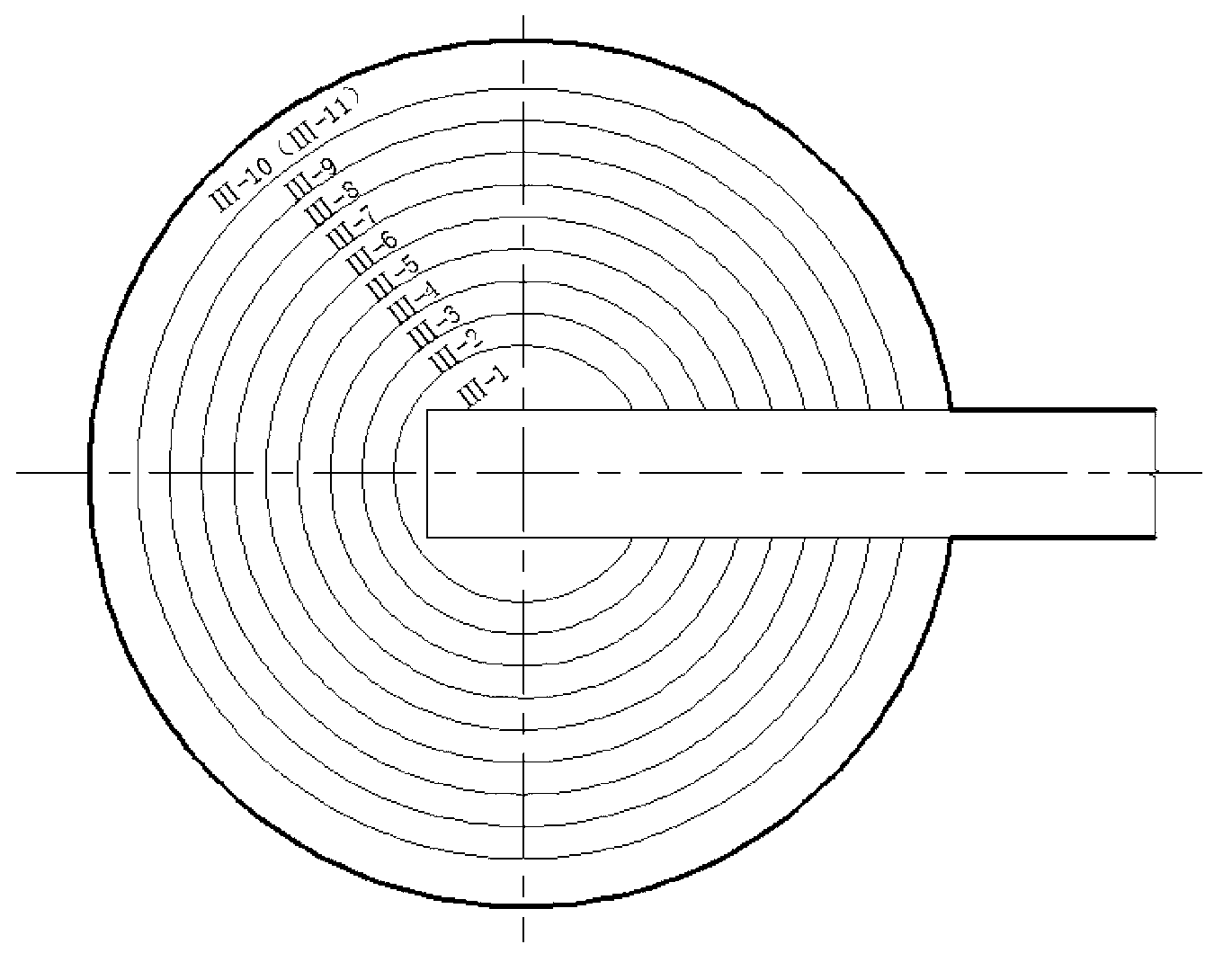

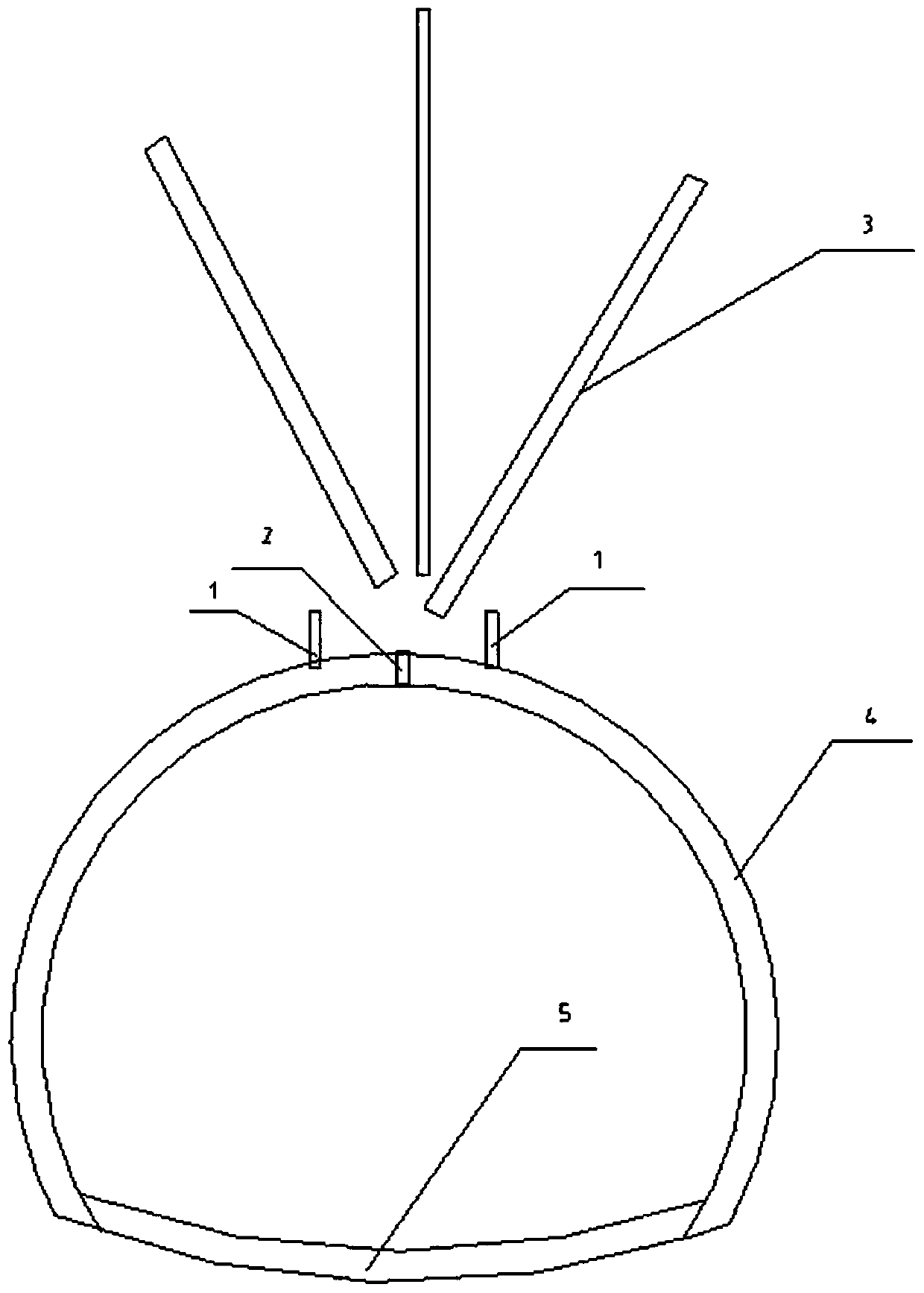

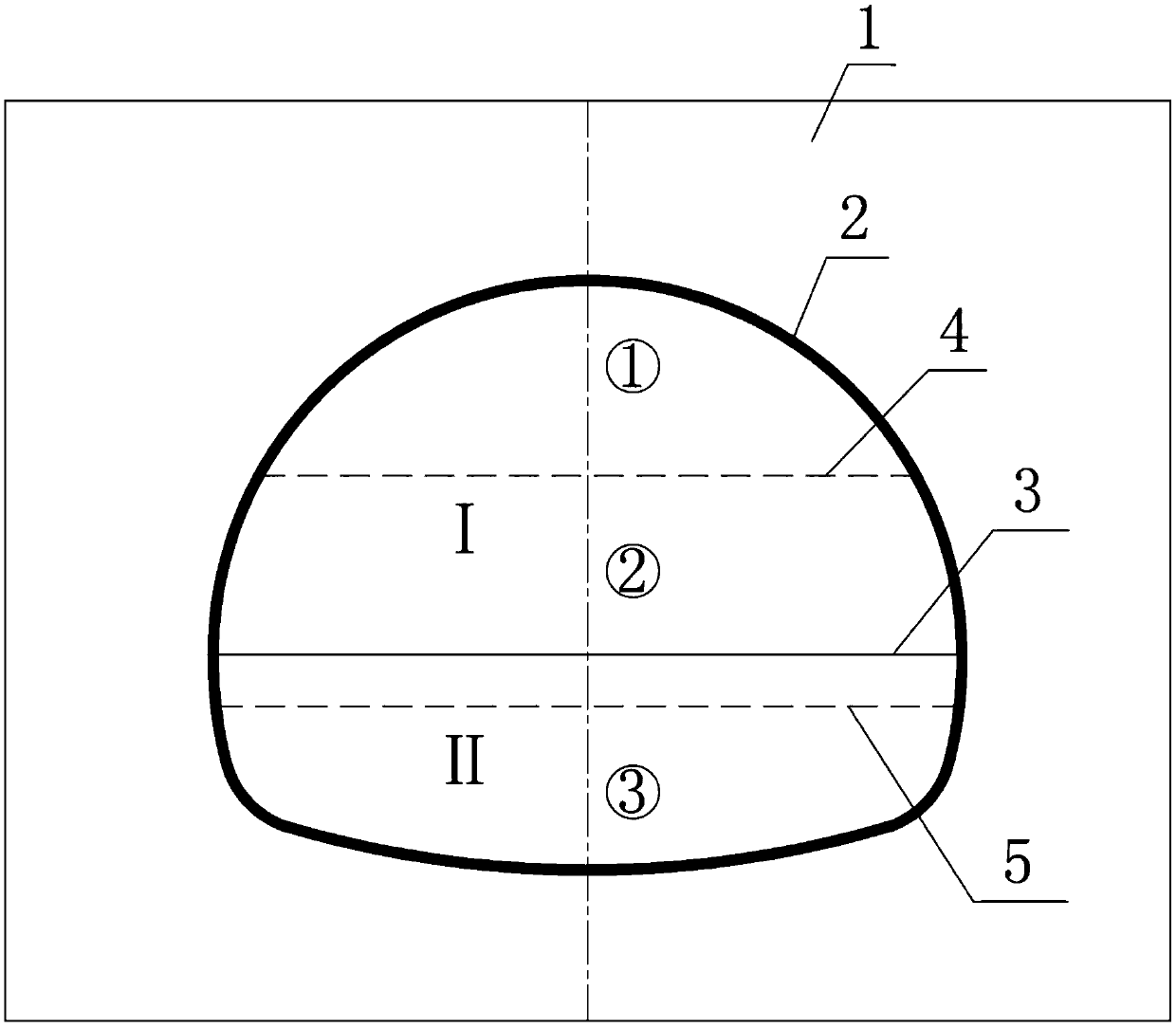

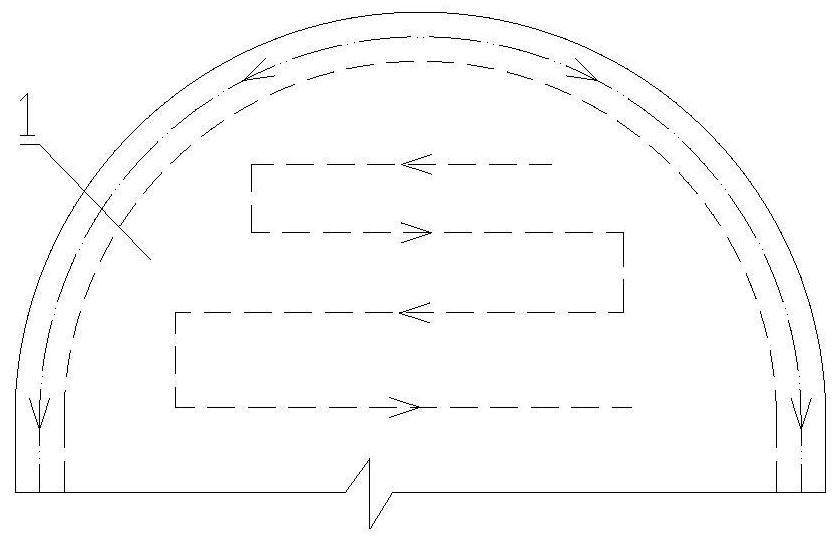

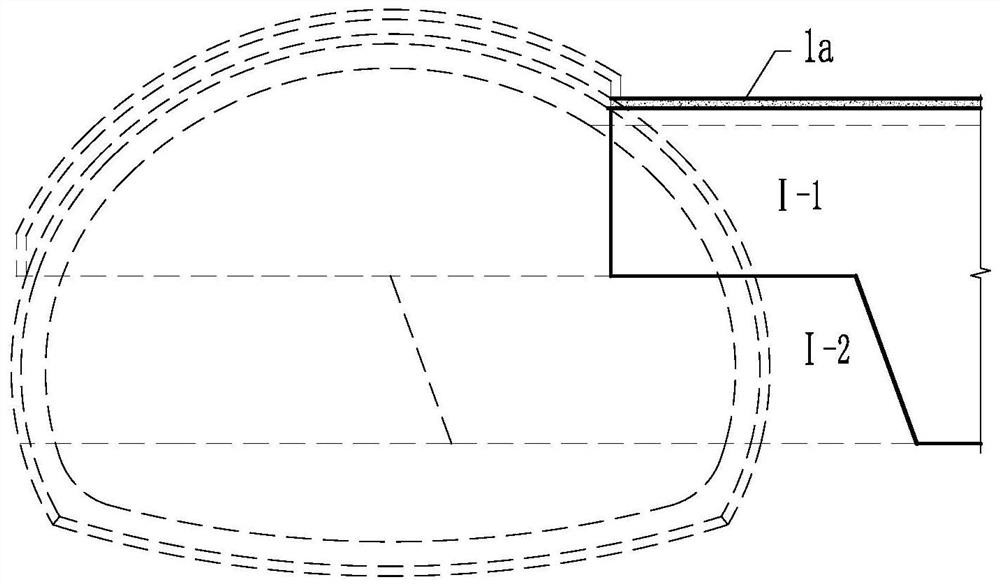

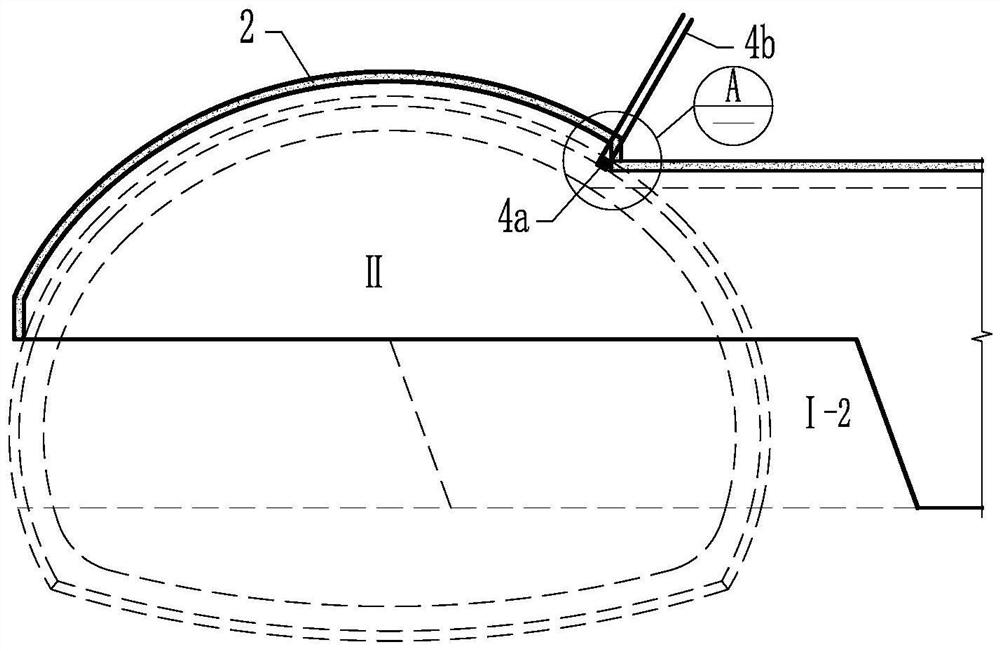

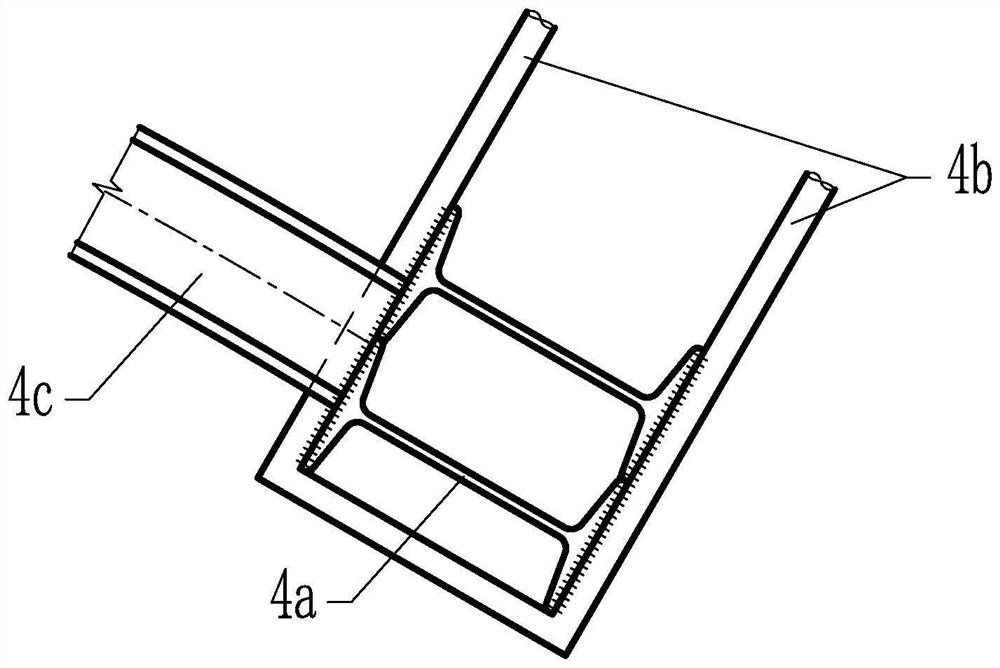

Excavation and construction method of underground cavity ball coronary dome

ActiveCN103256053AEnsure surrounding rock stabilityEasy and accurate workUnderground chambersTunnel liningPart iiiWire rope

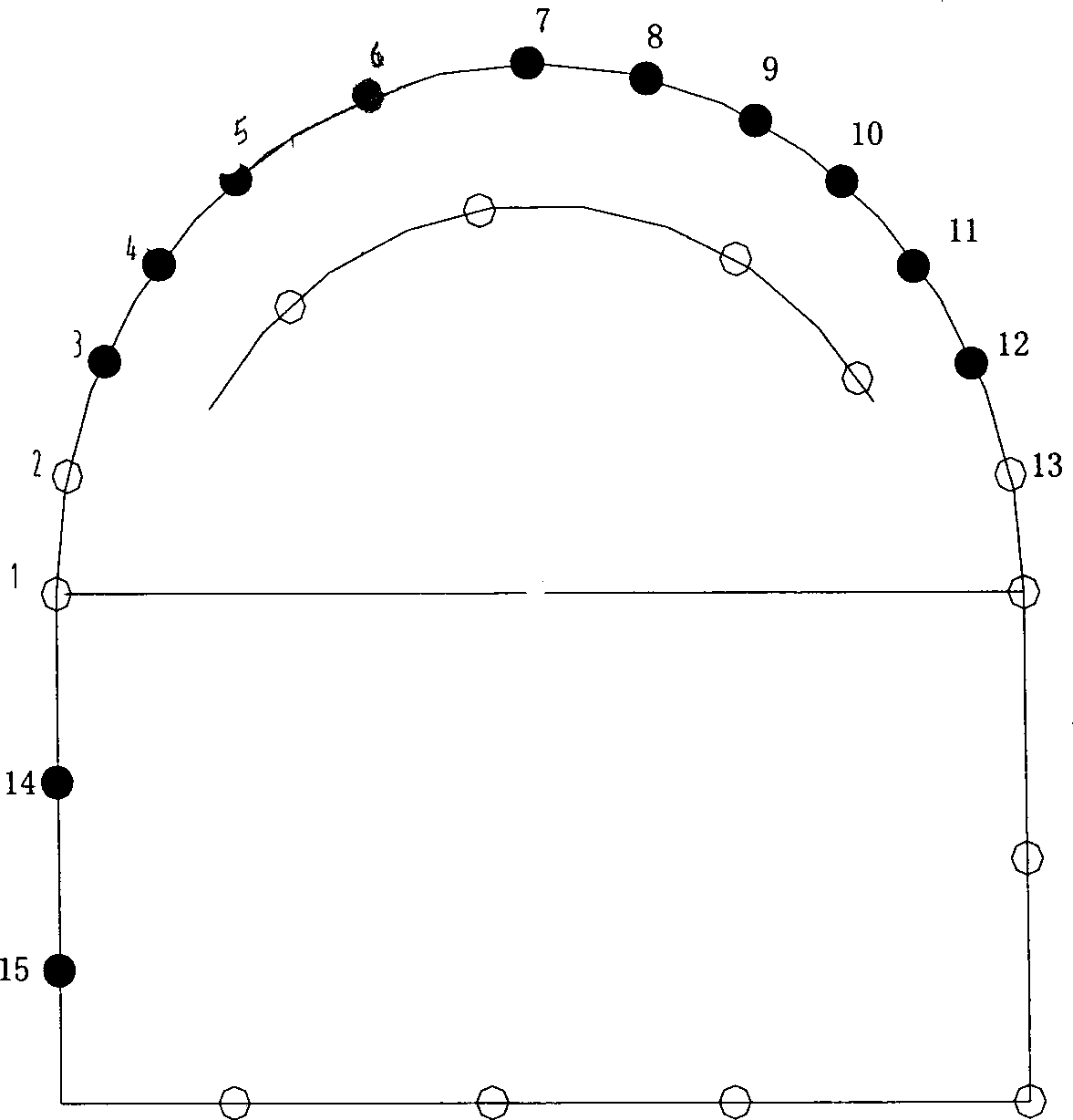

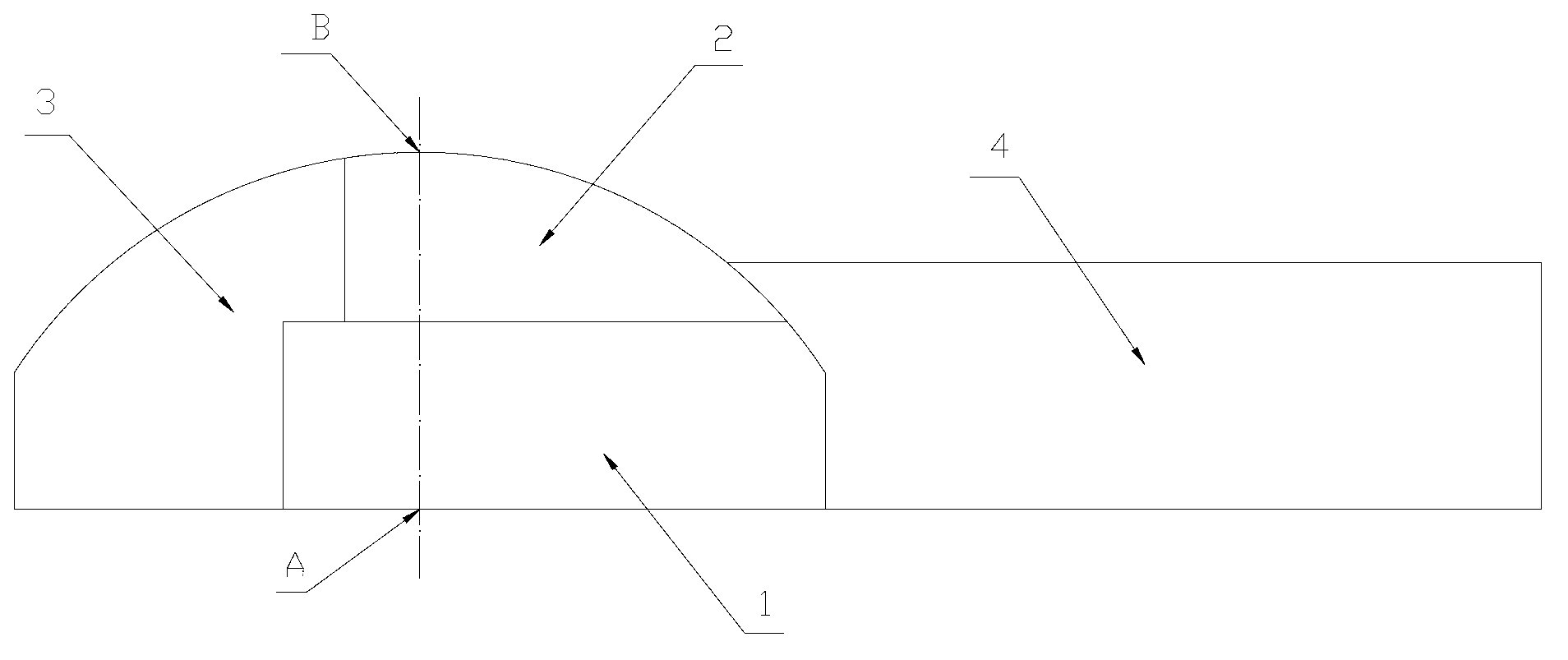

The invention relates to an excavation and construction method of an underground cavity ball coronary dome. The excavation and construction method includes the following steps: S1, a channel is constructed; S2, a dome part I is excavated, primary support is conducted on the dome part I, S3, a dome part II is excavated, primary support is conducted on the dome part II, S4, a dome part III is excavated, a steel wire rope which is connected with the central point of the bottom of the dome and the central point of the top of the dome is used as a center, the vertical layered construction height marked on the steel wire rope is used as a control height, and the dome part III is constructed in a layering and loop mode from top to bottom. Each layer is excavated in a segmentation mode, and the primary support is conducted on each segment. The excavation and construction method of the underground cavity ball coronary dome has the advantages that geology is ascertained through an advance pilot tunnel, therefore, reinforcing supporting measures can be made in advance, and the stability of surrounding rock is guaranteed. An annular excavation method in which a dome central line is used as a standard from top to bottom is adopted, the line type control of a fracture surface is benefited, the construction space is enlarged, mechanical operation is convenient, and construction efficiency is high.

