Construction method for drainage of tunnel vault in karst area

A construction method and tunnel technology, applied in drainage, tunnel, tunnel lining, etc., can solve problems such as lining deformation, tunnel water leakage, and endangering driving safety, so as to avoid quality and safety hazards, landslide events, and stress concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A construction method for drainage of tunnel vaults in karst areas proposed by the present invention has been applied in the construction of the Xizuo Tunnel of Ziwang Expressway in Guizhou. The general situation of the tunnel project is as follows:

[0024] The length of Xizuo Tunnel is 4,234 meters, and the left and right holes are arranged separately. The total length of the left tunnel is 2,130 meters, and the total length of the right tunnel is 2,104 meters. Level Ⅴ) Two kinds of surrounding rocks.

[0025] Its construction steps are:

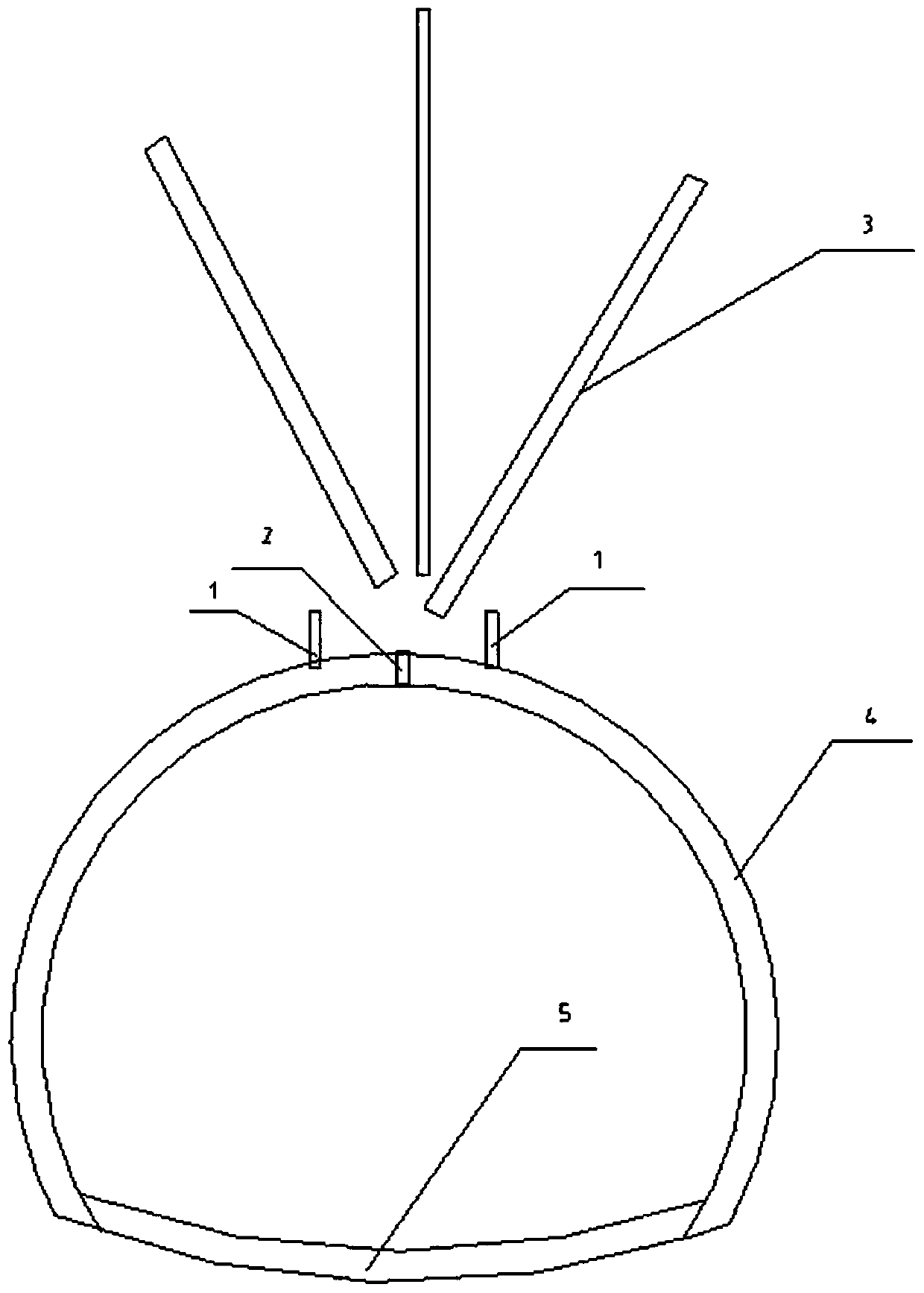

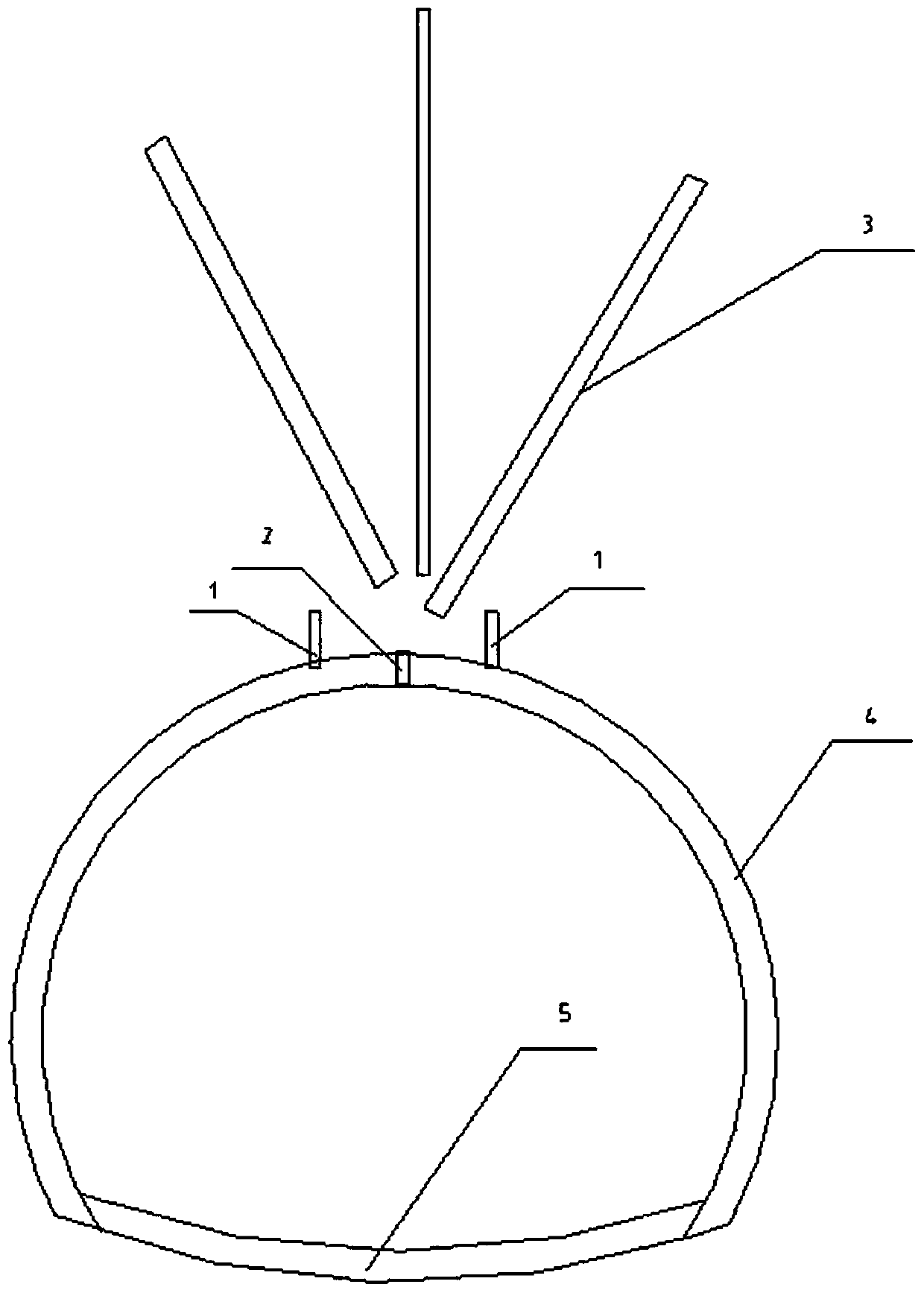

[0026] One), the conduit 3 is driven into the surrounding rock of the tunnel that has been excavated with a certain footage (the footage is determined according to the design). The penetration of the conduit 3 is to be supported by ordinary temporary supports. ) of the lower surface from bottom to top to drill a straight hole first, and then drive a conduit 3 into the straight hole. This conduit 3 is made of a steel pipe with an ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com