Owner:THE 4TH ENG CO LTD OF CHINA RAILWAY 16TH BUREAU GRP CO LTD

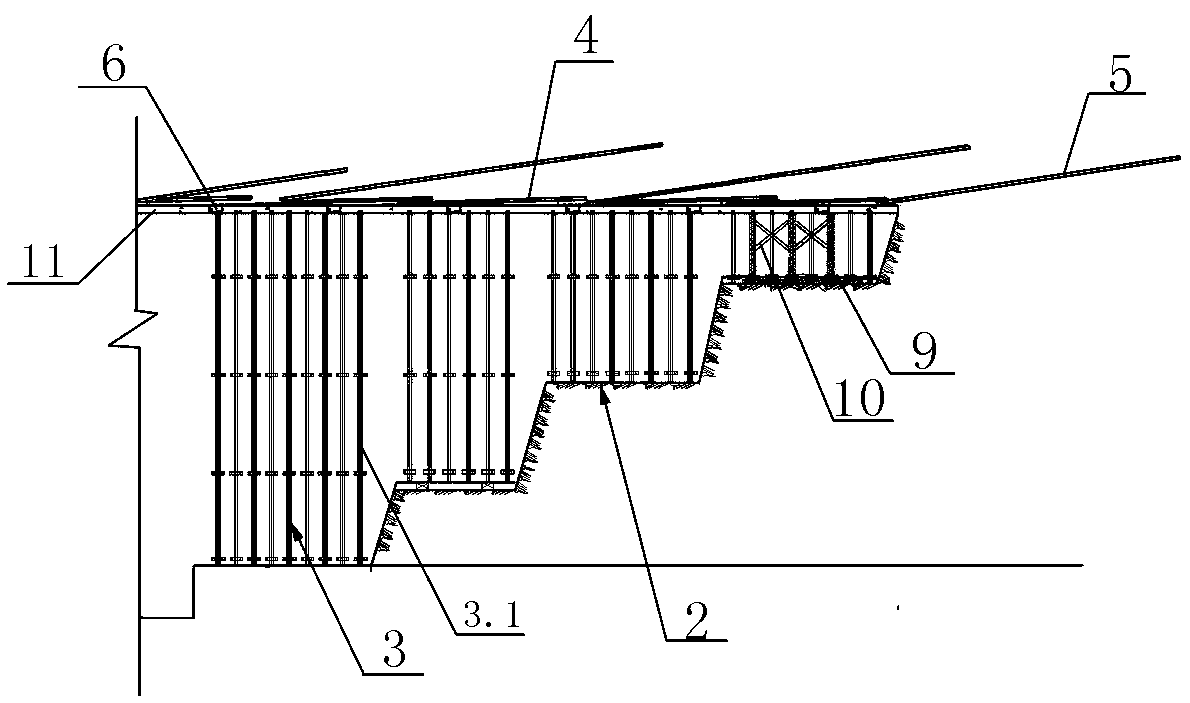

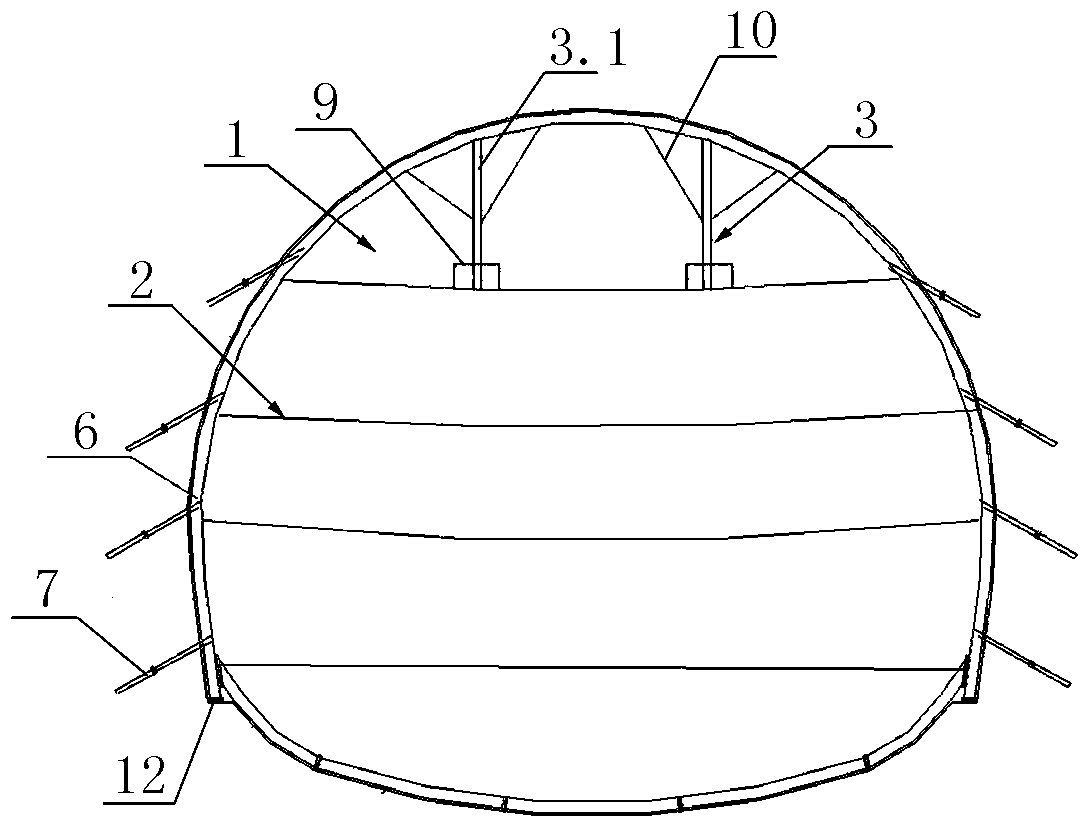

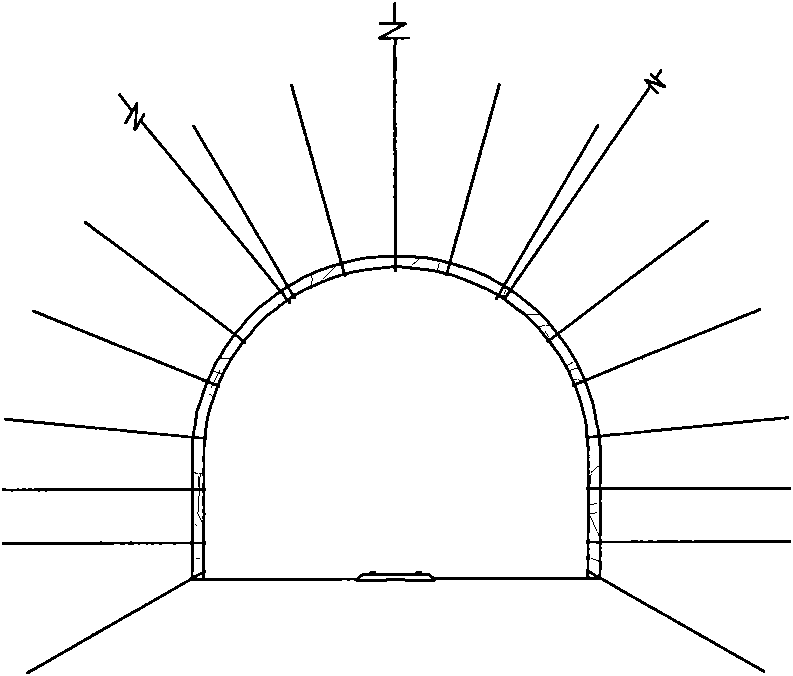

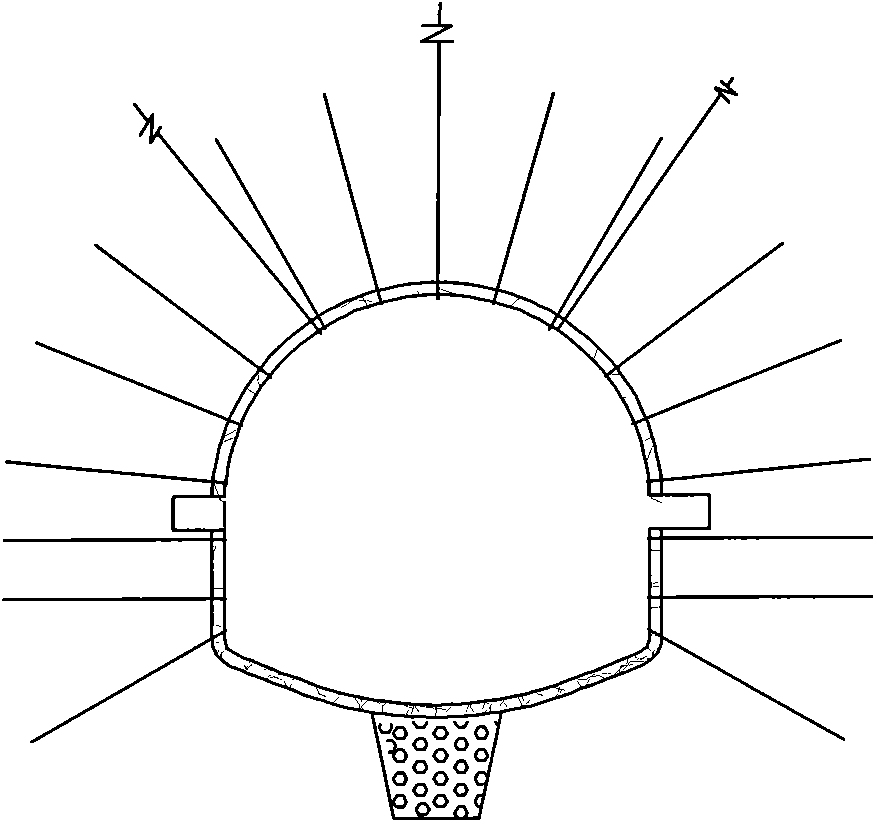

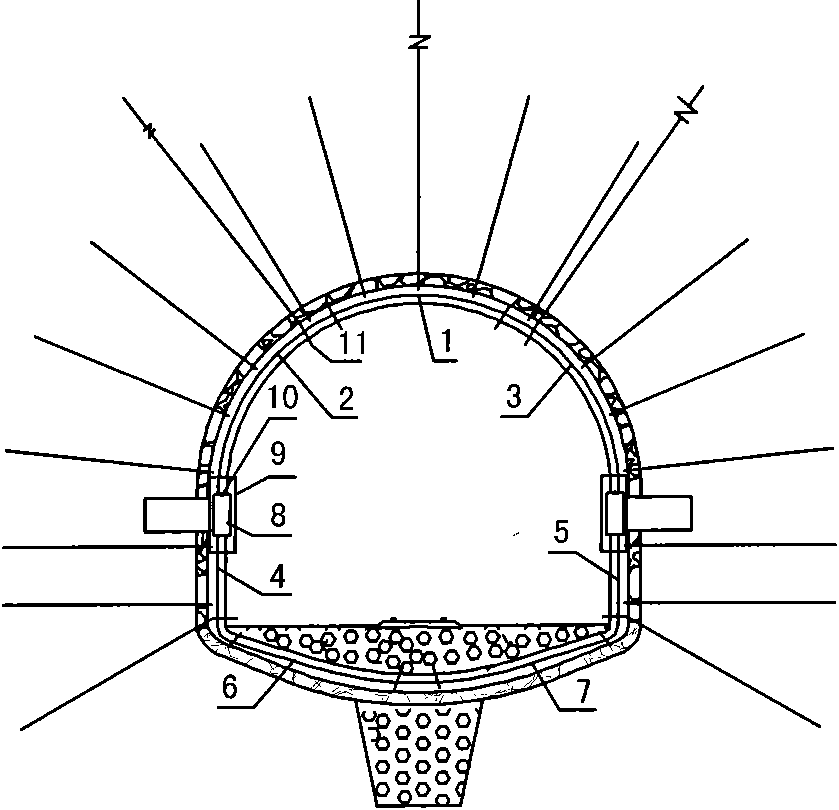

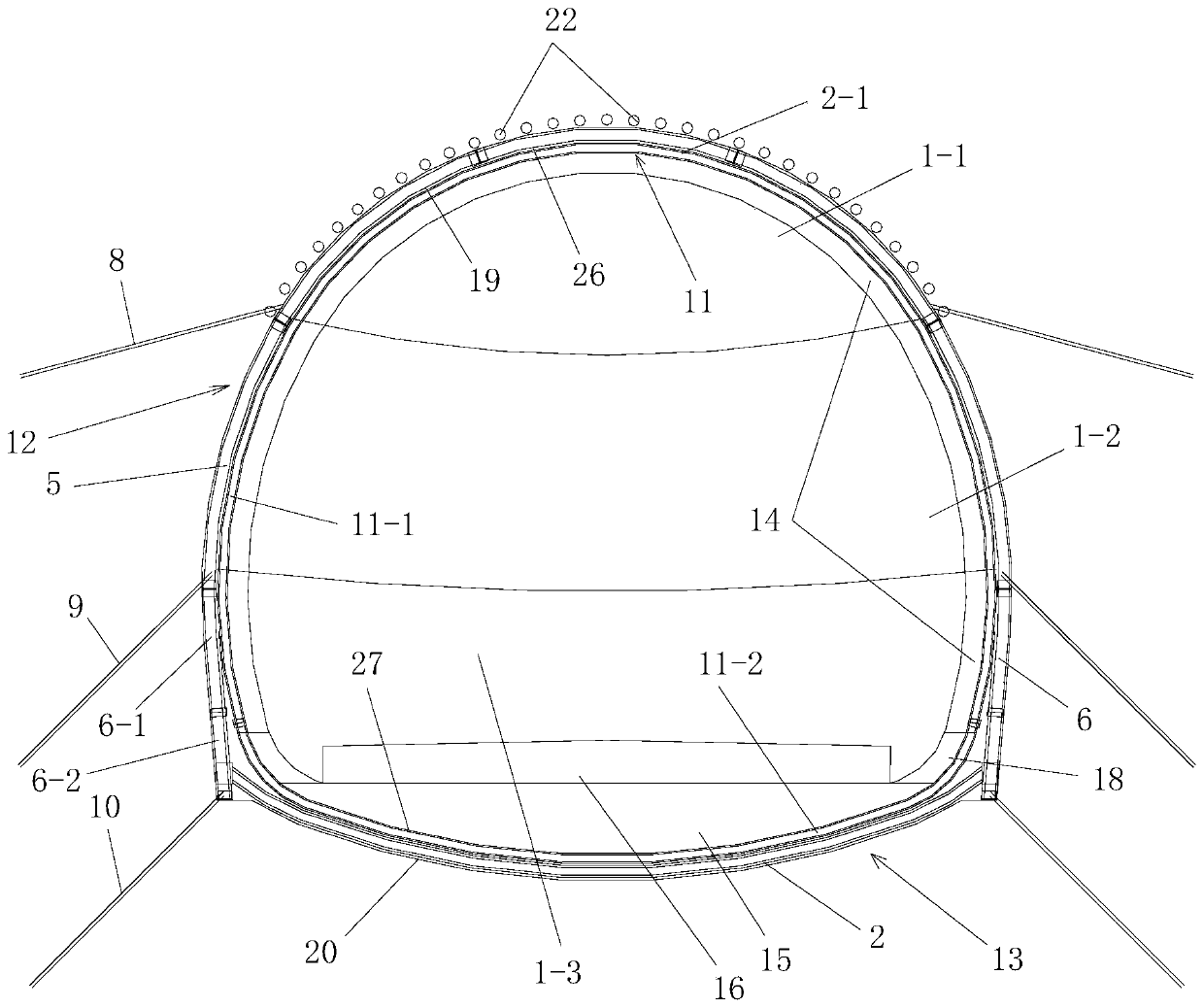

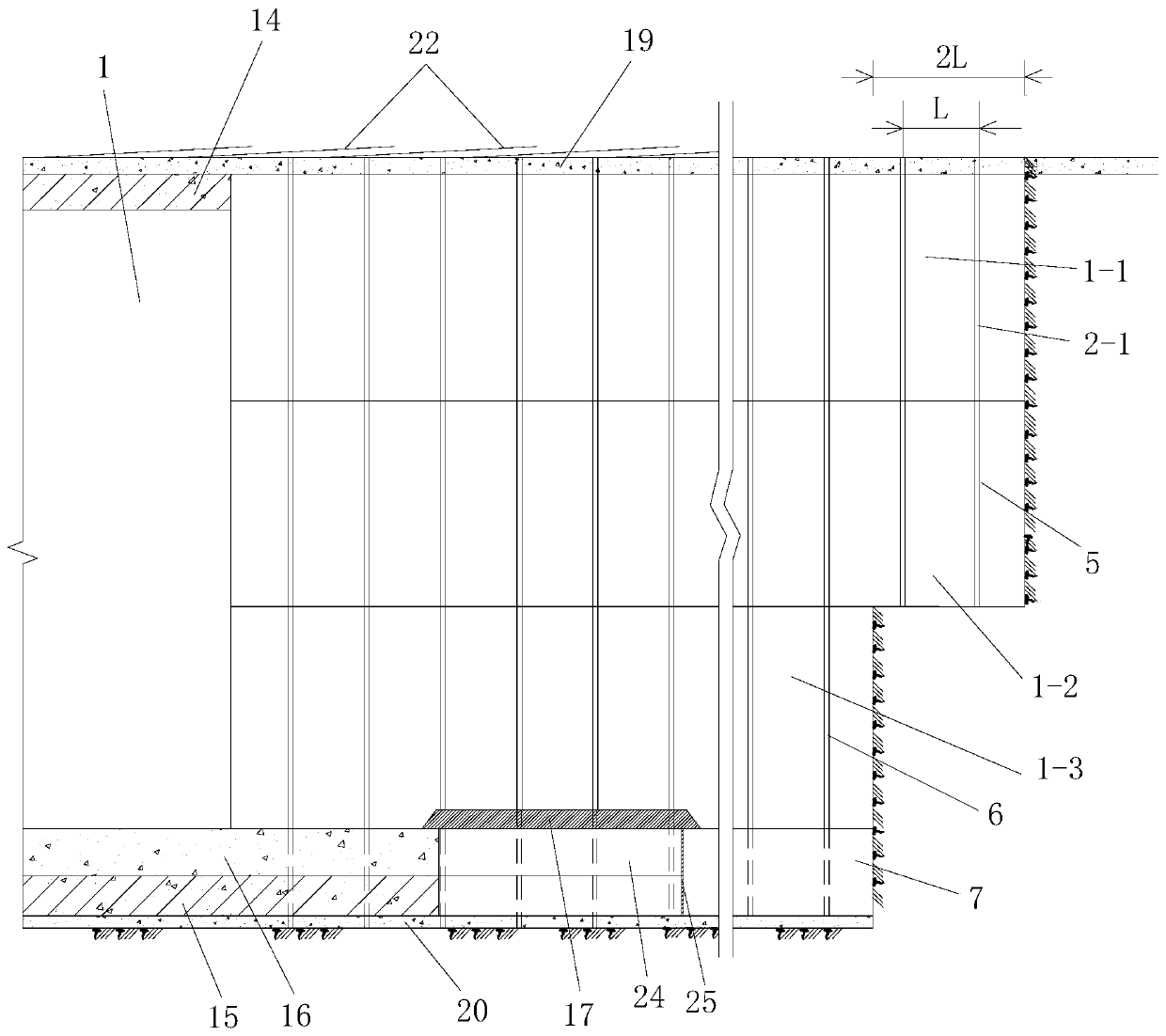

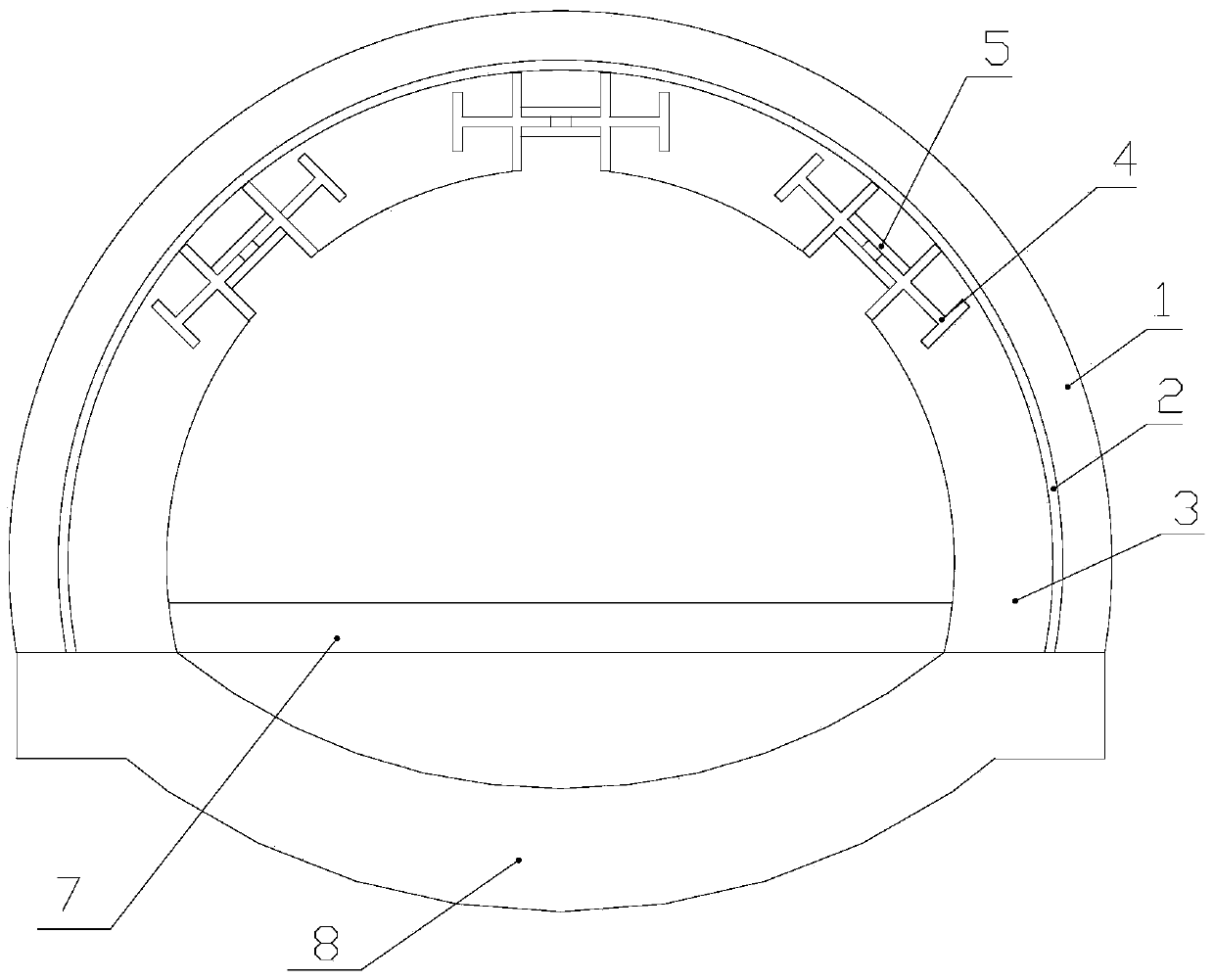

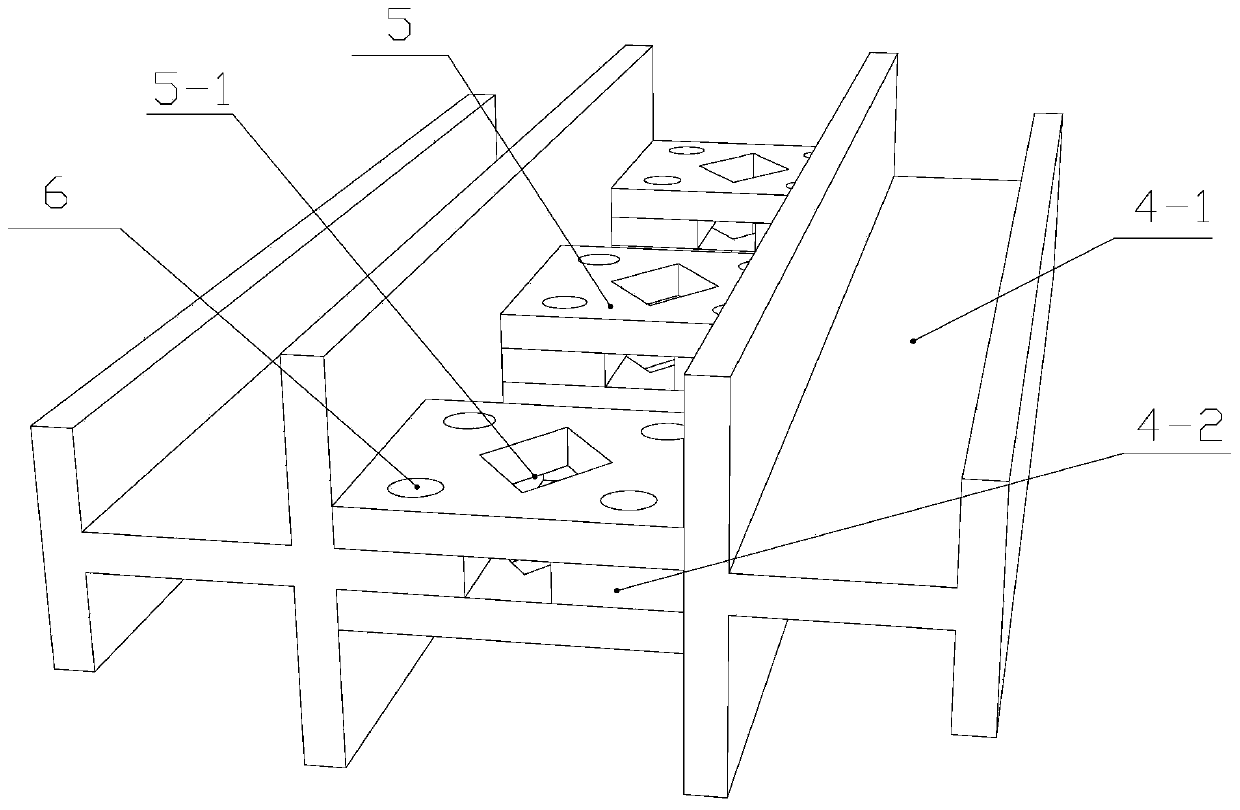

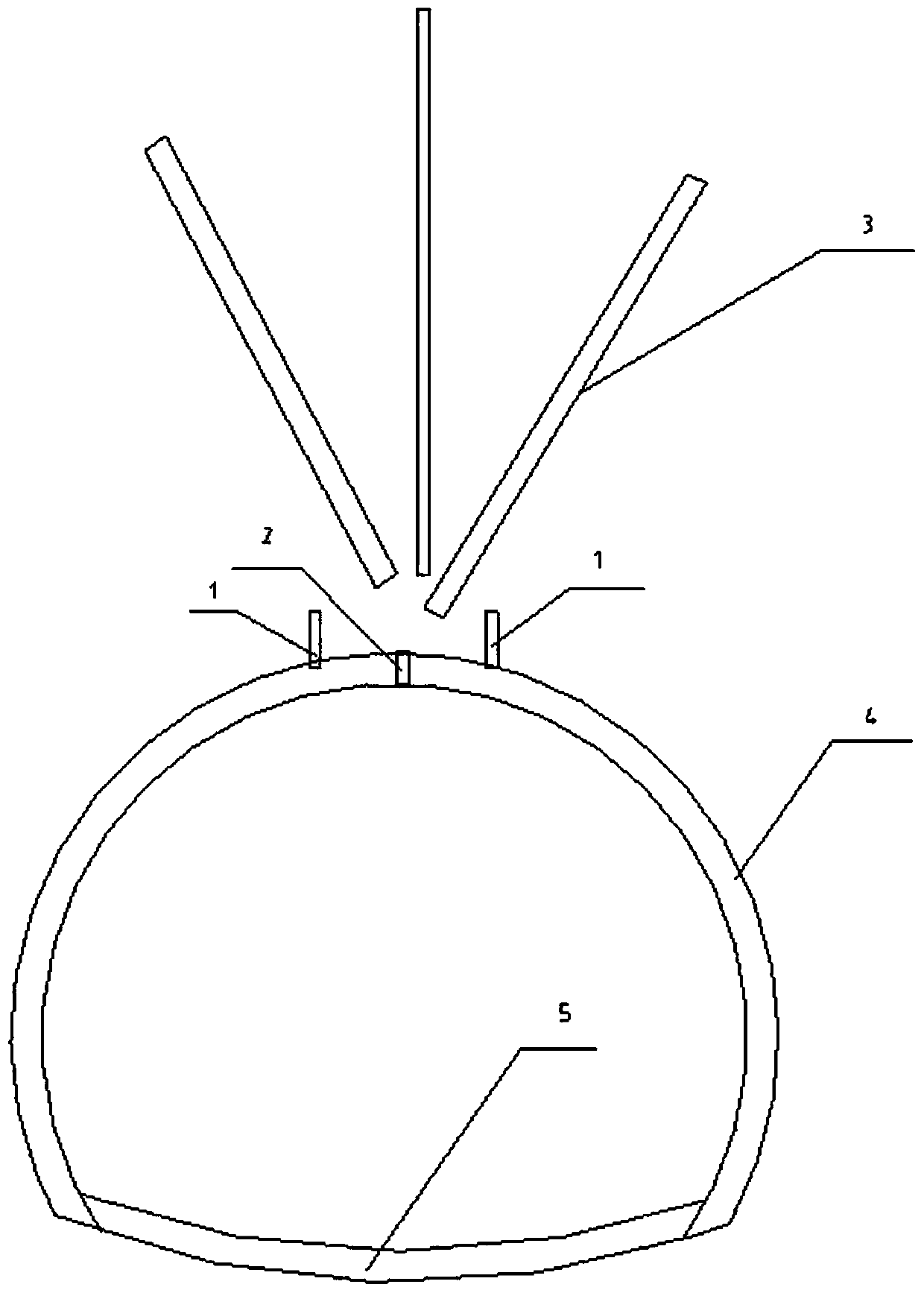

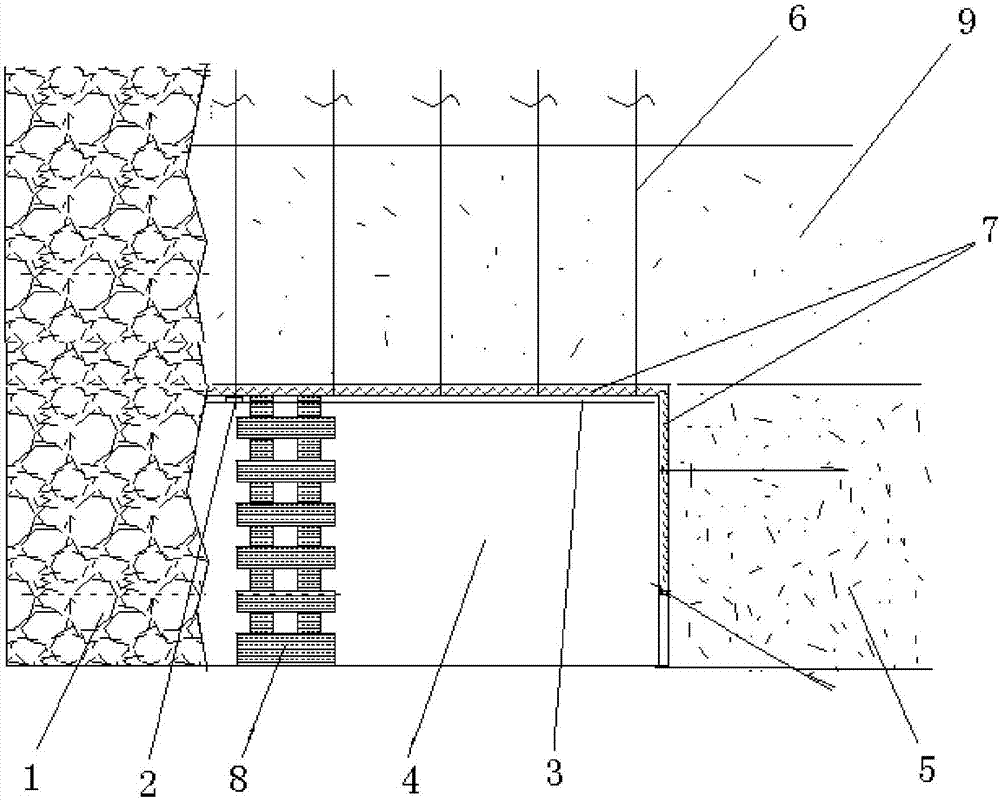

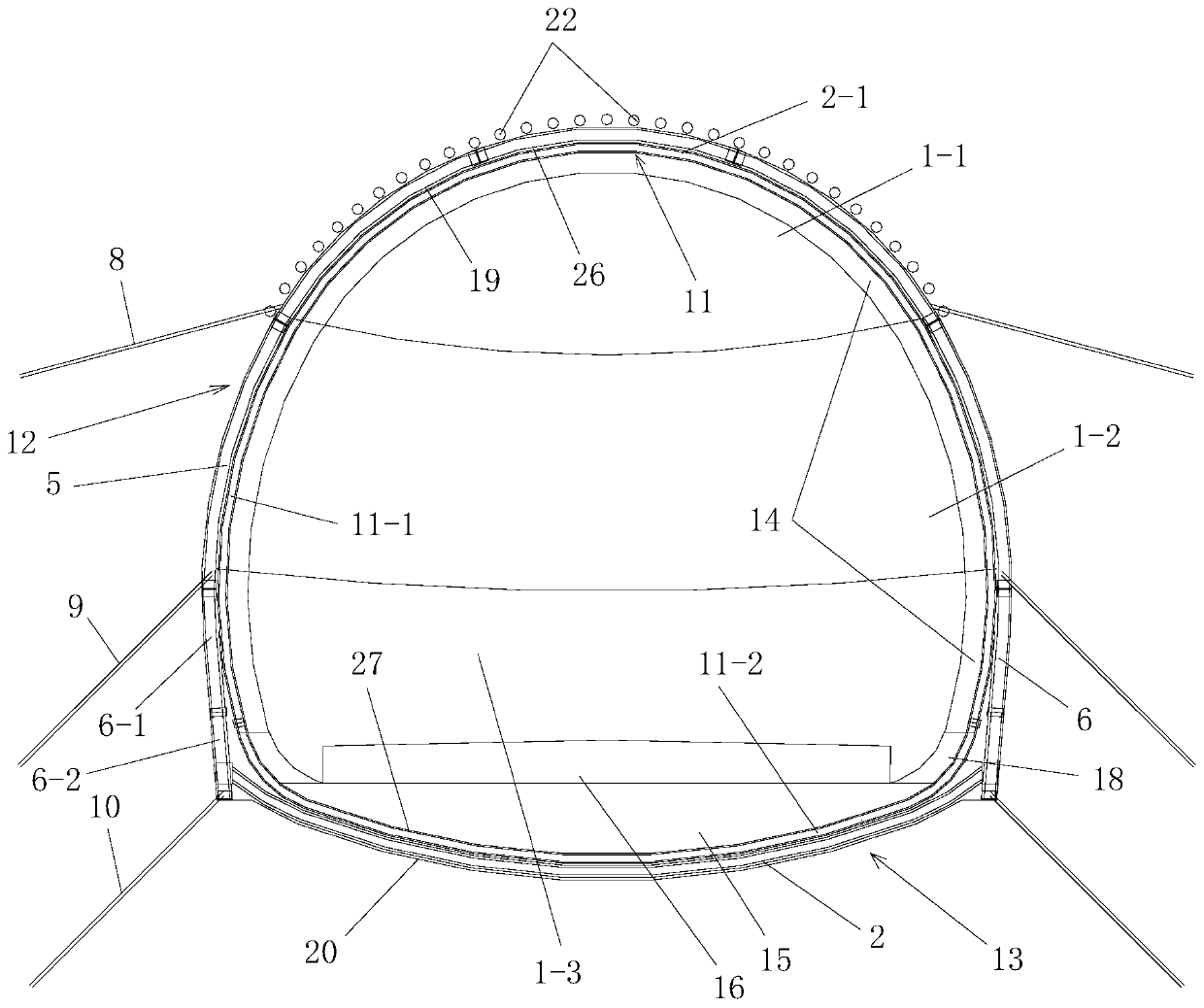

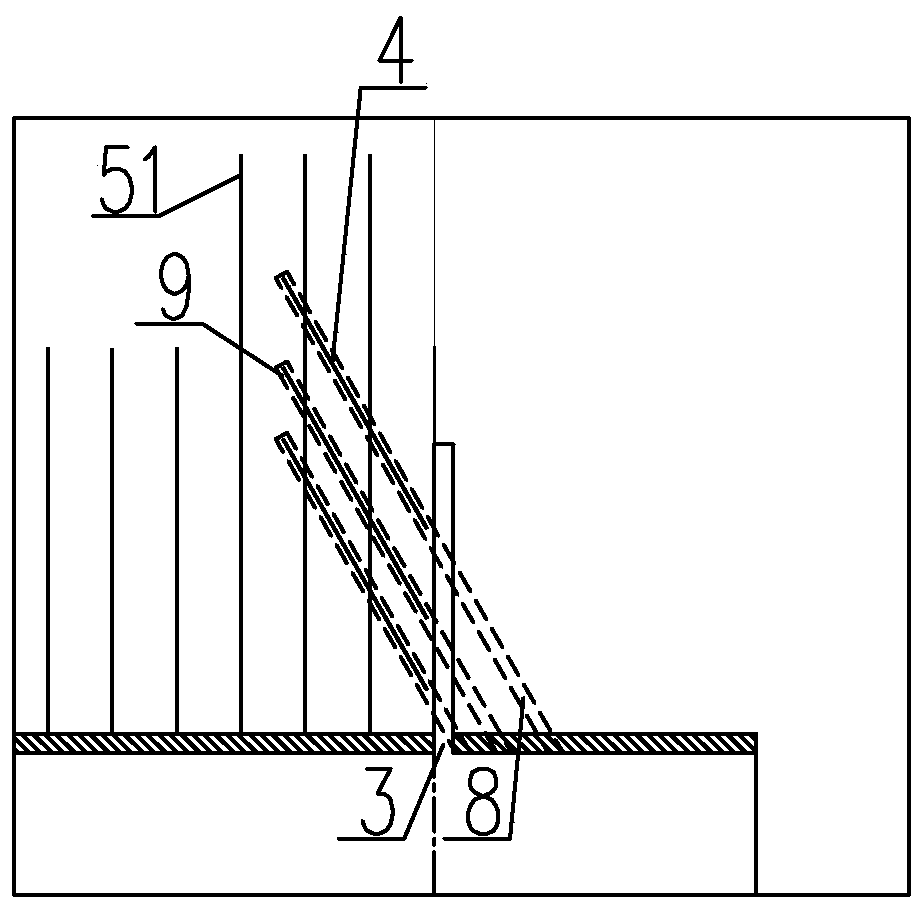

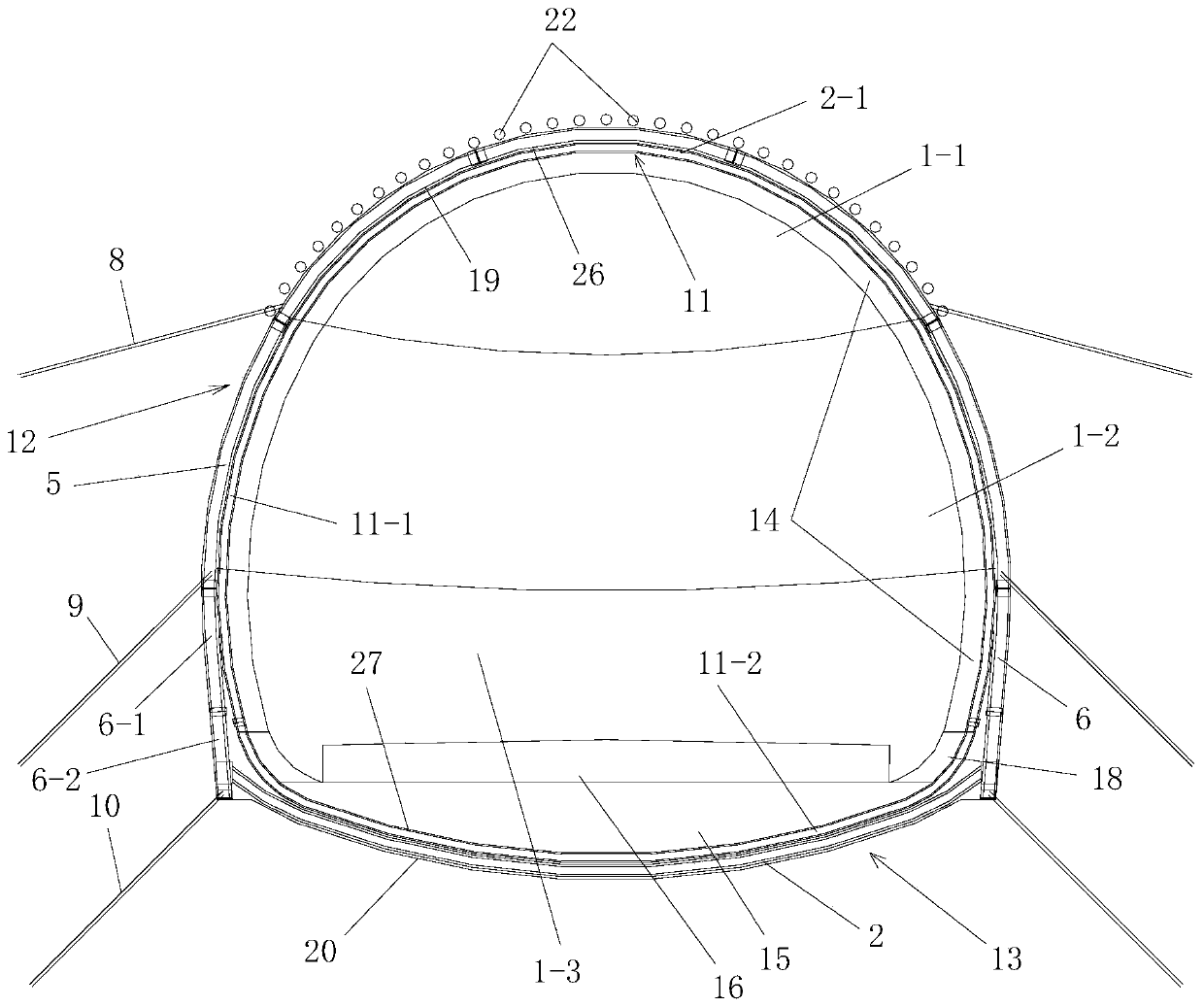

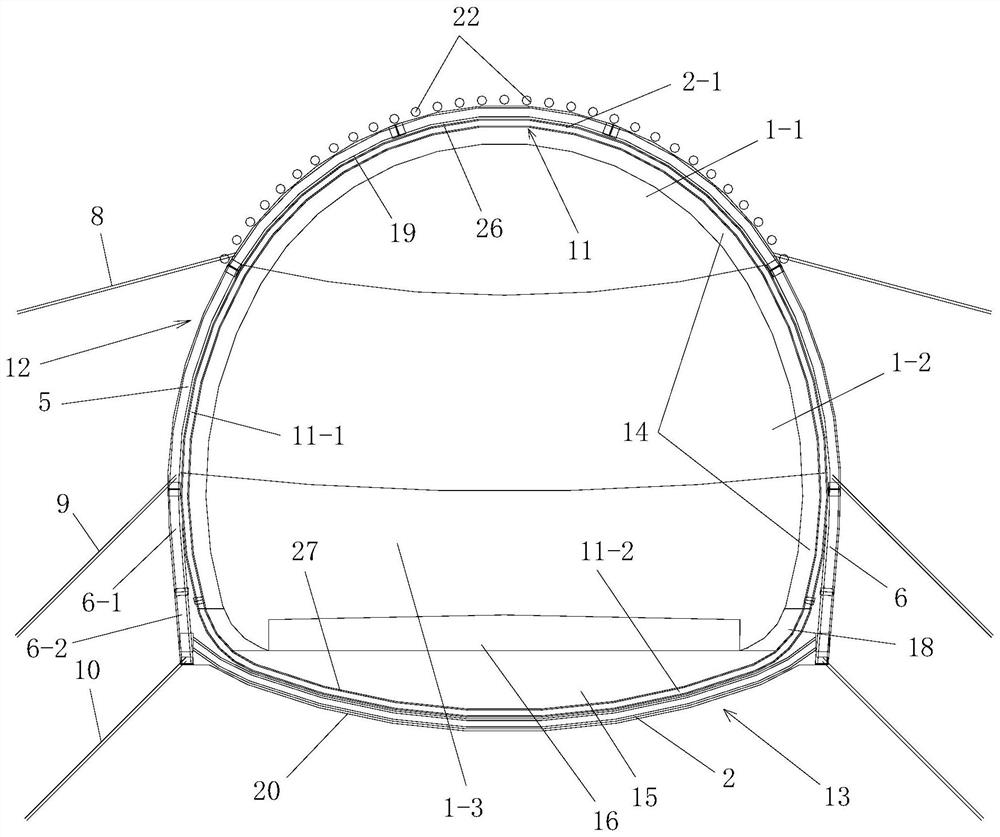

Supporting system of water-rich drifting sand stratum full-weathering surrounding rock tunnel and construction method

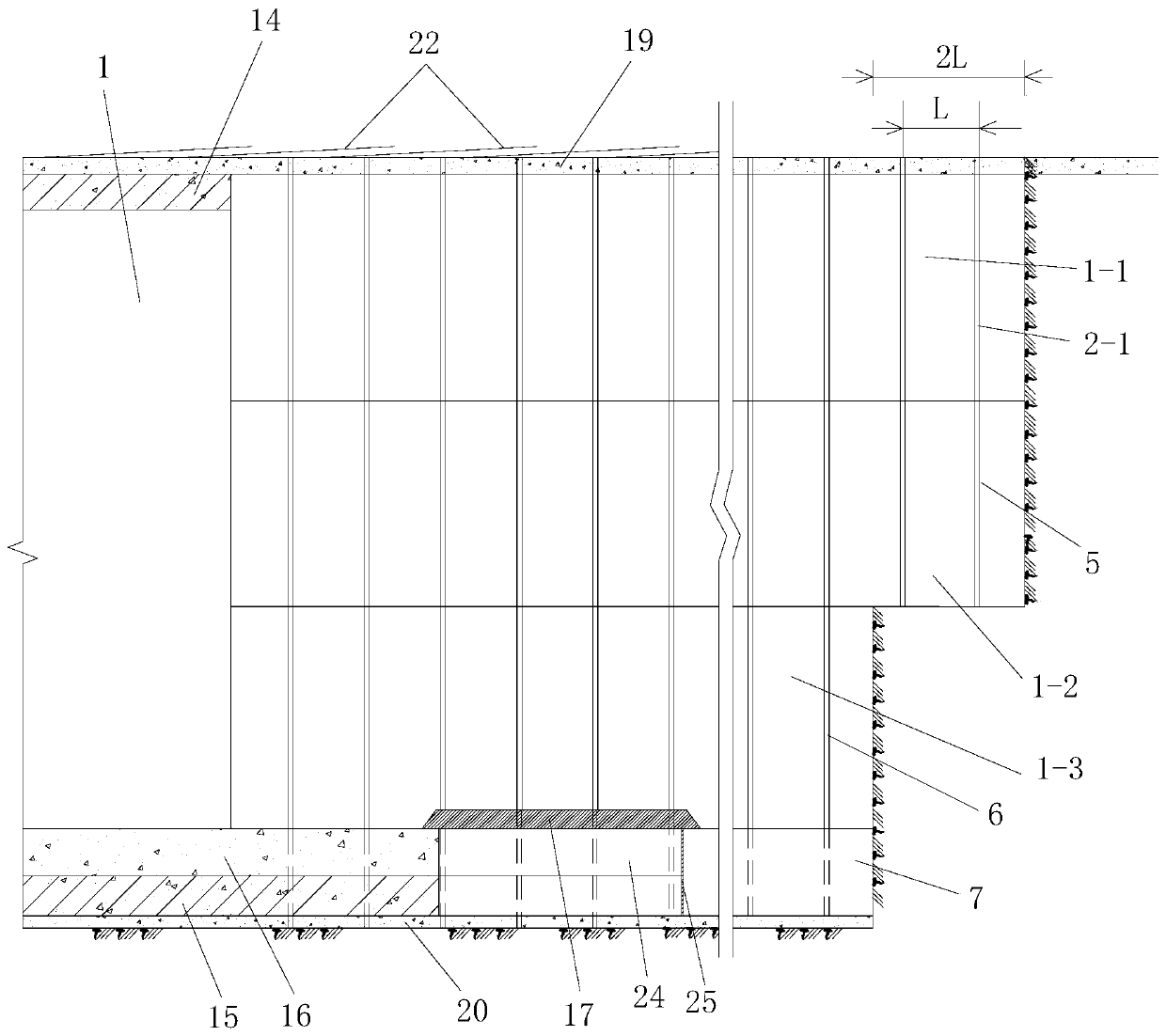

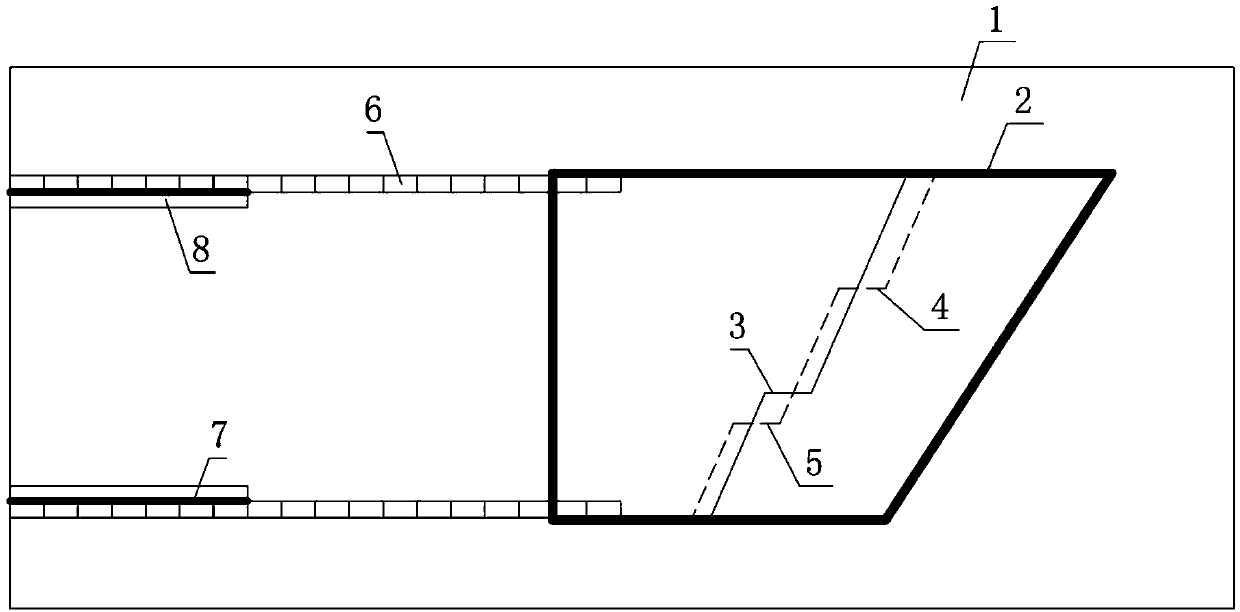

InactiveCN110541721ASettlement controlEnsure stability and securityUnderground chambersDrainageSupporting systemStructure of the Earth

The invention discloses a supporting system of a water-rich drifting sand stratum full-weathering surrounding rock tunnel and a construction method. At least four layers of steps are arranged in a tunnel. Steel row frame supports are arranged between the steps and the top of the tunnel. An advanced small guide pipe and an advanced pipe shed are arranged at the top of the tunnel. A group of steel arch frames are arranged in the tunnel and are arranged at intervals in the longitudinal direction. The shapes of the steel arch frames are matched with the shape of the section of the tunnel. Pipe shed lock feet are arranged on the two sides of each layer of steps and on the steel arch frames respectively. Steel bar mesh pieces are laid and hung on the portions, between adjacent steel arch frames,of the inner lateral side of the tunnel. Concrete layers fully sprayed on the outer sides of the steel arch frames and the steel bar mesh pieces. Bar-shaped foundations are arranged on the positions,corresponding to the steel row frame supports, of the horizontal planes of the steps. Inclined supports are arranged between the steel row frame supports and the steel arch frames. The supporting system of the water-rich drifting sand stratum full-weathering surrounding rock tunnel and the construction method solve the technical problems that a traditional construction method easily causes settlement of an integral initial support structure, the construction space is small, steel frame arch foot pipe shed locking feet cannot be reinforced, the risk of median septum dismantling is large, the working procedures are complex and the construction speed is low.

Owner:中国建筑土木建设有限公司

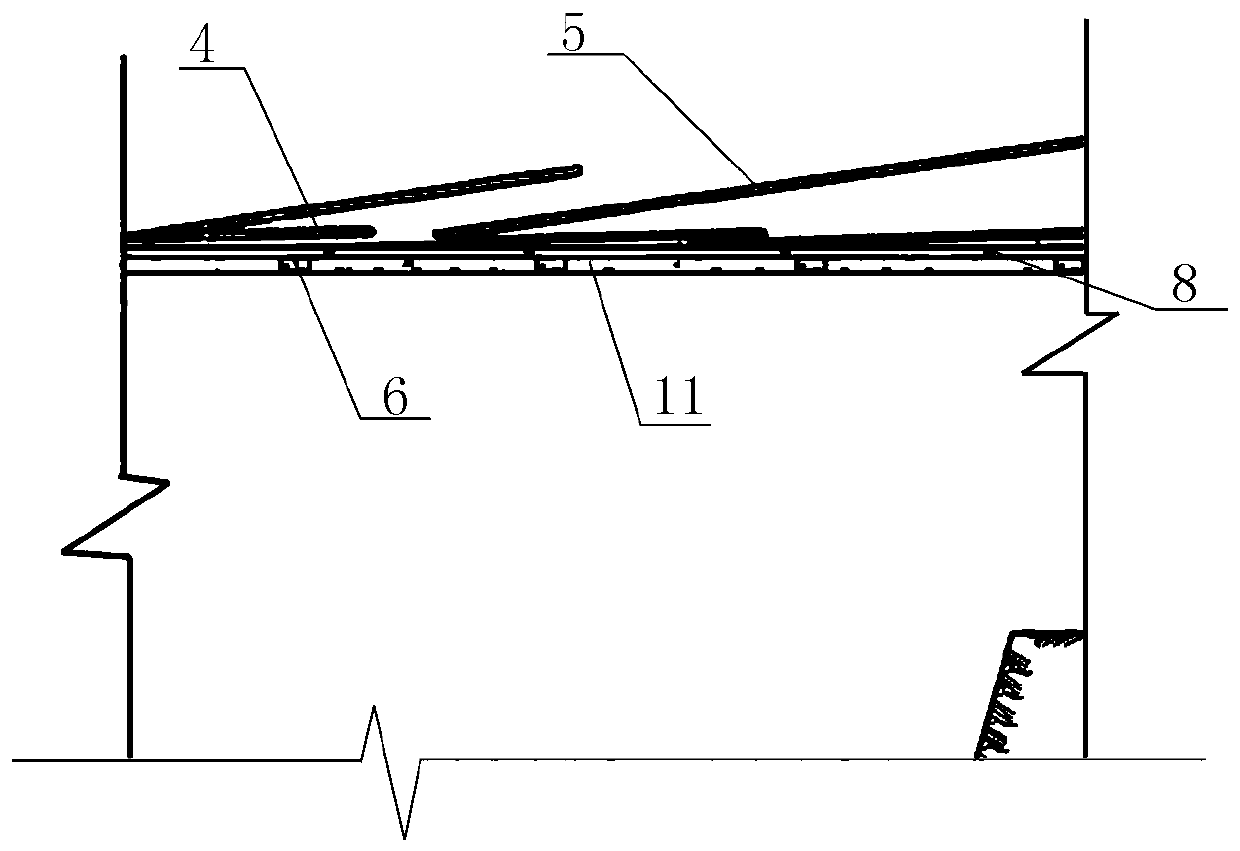

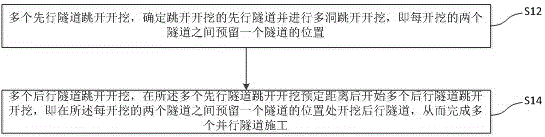

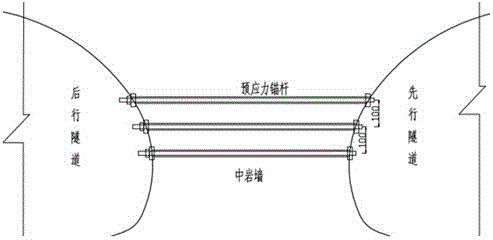

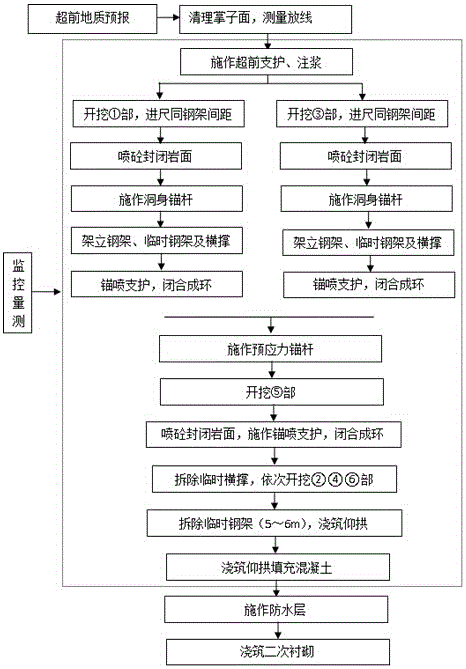

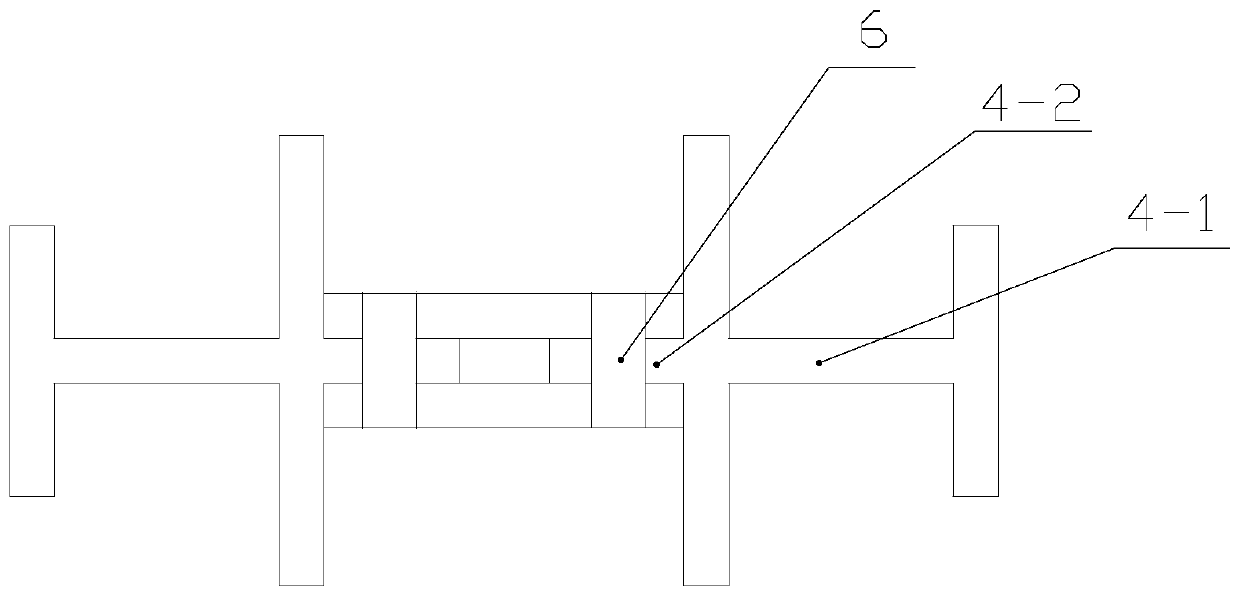

Super-shallow-buried small-spacing large-section multi-tunnel concurrent construction method

ActiveCN106050243ASolve Bias ProblemsAddresses side pressure effectsTunnelsCounter-pullEnvironmental geology

The invention discloses a super-shallow-buried small-spacing large-section multi-tunnel concurrent construction method for excavating multiple parallel tunnels. The super-shallow-buried small-spacing large-section multi-tunnel concurrent construction method comprises the steps that S12, multiple antecedent tunnels are excavated in a spaced mode, antecedent tunnels excavated in the spaced mode are determined, and multi-hole spaced excavation is performed, namely one tunnel position is reserved between every two adjacent excavated tunnels; S14, multiple following tunnels are excavated in a spaced mode, spaced excavation of the multiple following tunnels is performed after the antecedent tunnels are excavated in the spaced mode for a predetermined distance, namely each following tunnel is excavated at the tunnel position reserved between every two adjacent excavated tunnels, and accordingly multi-tunnel concurrent construction is completed. On the basis that a single-side double-side pit guiding excavating method and a composite lining principle are adopted, the problem of pressure bias is effectively solved during replacement and filling at opening top low-lying positions, prestressed counter-pulled anchor rods are arranged among openings to connect the openings to form a whole, surrounding rocks among the openings are further stabilized, and the lateral pressure influence of the openings is effectively solved.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Construction technology for soft rock large-deformation tunnel by de-stressing method and matched bracket

The invention discloses construction technology for a soft rock large-deformation tunnel by a de-stressing method and a matched bracket, and belongs to a high-burial depth large-deformation soft rock tunnel method and a support. The technology comprises the following steps: 1, performing tunnel tunneling construction and tunneling; 2, constructing mesh beam and shotcrete supports of the tunnel; 3, excavating a bottom plate de-stressing groove backwards from the tunneled working surface at the tunneled tunnel bottom plate; 4, constructing a tunnel wall de-stressing groove at the wall position of the tunnel; 5, setting up the matched bracket from the rear to the front; and 6, concreting at the bottom plate of the tunnel. The construction technology has the advantages that: 1, the de-stressing groove is excavated at a bottom groove, so that the tunnel is positioned in a low stress region at the initial stage of the excavation and the influence on and damage to the tunnel due to high stress are reduced after the tunnel excavation; 2, an enclosed structure where a full section and the tunnel section are adapted has high deformation resistance; 3, the bracket has a multi-stage variable bearing structure, and can prolong the time in the tunnel; and 4, an intensity-controlled buffer cushion block controls the variation rate of the bracket timely. In addition, the construction technology also has the advantages of simple structure and strong engineering practicability.

Owner:XUZHOU MINING BUSINESS GROUP

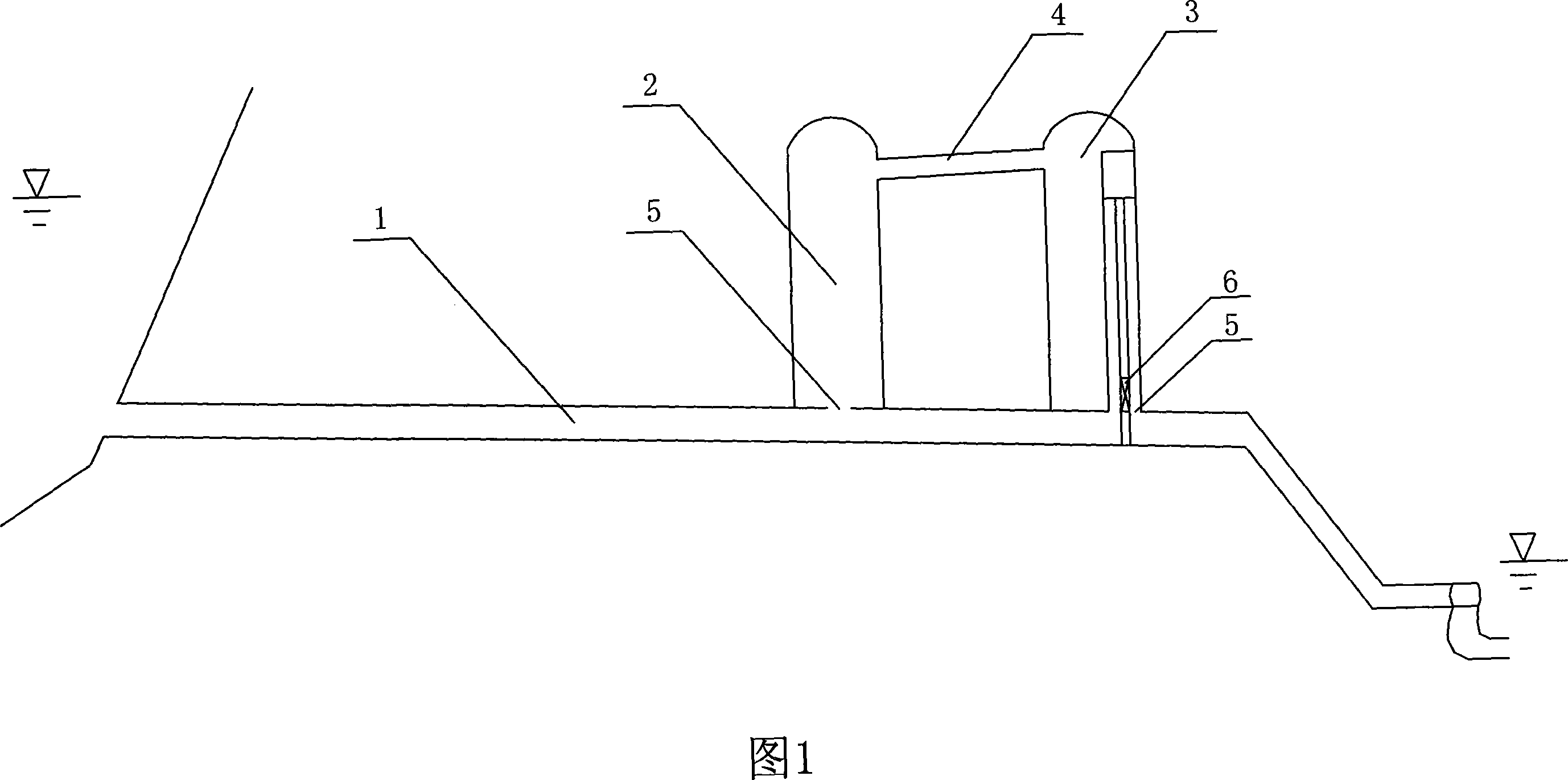

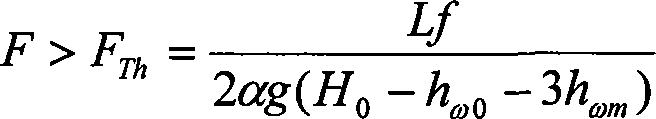

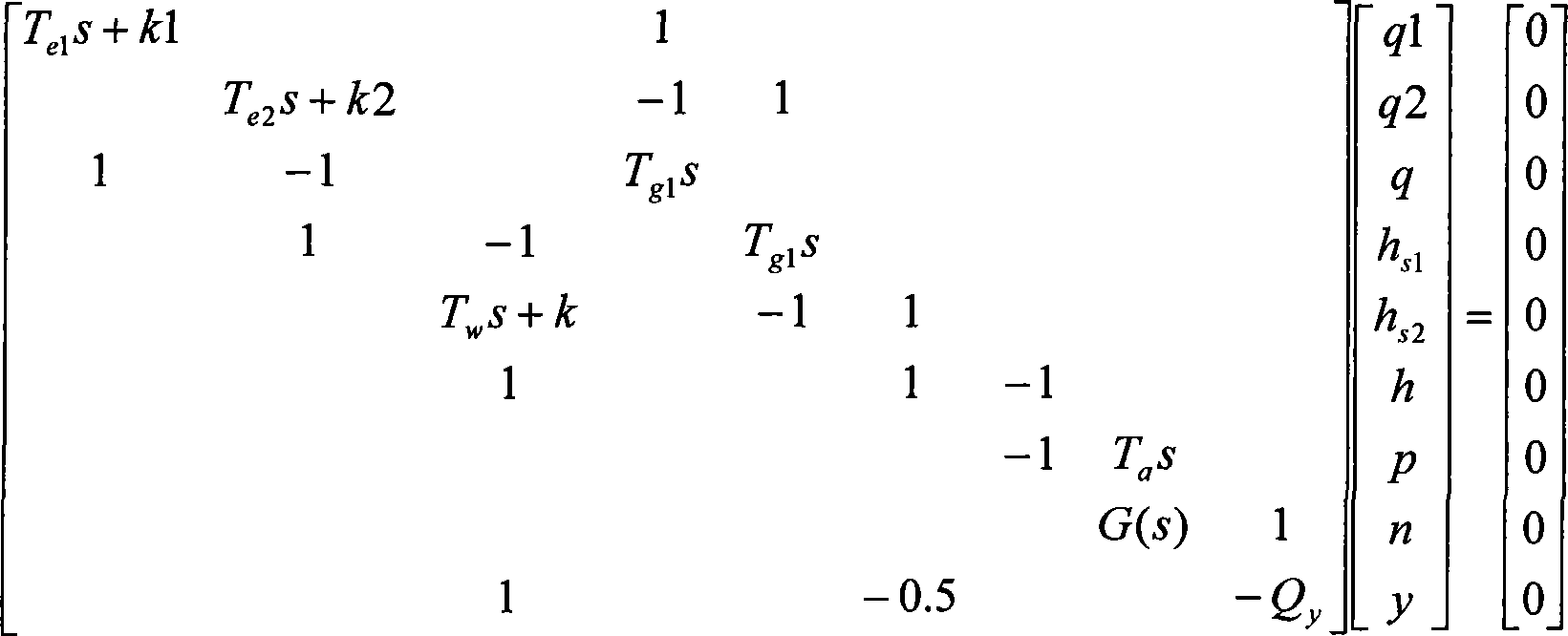

Cave system differential surge chamber

ActiveCN101178051ASmall amount of workFlexible layoutHydro energy generationMachines/enginesUltrasound attenuationDifferential pressure

The invention relates to a cavity group differential pressure regulation room. The technical problem to be solved by the invention is to provide a cavity group differential pressure regulation room which solves the arrangement of ultra-great scale pressure regulation room by the type of pressure regulation room group and restrains the amplitude of a ground swell and speeds up the fluctuation attenuation speed of the ground swell by adopting a differential pressure regulation room, thus ensuring the safety of the structure of the pressure regulation room and improving the stability of the operation of the unit and the power supply quality of the unit. The technical proposal to solve the problem is that the cavity group differential pressure regulation room is characterized in that the end of a long water-traction tunnel is connected in series with 2 through 4 pressure regulation room group with small scales; furthermore, an upper chamber communicated hole is arranged between the pressure regulation rooms. The invention can be applied to hydropower engineering.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Mine paste filling aggregate prepared from building waste materials and preparation method of mine paste filling aggregate

InactiveCN102775105AImprove working environmentHigh recovery rateSolid waste managementCompressive strengthUltimate tensile strength

The invention discloses mine paste filling aggregate prepared from building waste materials and a preparation method of the mine paste filling aggregate. The mine paste filling aggregate and the preparation method adopt the following design scheme that the mine paste filling aggregate prepared from building waste materials comprises the following ingredients in percentage by mass: 35 percent to 50 percent of building waste materials, 3 percent to 8 percent of cementing materials, 20 percent to 25 percent of coal ash, 0.5 percent to 1.5 percent of additives and 18 percent to 25 percent of water, wherein the total quantity is 100 percent, and the quality requirements on each composition ingredient are as follows: the grain diameter of the building waste materials is distributed between 0.05mm and 25mm, the mud content is lower than 10 percent, and the cement is ordinary silicate cement. The mine filling paste filling aggregate is manufactured according to the production flow process of the building waste materials. After the materials are prepared according to the proportion, the following performance can be reached: the pressure strength is 7.5MPa (28 days), and the slump is 15 to 28 cm.

Owner:滕州市级翔(集团)级索煤矿

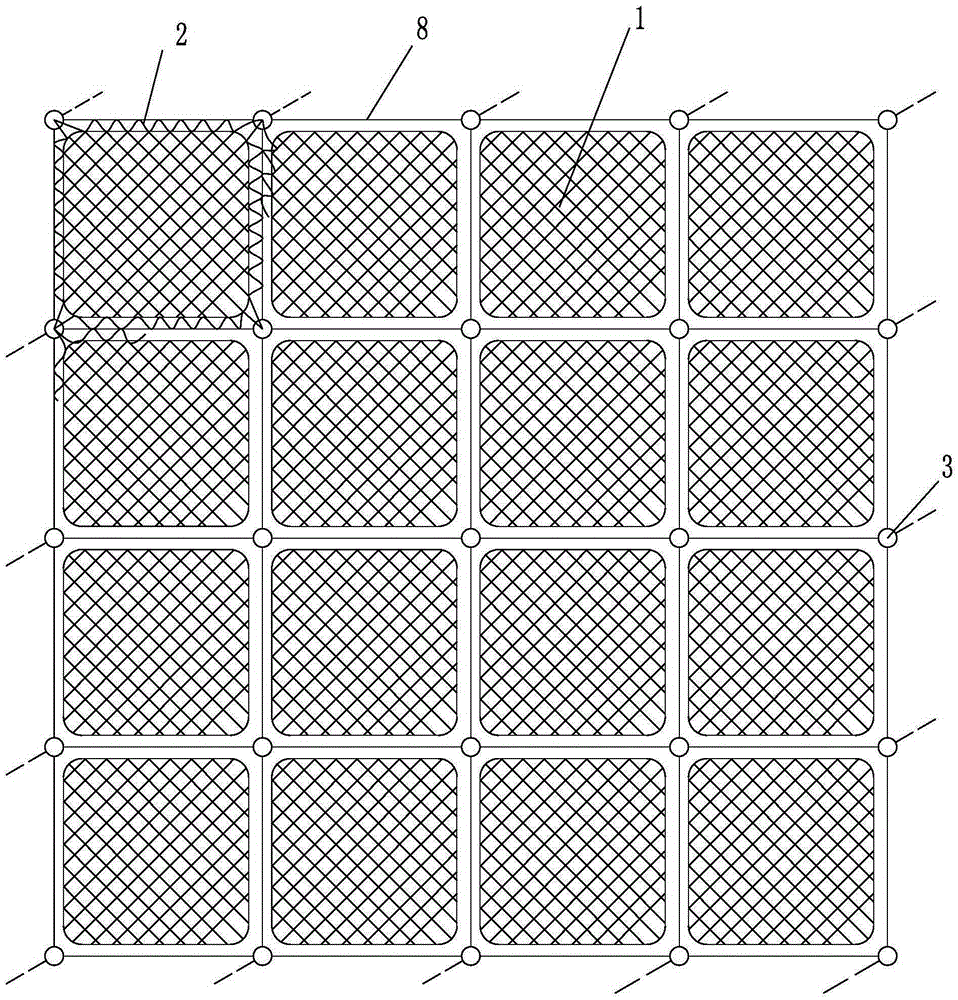

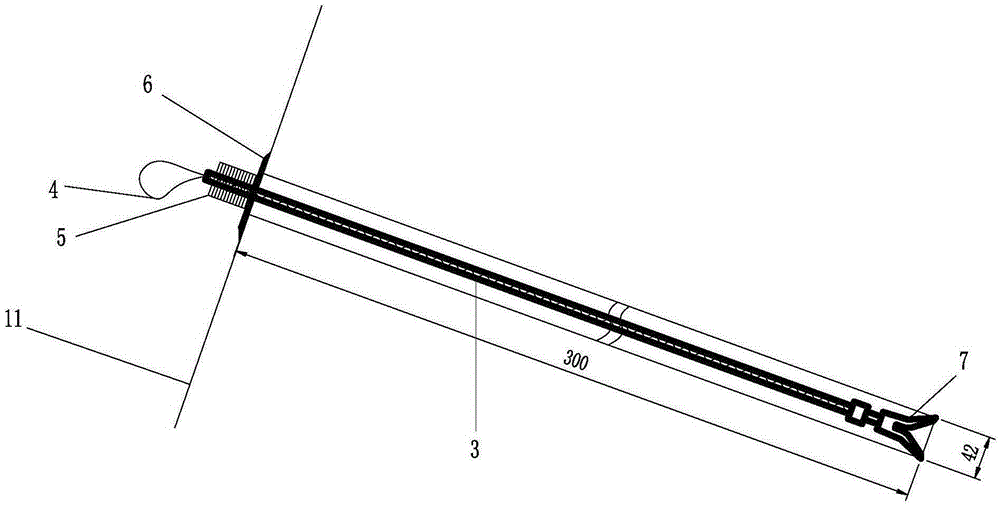

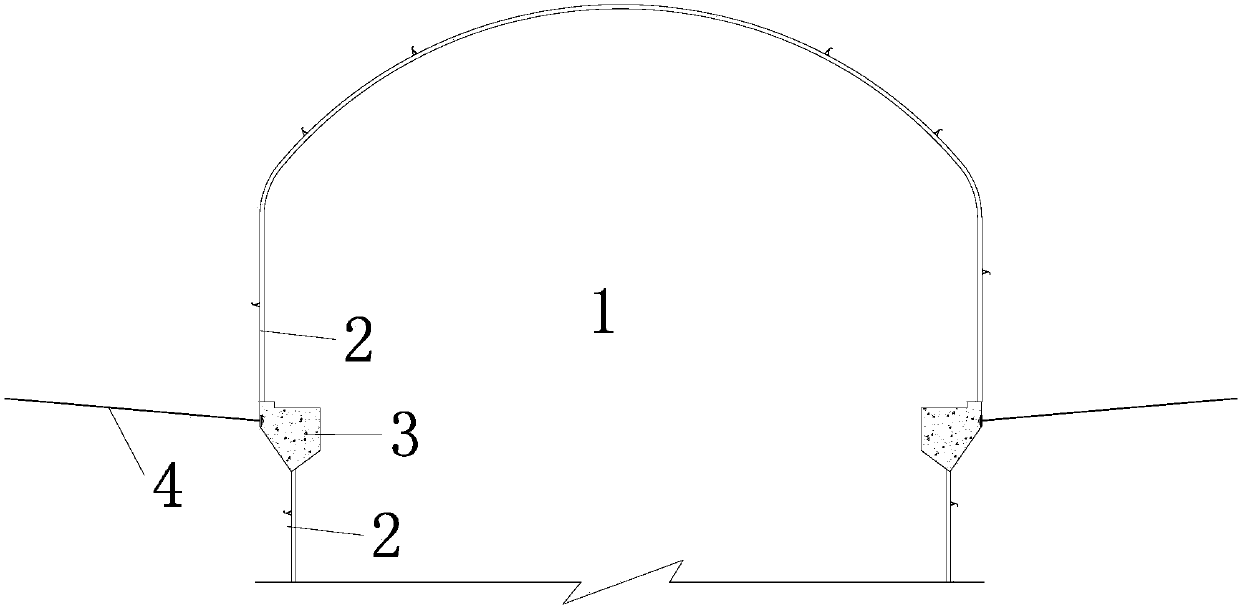

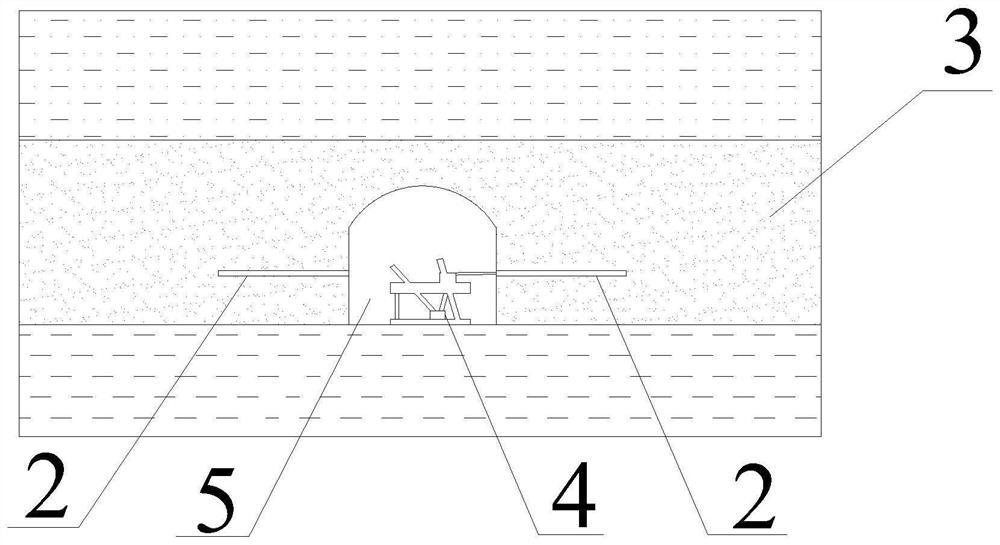

Anti-rock burst and anti-rockfall flexible protection device and construction method for tunnel excavation

ActiveCN105401956AImprove stabilityReduce exposure timeUnderground chambersTunnel liningStructural engineeringRockfall

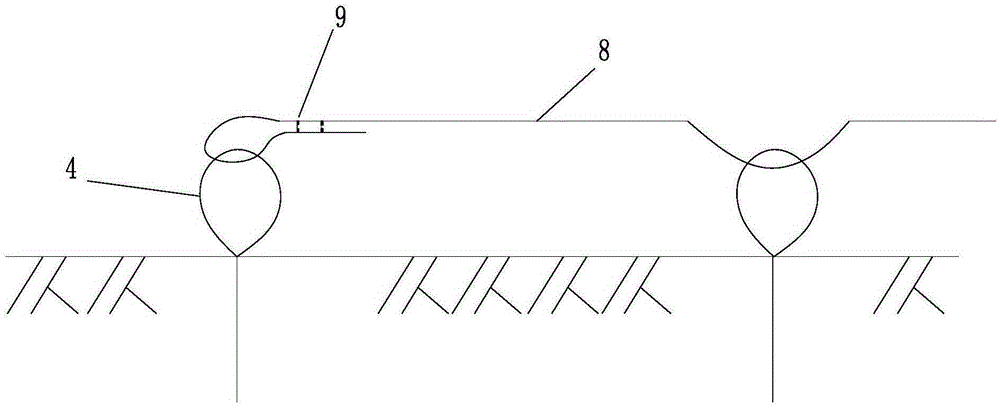

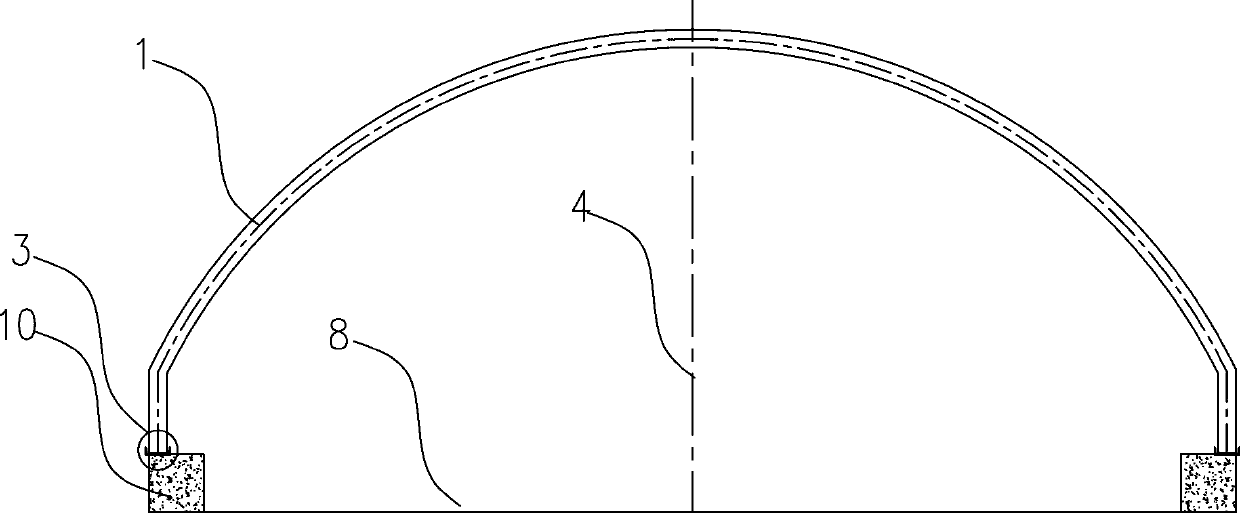

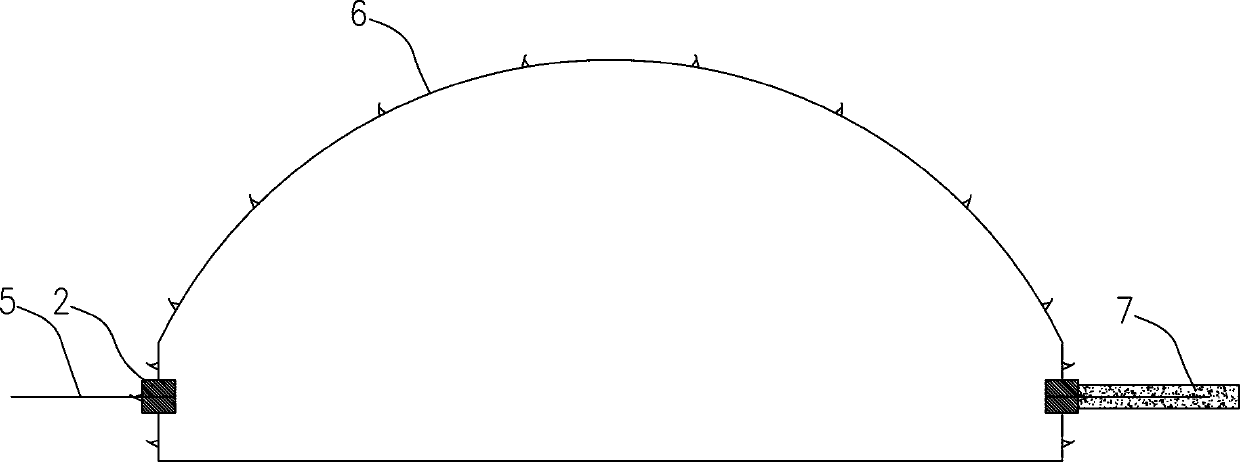

The invention discloses an anti-rock burst and anti-rockfall flexible protection device and a construction method for tunnel excavation. The device comprises a steel rope net (1), a sewing rope (2), a expansion type anchor rod (3), supporting ropes (8) and a fixing plate (10). The supporting ropes (8) are intersected to form square grids. The number of grids in the steel rope net (1) is equal to the number of the above square grids. The steel rope net (1) is sewn inside grid via the sewing rope (2). The sewing rope (2) is pre-tightened via a rope tightener. By means of the device, the rock stability is improved, and the exposure duration of surrounding rocks is shortened. Meanwhile, the occurrence of rock burst and stone collapse is prevented as much as possible. Moreover, small collapsed stones are limited within a confined space. Therefore, the rock-burst and rockfall problem, that might occur after tunnel excavation blasting and supporting process, can be well solved.

Owner:SICHUAN CHUANJIAO ROAD & BRIDGE

Anchoring slurry material of prestressed anchoring cable of large cross-section tunnel of high-speed rail

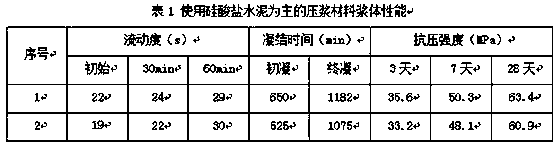

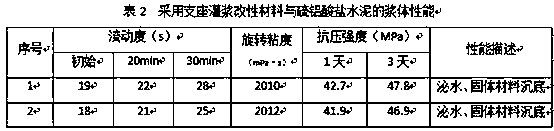

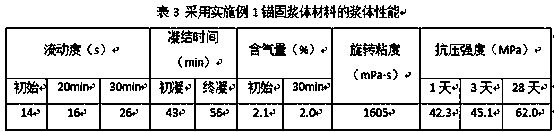

The invention discloses an anchoring slurry material of a prestressed anchoring cable. The anchoring slurry material is prepared by compounding early-strength sulphoaluminate cement, a polycarboxylatesuperplasticizer, a retarder, an air entraining agent and a thickening stabilizing agent; the materials reach the optimal composition by research, and thus the grouting slurry, which is extremely high in mobility, low in viscosity, proper in consistence, free from segregation, free from bleeding, quick to cure, and high in early strength, can be prepared; the components in percentage by mass of solid are that 98-99.7% of sulphoaluminate cement, 0.05-0.3% of water reducing agent, 0.1-0.5% of retarder, 0-0.08% of air entraining agent, and 0.04-0.20% of thickening stabilizing agent. The anchoring slurry material is high in workability, and low in workability; the problems of pipe blocking and locking of a stirring machine are decreased; proper working time is provided for construction; the slurry can smoothly flow through a 20mm fine pipeline to be poured into a hole being beyond 30m in height.

Owner:THE 4TH ENG OF CHINA RAILWAY 5TH ENG GROUP

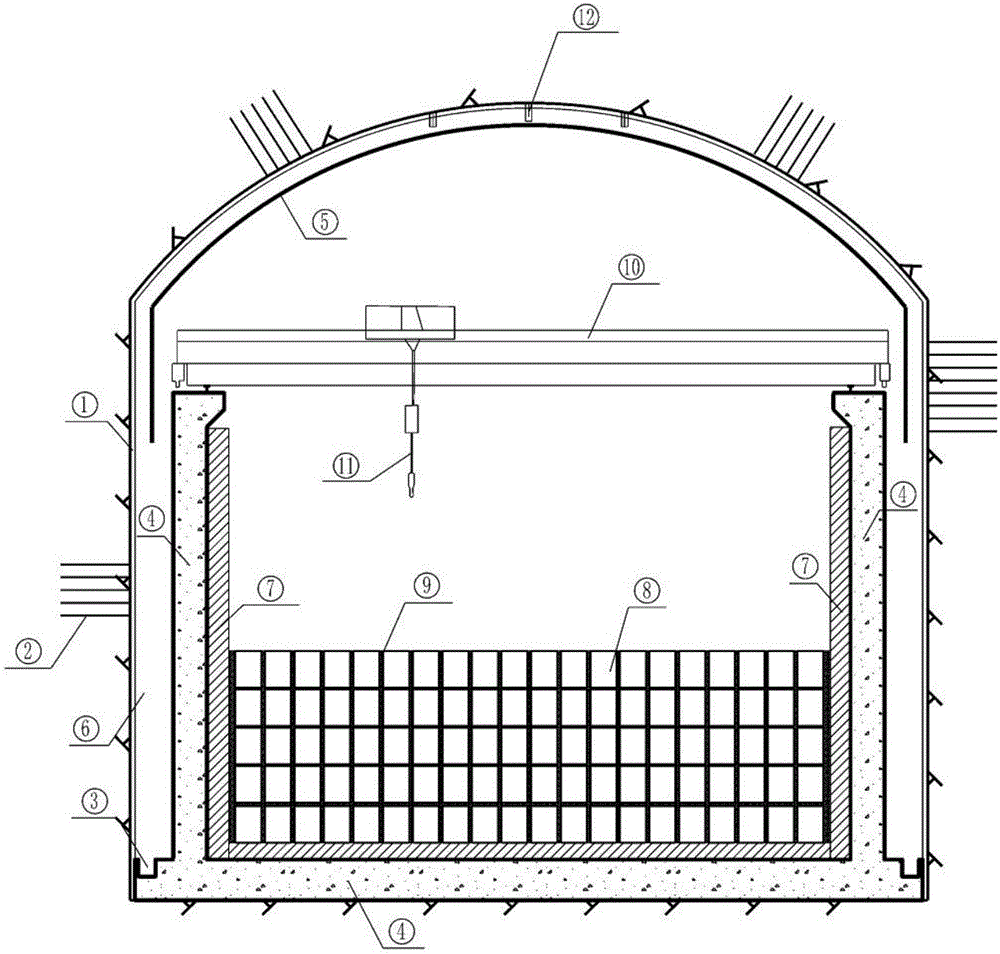

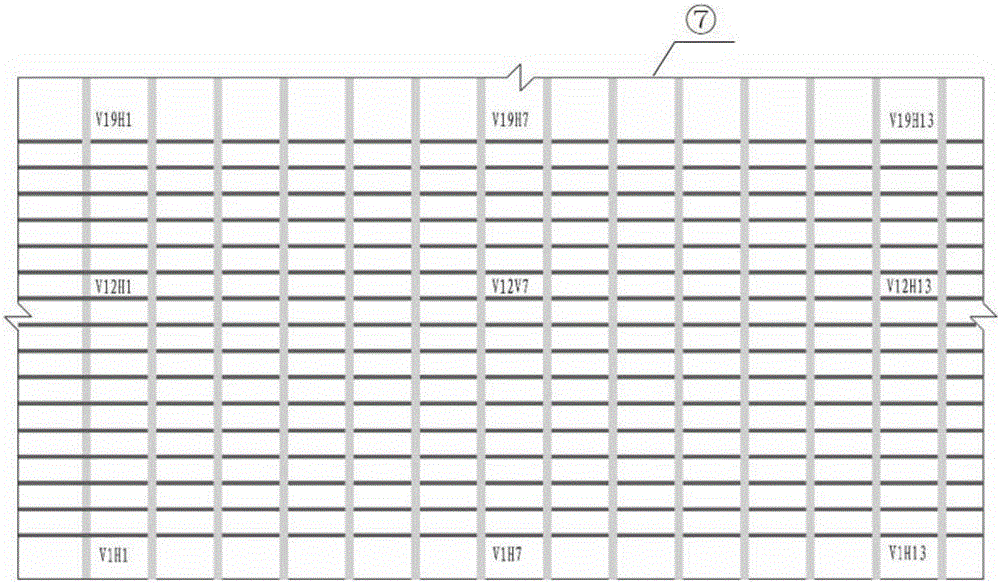

Waterproof and drainage system and construction method of low-medium radioactive waste grotto type disposal site

ActiveCN106499416AImprove securityNo propagation mediumUnderground chambersDrainageOpen waterRadiation injury

The invention discloses a waterproof and drainage system and a construction method of a low-medium radioactive waste grotto type disposal site. The waterproof and drainage system comprises a seepage-preventing side wall and base plate and a waterproof ceiling, wherein the seepage-preventing side wall and base plate is located in a grotto and is U-shaped, the waterproof ceiling is in an inverted-U shape, the waterproof ceiling and the seepage-preventing side wall and base plate are in a buckled-closed state, a clay side wall and base plate is arranged on the inner side of the seepage-preventing side wall and base plate, waste buckets are arranged inside the clay side wall and base plate, an open water draining drain is formed in the outside of the seepage-preventing side wall and base plate and located below the end of the waterproof ceiling, a crane beam is arranged at the top of the seepage-preventing side wall and base plate and located inside the waterproof ceiling, a crane, a grouting pipeline and a spray nozzle are arranged on the crane beam, and a top arched embedded pipeline is arranged in a grotto top arch. The problem that a grotto protection structure existing in an existing project measure is simple and can only retard and reduce the release speed and amplitude of pollutants from a protective facility is well solved, and a series of problems including personal radiation injury and the like due to the grouting and vibrating construction in gaps among the waste buckets are solved.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

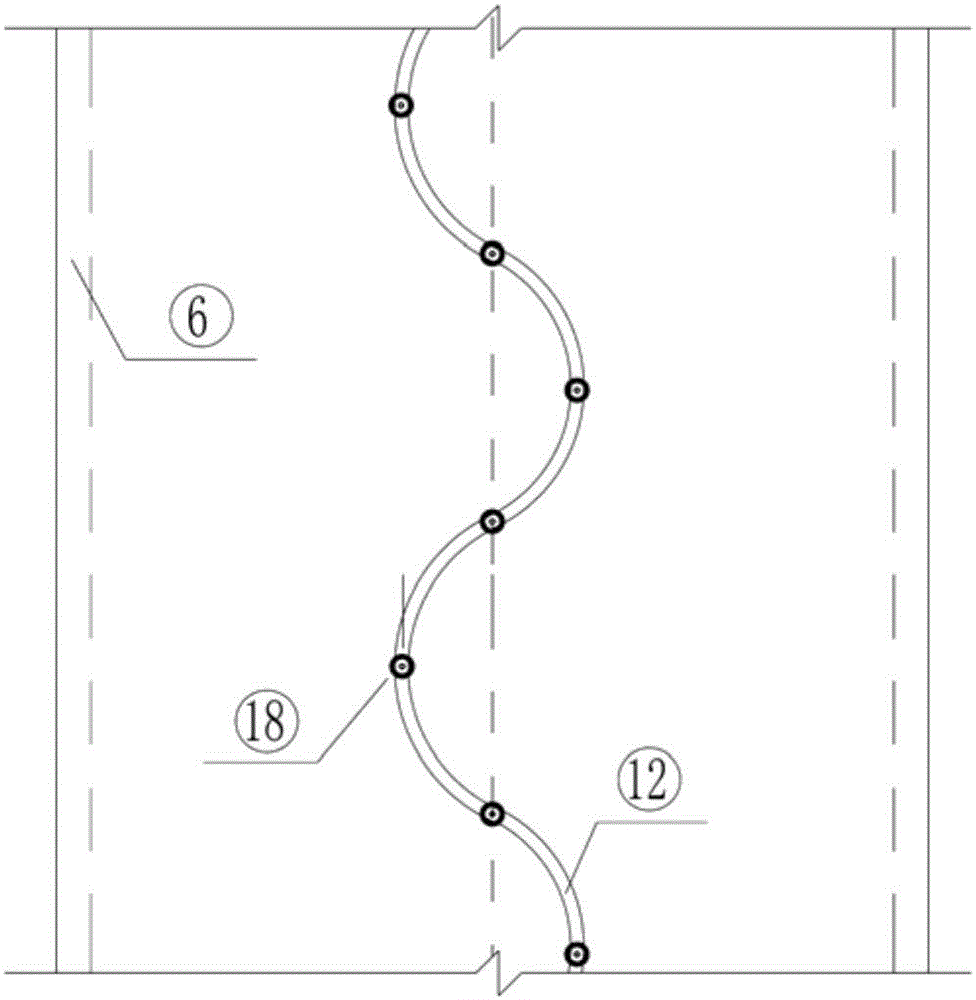

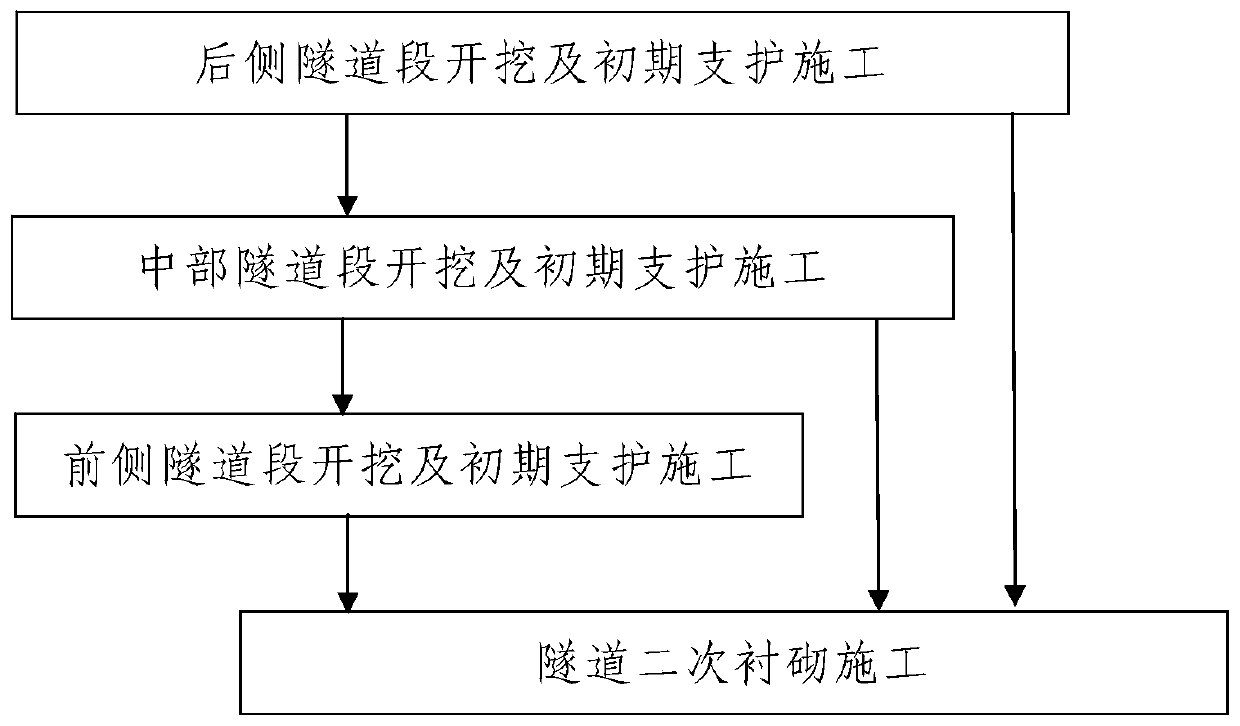

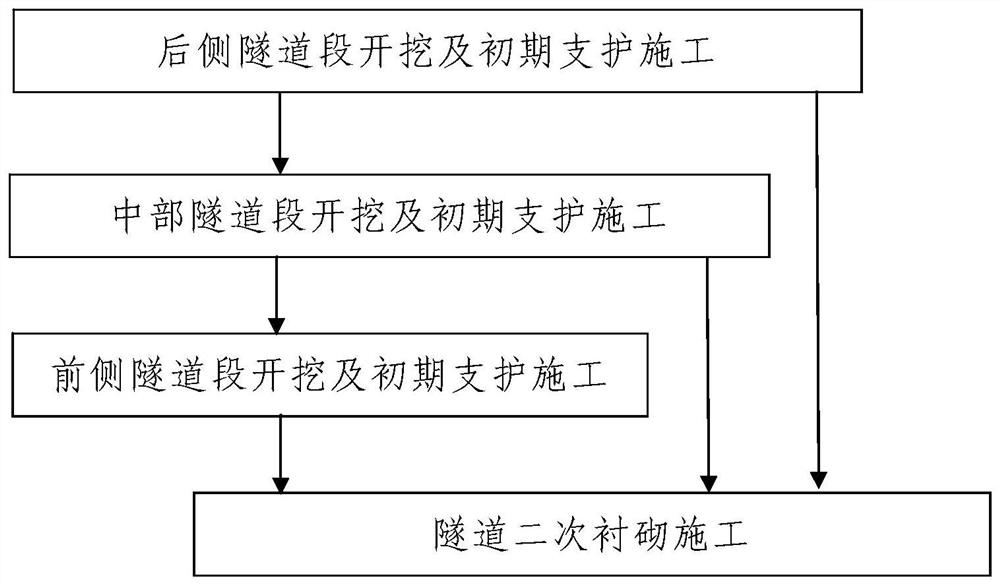

Tunnel construction method for passing through boundary strata of earth and stone

ActiveCN110985003AEffective reinforcementThe method steps are simpleUnderground chambersDrainageArchitectural engineeringDrilling and blasting

The invention discloses a tunnel construction method for passing through the boundary stratum of earth and stone. The tunnel construction method comprises the following steps: I, excavation of a reartunnel segment and initial supporting construction; II, excavation of a middle tunnel segment and initial supporting construction; III, excavation of a front tunnel segment and initial supporting construction, wherein the rear tunnel segment, the middle tunnel segment and the front tunnel segment are all three-step synchronous excavated tunnel segments; and in the process of excavation from rear to front, constructing the secondary lining of the tunnel on the inner side of the initial supporting structure of the constructed tunnel from rear to front. The tunnel construction method has the advantages of reasonable design, simple construction and good use effect. The tunnel construction method selects an appropriate drilling and blasting method according to the position relationship betweenthe earth and stone interface and a tunnel hole, adopts a three-step synchronous excavation way to carry out blasting excavation, can ensure the safe and reliable excavation process of the tunnel passing through the boundary stratum of earth and stone, and can ensure the stable structure of the tunnel. Moreover, in the excavation process, the initial supporting structure and the secondary lining of the tunnel are adopted to provide stable and reliable supporting for the large-section tunnel.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

Tunnel earthquake absorbing structure for rapid repairing after earthquake

Owner:HARBIN INST OF TECH

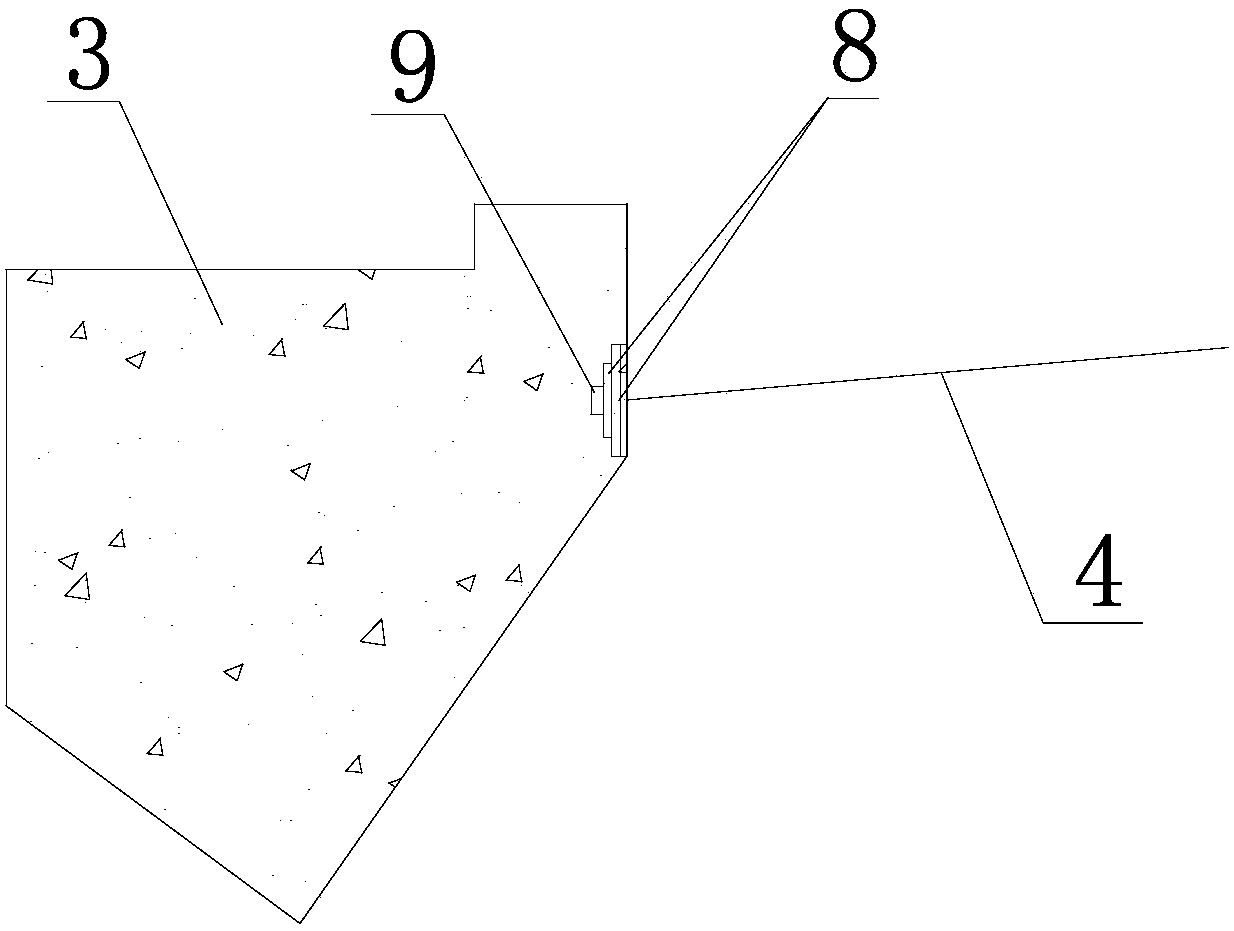

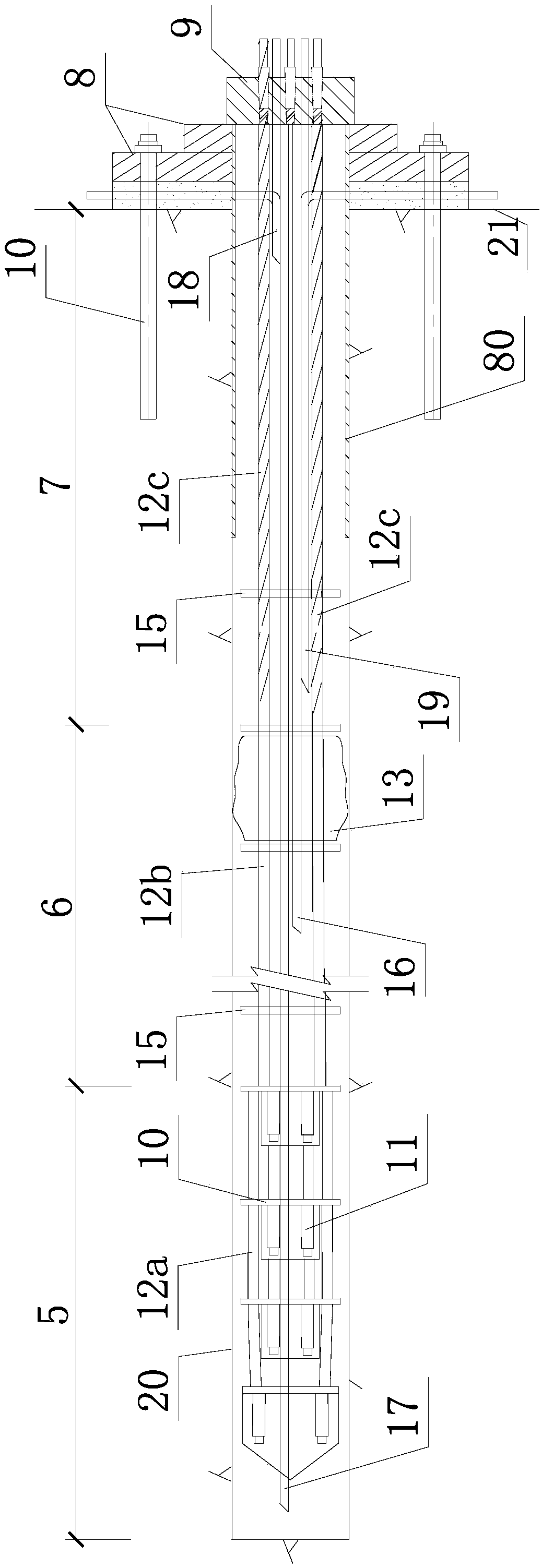

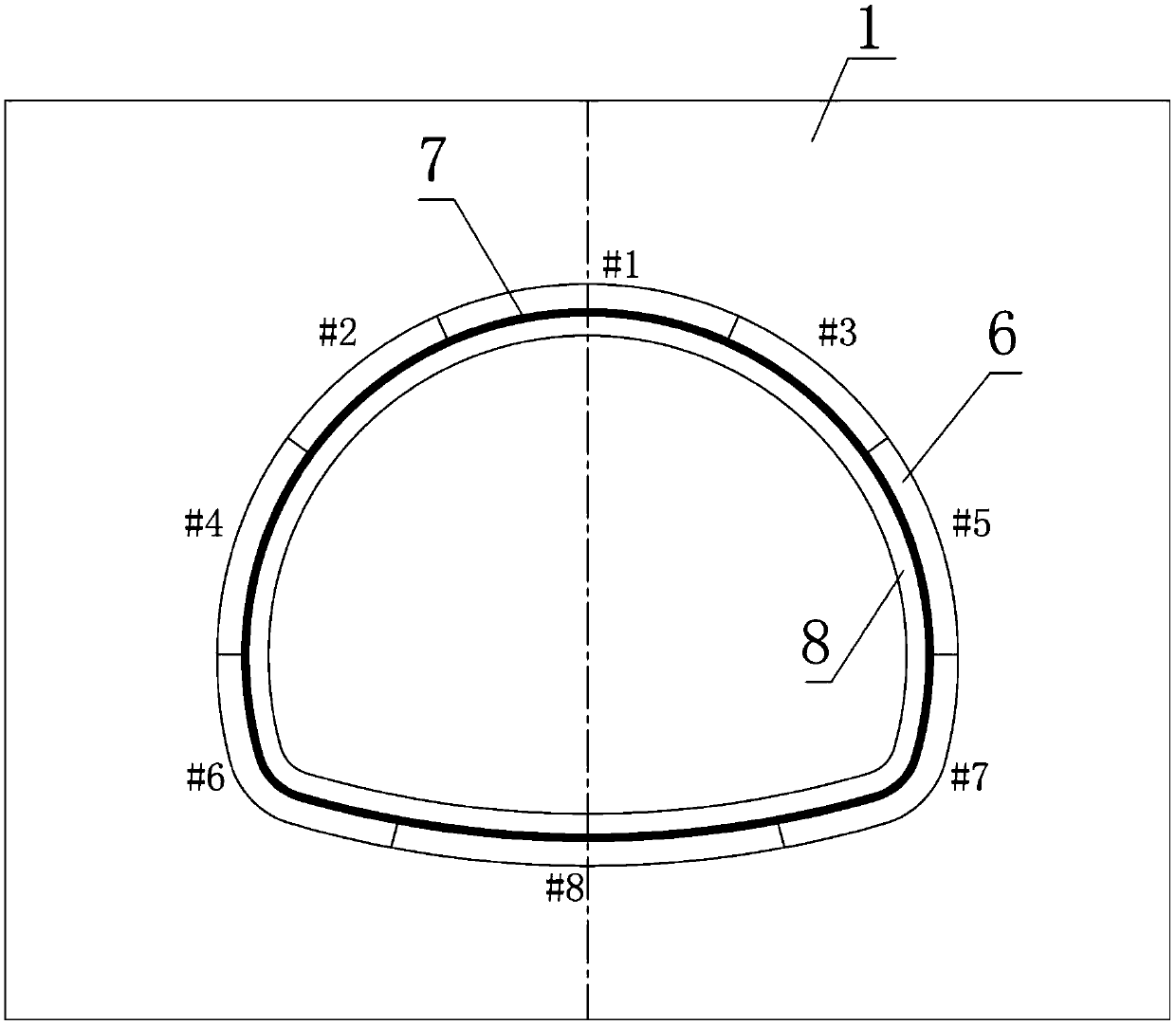

Pre-stress anchor cable structure applicable to underground powerhouse rock wall crane beam portion

InactiveCN107905260AEffective control of surrounding rock deformationSurrounding rock stabilityArtificial islandsUnderwater structuresPre stressPre stressing

The invention provides a pre-stress anchor cable structure applicable to an underground powerhouse rock wall crane beam portion. Anchoring segments of the structure are divided into the inner anchoring segment and the outer anchoring segment; the inner anchoring segment is located on the inner side in a drill hole, and the outer anchoring segment is located on the outer side in the drill hole; a tensioning segment is located between the inner anchoring segment and the outer anchoring segment; and in the drill hole, a hole segment corresponding to the tensioning segment and a hole segment corresponding to the outer anchoring segment are partitioned through a slurry stopping bag, and cement slurry is poured in different stages. The pre-stress anchor cable structure applicable to the underground powerhouse rock wall crane beam portion can perform pre-stress anchor cable supporting of a system on a high-edge wall in time, and therefore surrounding rock deformation can be limited, stabilityand safety of a rock wall crane beam structure are guaranteed, and overall surrounding rock stability of an underground powerhouse is facilitated.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

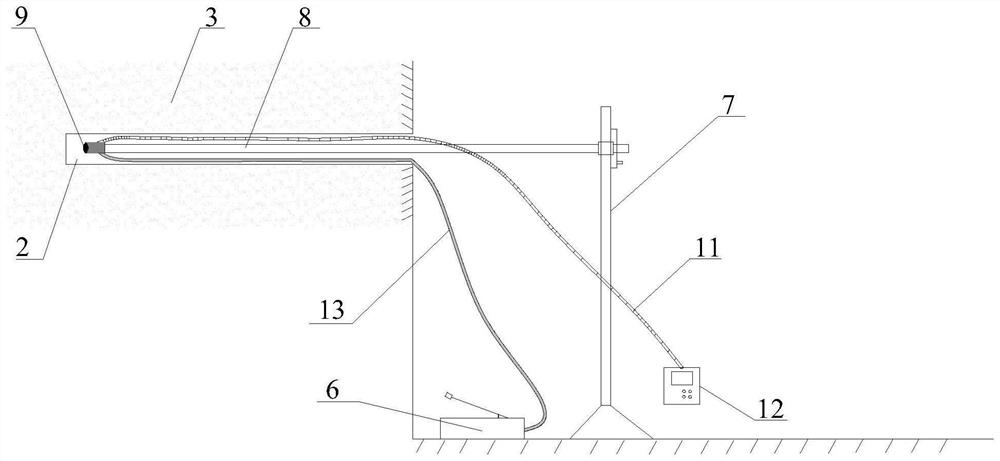

Construction method for drainage of tunnel vault in karst area

ActiveCN109973115AElimination of hidden dangers of qualityRelease stressUnderground chambersDrainageShotcreteStress concentration

The invention provides a construction method for drainage of a tunnel vault in a karst area, and belongs to a construction method of a tunnel. The construction method is characterized in that in tunnel construction, firstly, straight holes are drilled in a rock stratum of the excavated tunnel vault, guiding pipes are driven in the straight holes, the guiding pipes are arranged in a quincunx shape,grouting is conducted between every two adjacent guiding pipes at intervals or grouting is not conducted between every two adjacent guiding pipes, the grouted guiding pipes have the function of stabilizing surrounding rock, the non-grouted guiding pipes have the function of late draining water in the surrounding rock, after the surrounding rock is fixed, the tunnel continues to be excavated; after the guiding pipes are driven into the vault of the tunnel wall, grooves in right-angle n shapes are dug in the position, corresponding to the parts located on the left side and the right side of thecenter line of a circular-arc-shaped vault of the tunnel by 15 degrees, of the tunnel wall with sprayed concrete layers, cuboid steel plates with evenly-distributed circular holes are correspondinglyembedded in the grooves, the steel plates are pitched into the rock stratum of the vault, thus part of water amount of a karst water system can be released, later stress concentration caused by a large amount of water is effectively avoided, and the serious quality and safety problems of the tunnel are avoided.

Owner:CHINA MCC17 GRP

Method for relieving pressure of surrounding rock of rock burst roadway

ActiveCN112096381AImport size is smallLarge export sizeSurveyUnderground chambersData acquisitionClassical mechanics

The invention provides a method for relieving pressure of surrounding rock of a rock burst roadway. The method comprises the following steps of: horizontally arranging a drill hole in each of the upper parts on the left side and the right side of the roadway; detecting the drill holes by using a drill hole penetrometer to obtain pressure conditions and displacement information data of different depths; analyzing the stress conditions of the upper parts at different depths by using a data acquisition instrument according to the obtained information data of pressure and displacement in the drillholes, and determining the pressure relieving depth of a kerf; arranging a row of drill holes in the middle of the vertical surfaces of the upper parts on the left side and the right side of the roadway at certain intervals according to the obtained kerf depth; operating the drill holes in a bottom plate of the roadway by using an electric pulse device to perform fracturing operation; after an expected effect is achieved, taking out the electric pulse device, and performing impact operation of the next adjacent drill hole until the fracturing operation of the upper parts of the whole roadwayis completely finished; finishing the fracturing operation of the drill holes in the other side of the bottom plate of the roadway; and grouting and reinforcing the fractured surfaces of the upper parts of the roadway. The method is high in detection precision, high in kerf speed and good in pressure relieving effect.

Owner:CHINA UNIV OF MINING & TECH

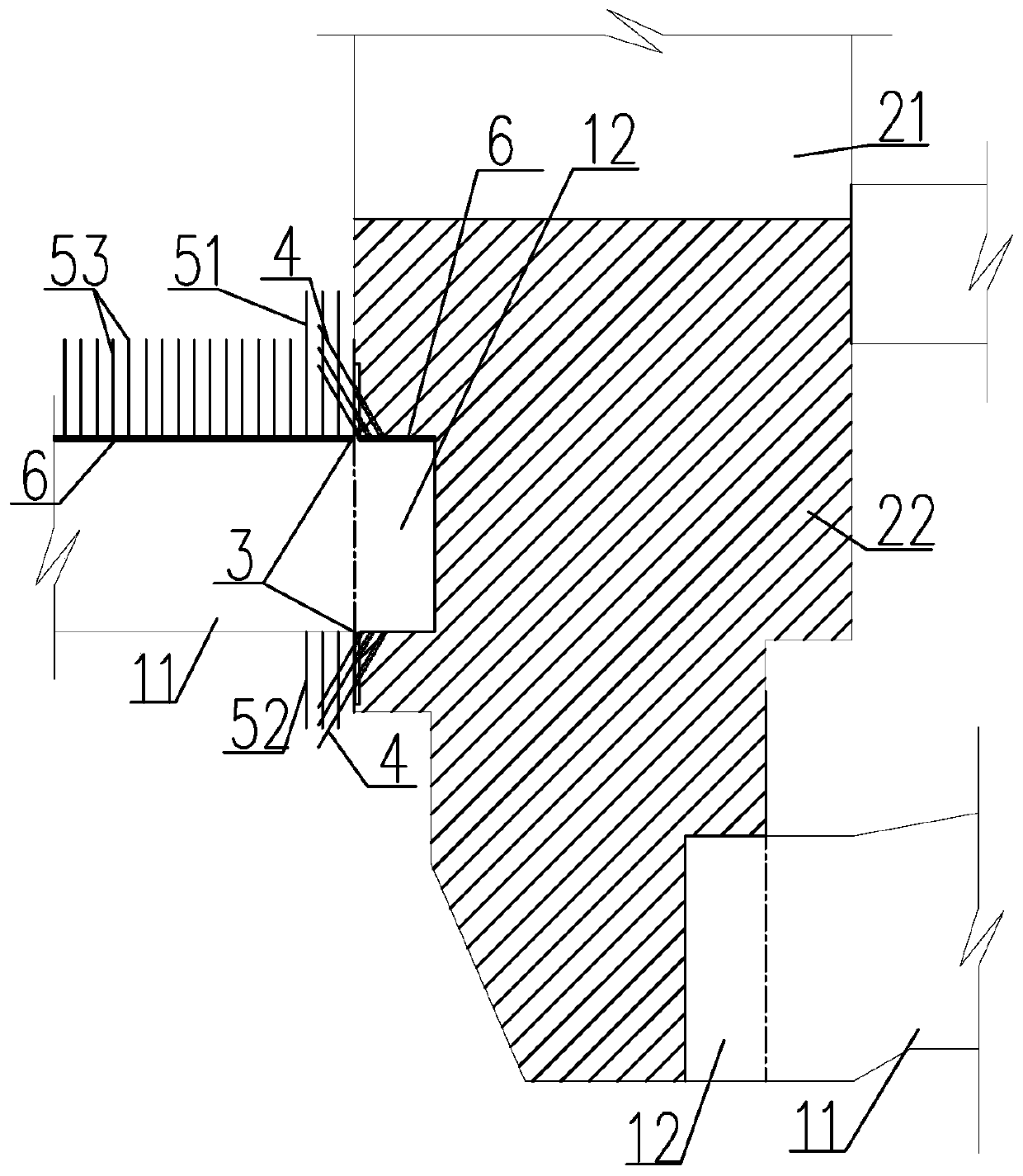

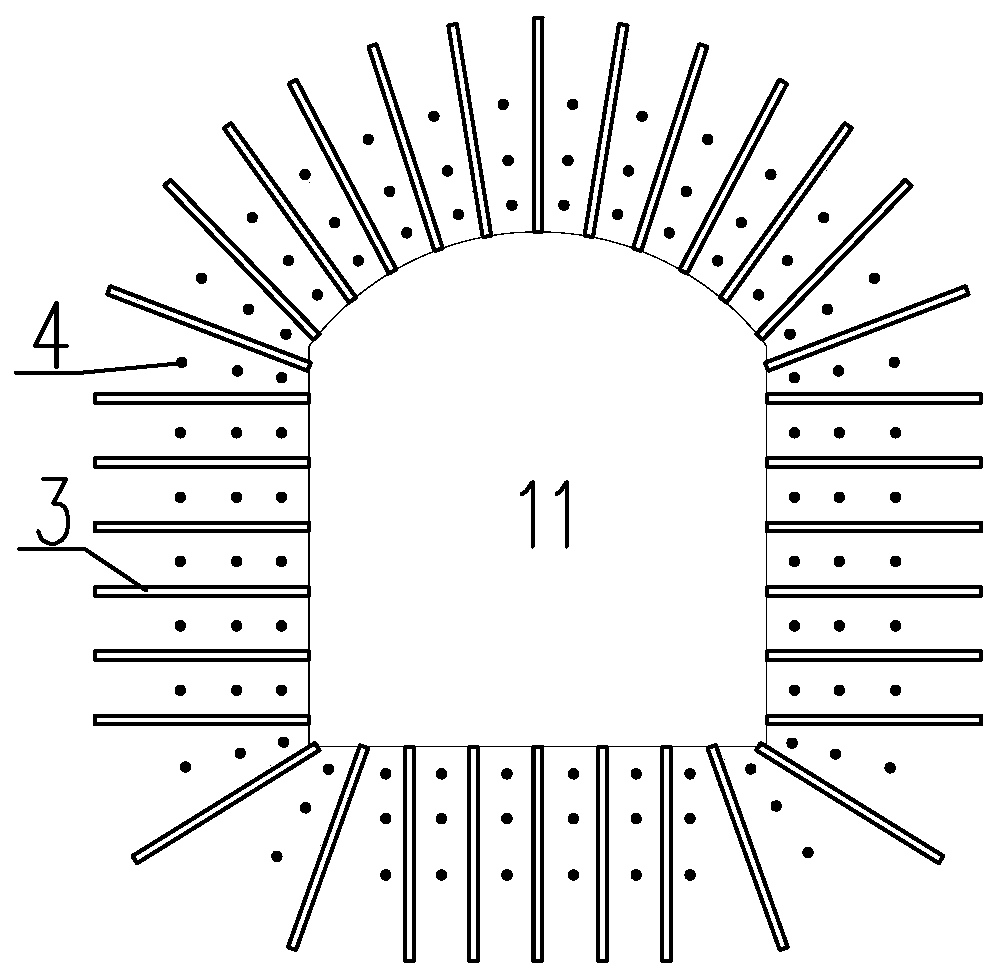

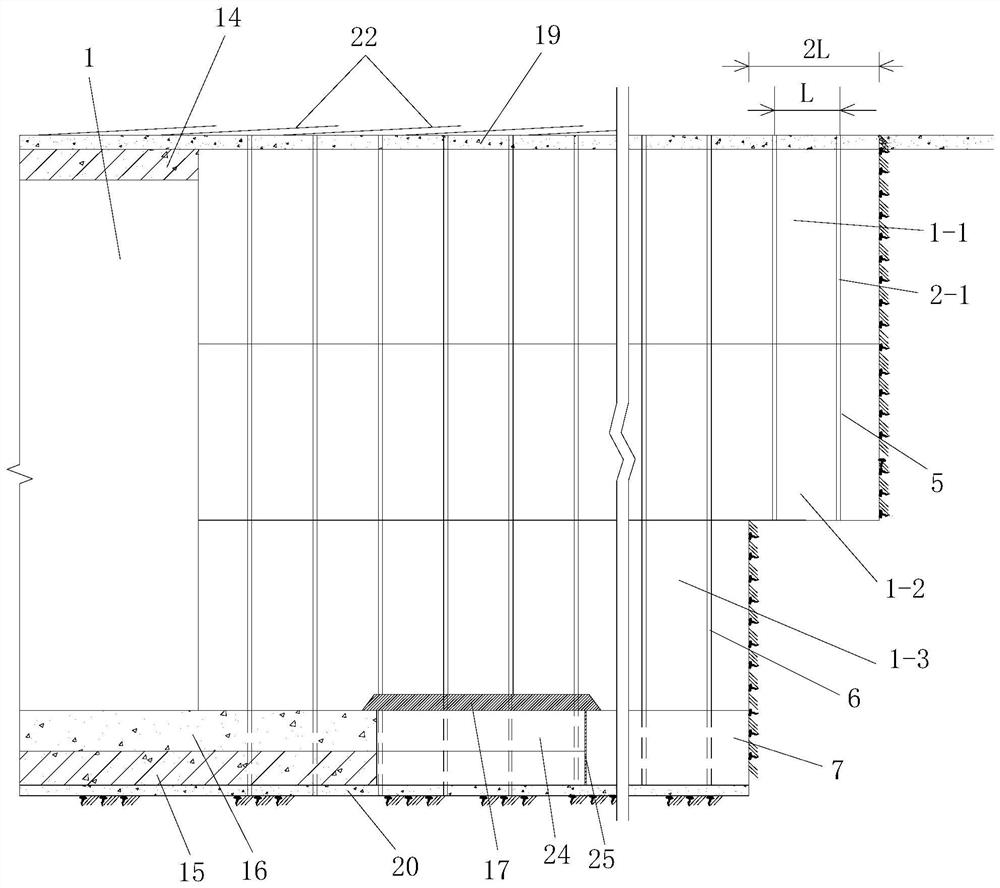

Construction method suitable for ultra-large fracture surface underground chamber excavating and steel arch frame fixing

ActiveCN110159323AAccelerate the construction progress of excavation and supportImprove construction progressUnderground chambersTunnel liningSteel frameBuilding construction

The invention provides a construction method suitable for ultra-large fracture surface underground chamber excavating and steel arch frame fixing. The construction method comprises the following stepsthat an ultra-large fracture surface underground chamber is excavated through at least two layers from top to bottom; a section of a top arch is excavated, and a dome arch frame is installed closelyattached to the chamber wall; after a section of the dome arch frame is installed, concrete spraying protecting is conducted on the dome, a longitudinal rock anchor beam is arranged along a chamber side wall support of the dome arch frame, the section of the dome arch frame is connected into a whole, and accordingly the whole dome arch frame can be fixed; after dome concrete and rock anchor beam concrete reach the age, lower-layer chamber layer excavation and support construction are synchronously conducted from the firstly-excavated part of the top arch layer; and through the above steps, ultra-large fracture surface underground chamber excavating and steel arch frame fixing construction are achieved. Through layering excavation, the scheme that dome arch frame support is conducted firstly, and then the rock anchor beam is constructed is adopted, stability of the surrounding rock of the dome top arch layer can be ensured, and lower-layer chamber excavation construction safety is ensured. Upper-lower-layer excavation support construction of the chamber can be synchronously arranged and implemented.

Owner:国能大渡河猴子岩发电有限公司 +1

Method for realizing gob-side entry retaining through grouting anchor cable

InactiveCN107503778APrevent weatheringReduce intensityAnchoring boltsHorizontal stressStructural engineering

The invention discloses a method for realizing gob-side entry retaining through a grouting anchor cable. The method includes the steps of designing a tunnel needing to be reserved for use, isolating a goaf, and keeping the tunnel complete to serve as a transportation, ventilation and pedestrian tunnel of a next working face; constructing an anchor cable hole according to design, installing and anchoring the anchor cable and sealing the hole; reinforcing a top plate through early grouting during pushing-gathering so that the tunnel and the top plate can be glued into a whole, arranging the anchor cable along the boundary of the goaf, erecting nogs, point pillars and gangue bags along the boundary for blocking after pushing-gathering of the tunnel so that boundary overlocking and topping of the goaf can be achieved, and pressing the top plate through the goaf till the top plate breaks and naturally collapses because no support exists above the goaf so that the tunnel can be reserved. The top plate is secondarily reinforced through grouping by reasonably using the grouping anchor cable, the reinforcing effect is remarkable, the surrounding rock of the top plate is stable, the overall mechanical performance is remarkable, the horizontal stress of two banks is reduced, the overall deformation of the tunnel is reduced by about 70%, the support cost is reduced, the tunnel is not secondarily repaired, and later-period workloads are reduced.

Owner:XINWEN MINING GROUP +1

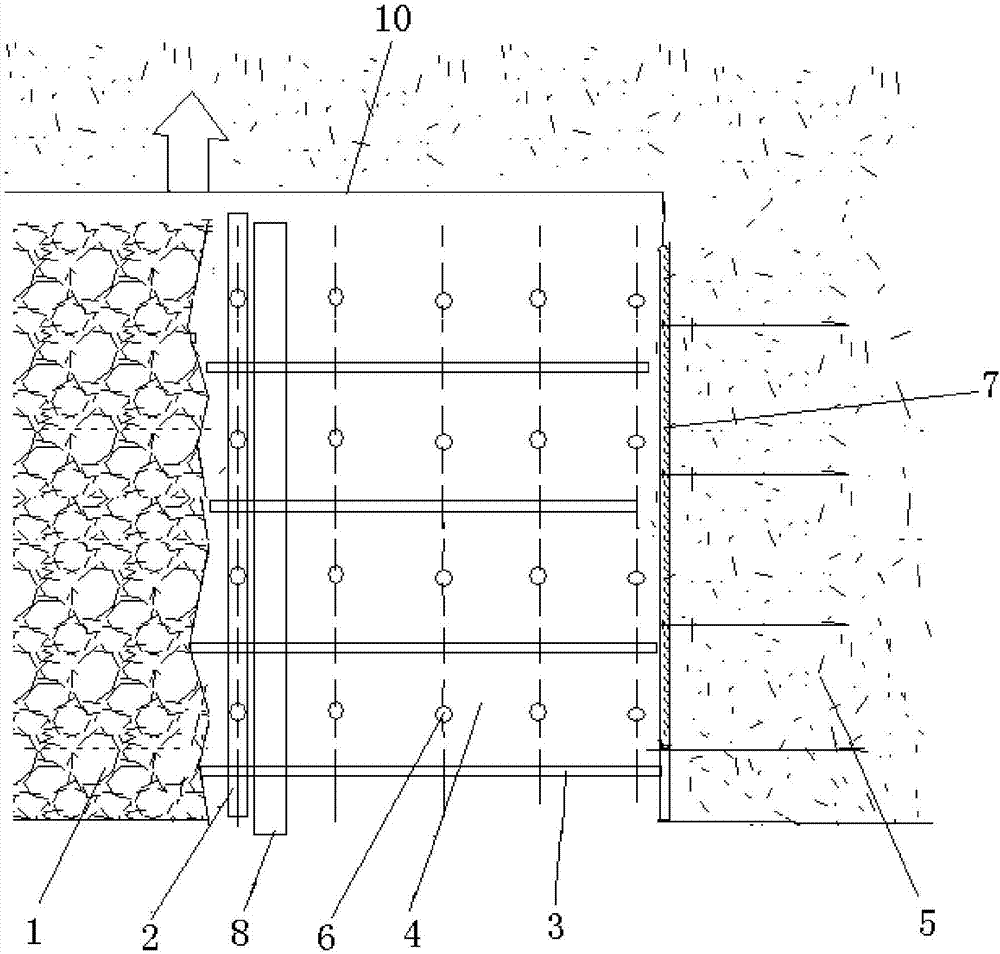

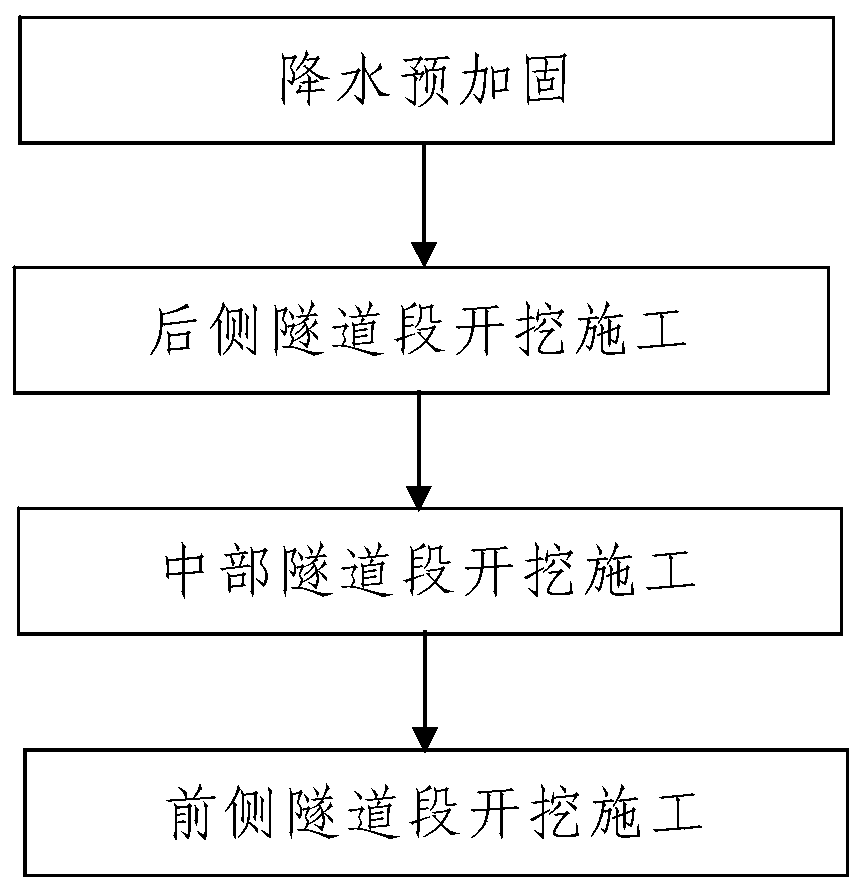

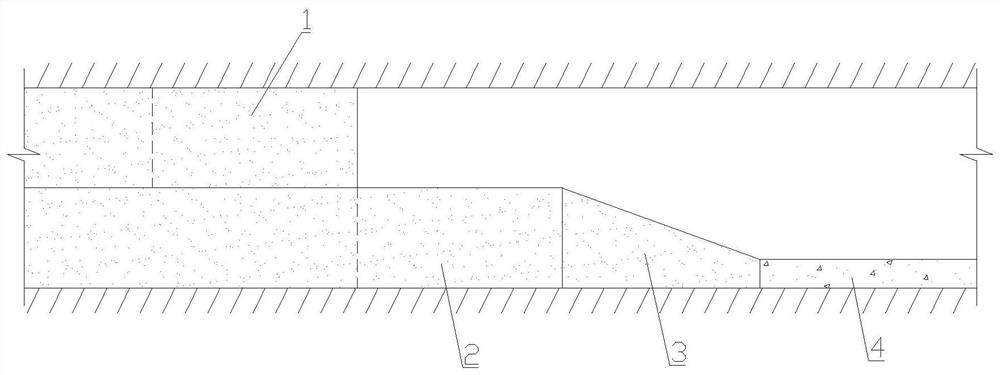

Construction method of soil-stone boundary tunnel passing through loess valleys

ActiveCN110700860AEffective reinforcementThe method steps are simpleUnderground chambersTunnel liningGround water levelStructure support

The invention discloses a construction method of a soil-stone boundary tunnel passing through loess valleys. The construction method comprises the following steps of 1, precipitation pre-reinforcement; 2, excavation construction of a rear side tunnel section; 3, excavation construction of a middle tunnel section; and 4, excavation construction of a front side tunnel section, wherein the middle tunnel section and the front side tunnel section are three-step synchronous excavation tunnel sections; and in the excavation process from back to front in the step 2, the step 3 and the step 4, primarysupport is synchronously carried out on the excavated tunnel from back to front, and secondary lining of the tunnel is constructed on the inner side of the constructed and formed tunnel primary support structure from back to front. The construction method is reasonable in design, simple and convenient to construct and good in use effect, the underground water level is reduced through precipitationpre-reinforcement, surrounding rock is effectively reinforced, then blasting excavation is carried out in a three-step excavation mode, so that the excavation process of the soil-stone boundary tunnel passing through the loess valleys can be ensured to be safe and reliable, and the stability of the tunnel structure can be ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

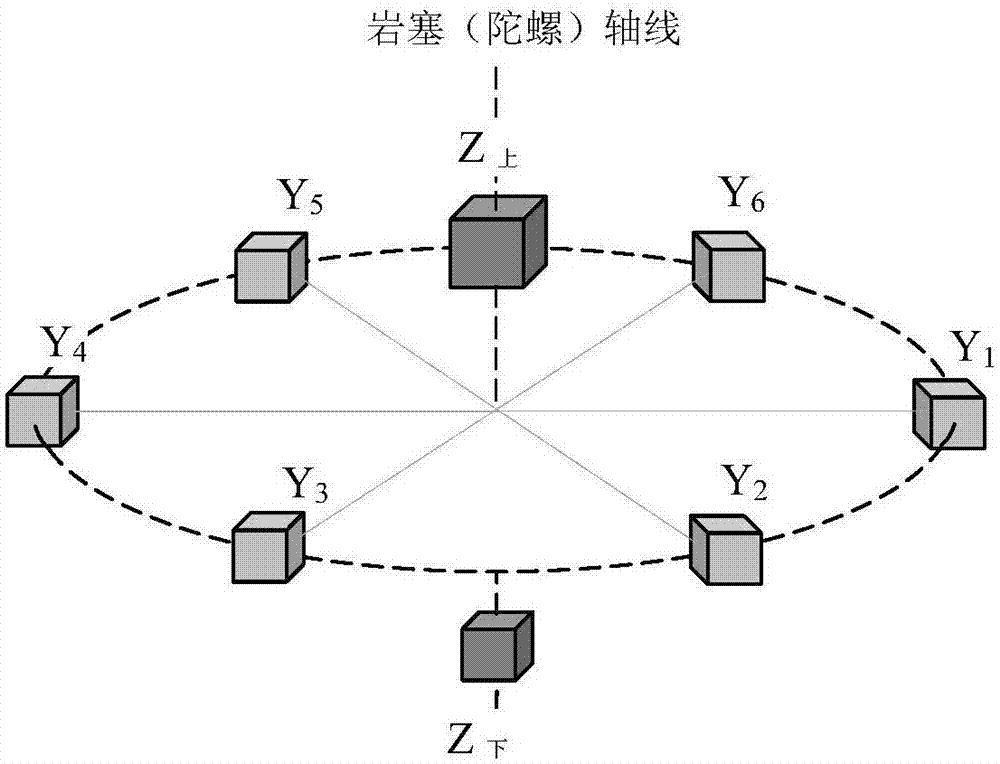

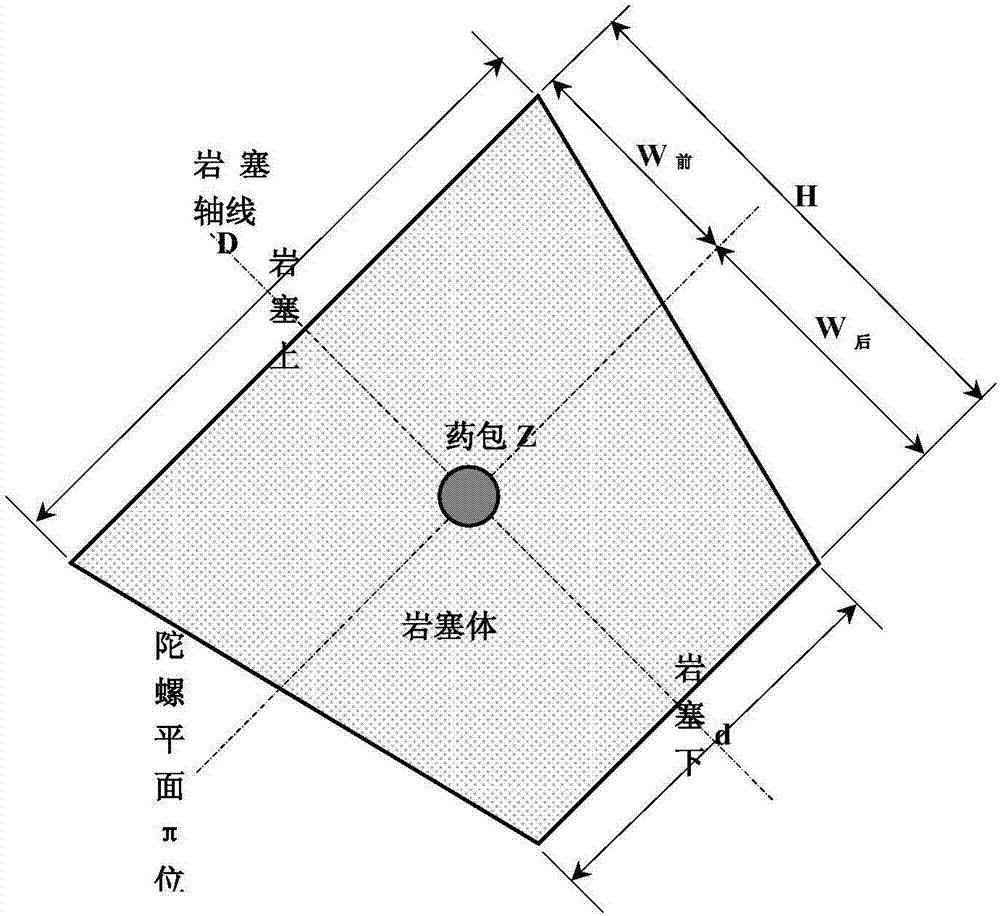

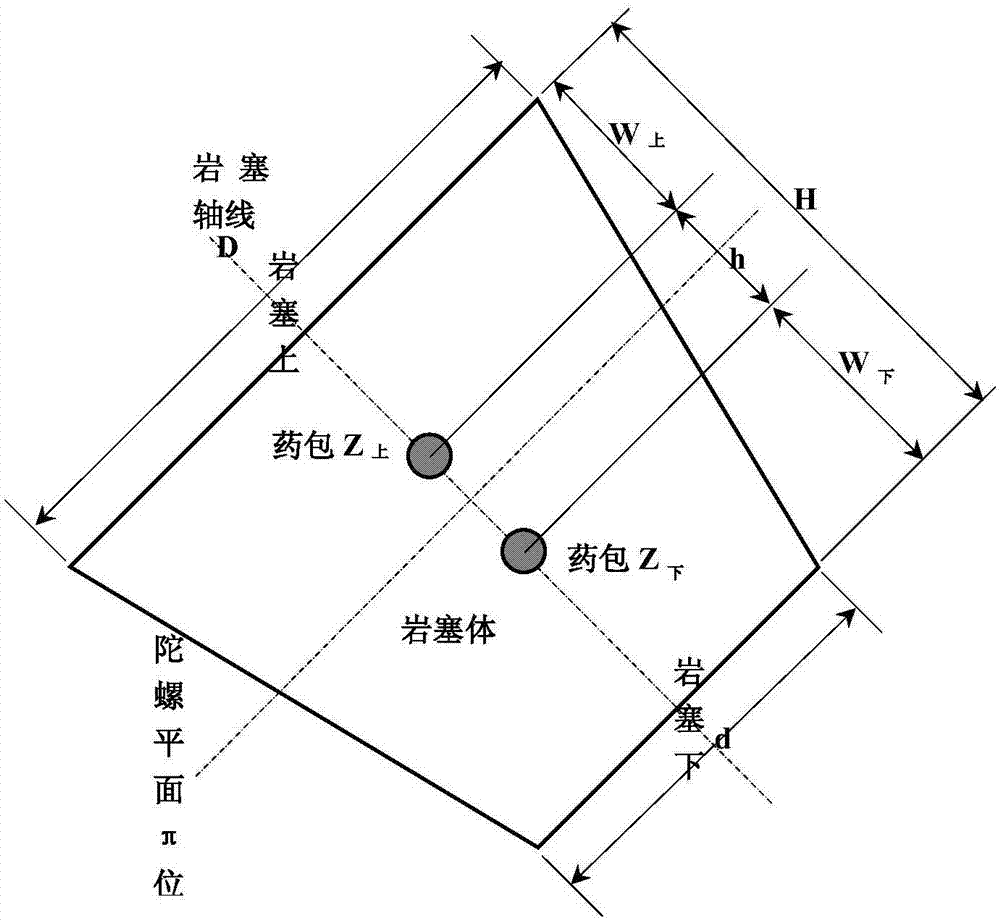

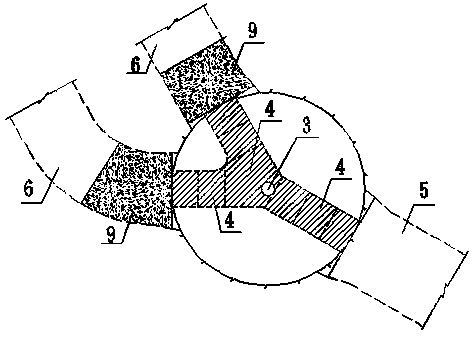

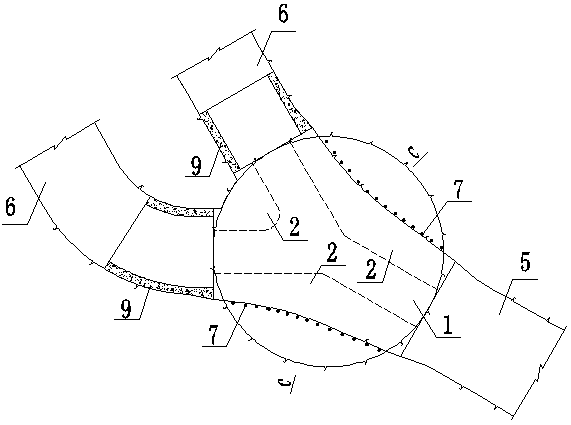

Underwater rock plug blasting gyroscopic distributed chamber method

The invention relates to an underwater rock plug blasting gyroscopic distributed chamber method and belongs to rock plug body blasting methods in underwater rock plug blasting engineering. Presplit holes are drilled in the periphery of a rock plug according to the size of the rock plug body, the gyroscope plane position is worked out, the positions and explosive amount of an upper blasting cartridge Zupper and a lower blasting cartridge Zlower on the gyroscope axis are computed, the positions and the explosive amount of blasting cartridges Y1-Ym on the gyroscope plane are computed, layout of gyroscopic distributed chambers is finally determined, blasting of the chambers and a construction channel is conducted, and the blasting sequence and explosive time interval are set. The method has the advantages that the chambers are well arranged, the mutual relation of all the chambers is clear, the blasting mechanism and the action objects are specific, the structure is simple, and the method is easy to master; and the application prospects are wide, the gap between the large underwater rock plug blasting concentrated cartridge layout principle and practices is filled, and the method is a new breakthrough for underwater rock plug blasting chamber layout and has obvious practical application significances for underwater rock plug blasting design and construction.

Owner:CHINA WATER NORTHEASTERN INVESTIGATION DESIGN & RES

Micro-disturbance mechanical separate tunneling construction method for tunnel in weak surrounding rock

InactiveCN109594995AReduce disturbanceControl deformationUnderground chambersTunnel liningLarge deformationBuilding construction

The invention discloses a micro-disturbance mechanical separate tunneling construction method for a tunnel in weak surrounding rock. The method comprises the following steps: firstly, a shield is divided into multiple sub-shields from top to bottom, the multiple sub-shields are jacked gradually from bottom to top, and disturbance to the surrounding rock is reduced; then step separate excavation isperformed on a tunnel face, excavation disturbance is reduced as compared with overall excavation, surrounding rock deformation is controlled, tunnel deformation is prevented, and construction safetyis improved; secondly, the excavated tunnel is subjected to primary support with prefabricated members, and rapid sealing and primary support reinforcement are realized; finally, secondary lining isperformed on the primary support, and waterproof plates are arranged between the secondary lining and the primary support. The construction method is safe, efficient and economical, effectively controls large disturbance and large deformation of surrounding rock during excavation and reduces disaster losses of engineering construction.

Owner:CHANGAN UNIV

Tunnel-before-wall-type crossed tunnel portal excavation supporting construction method

ActiveCN110107323AGuaranteed excavationSurrounding rock stabilityUnderground chambersTunnel liningUnderground cavernRock bolt

The invention provides a tunnel-before-wall-type crossed tunnel portal excavation supporting construction method. A tunnel is excavated before cavern side walls, after system supporting is completed,the tunnel extends into a cavern, temporary supporting is conducted to ensure site construction safety, locked anchor bars and countersunk anchor bars are implemented to protect intersections, pre-splitting holes are formed in the circumferential direction along the cavern side walls for blasting, rock mass, nearby the intersections, inside and outside the cavern side walls is separated, during later excavation of the cavern, the rock mass within the pre-splitting range is mechanically excavated, secondary blasting damage is avoided, and system supporting follows till the intersections are excavated. A scheme for solving the problem of excavation supporting of the large underground cavern intersections is provided for a tunnel-before-wall-type excavation mode, excavation forming of the intersections can be ensured to a great extent, stability of surrounding rock of the tunnel intersections and the cavern high side walls is facilitated, overexcavation is reduced, later backfilling of alarge amount of concrete is avoided, the construction period is shortened, and the engineering cost is saved.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

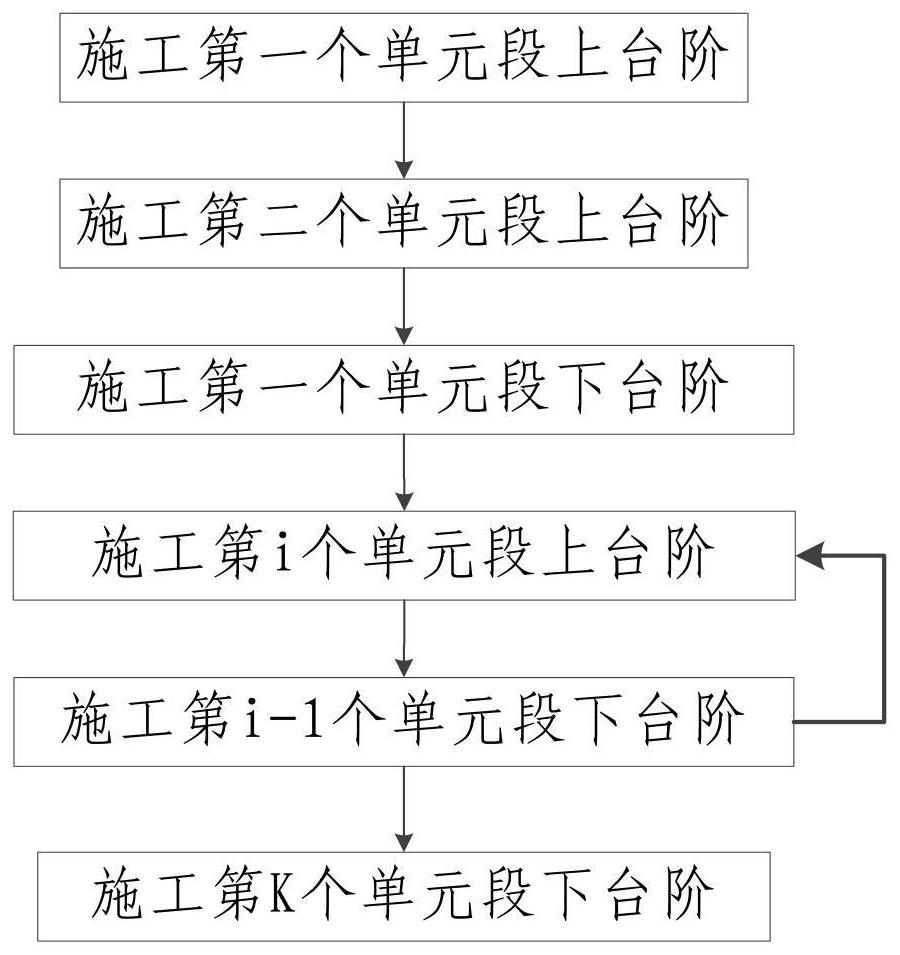

Cantilever excavator-based construction method for single-line tunnel close to operation line

InactiveCN112459801AEnsure safetyImprove working environmentUnderground chambersTunnel liningShotcreteArchitectural engineering

The invention discloses a cantilever excavator-based construction method for a single-line tunnel close to an operation line. The construction method comprises the following steps that firstly, an upper step of a first unit section is constructed; secondly, an upper step of a second unit section is constructed; thirdly, a lower step of the first unit section is constructed; fourthly, an upper stepof an i unit section is constructed; fifthly, a lower step of an i-1 unit section is constructed; sixthly, the fourth step to the fifth step are repeated till excavation of an upper step of aK unit section and excavation of a lower step of a K-1 unit section are completed; and seventhly, a lower step of the K unit section is constructed. A cantilever tunneling machine is applied to construction of the single-line tunnel close to the operation line, the tunnel is excavated through a non-blasting method, the influence of blasting vibration on the operation line is avoided,multi-cycle excavation supporting construction can be conducted every day, the safety of the operation line can be effectively guaranteed, tunnel overexcavation is effectively controlled, the use amount of primary supporting sprayed concrete is reduced, the construction cost investment is reduced, and the concrete ultra-consumption construction problem which is difficult to solve by a traditionaldrilling and blasting method is solved.

Owner:中铁二十局集团市政工程有限公司

Construction method of tunnel ventilation opening structure under weak surrounding rock condition

PendingCN114856609ASurrounding rock stabilityEasy constructionUnderground chambersHydro energy generationCross connectionArchitectural engineering

The invention discloses a construction method of a tunnel ventilation opening structure under a weak surrounding rock condition, the ventilation opening structure adopts a side expansion type cross connection mode, an excavation section adopts a curved wall or an arched section, a connection channel and a main hole are not interfered in excavation, and a gradual change section does not exist in excavation; the section of the widened belt is the same as the section of the tunnel emergency parking strip, and the emergency parking strip can be used for lining a trolley and a template; active excavation operation is assisted through the connecting channel, the excavation working face of the main hole can be increased, and the construction period is shortened. When the ventilation opening structure is located in weak surrounding rock and needs to enter the main tunnel from the connection channel to assist excavation of the main tunnel, the ventilation opening structure is constructed through the construction method, and good safety guarantee and construction efficiency can be obtained.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

Excavating method for jump-digging of double-side wall guide pit combined arch part of tunnel

ActiveCN102182466BReduce stress concentrationReduce distortionUnderground chambersTunnel liningStress concentrationSubsidence

The invention relates to a novel large-span tunnel excavating construction method, namely, an excavating method for jump-digging of a double-side wall guide pit combined arch part. After the construction of a double-side wall guide pit and side wall secondary lining is completed, a large-span tunnel arch soil body is excavated by blocks. During the excavation of the arch part of the tunnel, a middle guide pit of the arch part is excavated first, then two side guide pits of the arch part of the tunnel are excavated from the excavation surface of the middle guide pit to the two sides by departing from an opening, a primary supporting structure and the secondary lining of the arch part at the position are constructed, and then the excavation of a arch part structure of the tunnel with large span is completed gradually from inside to outside. The method considers the space effect of tunnel excavation and support, reduces stress concentration at the opening during the excavation of the arch part, and has remarkable effects in ensuring the stability of excavating surrounding rocks at the section of the tunnel with large span and controlling the settlement of a larger area caused by the tunnel excavation.

Owner:CHINA RAILWAY SHANGHAI DESIGN INST GRP

Excavation method of large-diameter cylindrical tailrace surge chamber

ActiveCN108755622AEnsure safetyReduce the maximum spanWater-power plantsHydro energy generationStress concentrationCarrying capacity

The invention relates to an excavation method of a large-diameter cylindrical tailrace surge chamber and belongs to the technical field of water conservancy and hydropower underground engineering construction. The excavation method adopts the technical scheme that firstly, middle drift penetrating and reserved protection layer stage excavation are performed, partitioning penetrating is conducted from inside to outside, and thin-layer excavation and layer-by-layer supporting are adopted; stage adjustment and releasing of surrounding rock stress are achieved, and stress drastic adjustment aftersurrounding rock excavation decompression caused by deep-hole-bench large-charge blasting is avoided; fork segment tailwater pipes adopt pre-stressed anchor cable reinforced supporting and first-stageside wall and vault concrete pouring which are are combined, and the two adjacent tailwater pipes adopt the comprehensive excavation construction scheme of drift vertical excavation and layer-by-layer supporting, and the carrying capacity of a bottom fork reserved rock partition wall is remarkably improved. Since the two adjacent tailwater pipes adopt the comprehensive excavation construction scheme of drift vertical excavation and layer-by-layer supporting, the problems that the surrounding rock stress state after practical engineering construction excavation is implemented is complex, driftintersection positions have stress concentration and large plastic zones, and the construction technical difficulty is high are solved.

Owner:SINOHYDRO BUREAU 14 CO LTD

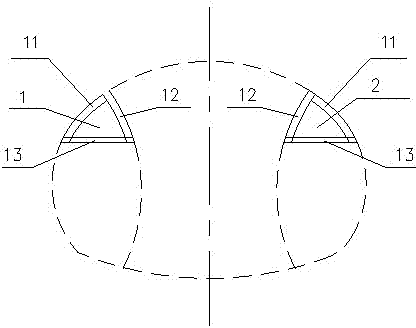

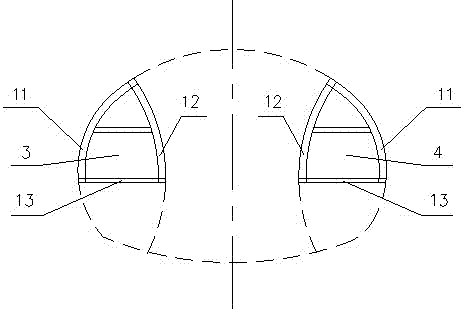

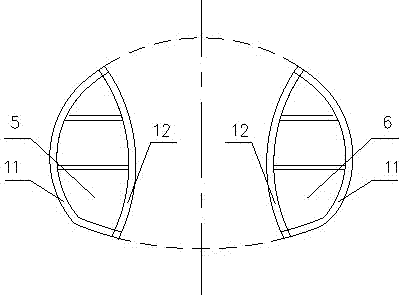

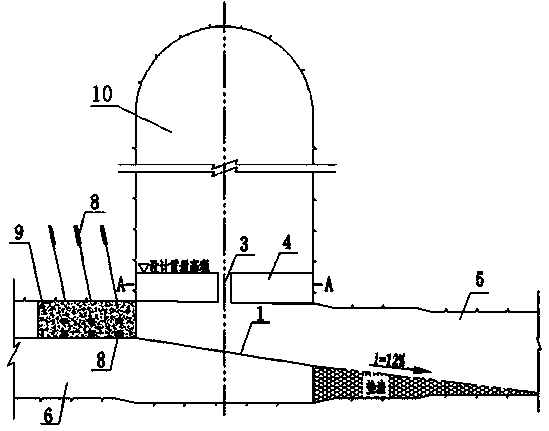

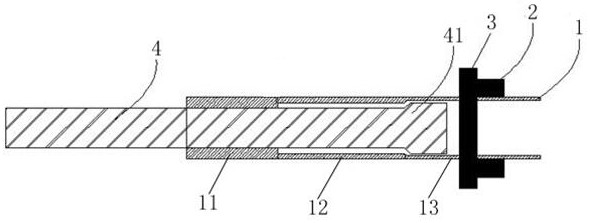

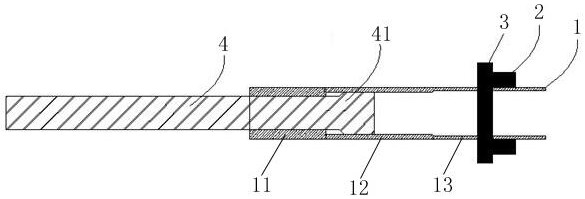

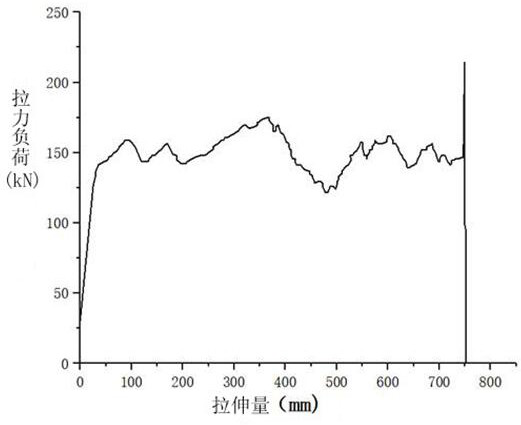

Large-deformation self-adaptive energy release anchor rod

PendingCN112282810AImprove early support abilityHigh strengthExcavationsAnchoring boltsInterference fitUltimate tensile strength

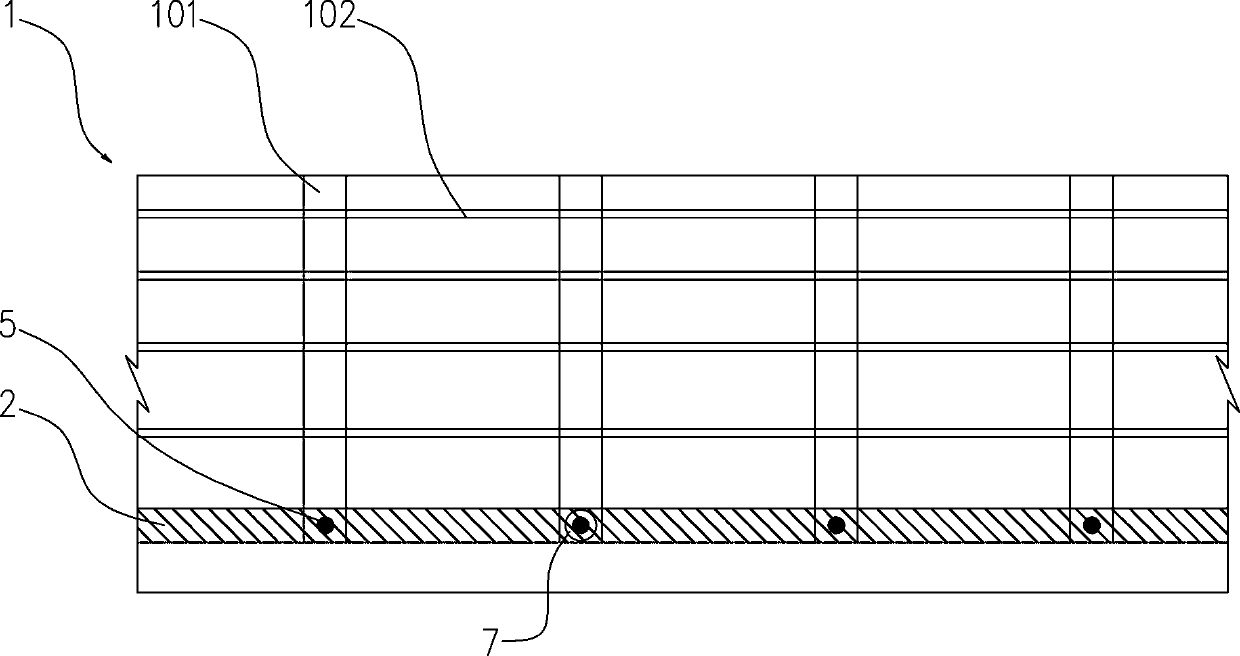

The invention discloses a large-deformation self-adaptive energy release anchor rod. The anchor rod comprises a rod body (4) and an inner stepped pipe barrel (1) arranged on the rear section of the rod body (4) in a sleeving mode, and a abrasion-resistant magnesium alloy friction head (41) is arranged at the tail of the rod body (4); the inner stepped pipe barrel (1) is provided with at least twostages of stepped surfaces, and the inner stepped pipe barrel is sequentially divided into a small-diameter pipe barrel (11), at least one stage of medium-diameter pipe barrel (12) and a large-diameter pipe barrel (13) from front to back; and the outer diameter of the abrasion-resistant magnesium alloy friction head (41) is larger than the inner diameter of any one of the medium-diameter pipe barrels (12), the abrasion-resistant magnesium alloy friction head (41) is pre-arranged in the large-diameter pipe barrel (13) and initially positioned on the rear-stage stepped surface, and the rod body(4) is in transition fit or interference fit with the small-diameter pipe barrel (11). The anchor rod has the technical effects that the elongation rate is increased, energy generated by surrounding rock deformation is effectively released, the early-stage supporting capacity and breaking strength of the anchor rod are greatly improved, a good supporting effect is achieved, and surrounding rock isstabilized for a long time.

Owner:CHONGQING UNIV

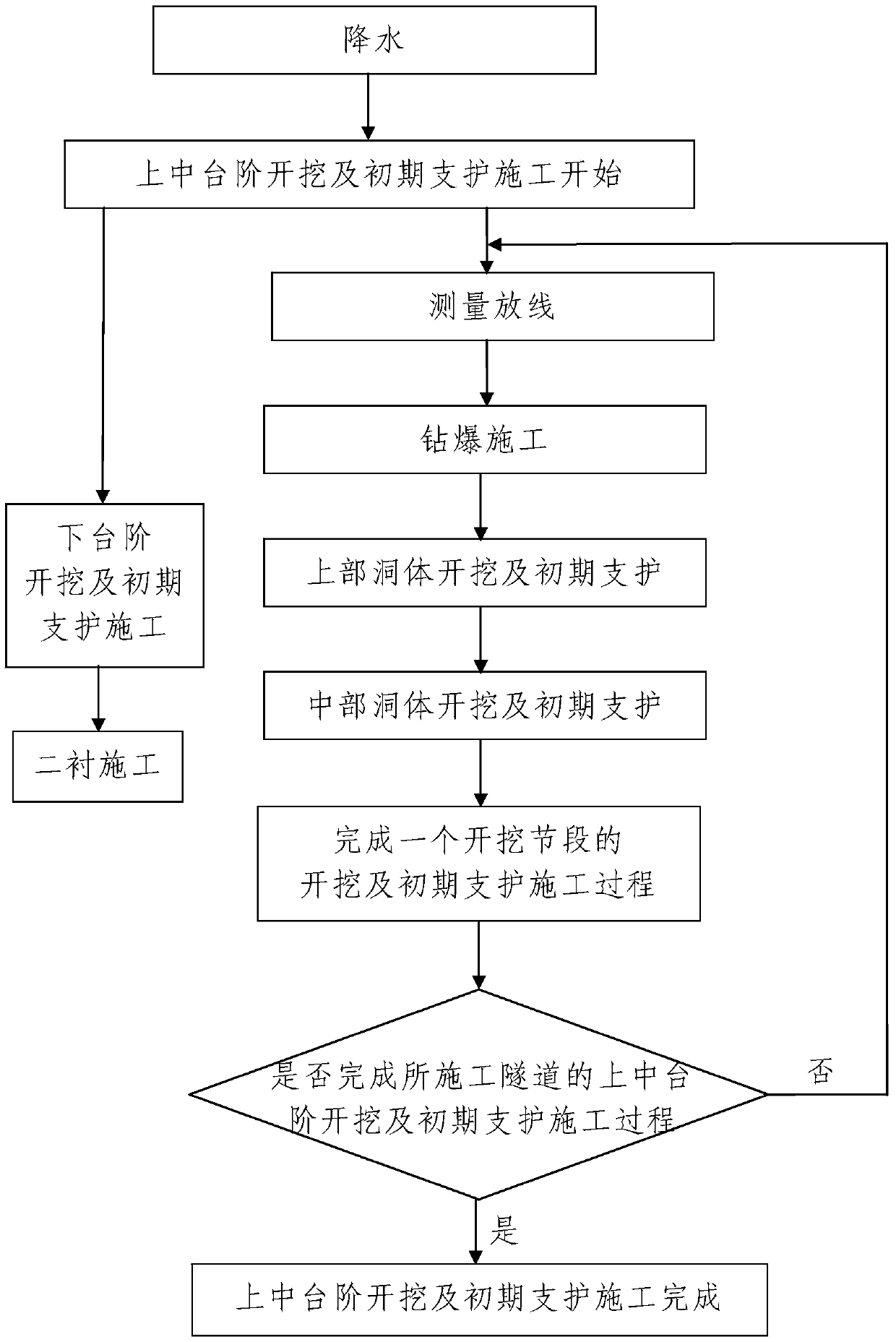

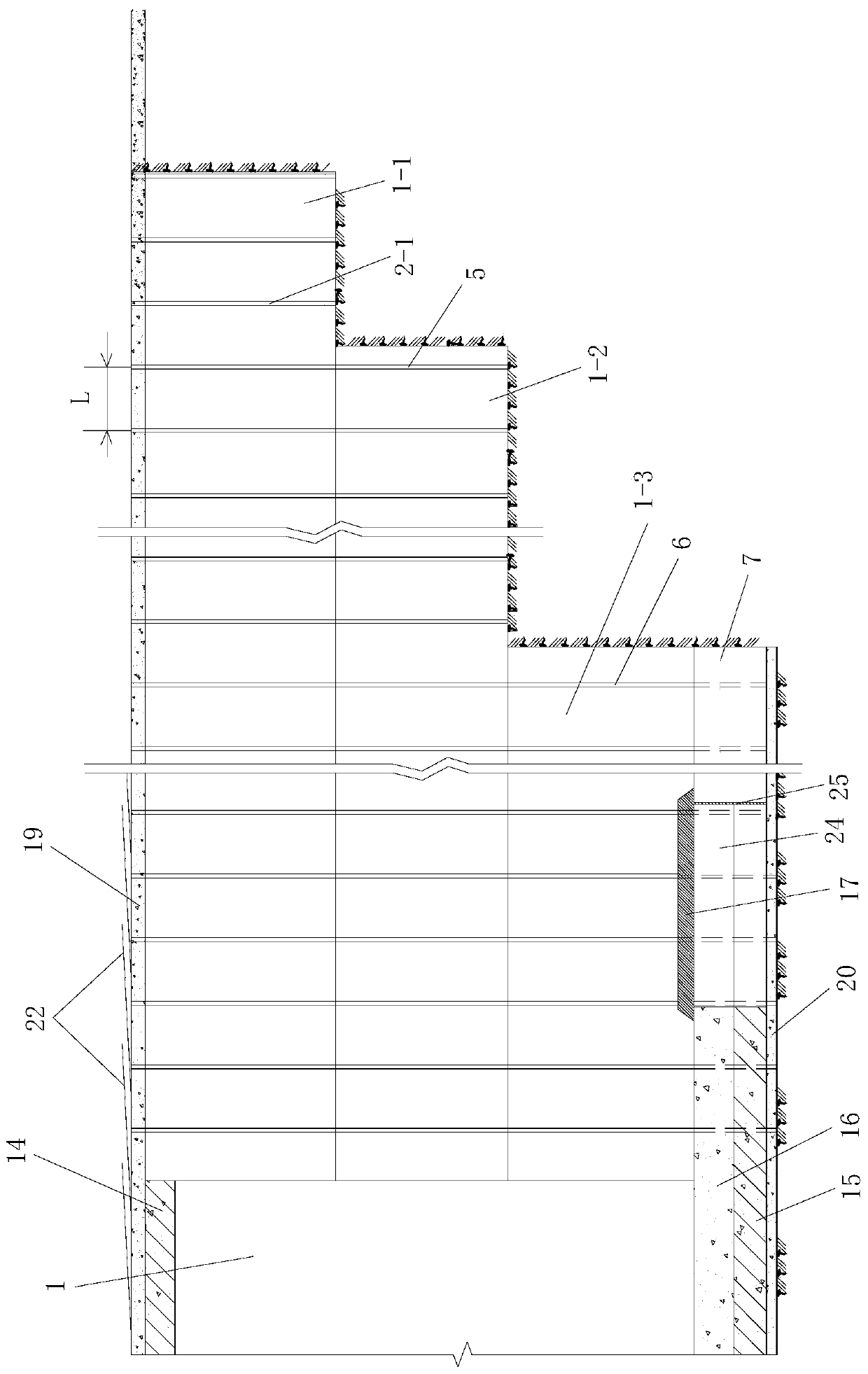

Large-section tunnel excavation and support construction method for crossing soil-rock boundary stratum

ActiveCN110821500AThe method steps are simpleReasonable designUnderground chambersBlastingStructural engineeringCave

The invention discloses a large-section tunnel excavation and support construction method for crossing a soil-rock boundary stratum. The method comprises the following steps of first, upper middle step excavation and initial support construction, specifically, carrying out upper step excavation and initial support construction on a construction tunnel by a plurality of excavation sections from rear to front, and when any excavation section is subjected to upper step excavation and initial support construction, the process comprises the following steps of measuring pay-off, drilling and blasting construction, excavation and initial support of an upper cave, and excavation and initial support of a middle cave; second, lower step excavation and initial support construction; and third, carrying out secondary lining construction. The method is reasonable in design, simple and convenient to construct and good in use effect, the upper blasting area in the upper step and the middle blasting area on the middle step are separately subjected to blasting zone division, the arrangement position of each shot hole in each blasting zone is defined, the collapse of a tunnel face or the collapse ofa vault caused by large vibration generated by blasting when one-time loading of the large section is excessive can be effectively prevented, the safety and reliability of the tunnel excavation process are ensured, and the stability of the tunnel structure is ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

Tunnel IV-type and V-type surrounding rock advanced tied arch damping reinforcing method

ActiveCN109441478ASurrounding rock stabilityWeaken the disturbanceUnderground chambersTunnel liningThin walledEnvironmental geology

The invention discloses a tunnel IV-type and V-type surrounding rock advanced tied arch damping reinforcing method. The tunnel IV-type and V-type surrounding rock advanced tied arch damping reinforcing method comprises the steps that firstly, a steel arch frame used for supporting an exposed surrounding rock mass is erected on a tunnel face; then an arched advanced thin-walled groove hole with thecentral angle being 90-180 degrees is excavated in the top of the face and expanded outwards at the angle of 2-5 degrees in the tunneling direction; damping gaskets are mounted on the bottom wall ofthe arched advanced thin-walled groove hole, then trussing beams are mounted on the damping gaskets, and a grouting steel pipe is placed between every three to four trussing beams; backfill grouting is conducted in the arched advanced thin-walled groove hole through the grouting steel pipes, the trussing beams and the grouting steel pipes form a trussing arch body structure through slurry solidifying, then the trussing arch body structure and the steel arch frame are connected together; and finally, tunnel excavation is conducted, and construction is completed. According to the tunnel IV-typeand V-type surrounding rock advanced tied arch damping reinforcing method, safety in the large section excavation construction period and the drilling and blasting construction period of a tunnel canbe ensured; and meanwhile, the possibility of anchorage connection of an arch body and a surrounding rock deep layer is achieved.

Owner:YELLOW RIVER ENG CONSULTING

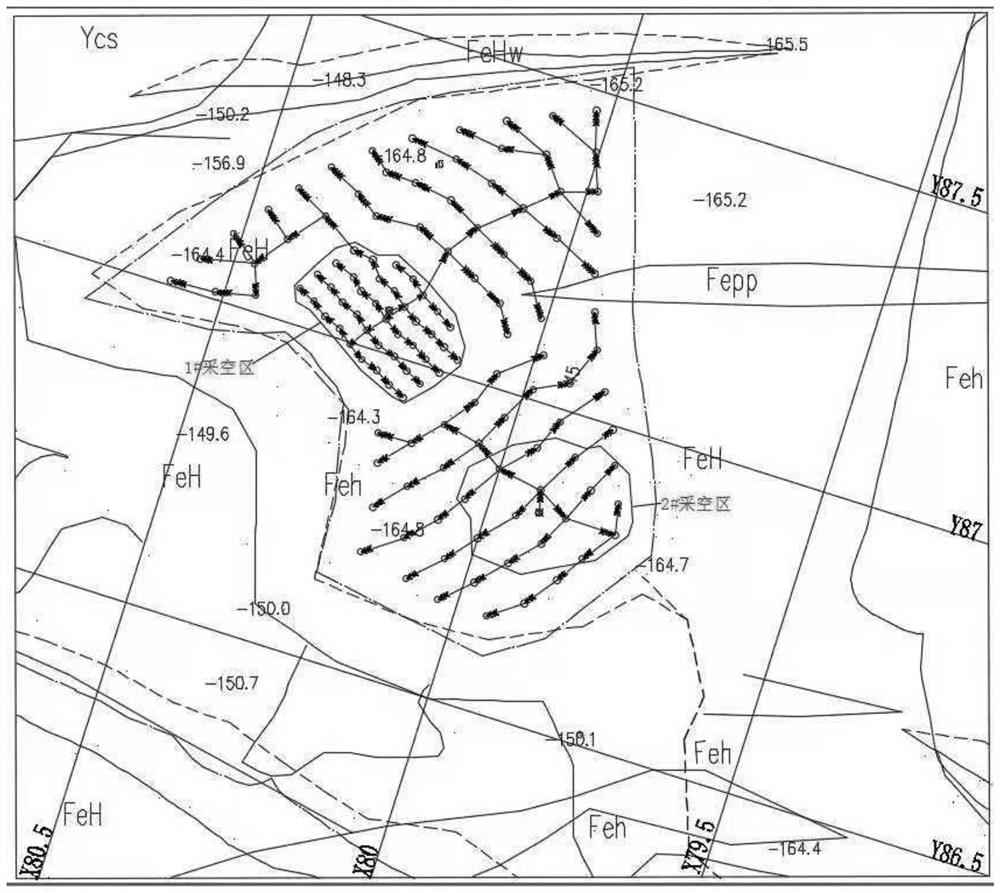

Blasting method for shallow-buried goaf of strip mine

ActiveCN113670147AReduce distractionsReduce engineering costsMining devicesBlastingMining engineeringStructural engineering

The invention provides a blasting method for a shallow-buried goaf of a strip mine and belongs to the technical field of engineering blasting. The blasting method comprises the following steps that step1, properties, occurrence conditions and geometric spatial characteristics of ores around the goaf are confirmed; step2, the safety thickness of a top plate above the goaf is confirmed, perforating equipment is selected, and a perforating scheme is designed; step3, hole net parameters of goaf top plate loose blasting and lateral throwing blasting are confirmed, and a charging structure and a detonating network are designed; step4, the muck pile size is estimated; step5, goaf volume balance calculation is performed, and the blasting collapse volume is confirmed; step6, blast hole arranging, charging and filling are performed; and step7, the detonating network is connected, detonating is performed, and the caving filling effect is observed and recorded. According to the blasting method for the shallow-buried goaf of the strip mine, the lateral free surface condition created by the underground goaf is fully utilized, lateral throwing filling is assisted while top plate caving filling is implemented, single-side, double-side or multi-side lateral blasting throwing filling can be implemented, the filling rate of the underground goaf is increased, and secondary manual filling is reduced or avoided.

Owner:鞍钢矿业爆破有限公司

Tunnel Construction Method Crossing Earth-rock Boundary Strata

ActiveCN110985003BEffective reinforcementThe method steps are simpleUnderground chambersDrainageArchitectural engineeringDrilling and blasting

The invention discloses a tunnel construction method for crossing the earth-rock boundary layer, which comprises the following steps: 1. Excavation of the rear tunnel section and initial support construction; 2. Excavation of the middle tunnel section and initial support construction; 3. Front side The excavation and initial support construction of the tunnel section; the rear tunnel section, the middle tunnel section and the front tunnel section are all three-step synchronous excavation tunnel sections; during the excavation process from the back to the front, the construction is formed from the back to the front Construction of the secondary lining of the tunnel is carried out on the inner side of the primary support structure of the tunnel. The invention is reasonable in design, easy in construction and good in use effect. According to the positional relationship between the soil-rock interface and the tunnel hole, a suitable drilling and blasting method is selected, and three-step synchronous excavation is used for blasting excavation, which can ensure the tunnel's tunnel crossing the soil-rock boundary. The excavation process is safe and reliable, and can ensure the stability of the tunnel structure; and during the excavation process, the tunnel primary support structure and the secondary lining of the tunnel are used to provide stable and reliable support for the large-section tunnel.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com